ASTM F68-05e1

(Specification)Standard Specification for Oxygen-Free Copper in Wrought Forms for Electron Devices

Standard Specification for Oxygen-Free Copper in Wrought Forms for Electron Devices

ABSTRACT

This specification establishes the requirements for wrought forms and fabricated shapes of oxygen-free copper with UNS No. C10100 suitable for use in electron devices. Specimens shall be appropriately sampled and shall undergo hydrogen embrittlement (reverse bend) test, special macro examination, and special microscopical examination. Materials shall adhere to specified mechanical, dimensional, chemical composition, electrical resistivity, and grain size requirements.

SCOPE

1.1 This specification establishes the requirements for wrought and fabricated shapes made from Copper UNS No. C10100, conforming to the chemical requirements of Specification B 170, Grade 1, and suitable for use in electron devices.

1.2 The requirements of this specification are in addition to those prescribed in the following product specifications appropriate to the material being ordered: B 1, B 2, B 75, B 75M, B 152/B 152M, B 170, B 187/B 187M, B 272, and B 372. In case of conflict, however, this specification shall take precedence.

1.3 The inch-pound units are the standard for this specification except for grain sizes which are in metric units. Metric values given in parentheses are for information only.

1.4 The following safety hazard caveat applies to sections 17.4, 17.5 and 18.7 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

´1

Designation: F68 – 05

Standard Specification for

Oxygen-Free Copper in Wrought Forms for Electron

1

Devices

This standard is issued under the fixed designation F68; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Section 2 was corrected editorially in August 2009.

1. Scope* B152/B152M Specification for Copper Sheet, Strip, Plate,

and Rolled Bar

1.1 This specification establishes the requirements for

2

B170 Specification for Oxygen-Free Electrolytic Copper—

wrought and fabricated shapes made from Copper UNS No.

Refinery Shapes

C10100, conforming to the chemical requirements of Specifi-

B187/B187M Specification for Copper, Bus Bar, Rod, and

cation B170, Grade 1, and suitable for use in electron devices.

Shapes and General Purpose Rod, Bar, and Shapes

1.2 The requirements of this specification are in addition to

B188 Specification for Seamless Copper Bus Pipe andTube

those prescribed in the following product specifications appro-

B193 Test Method for Resistivity of Electrical Conductor

priate to the material being ordered: B1, B2, B75, B75M,

Materials

B152/B152M, B170, B187/B187M, B272, and B372. In case

B248 Specification for General Requirements for Wrought

of conflict, however, this specification shall take precedence.

Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled

1.3 The inch-pound units are the standard for this specifi-

Bar

cation except for grain sizes which are in metric units. Metric

B248M Specification for General Requirements for

values given in parentheses are for information only.

Wrought Copper and Copper-Alloy Plate, Sheet, Strip, and

1.4 The following safety hazard caveat applies to sections

Rolled Bar (Metric)

17.4,17.5and18.7ofthisspecification: This standard does not

B249/B249M Specification for General Requirements for

purport to address all of the safety concerns, if any, associated

Wrought Copper and Copper-Alloy Rod, Bar, Shapes and

with its use. It is the responsibility of the user of this standard

Forgings

to establish appropriate safety and health practices and

B250/B250M Specification for General Requirements for

determine the applicability of regulatory limitations prior to

Wrought Copper Alloy Wire

use.

B272 Specification for Copper Flat Products with Finished

2. Referenced Documents

(Rolled or Drawn) Edges (Flat Wire and Strip)

3

B372 Specification for Seamless Copper and Copper-Alloy

2.1 ASTM Standards:

Rectangular Waveguide Tube

B1 Specification for Hard-Drawn Copper Wire

B577 Test Methods for Detection of Cuprous Oxide (Hy-

B2 Specification for Medium-Hard-Drawn Copper Wire

drogen Embrittlement Susceptibility) in Copper

B3 Specification for Soft or Annealed Copper Wire

E29 Practice for Using Significant Digits in Test Data to

B75 Specification for Seamless Copper Tube

Determine Conformance with Specifications

B75M Specification for Seamless Copper Tube (Metric)

E112 Test Methods for Determining Average Grain Size

E527 Practice for Numbering Metals and Alloys in the

Unified Numbering System (UNS)

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

2.2 ASTM Adjunct:

and CopperAlloys and is the direct responsibility of Subcommittee B05.02 on Rod,

4

Comparison Chart

Bar, Wire, Shapes and Forgings.

