ASTM D7261-06

(Test Method)Standard Test Method for Determining Water Separation Characteristics of Diesel Fuels by Portable Separometer

Standard Test Method for Determining Water Separation Characteristics of Diesel Fuels by Portable Separometer

SCOPE

1.1 This test method covers a rapid portable means for field and laboratory use to rate the ability of diesel fuels (both neat and those containing additives) to release entrained or emulsified water when passed through fiberglass coalescing material.

1.2 This test method is applicable to diesel fuels such as D 975 Grade No. 1 and Grade No. 2 of all sulfur levels, and MIL-F-16884, naval distillate fuel (NATO F-76).Note 1

This test method is similar to Test Method D 3948 which is applicable to aviation turbine fuels.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 7261 – 06

Standard Test Method for

Determining Water Separation Characteristics of Diesel

Fuels by Portable Separometer

This standard is issued under the fixed designation D 7261; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 4306 Practice for Aviation Fuel Sample Containers for

Tests Affected by Trace Contamination

1.1 This test method covers a rapid portable means for field

D 4860 Test Method for Free Water and Particulate Con-

and laboratory use to rate the ability of diesel fuels (both neat

tamination in Mid-Distillate Fuels (Clear and Bright Nu-

and those containing additives) to release entrained or emulsi-

merical Rating)

fied water when passed through fiberglass coalescing material.

D 6426 Test Method for Determining Filterability of

1.2 This test method is applicable to diesel fuels such as

Middle Distillate Fuel Oils

D 975 Grade No. 1 and Grade No. 2 of all sulfur levels, and

2.2 Military Standard:

MIL-F-16884, naval distillate fuel (NATO F-76).

MIL-F-16884 Fuel, Naval Distillate (NATO F-76)

NOTE 1—This test method is similar to Test Method D 3948 which is

applicable to aviation turbine fuels.

3. Terminology

1.3 The values stated in SI units are to be regarded as the

3.1 Definitions:

standard. The values given in parentheses are for information

3.1.1 Micro-Separometer rating (DSEP rating), n—a nu-

only.

mericalvalueindicatingtheeaseofseparatingemulsifiedwater

1.4 This standard does not purport to address all of the

from fuel by coalescence as affected by the presence of surface

safety concerns, if any, associated with its use. It is the

active materials (surfactants) in the fuel.

responsibility of the user of this standard to establish appro-

3.1.2 reference fluid, n—a reference fluid base to which

priate safety and health practices and determine the applica-

prescribed quantities of a known surface active agent have

bility of regulatory limitations prior to use.

been added.

3.1.2.1 Discussion—The known surface active agent is

2. Referenced Documents

typically bis-2-ethylhexyl sodium sulfosuccinate, commonly

2.1 ASTM Standards:

referred to as AOT, dissolved in toluene.

D 975 Specification for Diesel Fuel Oils

3.1.3 surfactants, n—in petroleum fuels, surface active ma-

D 1193 Specification for Reagent Water

terials that could disarm (de-activate) filter separator (coalesc-

D 3948 Test Method for Determining Water Separation

ing) elements so that free water is not removed from the fuel in

Characteristics of Aviation Turbine Fuels by Portable

actual service.

Separometer

3.1.3.1 Discussion—Technically, surfactants affect the in-

D 4057 Practice for Manual Sampling of Petroleum and

terfacial tension between water and fuel which affects the

Petroleum Products

tendency of water to coalesce into droplets or not.

D 4176 Test Method for Free Water and Particulate Con-

3.1.4 strong surfactants, n—in petroleum fuels, surface

tamination in Distillate Fuels (Visual Inspection Proce-

active materials that disarm filter separator elements.

dures)

3.1.4.1 Discussion—Strong surfactants can be refinery pro-

D 4177 Practice for Automatic Sampling of Petroleum and

cess chemicals left in the fuel or contaminants introduced

Petroleum Products

during transportation of the fuel.

