ASTM D5405-98(2004)

(Test Method)Standard Test Method for Conducting Time-to-Failure (Creep-Rupture) Tests of Joints Fabricated from Nonbituminous Organic Roof Membrane Material

Standard Test Method for Conducting Time-to-Failure (Creep-Rupture) Tests of Joints Fabricated from Nonbituminous Organic Roof Membrane Material

SIGNIFICANCE AND USE

An important factor affecting the performance of joints of nonbituminous membranes is their ability to remain bonded over the membrane’expected service life. Time-to-failure tests provide a means of characterizing the behavior of joints under constant load over time.

Creep is a sensitive index of rheological properties that depend on material, load, temperature, and time. Time-to-failure data that are obtained over a relatively short time period can evaluate one factor affecting a joint’ability to withstand static loading over a relatively long time period.

Time-to-failure data for joints of nonbituminous organic roof membrane specimens can be used for the following: (1) to provide a measure of the load-carrying ability of the joint as a function of time at various levels of load, temperature, and relative humidity; (2) to characterize the joint with regard to factors affecting performance, such as surface preparation of the adherend, solvent-based adhesive thickness and open time, environment during adhesive application and cure, and temperature of thermal welding processes; and (3) to compare the effects of different bonding processes or adhesive bonding materials on joint performance.

While it is considered that the results obtained by this laboratory test may afford a measure of the performance of seams in service, provided that load, temperature, and humidity conditions are known, no direct correlation has been established.

SCOPE

1.1 This test method covers laboratory determination of the time-to-failure (creep-rupture) of joints fabricated from nonbituminous organic roof membrane material. The test method covers both T-peel and lap-shear joints subjected to constant tensile load under controlled environmental conditions. The joints, made from either unreinforced or fabric-reinforced membrane material, are prepared in the laboratory or sampled from roofs in service.

1.2 Sheet materials from which the joints are fabricated include vulcanized rubbers, nonvulcanized polymeric sheets, and thermoplastics. The bonding methods for joint formation include the use of liquid-based adhesives, preformed tapes, and thermal and solvent weld processes.

1.3 The values stated in S.I. units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5405 – 98 (Reapproved 2004)

Standard Test Method for

Conducting Time-to-Failure (Creep-Rupture) Tests of Joints

Fabricated from Nonbituminous Organic Roof Membrane

Material

This standard is issued under the fixed designation D5405; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers laboratory determination of the 3.1 Definitions—For definitions of terms used in this test

time-to-failure (creep-rupture) of joints fabricated from nonbi- method, refer to Terminology D907 and D1079.

tuminous organic roof membrane material. The test method 3.2 Definitions of Terms Specific to This Standard:

covers both T-peel and lap-shear joints subjected to constant 3.2.1 creep-rupture test—a test that measures the time-to-

tensile load under controlled environmental conditions. The failure of a specimen subjected to a constant load; progressive

joints, made from either unreinforced or fabric-reinforced specimen deformation may also be measured.

membrane material, are prepared in the laboratory or sampled 3.2.2 failure—rupture of the bond resulting in complete

from roofs in service. separation of its adherends under the test conditions; or,

1.2 Sheet materials from which the joints are fabricated alternatively, rupture of the membrane material away from the

include vulcanized rubbers, nonvulcanized polymeric sheets, bonded section of the test specimen (that is, material rupture).

and thermoplastics. The bonding methods for joint formation 3.2.3 time-to-failure—the period of time beginning when a

includetheuseofliquid-basedadhesives,preformedtapes,and joint specimen is placed under load and ending when failure

thermal and solvent weld processes. occurs.

1.3 The values stated in S.I. units are to be regarded as the

4. Summary of Test Method

standard. The values given in parentheses are for information

4.1 This test method is a creep-rupture test without mea-

only.

1.4 This standard does not purport to address all of the surement of specimen deformation. The time-to-failure, in

safety concerns, if any, associated with its use. It is the hours, of joints fabricated from nonbituminous organic roof

membrane materials is measured when subject to constant

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- deadweight loads under controlled temperature and humidity

conditions.

bility of regulatory limitations prior to use.