Current edition approved Oct. 1, 2005. Published October 2005. Originally

approved in 1966. Last previous edition approved in 2004 as F68 – 99 (2004). DOI: 3. Terminology

10.1520/F0068-05E01.

3.1 For definitions of terms related to this product, refer to

2

The UNS System for copper and copper alloys (see Practice E527) is a simple

the terminology sections of Specifications B3, B188, B248,

expansion of the former standard designation system accomplished by the addition

of a prefix “C” and a suffix “00”. The suffix can be used to accommodate

B248M, B249/B249M, B250/B250M, or B251.

composition variations of the base alloy.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on Available from ASTM International Headquarters. Order Adjunct No.

the ASTM website. ADJF0068. Original adjunct produced in 1966 .

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

F68–05

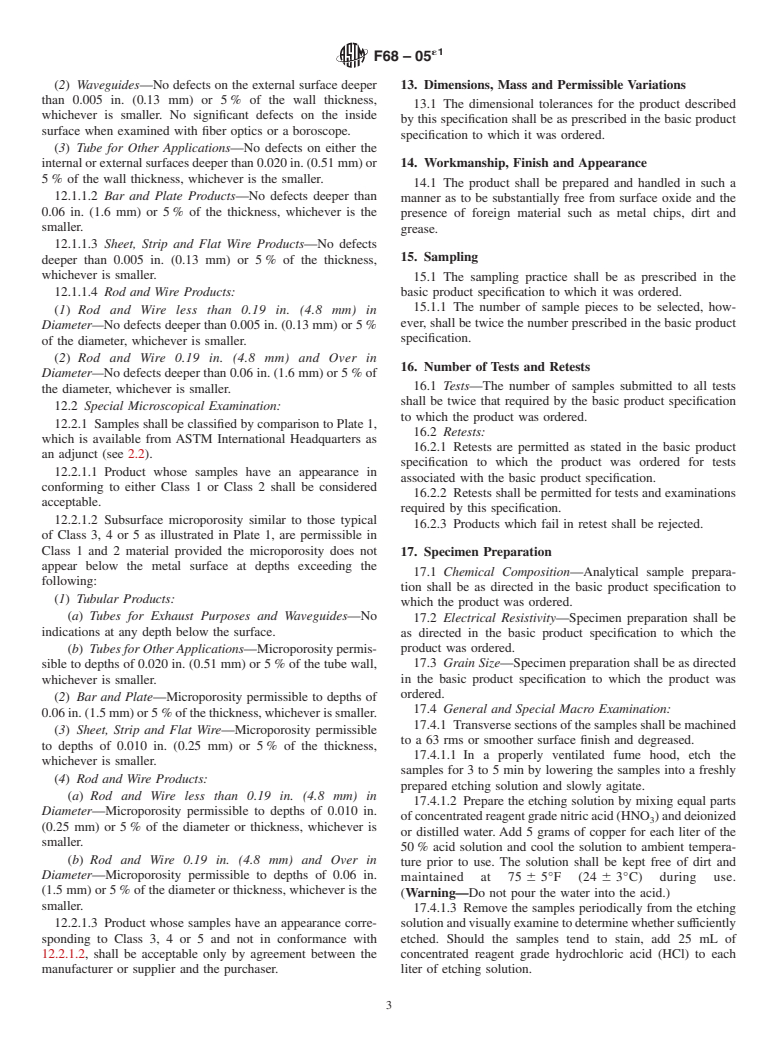

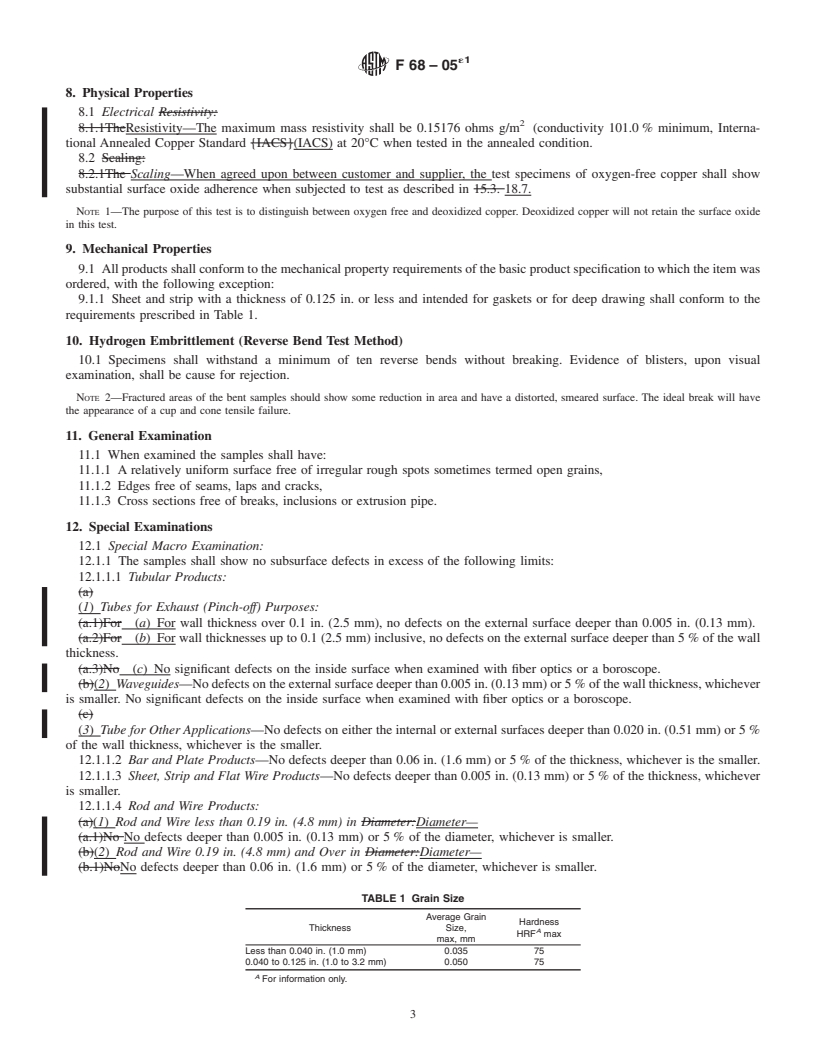

3.2 Definition of Terms Specific to This Standard: 8. Physical Properties

3.2.1 extrusion pipe, n—a lamination resulting from the

8.1 Electrical Resistivity—Th

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:F 68–99 (Reapproved 2004) Designation: F 68 – 05

Standard Specification for

Oxygen-Free Copper in Wrought Forms for Electron

1

Devices

This standard is issued under the fixed designation F 68; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Section 2 was corrected editorially in August 2009.

1. Scope*

2

1.1 This specification establishes the requirements for wrought and fabricated shapes made from Copper UNS No. C10100,

conforming to the chemical requirements of Specification B 170, Grade 1, and suitable for use in electron devices.

1.2 The requirements of this specification are in addition to those prescribed in the following product specifications appropriate

to the material being ordered: B 1, B 2, B 75, B 75M, B 152/B 152M, B 170, B 187/B 187M, B 272, and B 372. In case of conflict,

