ASTM B508-97(2003)

(Specification)Standard Specification for Copper Alloy Strip for Flexible Metal Hose

Standard Specification for Copper Alloy Strip for Flexible Metal Hose

SCOPE

1.1 This specification establishes the requirements for annealed copper-alloy strip for the manufacture of flexible metal hose produced from Copper Alloy UNS Nos. C41100 and C50500.

1.1.1 The nominal compositions are as follows:Copper Alloy UNS No.CopperZincTin C4110091.08.50.5 C5050098.7...1.3

1.2 The values stated in inch-pound units are to be regarded as the standard, except grain size, which is given in SI units. The values given in parentheses are for information only.

1.3 The following precautionary statement pertains only to the test method portion, Section 13, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 508 – 97 (Reapproved 2003)

Standard Specification for

Copper Alloy Strip for Flexible Metal Hose

This standard is issued under the fixed designation B 508; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* E 478 Test Methods for Chemical Analysis of Copper

Alloys

1.1 This specification establishes the requirements for an-

nealed copper-alloy strip for the manufacture of flexible metal

3. Terminology

hose produced from Copper Alloy UNS Nos. C41100 and

3.1 Definitions:

C50500.

3.1.1 For definitions of terms related to copper and copper

1.1.1 The nominal compositions are as follows:

alloys, refer to Terminology B 846.

Copper Alloy Copper Zinc Tin

3.2 Definitions of Terms Specific to This Standard:

UNS No.

C41100 91.0 8.5 0.5

3.2.1 coil (as applied to a flat product)—a length of the

C50500 98.7 . 1.3

product spirally wound into a series of connected turns. The

1.2 The values stated in inch-pound units are to be regarded unqualified term “coil” as applied to “flat product” usually

as the standard, except grain size, which is given in SI units. refers to a coil in which the product is spirally wound, with the

The values given in parentheses are for information only. successive layers on top of one another (sometimes called a

1.3 The following precautionary statement pertains only to “roll”).

the test method portion, Section 13, of this specification: This 3.2.2 level or traverse wound—a coil in which the turns are

standard does not purport to address all of the safety concerns, positioned into layers parallel to the axis of the coil such that

if any, associated with its use. It is the responsibility of the user successive turns in a given layer are next to one another.

of this standard to establish appropriate safety and health

3.2.3 level or traverse wound on a reel or spool—a coil in

practices and determine the applicability of regulatory limita- which the turns are positioned into layers on a reel or spool

tions prior to use.

parallel to the axis of the reel or spool such that successive

turns in a given layer are next to one another.

2. Referenced Documents

3.2.4 reel or spool—a cylindrical device that has a rim at

2.1 ASTM Standards:

each end and an axial hole for a shaft or spindle, and on which

B 601 Classification for Temper Designations for Copper the product is wound to facilitate handling and shipping.

and Copper Alloys—Wrought and Cast

3.2.5 strip—a rolled flat product, other than flat wire, up to

B 846 Terminology for Copper and Copper Alloys and including 0.188 in. [4.78 mm] thick, in straight lengths,

E 29 Practice for Using Significant Digits in Test Data to

coils (rolls), or traverse wound on reels or spools: with slit,

Determine Conformance with Specifications sheared, or slit and rolled edges in widths up to 24 in. [610

E 62 Test Methods for Chemical Analysis of Copper and

mm] inclusive; or, with finished drawn or rolled edges in

Copper Alloys (Photometric Method) widths over 1 ⁄4 to 12 in. [31.8 to 305 mm] inclusive.

E 112 Test Methods for Determining the Average Grain

4. Ordering Information

Size

E 255 Practice for Sampling Copper and CopperAlloys for 4.1 Orders for product under this specification should in-

Determination of Chemical Composition clude the following information:

4.1.1 ASTM designation and year of issue,

4.1.2 Copper Alloy UNS No. (see Section 1 and Table 1),

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

4.1.3 Temper (see 7.1 and Table 2),

and Copper Alloys and is direct responsibility of Subcommittee B05.01 on Plate,

4.1.4 Quantity, number of pieces or total weight of each

Sheet, and Strip.