2. Referenced Documents 5. Significance and Use

5.1 An important factor affecting the performance of joints

2.1 ASTM Standards:

D816 Test Methods for Rubber Cements of nonbituminous membranes is their ability to remain bonded

over the membrane’s expected service life. Time-to-failure

D907 Terminology of Adhesives

D1079 Terminology Relating to Roofing andWaterproofing tests provide a means of characterizing the behavior of joints

under constant load over time.

D1876 Test Method for Peel Resistance of Adhesives (T-

Peel Test) 5.2 Creep is a sensitive index of rheological properties that

depend on material, load, temperature, and time. Time-to-

failure data that are obtained over a relatively short time period

This test method is under the jurisdiction ofASTM Committee D08 on Roofing can evaluate one factor affecting a joint’s ability to withstand

and Waterproofing and is the direct responsibility of Subcommittee D08.18 on

static loading over a relatively long time period.

Nonbituminous Organic Roof Coverings.

5.3 Time-to-failure data for joints of nonbituminous organic

Current edition approved July 1, 2004. Published July 2004. Originally approved

roof membrane specimens can be used for the following: (1)to

in 1993. Last previous edition approved in 1998 as D5405 – 98. DOI: 10.1520/

D5405-98R04.

provide a measure of the load-carrying ability of the joint as a

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

function of time at various levels of load, temperature, and

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

relative humidity; (2) to characterize the joint with regard to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. factors affecting performance, such as surface preparation of

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5405 – 98 (2004)

the adherend, solvent-based adhesive thickness and open time,

environment during adhesive application and cure, and tem-

perature of thermal welding processes; and (3) to compare the

effects of different bonding processes or adhesive bonding

materials on joint performance.

5.4 While it is considered that the results obtained by this

laboratory test may afford a measure of the performance of

seamsinservice,providedthatload,temperature,andhumidity

conditions are known, no direct correlation has been estab-

lished.

6. Apparatus

6.1 Test Chamber, of sufficient size to hold a minimum of

15 specimens. The height of the chamber shall be sufficient to

allow suspension of the deadweight loads and specimen

deformation during testing. The chamber shall be structurally

capable of supporting the loads anticipated during testing

without appreciable deflection.

NOTE 1—A minimum height of 600 mm (24 in.) is suitable for the

specimen sizes described in this test method if they are not extremely

extensible. A taller chamber may be needed if they are extremely

extensible.

FIG. 1 Schematic of a T-Peel Specimen Clamped Under Load

6.1.1 Temperature and Humidity Control—The control of

temperature and humidity is important, since small changes in

these variables may produce large changes in time-to-failure.

NOTE 4—If each specimen has its own timer device (see 6.5), it is not

The temperature and relative humidity within the chamber

necessary to load all specimens simultaneously.

shall be controlled within 63°C (6 5°F) and 65 % relative

humidity, respectively, over the duration of the test. Any 6.5 Timer Device, for recording the total time over which

deviations from these limits shall be given in the test report. eachindividualspecimenisunderload,orformarkingthetime

The selected temperature and humidity conditions shall be at which failure of each specimen occurs.The sensitivity of the

uniform throughout the enclosed space (63°C or 65°F and timer shall be as follows:

65 %relativehumidity).Ifthisuniformityisachievedthrough

Failure Time Timer Sensitivity

#25 h 0.1 min

mechanical air circulation, it shall not cause the specimens to

>25 and#100 h 0.01 h

sway, vibrate, or be otherwise disturbed.

