ASTM E1068-85(2003)

(Test Method)Standard Test Method for Testing Nonmetallic Seal Materials by Immersion in a Simulated Geothermal Test Fluid

Standard Test Method for Testing Nonmetallic Seal Materials by Immersion in a Simulated Geothermal Test Fluid

SIGNIFICANCE AND USE

This test method is intended for laboratory screening of materials. Due to large differences in the composition, pressure, and temperature of geothermal fluids, this test method may not correlate with actual service conditions. It does not consider the effects of geothermal fluid combined with oxidizing environments, stress loading, or thermal cycling.

SCOPE

1.1 This test method covers a procedure for a laboratory test for performing an initial evaluation (screening) of non-metallic seal materials by immersion in a simulated geothermal test fluid.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 6 and 11.7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1068–85(Reapproved2003)

Standard Test Method for

Testing Nonmetallic Seal Materials by Immersion in a

Simulated Geothermal Test Fluid

This standard is issued under the fixed designation E1068; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Method

1.1 Thistestmethodcoversaprocedureforalaboratorytest 3.1 Separate sets of material specimens are subjected to

forperforminganinitialevaluation(screening)ofnon-metallic both the test liquid and its vapor at saturation conditions at the

seal materials by immersion in a simulated geothermal test test temperature.

fluid. 3.2 Specimens exposed to the test fluid for a given test may

1.2 The values stated in SI units are to be regarded as the be from a single material to prevent interaction between

standard. dissimilar materials.

1.3 This standard does not purport to address all of the 3.3 The samples shall be unstressed during exposure to the

safety concerns, if any, associated with its use. It is the test fluid.

responsibility of the user of this standard to establish appro- 3.4 Tests of mechanical and physical properties shall be

priate safety and health practices and determine the applica- performed on specimens before and after immersion testing.

bility of regulatory limitations prior to use. For specific

4. Significance and Use

precautionary statements, see Section 6 and 11.7.

4.1 This test method is intended for laboratory screening of

2. Referenced Documents

materials. Due to large differences in the composition, pres-

2.1 ASTM Standards: sure, and temperature of geothermal fluids, this test method

D395 Test Methods for Rubber Property—Compression may not correlate with actual service conditions. It does not

Set consider the effects of geothermal fluid combined with oxidiz-

D412 Test Methods for Vulcanized Rubber and Thermo- ing environments, stress loading, or thermal cycling.

plastic Elastomers—Tension

5. Apparatus

D471 Test Method for Rubber Property—Effect of Liquids

D575 Test Methods for Rubber Properties in Compression 5.1 Test Vessel, shall be capable of containing the test fluid

at the test pressure and temperature. It is suggested that

D1415 Test Method for Rubber Property—International

Hardness reference be made to the ASME Boiler and Pressure Vessel

Code, Section VIII.

D 2240 Test Method for Rubber Property—Durometer

Hardness 5.2 Specimen Supports, shall be capable of holding speci-

mens submerged in the liquid and specimens suspended in the

2.2 ASME Standard:

Boiler and Pressure Vessel Code, Section VIII vapor so that the specimens are unstressed and do not touch

other specimens or the walls of the vessel.

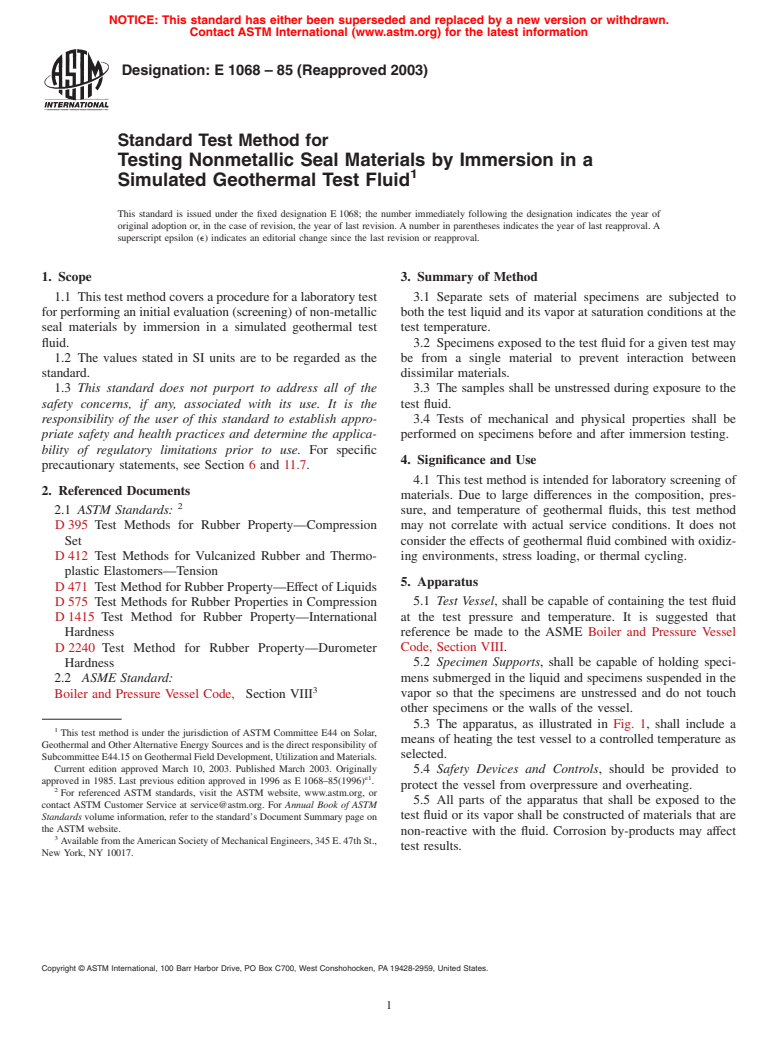

5.3 The apparatus, as illustrated in Fig. 1, shall include a

This test method is under the jurisdiction of ASTM Committee E44 on Solar,

means of heating the test vessel to a controlled temperature as

GeothermalandOtherAlternativeEnergySourcesandisthedirectresponsibilityof

selected.

SubcommitteeE44.15onGeothermalFieldDevelopment,UtilizationandMaterials.

Current edition approved March 10, 2003. Published March 2003. Originally

5.4 Safety Devices and Controls, should be provided to

e1

approved in 1985. Last previous edition approved in 1996 as E1068–85(1996) .

protect the vessel from overpressure and overheating.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.5 All parts of the apparatus that shall be exposed to the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on test fluid or its vapor shall be constructed of materials that are

the ASTM website.

non-reactive with the fluid. Corrosion by-products may affect

AvailablefromtheAmericanSocietyofMechanicalEngineers,345E.47thSt.,

test results.

New York, NY 10017.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1068–85 (2003)

TABLE 2 Standard Test Temperatures

°C °F

85 62°C 185 64°F

100 62°C 212 64°F

150 62°C 302 64°F

200 62°C 392 64°F

250 62°C 482 64°F

300 65°C 572 69°F

350 65°C 662 69°F

11.2 Place dry ingredients (Na S·9H O, NaCl, and

2 2

NaHCO ) into the apparatus vessel.

11.3 Seal and purge the vessel with nitrogen to remove air

from the vessel.

11.4 Inject the liquid ingredients (HCl and H O). Note that

FIG. 1 Schematic of Test Apparatus

hazardousgas(H S)willbeevolvedandpressurewilldevelop

when the acid is added. All the evolved gases shall be

contained in the vessel as part of th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.