Current edition approved Apr. 10, 2003. Published June 2003. Originally alloy and size, and

approved in 1969. Last previous edition approved in 1997 as B 508 – 97.

4.1.5 Dimensions—Thickness and width; and length, if

Annual Book of ASTM Standards, Vol 02.01.

applicable (see 8.2 and 8.3).

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 03.05.

Annual Book of ASTM Standards, Vol 03.01.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 508 – 97 (2003)

TABLE 1 Chemical Requirements

6.2 These composition limits do not preclude the presence

Composition, % of other elements. Limits for unnamed elements may be

established and analysis required by agreement between the

Element Copper Alloy UNS Nos.

manufacturer or supplier and purchaser.

C41100 C50500

6.3 Zinc, when given as the “remainder,” is the differences

Copper 89.0–92.0 .

between the sum of the results for all elements analyzed and

Tin 0.30–0.7 1.0–1.7

Phosphorus . 0.03–0.35

100 %.

Iron, max 0.05 0.10

6.3.1 Copper may be taken as the difference between the

Lead, max 0.10 0.05

Zinc remainder 0.30 max sum of all elements analyzed and 100 % and, when so

Copper + tin + . 99.5

determined, the difference value shall conform to the require-

phosphorus, min

ments given in Table 1.

6.4 Whenanalyzed,thesumofresultsforallelementslisted

in Table 1 for Copper Alloy UNS C41100 shall be 99.7 %

TABLE 2 Grain Size Requirements

minimum and 99.5 % minimum for Copper Alloy UNS

Grain Size, mm

Temps Standard

A C50500.

Designation

Nominal Minimum Maximum

OS050 0.050 0.035 0.090

7. Grain Size of Annealed Tempers

OS035 0.035 0.025 0.050

OS025 0.025 0.015 0.035

7.1 The average grain size of each of two samples of

B

OS015 0.015 0.025

annealed material, as determined on a longitudinal cross

A

Standard designations defined in Classification B 601.

section, shall be within the limit prescribed of the four nominal

B

Although no minimum grain size is required, this material must be fully

recrystallized. grain sizes listed in Table 2 when tested in accordance with

Test Method E 112.

7.2 In the case of thin-gage material 0.010 in. [0.25 mm]

4.2 The following options are available and should be

and under, there shall exist no less than six grains per stock

specified at the time of placing the order, when required:

thickness, averaged for five locations one thickness apart.

4.2.1 How furnished—Coils (inside and outside diameters),

pounds per inch of width; stock or specific lengths, with or

8. Dimensions, Mass, and Permissible Variations

without ends;

8.1 General—For the purpose of determining conformance

4.2.2 Packing—Type of pallet, skid, or box: interleaving,

with the dimensional requirements prescribed in this specifi-

banding, maximum weight, and so forth; and

cation, any measured value outside the specified limiting

4.2.3 Special surface condition requirements, if any (see

values for any dimension may be cause for rejection.

9.3).

8.2 Thickness—The standard method of specifying thick-

5. Materials and Manufacture

nessshallbeindecimalfractionsofaninch.Formaterial0.021

in. [0.533 mm] and under in thickness, it is recommended that

5.1 Material:

the nominal thickness be stated not closer than the nearest

5.1.1 The material of manufacture shall be cast bar, slab,

0.0005 in. [0.013 mm]. For example, specify 0.006 or 0.0065

cake, billet, or so forth of Copper Alloy UNS No. C41100 or

in. [0.152 or 0.165 mm], but not 0.0063 in. [0.160 mm]. For

C50500ofsuchsoundnessastobesuitableforprocessinginto

material over 0.021 [0.533 mm] in thickness, it is recom-

the products prescribed herein.

mended that the nominal thickness’ be stated not closer than

5.1.2 In the event heat identification or traceability is

the nearest 0.001 in. [0.025 mm]. For example, specify 0.128

required, the purchaser shall specify the details desired.

or 0.129 in. [3.25 or 3.28 mm] but not 0.1285 in. [3.26 mm].

