ASTM D5405-98(2004)

(Test Method)Standard Test Method for Conducting Time-to-Failure (Creep-Rupture) Tests of Joints Fabricated from Nonbituminous Organic Roof Membrane Material

Standard Test Method for Conducting Time-to-Failure (Creep-Rupture) Tests of Joints Fabricated from Nonbituminous Organic Roof Membrane Material

SIGNIFICANCE AND USE

An important factor affecting the performance of joints of nonbituminous membranes is their ability to remain bonded over the membrane’expected service life. Time-to-failure tests provide a means of characterizing the behavior of joints under constant load over time.

Creep is a sensitive index of rheological properties that depend on material, load, temperature, and time. Time-to-failure data that are obtained over a relatively short time period can evaluate one factor affecting a joint’ability to withstand static loading over a relatively long time period.

Time-to-failure data for joints of nonbituminous organic roof membrane specimens can be used for the following: (1) to provide a measure of the load-carrying ability of the joint as a function of time at various levels of load, temperature, and relative humidity; (2) to characterize the joint with regard to factors affecting performance, such as surface preparation of the adherend, solvent-based adhesive thickness and open time, environment during adhesive application and cure, and temperature of thermal welding processes; and (3) to compare the effects of different bonding processes or adhesive bonding materials on joint performance.

While it is considered that the results obtained by this laboratory test may afford a measure of the performance of seams in service, provided that load, temperature, and humidity conditions are known, no direct correlation has been established.

SCOPE

1.1 This test method covers laboratory determination of the time-to-failure (creep-rupture) of joints fabricated from nonbituminous organic roof membrane material. The test method covers both T-peel and lap-shear joints subjected to constant tensile load under controlled environmental conditions. The joints, made from either unreinforced or fabric-reinforced membrane material, are prepared in the laboratory or sampled from roofs in service.

1.2 Sheet materials from which the joints are fabricated include vulcanized rubbers, nonvulcanized polymeric sheets, and thermoplastics. The bonding methods for joint formation include the use of liquid-based adhesives, preformed tapes, and thermal and solvent weld processes.

1.3 The values stated in S.I. units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5405 – 98 (Reapproved 2004)

Standard Test Method for

Conducting Time-to-Failure (Creep-Rupture) Tests of Joints

Fabricated from Nonbituminous Organic Roof Membrane

1

Material

This standard is issued under the fixed designation D5405; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers laboratory determination of the 3.1 Definitions—For definitions of terms used in this test

time-to-failure (creep-rupture) of joints fabricated from nonbi- method, refer to Terminology D907 and D1079.

tuminous organic roof membrane material. The test method 3.2 Definitions of Terms Specific to This Standard:

covers both T-peel and lap-shear joints subjected to constant 3.2.1 creep-rupture test—a test that measures the time-to-

tensile load under controlled environmental conditions. The failure of a specimen subjected to a constant load; progressive

joints, made from either unreinforced or fabric-reinforced specimen deformation may also be measured.

membrane material, are prepared in the laboratory or sampled 3.2.2 failure—rupture of the bond resulting in complete

from roofs in service. separation of its adherends under the test conditions; or,

1.2 Sheet materials from which the joints are fabricated alternatively, rupture of the membrane material away from the

include vulcanized rubbers, nonvulcanized polymeric sheets, bonded section of the test specimen (that is, material rupture).

and thermoplastics. The bonding methods for joint formation 3.2.3 time-to-failure—the period of time beginning when a

includetheuseofliquid-basedadhesives,preformedtapes,and joint specimen is placed under load and ending when failure

thermal and solvent weld processes. occurs.

1.3 The values stated in S.I. units are to be regarded as the

4. Summary of Test Method

standard. The values given in parentheses are for information

4.1 This test method is a creep-rupture test without mea-

only.

1.4 This standard does not purport to address all of the surement of specimen deformation. The time-to-failure, in

safety concerns, if any, associated with its use. It is the hours, of joints fabricated from nonbituminous organic roof

membrane materials is measured when subject to constant

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- deadweight loads under controlled temperature and humidity

conditions.

bility of regulatory limitations prior to use.

2. Referenced Documents 5. Significance and Use

2

5.1 An important factor affecting the performance of joints

2.1 ASTM Standards:

D816 Test Methods for Rubber Cements of nonbituminous membranes is their ability to remain bonded

over the membrane’s expected service life. Time-to-failure

D907 Terminology of Adhesives

D1079 Terminology Relating to Roofing andWaterproofing tests provide a means of characterizing the behavior of joints

under constant load over time.

D1876 Test Method for Peel Resistance of Adhesives (T-

Peel Test) 5.2 Creep is a sensitive index of rheological properties that

depend on material, load, temperature, and time. Time-to-

failure data that are obtained over a relatively short time period

1

This test method is under the jurisdiction ofASTM Committee D08 on Roofing can evaluate one factor affecting a joint’s ability to withstand

and Waterproofing and is the direct responsibility of Subcommittee D08.18 on

static loading over a relatively long time period.

Nonbituminous Organic Roof Coverings.