>100 h 0.1 h

NOTE 2—Suggested test conditions are as follows: (1) normal ambient

NOTE 5—For investigations involving multiple specimens in the cham-

temperature (approximately 23°C or 73°F) and humidity (50 % relative

ber, a computer-controlled timer that records the time-to-failure has been

humidity); and (2) extremes to which the seams may be subjected in

found to be satisfactory. In this case, a micro-electrical circuit connected

service.

to the computer is set up for each specimen. The circuit consists of a wire

loop,ofwhichonesegmentisashortlengthofwire(triggerwire)attached

6.2 Specimen and Load Clamping—The chamber shall be

to each grip on the test specimen and set to stop the computer clock when

equipped with a means for clamping the joint specimens

failure occurs. At the point of attachment at the top grip, the trigger wire

vertically to the top of the interior of the chamber, or other

is inserted in an electrical connector. When the specimen fails and the

suitable upper support. Also, a clamp shall be provided to

deadweight on the lower grip falls, the trigger wire is pulled from the

secure the deadweight loads to the bottom of the joint connector, breaking the circuit and stopping the clock.

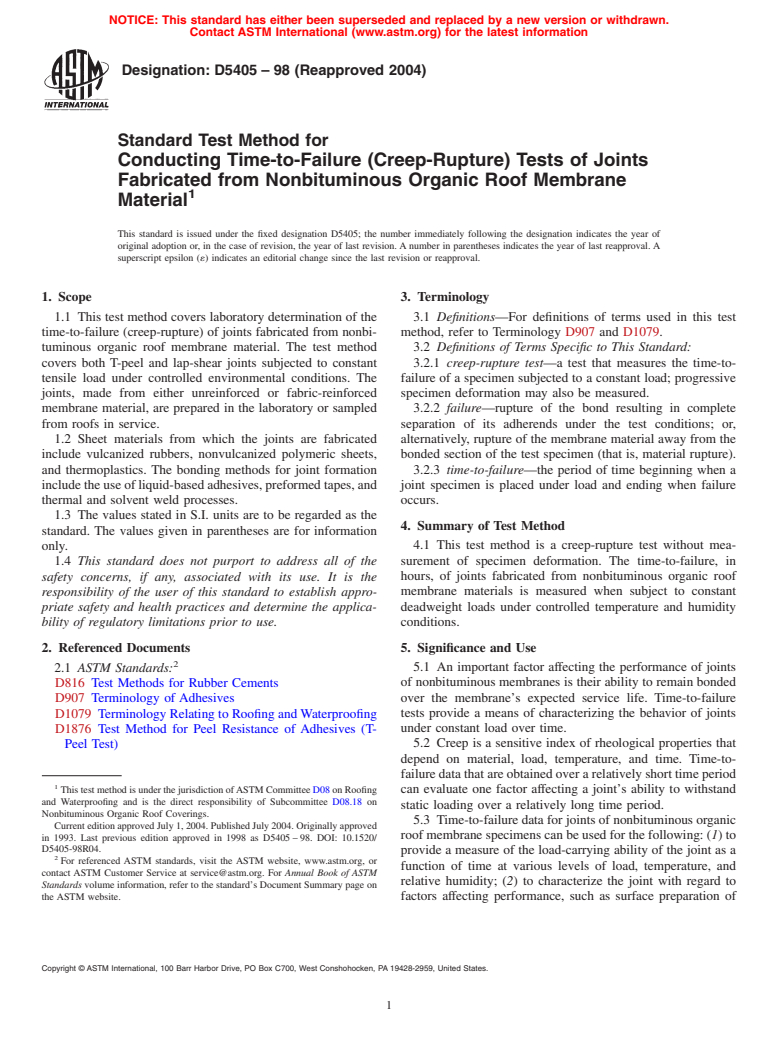

specimens. Figs. 1 and 2 show a suggested clamping arrange-

7. Vibration Control

ment including the deadweight load.

6.3 Deadweight Loads, of appropriate mass (see Section

7.1 Because the time-to-failure tests are sensitive to vibra-

10).

tion, select a location of the testing apparatus for minimum

disturbance.Whenavibration-freelocationisnotavailable,the

NOTE 3—It is convenient to have available a means of providing

testing apparatus shall be designed so that the specimens are

variableloadsthatmaydifferfromtesttotest,dependingontheproperties

of the joint specimens and test conditions. Hollow pipe nipples containing isolated from vibration. In addition, precautions shall be taken

lead shot and sealed with end caps provide convenient deadweights. The

to avoid vibration caused by the falling deadweights at

mass of the deadweights is adjusted by adding or removing lead shot.

specimen failure. Caution shall be exercised during testing to

avoid vibration due to normal laboratory activities such as

6.4 Load Application Mechanism—This device allows for

placing all of the joint specimens under load simultaneously. opening and closing doors and bench drawers.