3.1.5 weak surfactants, n—in petroleum fuels, surface ac-

tive materials that do not adversely affect the performance of

This test method is under the jurisdiction of ASTM Committee D02 on

filter separator elements in actual service.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

3.1.5.1 Discussion—Weak surfactants are typically certain

D02.14 on Stability and Cleanliness of Liquid Fuels.

types of additives used in fuels.

Current edition approved Aug. 15, 2006. Published September 2006.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7261–06

tained in the fuel used to set the 100 reference level. The material was

3.2 Definitions of Terms Specific to This Standard:

subsequently removed during the coalescing portion of the test, thus, the

3.2.1 DSEP rating, n—the Micro-Separometer rating of

processed fuel had a higher light transmittance than the fuel sample used

diesel fuels as measured by this test method.

to obtain the 100 reference level resulting in the final rating measuring in

3.2.1.1 Discussion—The “D” in DSEP stands for diesel

excess of 100.

fuel. (See 14.1 for more information.)

3.2.2 reference fluid base, n—a distillate diesel fuel that has 6. Interferences

been carefully cleaned in a prescribed manner to remove all

6.1 Any suspended particles, whether solids or water drop-

surface-active contaminants, and having a minimum DSEP

lets or haze, in a fuel sample will interfere with this test

rating of 97.

method, which utilizes light transmission of a fuel sample after

3.2.2.1 Discussion—The reference fluid base should be a

emulsification with water and subsequent coalescence.

diesel fuel typical of fuels to be tested.

6.2 Non-hydrocarbon components such as oxygenates, es-

3.3 Abbreviations:

pecially alcohols, or emulsified water have not been verified

3.3.1 ac—alternating current

for this test method and will likely interfere.