5.3 Time-to-failure data for joints of nonbituminous organic

Current edition approved July 1, 2004. Published July 2004. Originally approved

roof membrane specimens can be used for the following: (1)to

in 1993. Last previous edition approved in 1998 as D5405 – 98. DOI: 10.1520/

D5405-98R04.

provide a measure of the load-carrying ability of the joint as a

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

function of time at various levels of load, temperature, and

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

relative humidity; (2) to characterize the joint with regard to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. factors affecting performance, such as surface preparation of

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

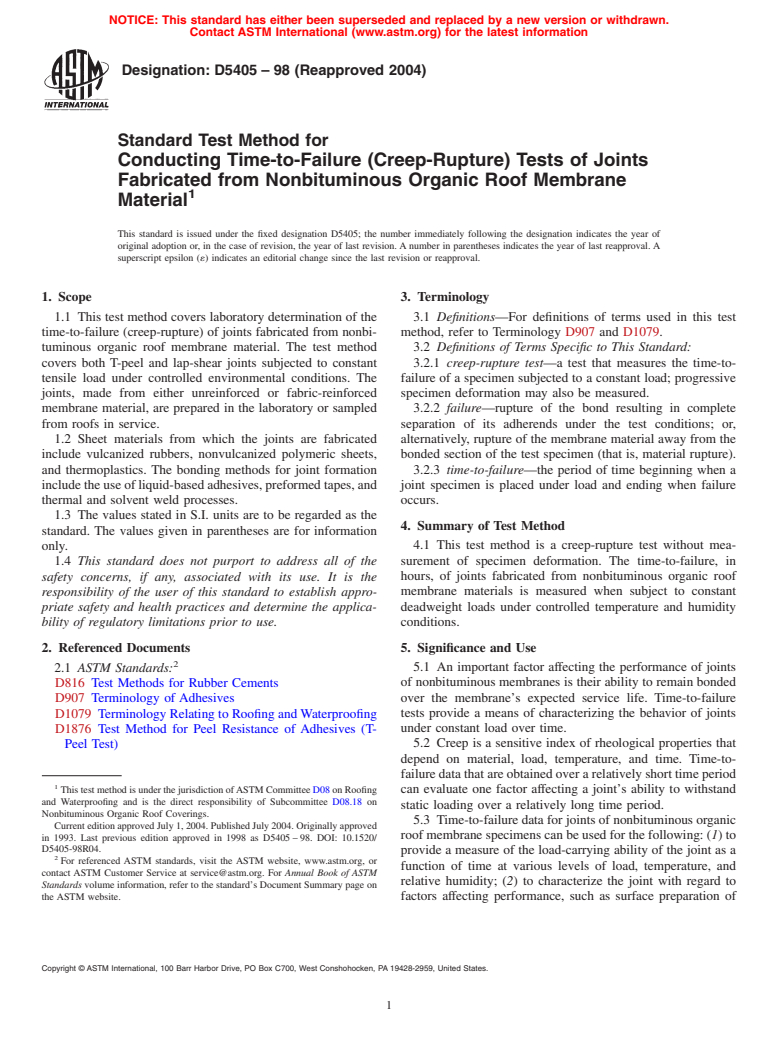

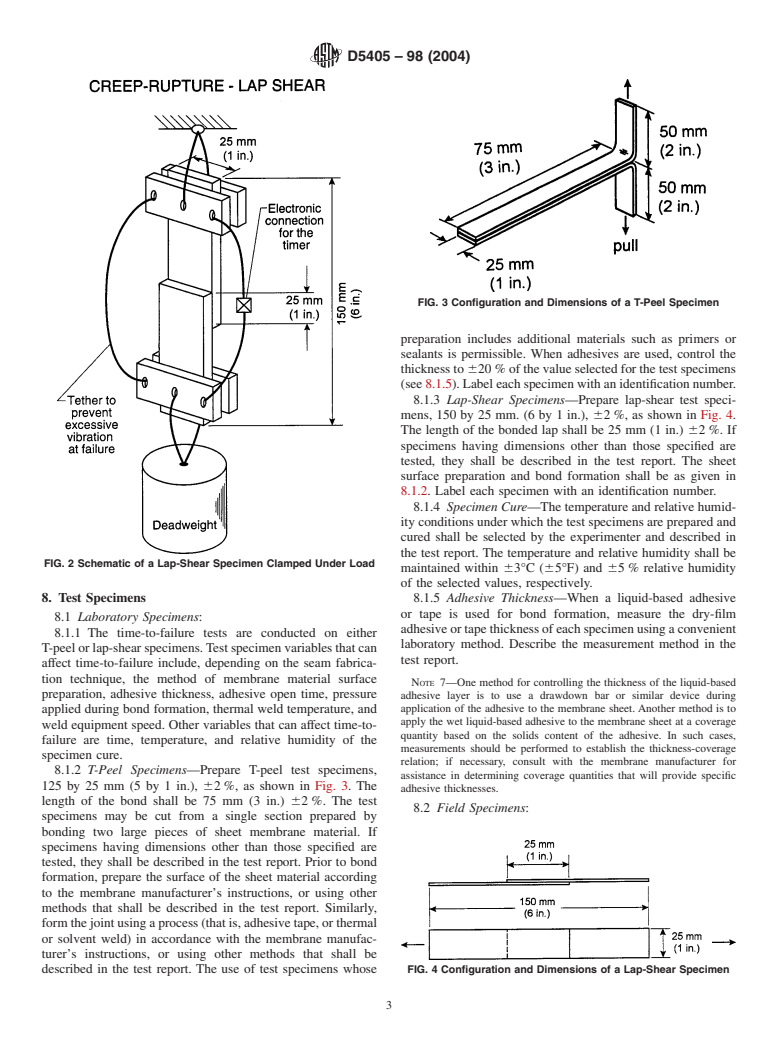

D5405 – 98 (2004)

the adherend, solvent-based adhesive thickness and open time,

environment during adhesive application and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.