An example of such a device is a large tray, suspended on

NOTE 6—A wire cord, attached to the deadweight and also upper

pulleys, which supports the loads attached to the bottom of the

specimen clamp, minimizes vibration at specimen failure.The cord length

specimens. Lowering the tray allows all test specimens and

mustbelongenoughtoallowfreefallofthedeadweight,butshortenough

deadweights attached to them to be suspended freely at once. to prevent it from striking the floor of the test chamber.

D5405 – 98 (2004)

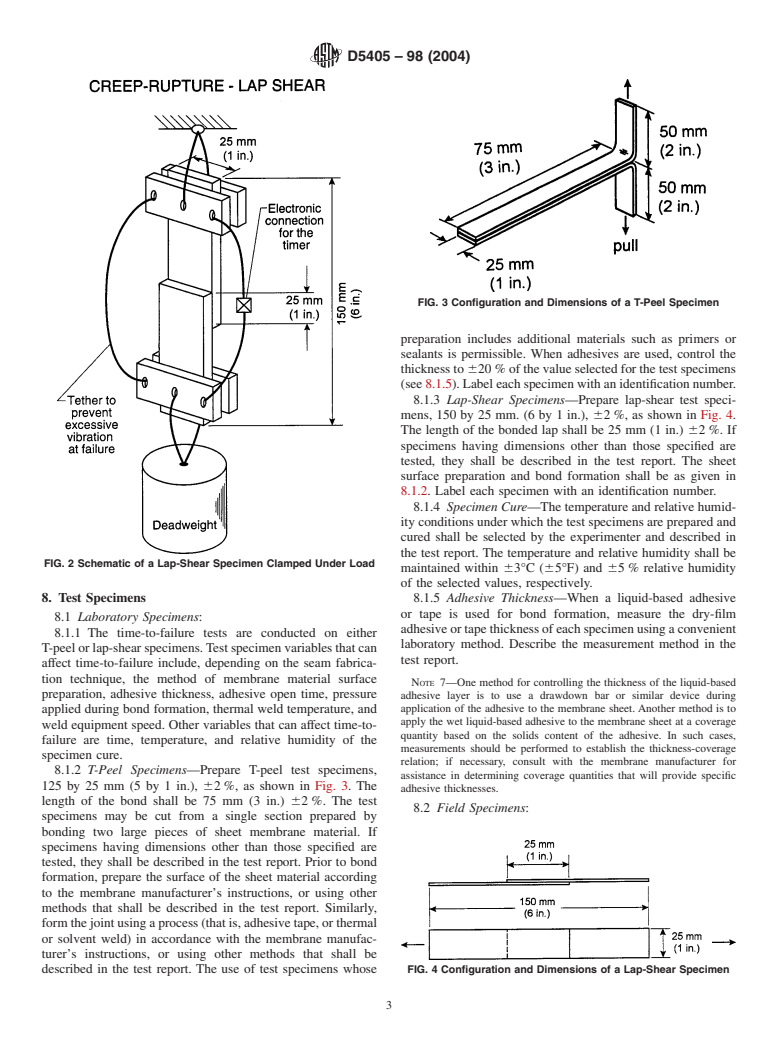

FIG. 3 Configuration and Dimensions of a T-Peel Specimen

preparation includes additional materials such as primers or

sealants is permissible. When adhesives are used, control the

thickness to 620 % of the value selected for the test specimens

(see8.1.5).Labeleachspecimenwithanidentificationnumber.

8.1.3 Lap-Shear Specimens—Prepare lap-shear test speci-

mens, 150 by 25 mm. (6 by 1 in.), 62 %, as shown in Fig. 4.