NOTE 1—Because of the discontinuous nature of the processing of

A list of preferred thickness is shown in Appendix X1. The

castings into wrought products, it is not always practical to identify

thickness tolerances shall be those shown in Table 3.

specific casting analysis with a specific quantity of finished material.

8.3 Width—The width tolerances shall be those shown in

5.2 Manufacture:

Table 4.

5.2.1 The product shall be manufactured by such hot work-

8.4 Straightness—The straightness tolerances shall be those

ing, cold working, and annealing processes as to produce a

shown in Table 5.

uniform wrought structure in the finished product.

5.2.2 Theproductshallbehotorcoldworkedtothefinished

9. Workmanship, Finish, and Appearance

size and subsequently annealed, if required, to meet the temper

9.1 The product shall be uniform in quality and soundness

properties specified.

and free of internal and external defects. However, surface

5.2.3 Edges—Slit edges shall be furnished unless otherwise

blemishes that do not interfere with the intended application

specified in the contract or purchase order.

are acceptable.

6. Chemical Composition

9.2 The product shall be well cleaned and free of dirt.

6.1 The material shall conform to the requirements pre- 9.3 A superficial film or residual light lubricant shall be

scribed in Table 1 for the alloy specified in the ordering permissible, unless otherwise specified in the contract or

information. purchase order.

B 508 – 97 (2003)

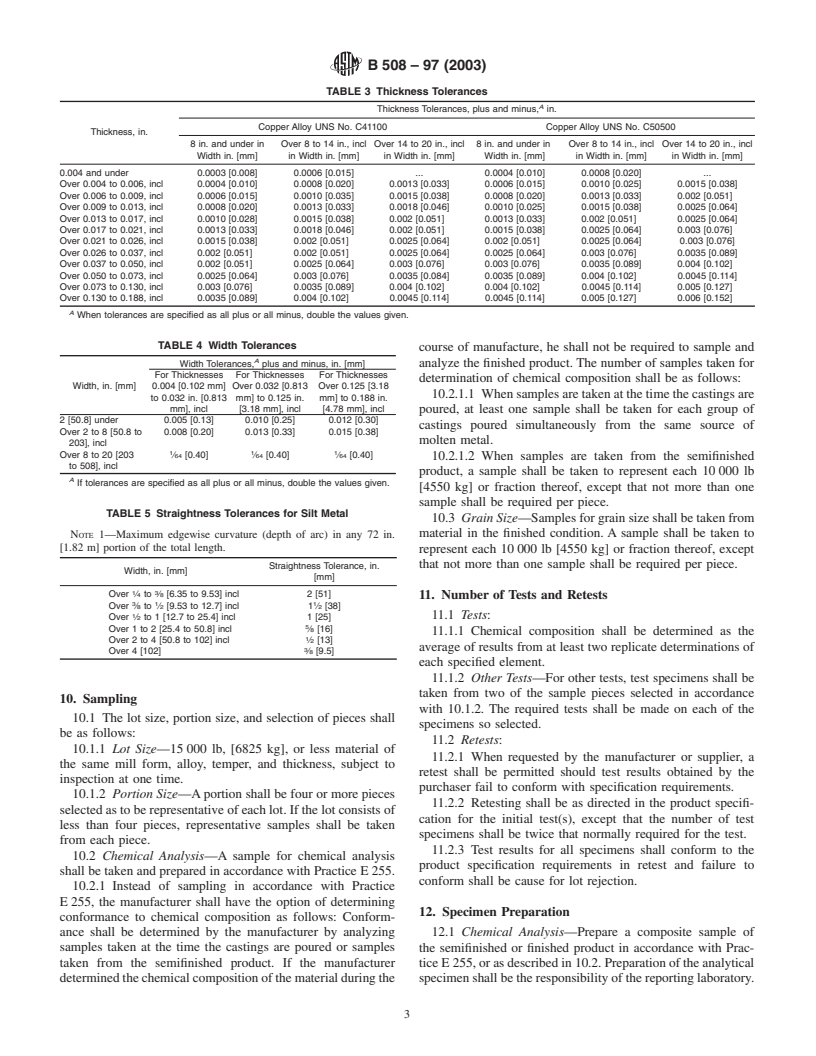

TABLE 3 Thickness Tolerances

A

Thickness Tolerances, plus and minus, in.