3.3.2 AOT—Aerosol OT (see 8.1)

3.3.3 C/S—collect sample 7. Apparatus

,

3.3.4 dc—direct current 4 5

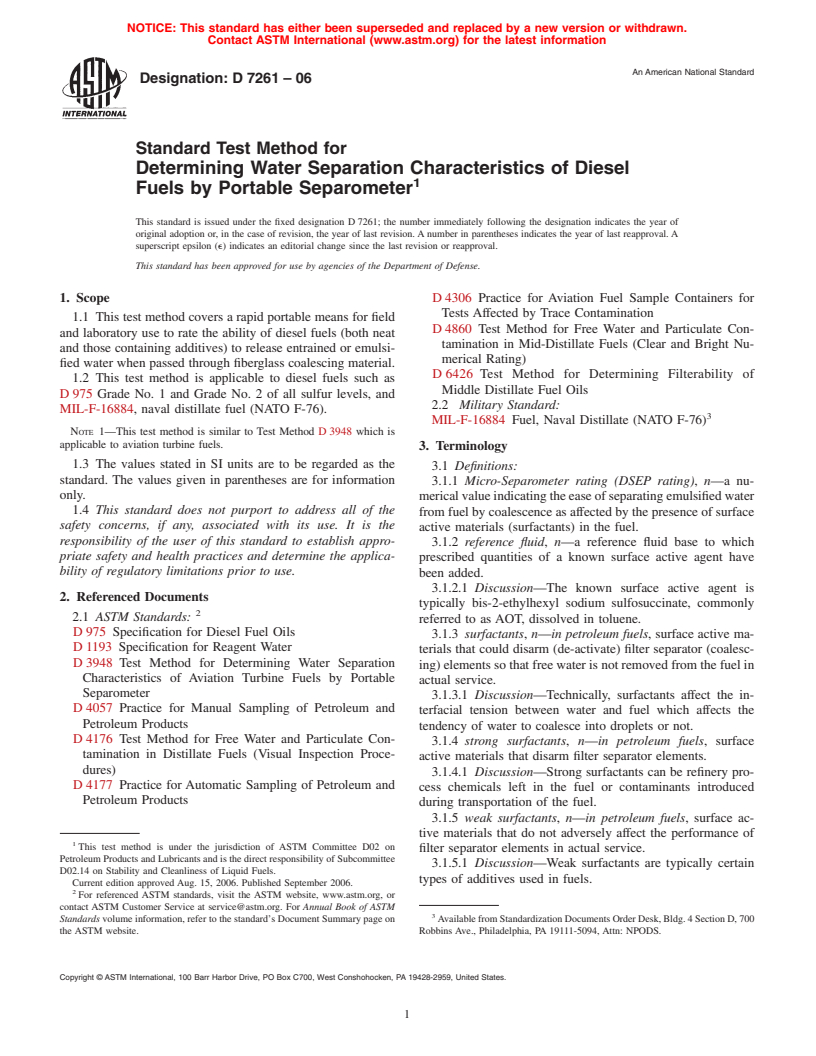

7.1 A Micro-Separometer instrument is used to perform

3.3.5 MSEP—Micro-Separometer

the test. The unit is portable and self-contained, capable of

3.3.6 DSEP—Micro-Separometer–Diesel

operating on an internal rechargeable battery pack or being

connected to an ac power source using power cords which are

4. Summary of Test Method

available for various voltages. Connection to an ac power

4.1 A 50 mL water/fuel sample emulsion is created in a source will provide power to the unit and affect battery

syringe using a high-speed mixer. The emulsion is then recharge. The accessories can be packed in the cover of the

expelled from the syringe at a programmed rate through a lockable case.

standard fiber-glass coalescer and the effluent is analyzed for 7.1.1 The Emcee Model 1140 Micro-Separometer Mark V

uncoalesced water by a light transmission measurement. Deluxe and associated control panel is shown in Fig. 1. The

4.2 The results are reported on a 0-to-100 scale to the emulsifier is on the right side of the raised panel and the

nearest whole number, however the effective range of the test syringe drive mechanism is on the left side. The control panel

equipment is from 50 to 100. High ratings indicate that water containing the operating controls (pushbuttons) is mounted on

is easily coalesced, implying that the fuel is relatively free of the fixed panel in the left side of the case. Table 1 lists the

surfactants. manualandaudiooperatingcharacteristicsoftheinstrument.A

circuit breaker located on the control panel provides protection

4.3 A test can be performed in 5 to 10 min.

for the ac power circuit. The turbidimeter is located under the

main control panel and consists of a well in which the sample

5. Significance and Use

vial is placed, a light source, and a photocell.

5.1 This test method provides a measure of the presence of

surfactants in diesel fuels, and can be performed in the field or

NOTE 3—Of the lettered (A-G) pushbuttons, only the D pushbutton is

in a laboratory. Like Test Method D 3948 used for jet fuel, this applicable to this test method.

test method can detect traces of some refinery treating chemi-

7.2 Beaker, Catch Pan, or Plastic Container—(Supplied

cals left in fuel. It can also detect surface active substances

with each Micro-Separometer) used to receive the waste fuel

added to or picked up by the fuel during handling from point

during the coalescence period of the test.

of production to point of use.

7.3 Pipet—An automatic 50-µL hand pipet (supplied with

5.2 Certain additives, which can act as weak surfactants,

each Micro-Separometer) designed to accept a disposable

give a slightly reduced DSEP rating. Other substances which

plastic tip.

are strong surfactants give much lower DSEP ratings.

5.3 While filter separators have not been common in diesel 8. Reagents and Materials

fuel systems, they could become more prevalent with ULSD

8.1 Aerosol OT, (AOT), solid (100 % dry) bis-2-ethylhexyl

containing increased additive content to ensure clean, dry fuels

sodium sulfosuccinate.

in new engine designs. Weak surfactants, with slightly reduced

DSEP ratings, do not affect the ability of filter separators to

The sole source of supply of the apparatus known to the committee at this time

separate free water from the fuel. Strong surfactants give a

is the Model 1140 Micro-Separometer Mark V Deluxe, available from EMCEE

much lower DSEP rating and adversely affect the ability of

Electronics, Inc., 520 Cypress Ave., Venice, FL 34285, U.S.A. www.emcee-

filter separators to separate free water from the fuel.

electronics.com If you are aware of alternative suppliers, please provide this

5.4 Results from this test method do not have a known information to ASTM International Headquarters. Your comments will receive

careful consideration at a meeting of the responsible technical committee. This test

relationship to the rate of water settling in tanks.

method is under the jurisdiction of ASTM Committee D02 on Petroleum Products

5.5 The Micro-Separometer has a measurement range from

and Lubricants and is the direct responsibility of Subcommittee D02.14 on

50to100.Valuesobtainedoutsideofthoselimitsareundefined

Cleanliness and Stability of Liquid Fuels.

