ASTM A252-10

(Specification)Standard Specification for Welded and Seamless Steel Pipe Piles

Standard Specification for Welded and Seamless Steel Pipe Piles

ABSTRACT

This specification covers nominal wall cylindrical steel pipe piles in which the steel cylinder acts as a permanent load-carrying member or as a shell to form cast-in-place concrete piles. Each welded pile shall be made by seamless, electric resistance welding, flash welding or fusion welding with longitudinal, helical-butt, or helical-lap seams. This specification also deals with material tensile requirements, minimum elongation values and common size and weights per unit length values.

SCOPE

1.1 This specification covers nominal (average) wall steel pipe piles of cylindrical shape and applies to pipe piles in which the steel cylinder acts as a permanent load-carrying member, or as a shell to form cast-in-place concrete piles.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The text of this specification contains notes and footnotes that provide explanatory material. Such notes and footnotes, excluding those in tables and figures, do not contain any mandatory requirements.

1.4 The following precautionary caveat pertains only to the test method portion, Section 16 of this specification. This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A252 −10

Standard Specification for

1

Welded and Seamless Steel Pipe Piles

This standard is issued under the fixed designation A252; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 Definitions of terms used in this specification shall be

in accordance with Terminology A941.

1.1 This specification covers nominal (average) wall steel

3.1.2 defect—animperfectionofsufficientsizeormagnitude

pipe piles of cylindrical shape and applies to pipe piles in

to be cause for rejection.

which the steel cylinder acts as a permanent load-carrying

3.1.3 imperfection—any discontinuity or irregularity found

member, or as a shell to form cast-in-place concrete piles.

in the pipe.

1.2 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

4. Ordering Information

conversions to SI units that are provided for information only

4.1 Ordersformaterialunderthisspecificationshallcontain

and are not considered standard.

information concerning as many of the following items as are

1.3 The text of this specification contains notes and foot-

required to describe the desired material adequately:

notes that provide explanatory material. Such notes and 4.1.1 Quantity (feet or number of lengths),

footnotes, excluding those in tables and figures, do not contain

4.1.2 Name of material (steel pipe piles),

any mandatory requirements. 4.1.3 Method of manufacture (seamless or welded),

4.1.4 Grade (Tables 1 and 2),

1.4 The following precautionary caveat pertains only to the

4.1.5 Size (outside diameter and nominal wall thickness),

test method portion, Section 16 of this specification. This

4.1.6 Lengths (single random, double random, or uniform)

standard does not purport to address all of the safety problems,

(see Section 13),

if any, associated with its use. It is the responsibility of the user

4.1.7 End finish (Section 15), and

of this standard to establish appropriate safety and health

4.1.8 ASTM specification designation and year of issue,

practices and determine the applicability of regulatory limita-

4.1.9 Location of purchaser’s inspection (see 19.1), and

tions prior to use.

4.1.10 Bar coding (see 22.2).

2. Referenced Documents

5. Materials and Manufacture

2

2.1 ASTM Standards:

5.1 The piles shall be made by the seamless, electric

A370Test Methods and Definitions for Mechanical Testing

resistance welded, flash welded, or fusion welded process.The

of Steel Products

seams of welded pipe piles shall be longitudinal, helical-butt,

A751Test Methods, Practices, and Terminology for Chemi-

or helical-lap.

cal Analysis of Steel Products

A941TerminologyRelatingtoSteel,StainlessSteel,Related

NOTE 1—For welded pipe piles, the weld should not fail when the

product is properly fabricated and installed and subjected to its intended

Alloys, and Ferroalloys

end use.

E29Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

6. Process

6.1 Thesteelshallbemadebyoneormoreofthefollowing

3. Terminology

processes: open-hearth, basic-oxygen, or electric-furnace.

3.1 Definitions:

7. Chemical Composition

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

7.1 The steel shall contain no more than 0.050% phospho-

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

rous.

A01.09 on Carbon Steel Tubular Products.

Current edition approved Oct. 1, 2010. Published November 2010. Originally

8. Heat Analysis

approved in 1944. Last previous edition approved in 2007 as A252–98(2007).

DOI: 10.1520/A0252-10.