Copper Alloy UNS No. C41100 Copper Alloy UNS No. C50500

Thickness, in.

8 in. and under in Over 8 to 14 in., incl Over 14 to 20 in., incl 8 in. and under in Over 8 to 14 in., incl Over 14 to 20 in., incl

Width in. [mm] in Width in. [mm] in Width in. [mm] Width in. [mm] in Width in. [mm] in Width in. [mm]

0.004 and under 0.0003 [0.008] 0.0006 [0.015] . 0.0004 [0.010] 0.0008 [0.020] .

Over 0.004 to 0.006, incl 0.0004 [0.010] 0.0008 [0.020] 0.0013 [0.033] 0.0006 [0.015] 0.0010 [0.025] 0.0015 [0.038]

Over 0.006 to 0.009, incl 0.0006 [0.015] 0.0010 [0.035] 0.0015 [0.038] 0.0008 [0.020] 0.0013 [0.033] 0.002 [0.051]

Over 0.009 to 0.013, incl 0.0008 [0.020] 0.0013 [0.033] 0.0018 [0.046] 0.0010 [0.025] 0.0015 [0.038] 0.0025 [0.064]

Over 0.013 to 0.017, incl 0.0010 [0.028] 0.0015 [0.038] 0.002 [0.051] 0.0013 [0.033] 0.002 [0.051] 0.0025 [0.064]

Over 0.017 to 0.021, incl 0.0013 [0.033] 0.0018 [0.046] 0.002 [0.051] 0.0015 [0.038] 0.0025 [0.064] 0.003 [0.076]

Over 0.021 to 0.026, incl 0.0015 [0.038] 0.002 [0.051] 0.0025 [0.064] 0.002 [0.051] 0.0025 [0.064] 0.003 [0.076]

Over 0.026 to 0.037, incl 0.002 [0.051] 0.002 [0.051] 0.0025 [0.064] 0.0025 [0.064] 0.003 [0.076] 0.0035 [0.089]

Over 0.037 to 0.050, incl 0.002 [0.051] 0.0025 [0.064] 0.003 [0.076] 0.003 [0.076] 0.0035 [0.089] 0.004 [0.102]

Over 0.0

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 508 – 97 (Reapproved 2003)

Standard Specification for

Copper Alloy Strip for Flexible Metal Hose

This standard is issued under the fixed designation B 508; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* E 478 Test Methods for Chemical Analysis of Copper

Alloys

1.1 This specification establishes the requirements for an-

nealed copper-alloy strip for the manufacture of flexible metal

3. Terminology

hose produced from Copper Alloy UNS Nos. C41100 and

3.1 Definitions:

C50500.

3.1.1 For definitions of terms related to copper and copper

1.1.1 The nominal compositions are as follows:

alloys, refer to Terminology B 846.

Copper Alloy Copper Zinc Tin

3.2 Definitions of Terms Specific to This Standard:

UNS No.

C41100 91.0 8.5 0.5

3.2.1 coil (as applied to a flat product)—a length of the

C50500 98.7 . 1.3

product spirally wound into a series of connected turns. The

1.2 The values stated in inch-pound units are to be regarded unqualified term “coil” as applied to “flat product” usually

as the standard, except grain size, which is given in SI units. refers to a coil in which the product is spirally wound, with the

The values given in parentheses are for information only. successive layers on top of one another (sometimes called a

1.3 The following precautionary statement pertains only to “roll”).

the test method portion, Section 13, of this specification: This 3.2.2 level or traverse wound—a coil in which the turns are

standard does not purport to address all of the safety concerns, positioned into layers parallel to the axis of the coil such that

if any, associated with its use. It is the responsibility of the user successive turns in a given layer are next to one another.

of this standard to establish appropriate safety and health

3.2.3 level or traverse wound on a reel or spool—a coil in

practices and determine the applicability of regulatory limita- which the turns are positioned into layers on a reel or spool

tions prior to use.

parallel to the axis of the reel or spool such that successive

turns in a given layer are next to one another.