The Model 1140 Micro-Separometers Mark III and Mark V Standard versions

and invalid.

may also be used, but they are no longer supported by the manufacturer. For

NOTE 2—In the event a value greater than 100 is obtained, there is a

operating procedures using these instruments, the user is referred to Test Method

good probability that light transmittance was reduced by material con- D 3948–87.

D7261–06

FIG. 1 Micro-Separometer Mark V Deluxe and Associated Control Panel

TABLE 1 Manual and Audio Operating Characteristics of the

Emcee Model 1140 Micro-Separometer Instrument for

Mode D Operation

Available Test Mode(s) Function Mark V Deluxe

Test Mode - Select Mode D

Depress D Pushbutton

Syringe Drive Not required

Speed Selection Not required

Clean Cycle

Depress START Pushbutton

Initiate Automatic Test Sequence

Depress START Pushbutton

Cancel Automatic Sequence

FIG. 2 Test Supplies and Small Parts

Depress RESET Pushbutton

1st Meter Read

1st Meter Adjust Depress ARROWED Pushbuttons

2nd Meter Read

2nd Meter Adjust Depress ARROWED Pushbuttons

Collect Sample Short Tone and C/S

Annunciator Lamp Illuminates

3rd Meter Read

Record Measurement Pulsed Tone Sounds5sinto3rdMeter Read

8.2 Dispersing Agent—Toluene solution (Warning—

Flammable. Vapor harmful.) containing 1 mg of Aerosol OT

per milliliter of toluene.