8.1 Each heat analysis shall conform to the requirement

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

specified in 7.1. When requested by the purchaser, the appli-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

cable heat analyses shall be reported to the purchaser ro the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. purchaser’s representative.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

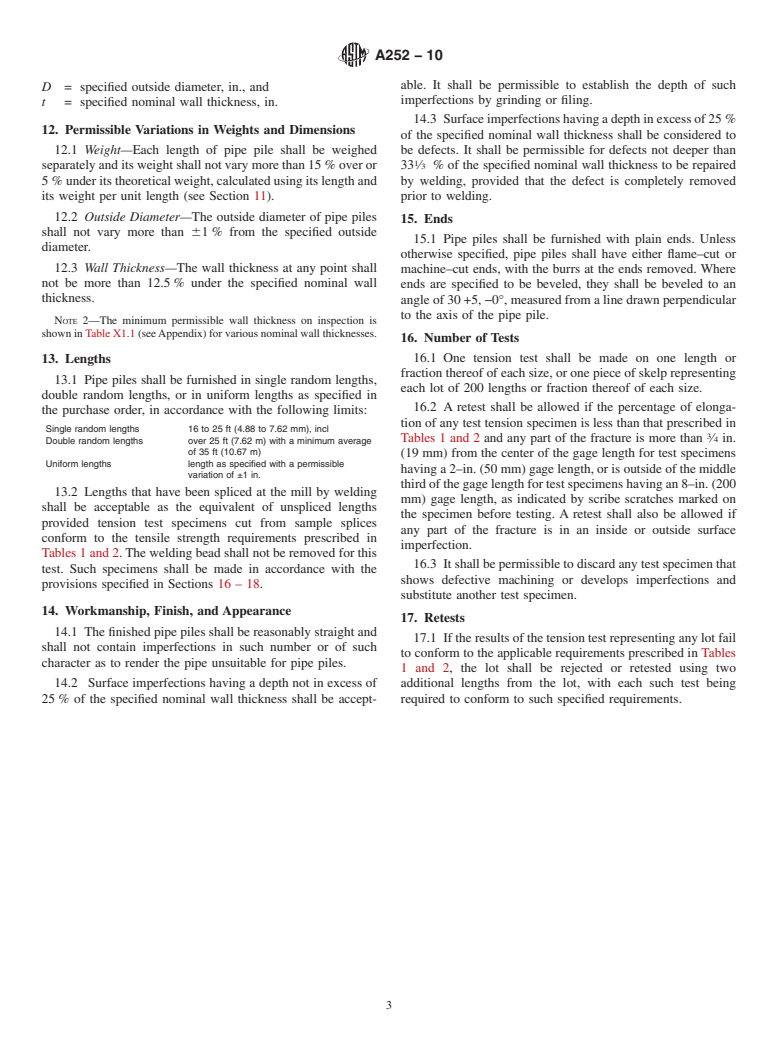

A252−10

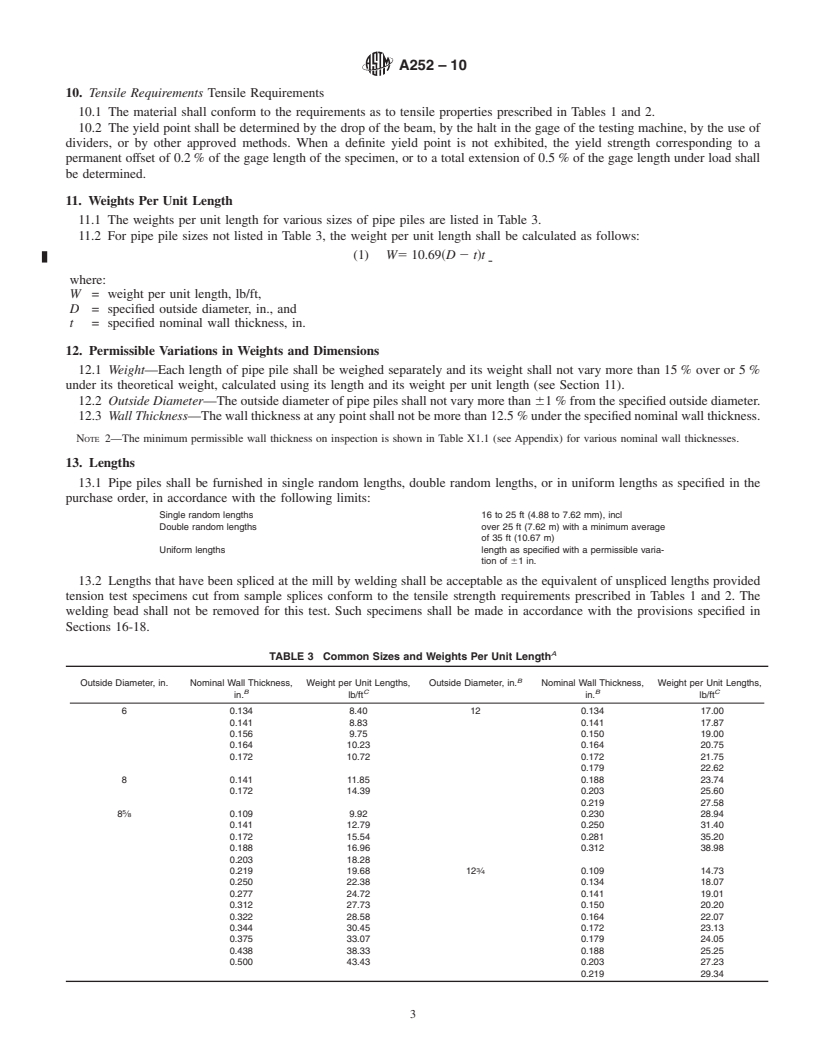

TABLE 1 Tensile Requirements

NOTE 1—Where an ellipsis (.) appears in this table, there is no requirement.

Grade 1 Grade 2 Grade 3

Tensile strength, min, psi (MPa) 50 000 (345) 60 000 (415) 66 000 (455)

Yield point or yield strength, min, psi (MPa) 30 000 (205) 35 000 (240) 45 000 (310)

5

Basic minimum elongation for nominal wall thicknesses ⁄16 in. (7.9 mm) or more:

Elongation i

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A252 – 10

Standard Specification for

1

Welded and Seamless Steel Pipe Piles

This standard is issued under the fixed designation A252; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers nominal (average) wall steel pipe piles of cylindrical shape and applies to pipe piles in which the

steel cylinder acts as a permanent load-carrying member, or as a shell to form cast-in-place concrete piles.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 The text of this specification contains notes and footnotes that provide explanatory material. Such notes and footnotes,

excluding those in tables and figures, do not contain any mandatory requirements.

1.4 The following precautionary caveat pertains only to the test method portion, Section 16 of this specification. This standard

does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

3. Terminology

3.1 Definitions—Definitions of terms used in this specification shall be in accordance with Terminology A941.

3.1.1 defect—an imperfection of sufficient size or magnitude to be cause for rejection.