2. Referenced Documents

3.2.4 reel or spool—a cylindrical device that has a rim at

2.1 ASTM Standards:

each end and an axial hole for a shaft or spindle, and on which

B 601 Classification for Temper Designations for Copper the product is wound to facilitate handling and shipping.

and Copper Alloys—Wrought and Cast

3.2.5 strip—a rolled flat product, other than flat wire, up to

B 846 Terminology for Copper and Copper Alloys and including 0.188 in. [4.78 mm] thick, in straight lengths,

E 29 Practice for Using Significant Digits in Test Data to

coils (rolls), or traverse wound on reels or spools: with slit,

Determine Conformance with Specifications sheared, or slit and rolled edges in widths up to 24 in. [610

E 62 Test Methods for Chemical Analysis of Copper and

mm] inclusive; or, with finished drawn or rolled edges in

Copper Alloys (Photometric Method) widths over 1 ⁄4 to 12 in. [31.8 to 305 mm] inclusive.

E 112 Test Methods for Determining the Average Grain

4. Ordering Information

Size

E 255 Practice for Sampling Copper and CopperAlloys for 4.1 Orders for product under this specification should in-

Determination of Chemical Composition clude the following information:

4.1.1 ASTM designation and year of issue,

4.1.2 Copper Alloy UNS No. (see Section 1 and Table 1),

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

4.1.3 Temper (see 7.1 and Table 2),

and Copper Alloys and is direct responsibility of Subcommittee B05.01 on Plate,

4.1.4 Quantity, number of pieces or total weight of each

Sheet, and Strip.

Current edition approved Apr. 10, 2003. Published June 2003. Originally alloy and size, and

approved in 1969. Last previous edition approved in 1997 as B 508 – 97.

4.1.5 Dimensions—Thickness and width; and length, if

Annual Book of ASTM Standards, Vol 02.01.

applicable (see 8.2 and 8.3).

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 03.05.

Annual Book of ASTM Standards, Vol 03.01.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 508 – 97 (2003)

TABLE 1 Chemical Requirements

6.2 These composition limits do not preclude the presence

Composition, % of other elements. Limits for unnamed elements may be

established and analysis required by agreement between the

Element Copper Alloy UNS Nos.

manufacturer or supplier and purchaser.

C41100 C50500

6.3 Zinc, when given as the “remainder,” is the differences

Copper 89.0–92.0 .

between the sum of the results for all elements analyzed and

Tin 0.30–0.7 1.0–1.7

Phosphorus . 0.03–0.35

100 %.

Iron, max 0.05 0.10

6.3.1 Copper may be taken as the difference between the

Lead, max 0.10 0.05

Zinc remainder 0.30 max sum of all elements analyzed and 100 % and, when so

Copper + tin + . 99.5

determined, the difference value shall conform to the require-

phosphorus, min

ments given in Table 1.

6.4 Whenanalyzed,thesumofresultsforallelementslisted

in Table 1 for Copper Alloy UNS C41100 shall be 99.7 %

TABLE 2 Grain Size Requirements

minimum and 99.5 % minimum for Copper Alloy UNS

Grain Size, mm

Temps Standard

A C50500.

Designation

Nominal Minimum Maximum

OS050 0.050 0.035 0.090

7. Grain Size of Annealed Tempers

OS035 0.035 0.025 0.050

OS025 0.025 0.015 0.035

7.1 The average grain size of each of two samples of

B

OS015 0.015 0.025

annealed material, as determined on a longitudinal cross

A

Standard designations defined in Classification B 601.

section, shall be within the limit prescribed of the four nominal

B

Although no minimum grain size is required, this material must be fully

recrystallized. grain sizes listed in Table 2 when tested in accordance with

Test Method E 112.

7.2 In the case of thin-gage material 0.010 in. [0.25 mm]

4.2 The following options are available and should be

and under, there shall exist no less than six grains per stock

specified at the time of placing the order, when required:

thickness, averaged for five locations one thickness apart.