The length of the bonded lap shall be 25 mm (1 in.) 62%.If

specimens having dimensions other than those specified are

tested, they shall be described in the test report. The sheet

surface preparation and bond formation shall be as given in

8.1.2. Label each specimen with an identification number.

8.1.4 Specimen Cure—The temperature and relative humid-

ity conditions under which the test specimens are prepared and

cured shall be selected by the experimenter and described in

the test report. The temperature and relative humidity shall be

FIG. 2 Schematic of a Lap-Shear Specimen Clamped Under Load

maintained within 63°C (65°F) and 65 % relative humidity

of the selected values, respectively.

8. Test Specimens 8.1.5 Adhesive Thickness—When a liquid-based adhesive

or tape is used for bond formation, measure the dry-film

8.1 Laboratory Specimens:

adhesiveortapethicknessofeachspecimenusingaconvenient

8.1.1 The time-to-failure tests are conducted on either

laboratory method. Describe the measurement method in the

T-peelorlap-shearspecimens.Testspecimenvariablesthatcan

test report.

affect time-to-failure include, depending on the seam fabrica-

tion technique, the method of membrane material surface

NOTE 7—One method for controlling the thickness of the liquid-based

preparation, adhesive thickness, adhesive open time, pressure adhesive layer is to use a drawdown bar or similar device during

application of the adhesive to the membrane sheet. Another method is to

applied during bond formation, thermal weld temperature, and

apply the wet liquid-based adhesive to the membrane sheet at a coverage

weld equipment speed. Other variables that can affect time-to-

quantity based on the solids content of the adhesive. In such cases,

failure are time, temperature, and relative humidity of the

measurements should be performed to establish the thickness-coverage

specimen cure.

relation; if necessary, consult with the membrane manufacturer for

8.1.2 T-Peel Specimens—Prepare T-peel test specimens,

assistance in determining coverage quantities that will provide specific

125 by 25 mm (5 by 1 in.), 62 %, as shown in Fig. 3. The

adhesive thicknesses.

length of the bond shall be 75 mm (3 in.) 62 %. The test

8.2 Field Specimens:

specimens may be cut from a single section prepared by

bonding two large pieces of sheet membrane material. If

specimens having dimensions other than those specified are

tested, they shall be described in the test report. Prior to bond

formation, prepare the surface of the sheet material according

to the membrane manufacturer’s instructions, or using other

methods that shall be described in the test report. Similarly,

formthejointusingaprocess(thatis,adhesivetape,orthermal

or solvent weld) in accordance with the membrane manufac-

turer’s instructions, or using other methods that shall be

described in the test report. The use of test specimens whose FIG. 4 Configuration and Dimensions of a Lap-Shear Specimen

D5405 – 98 (2004)

creep-rupture life of the joint specimen.

8.2.1 T-peel or lap-shear specimens, having the dimensions

given in Figs. 1 and 2, respectively, may be prepared from

11. Procedure

seams sampled from roofs in service. If the specimens have

11.1 Place the specimens in the upper clamps of the

dimensions other than those given in Figs. 1 and 2, the

chamber by gripping 25 mm (1 in.), 610 %, of the free

specimen dimensions shall be given in the test report. In the

(unadhered) specimen end. Take care to avoid eccentric load-

case of lap-shear specimens, when the length of the bond is

ing of the specimen.

greater than that given in Fig. 2, precautions must be taken to

11.2 Attach the lower clamps and selected loads to the

select sufficiently high deadloads so that failure will occur in a

specimens; grip 25 mm. (1.0 in), 610 %, of the free end of the

reasonable testing time.

specimens in the clamps. The initial distances between the

8.2.2 Record all available pertinent information, including,

clampsarethus50mm(2in.)and100mm(4in.)fortheT-peel

but not limited to, specimen age and type, type of membrane

and lap-shear specimens, respectively. Avoid pre-loading by

attachment, and location of the roof, in the test report.

preventingthedeadweightsfrombeingsuspendedprematurely.

Checktheentireassemblyofspecimenandloadingmechanism

9. Number of Test Specimens and Bond Strength

for alignment; make changes, as necessary, in the assembly

9.1 Prepare a sufficient number of specimens to conduct

until ali

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.