3.1.2 imperfection—any discontinuity or irregularity found in the pipe.

4. Ordering Information

4.1 Orders for material under this specification shall contain information concerning as many of the following items as are

required to describe the desired material adequately:

4.1.1 Quantity (feet or number of lengths),

4.1.2 Name of material (steel pipe piles),

4.1.3 Method of manufacture (seamless or welded),

4.1.4 Grade (Tables 1 and 2),

4.1.5 Size (outside diameter and nominal wall thickness),

4.1.6 Lengths (single random, double random, or uniform) (see Section 13),

4.1.7 End finish (Section 15), and

4.1.8 ASTM specification designation and year of issue,

4.1.9 Location of purchaser’s inspection (see 19.1), and

4.1.10 Bar coding (see 22.2).

5. Materials and Manufacture

5.1 The piles shall be made by the seamless, electric resistance welded, flash welded, or fusion welded process. The seams of

welded pipe piles shall be longitudinal, helical-butt, or helical-lap.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.09

on Carbon Steel Tubular Products.

Current edition approved Oct. 1, 2010. Published October 2010. Originally approved in 1944. Last previous edition approved in 2007 as A252 – 98(2007). DOI:

10.1520/A0252-10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A252 – 10

TABLE 1 Tensile Requirements

NOTE—Where an ellipsis (.) appears in this table, there is no requirement.

Grade 1 Grade 2 Grade 3

Tensile strength, min, psi (MPa) 50 000 (345) 60 000 (415) 66 000 (455)

Yield point or yield strength, min, psi (MPa) 30 000 (205) 35 000 (240) 45 000 (310)

5

Basic minimum elongation for nominal wall thicknesses ⁄16 in. (7.9 mm) or more:

Elongation in 8 in. (203.2 mm), min, % 18 14 . . .

Elongation in 2 in. (50.8 mm), min, % 30 25 20

A A A

5

For nominal wall thicknesses less than ⁄16 in. (7.9 mm), the deduction from 1.50 1.25 1.0

1

the basic m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.