4.2.1 How furnished—Coils (inside and outside diameters),

pounds per inch of width; stock or specific lengths, with or

8. Dimensions, Mass, and Permissible Variations

without ends;

8.1 General—For the purpose of determining conformance

4.2.2 Packing—Type of pallet, skid, or box: interleaving,

with the dimensional requirements prescribed in this specifi-

banding, maximum weight, and so forth; and

cation, any measured value outside the specified limiting

4.2.3 Special surface condition requirements, if any (see

values for any dimension may be cause for rejection.

9.3).

8.2 Thickness—The standard method of specifying thick-

5. Materials and Manufacture

nessshallbeindecimalfractionsofaninch.Formaterial0.021

in. [0.533 mm] and under in thickness, it is recommended that

5.1 Material:

the nominal thickness be stated not closer than the nearest

5.1.1 The material of manufacture shall be cast bar, slab,

0.0005 in. [0.013 mm]. For example, specify 0.006 or 0.0065

cake, billet, or so forth of Copper Alloy UNS No. C41100 or

in. [0.152 or 0.165 mm], but not 0.0063 in. [0.160 mm]. For

C50500ofsuchsoundnessastobesuitableforprocessinginto

material over 0.021 [0.533 mm] in thickness, it is recom-

the products prescribed herein.

mended that the nominal thickness’ be stated not closer than

5.1.2 In the event heat identification or traceability is

the nearest 0.001 in. [0.025 mm]. For example, specify 0.128

required, the purchaser shall specify the details desired.

or 0.129 in. [3.25 or 3.28 mm] but not 0.1285 in. [3.26 mm].