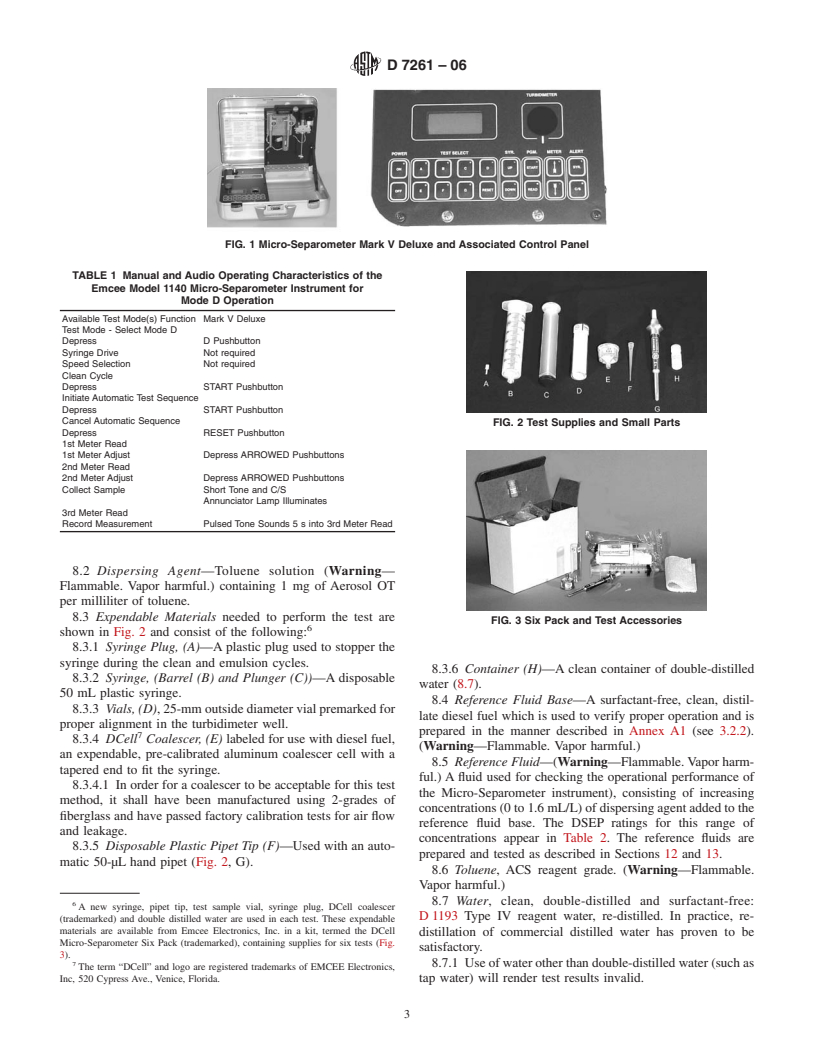

8.3 Expendable Materials needed to perform the test are

FIG. 3 Six Pack and Test Accessories

shown in Fig. 2 and consist of the following:

8.3.1 Syringe Plug, (A)—A plastic plug used to stopper the

syringe during the clean and emulsion cycles.

8.3.6 Container (H)—A clean container of double-distilled

8.3.2 Syringe, (Barrel (B) and Plunger (C))—A disposable

water (8.7).

50 mL plastic syringe.

8.4 Reference Fluid Base—A surfactant-free, clean, distil-

8.3.3 Vials, (D),25-mmoutsidediametervialpremarkedfor

late diesel fuel which is used to verify proper operation and is

proper alignment in the turbidimeter well.

prepared in the manner described in Annex A1 (see 3.2.2).

8.3.4 DCell Coalescer, (E) labeled for use with diesel fuel,

(Warning—Flammable. Vapor harmful.)

an expendable, pre-calibrated aluminum coalescer cell with a

8.5 Reference Fluid—(Warning—Flammable.Vapor harm-

tapered end to fit the syringe.

ful.) A fluid used for checking the operational performance of

8.3.4.1 In order for a coalescer to be acceptable for this test

the Micro-Separometer instrument), consisting of increasing

method, it shall have been manufactured using 2-grades of

concentrations (0 to 1.6 mL/L) of dispersing agent added to the

fiberglass and have passed factory calibration tests for air flow

reference fluid base. The DSEP ratings for this range of

and leakage.

concentrations appear in Table 2. The reference fluids are

8.3.5 Disposable Plastic Pipet Tip (F)—Used with an auto-

prepared and tested as described in Sections 12 and 13.

matic 50-µL hand pipet (Fig. 2, G).

8.6 Toluene, ACS reagent grade. (Warning—Flammable.

Vapor harmful.)

8.7 Water, clean, double-distilled and surfactant-free:

A new syringe, pipet tip, test sample vial, syringe plug, DCell coalescer

D 1193 Type IV reagent water, re-distilled. In practice, re-

(trademarked) and double distilled water are used in each test. These expendable

materials are available from Emcee Electronics, Inc. in a kit, termed the DCell

distillation of commercial distilled water has proven to be

Micro-Separometer Six Pack (trademarked), containing supplies for six tests (Fig.

satisfactory.

3).

8.7.1 Useofwaterotherthandouble-distilledwater(suchas

The term “DCell” and logo are registered trademarks of EMCEE Electronics,

Inc, 520 Cypress Ave., Venice, Florida. tap water) will render test results invalid.

D7261–06

A

TABLE 2 Expected Performance for Reference Fluids

at least 1-L, and preferably about 3-L, in a clean container in

AOT DSEP accordance with Practice D 4057 or D 4177.

Std Dev

mL/L Rating

NOTE 7—Test method results are known to be sensitive to trace

0.0 97 0.89

contamination from sampling containers. For recommended sampling

0.2 90 2.88

containers, refer to Practice D 4306. Special precautions concerning

0.4 85 2.58

sample containers and sampling technique are discussed inAppendix X1.

0.8 77 1.55

1.6 65 1.75 Extremecareandcleanlinessarerequiredintakingsampleseitherdirectly

A into the test syringe or into a sample container.

Expected range of values obtained by using increasing amounts of dispersing

agent AOT u

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.