NOTE 1—Because of the discontinuous nature of the processing of

A list of preferred thickness is shown in Appendix X1. The

castings into wrought products, it is not always practical to identify

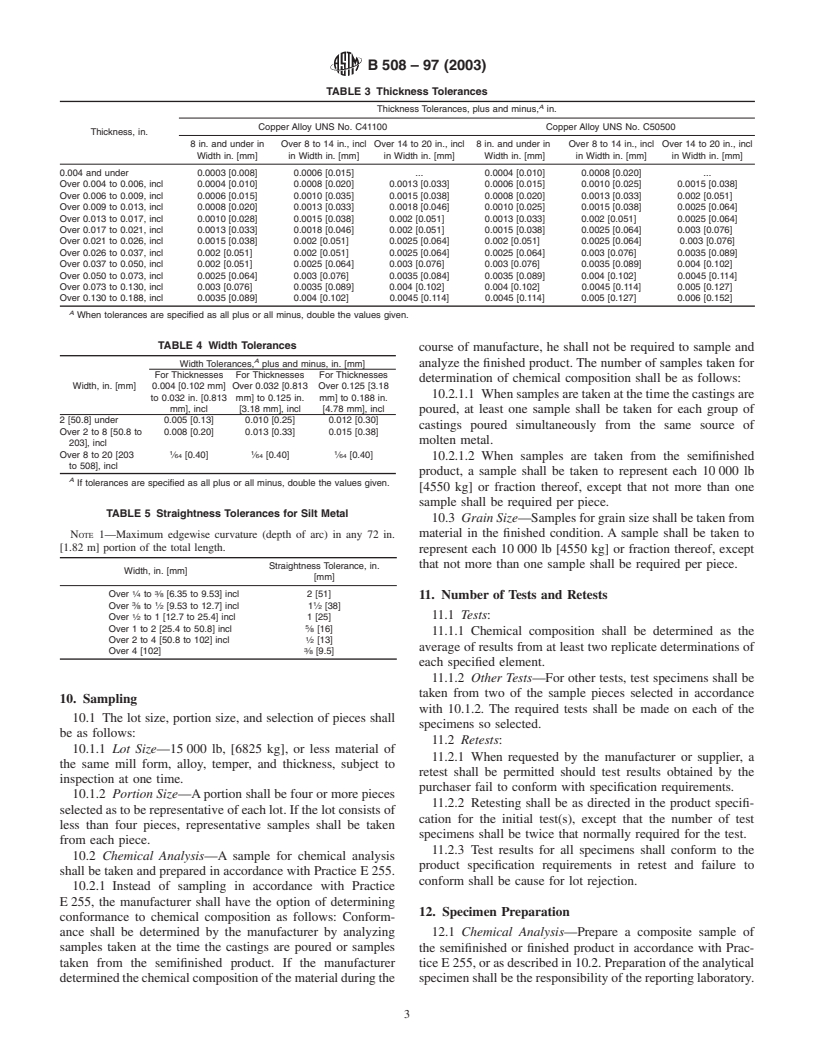

thickness tolerances shall be those shown in Table 3.

specific casting analysis with a specific quantity of finished material.

8.3 Width—The width tolerances shall be those shown in

5.2 Manufacture:

Table 4.

5.2.1 The product shall be manufactured by such hot work-

8.4 Straightness—The straightness tolerances shall be those

ing, cold working, and annealing processes as to produce a

shown in Table 5.

uniform wrought structure in the finished product.

5.2.2 Theproductshallbehotorcoldworkedtothefinished

9. Workmanship, Finish, and Appearance

size and subsequently annealed, if required, to meet the temper

9.1 The product shall be uniform in quality and soundness

properties specified.

and free of internal and external defects. However, surface

5.2.3 Edges—Slit edges shall be furnished unless otherwise

blemishes that do not interfere with the intended application

specified in the contract or purchase order.

are acceptable.

6. Chemical Composition

9.2 The product shall be well cleaned and free of dirt.

6.1 The material shall conform to the requirements pre- 9.3 A superficial film or residual light lubricant shall be

scribed in Table 1 for the alloy specified in the ordering permissible, unless otherwise specified in the contract or

information. purchase order.

B 508 – 97 (2003)

TABLE 3 Thickness Tolerances

A

Thickness Tolerances, plus and minus, in.

Copper Alloy UNS No. C41100 Copper Alloy UNS No. C50500

Thickness, in.

8 in. and under in Over 8 to 14 in., incl Over 14 to 20 in., incl 8 in. and under in Over 8 to 14 in., incl Over 14 to 20 in., incl

Width in. [mm] in Width in. [mm] in Width in. [mm] Width in. [mm] in Width in. [mm] in Width in. [mm]

0.004 and under 0.0003 [0.008] 0.0006 [0.015] . 0.0004 [0.010] 0.0008 [0.020] .

Over 0.004 to 0.006, incl 0.0004 [0.010] 0.0008 [0.020] 0.0013 [0.033] 0.0006 [0.015] 0.0010 [0.025] 0.0015 [0.038]

Over 0.006 to 0.009, incl 0.0006 [0.015] 0.0010 [0.035] 0.0015 [0.038] 0.0008 [0.020] 0.0013 [0.033] 0.002 [0.051]

Over 0.009 to 0.013, incl 0.0008 [0.020] 0.0013 [0.033] 0.0018 [0.046] 0.0010 [0.025] 0.0015 [0.038] 0.0025 [0.064]

Over 0.013 to 0.017, incl 0.0010 [0.028] 0.0015 [0.038] 0.002 [0.051] 0.0013 [0.033] 0.002 [0.051] 0.0025 [0.064]

Over 0.017 to 0.021, incl 0.0013 [0.033] 0.0018 [0.046] 0.002 [0.051] 0.0015 [0.038] 0.0025 [0.064] 0.003 [0.076]

Over 0.021 to 0.026, incl 0.0015 [0.038] 0.002 [0.051] 0.0025 [0.064] 0.002 [0.051] 0.0025 [0.064] 0.003 [0.076]

Over 0.026 to 0.037, incl 0.002 [0.051] 0.002 [0.051] 0.0025 [0.064] 0.0025 [0.064] 0.003 [0.076] 0.0035 [0.089]

Over 0.037 to 0.050, incl 0.002 [0.051] 0.0025 [0.064] 0.003 [0.076] 0.003 [0.076] 0.0035 [0.089] 0.004 [0.102]

Over 0.0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.