however, this specification shall take precedence.

1.3 The inch-pound units are the standard for this specification except for grain sizes which are in metric units. Metric values

given in parentheses are for information only.

1.4 The following safety hazard caveat applies to sections 17.4, 17.5 and 18.7 of this specification: This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1The following documents in the current issue of the Book of Standards form a part of this specification to the extent

referenced herein:

2.2

3

2.1 ASTM Standards:

B1 Specification for Hard-Drawn Copper Wire

B2 Specification for Medium-Hard-Drawn Copper Wire

B3

B3 Specification for Soft or Annealed Copper Wire

B75 Specification for Seamless Copper Tube

B 75M Specification for Seamless Copper Tube (Metric)

B 152/B 152M Specification for Copper Sheet, Strip, Plate and Rolled Bar

B 170 Specification for Oxygen-Free Electrolytic Copper—Refinery Shapes

B 187/B 187M Specification for Copper Bar, Bus Bar, Rod and Shapes

B188

B 188 Specification for Seamless Copper Bus Pipe and Tube

B 193 Test Method for Resistivity of Electrical Conductor Materials

B 248 Specification for General Requirements for Wrought Copper and Copper-Alloy Plate, Sheet, Strip and Rolled Bar

B248M

B 248M Specification for General Requirements for Wrought Copper and Copper-Alloy Plate, Sheet, Strip and Rolled Bar

[Metric]

B 249/B 249M Specification for General Requirements forWrought Copper and Copper-Alloy Rod, Bar, Shapes, and Forgings

B 250/B 250M Specification for General Requirements for Wrought Copper-Alloy Wire

1

This specification is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.02 on Rod, Bar,

Wire, Shapes,Shapes and Forgings.

Current edition approved MayOct. 1, 2004.2005. Published June 2004.October 2005. Originally approved in 1966. Last previous edition approved in 19992004 as

F 68 – 99 (2004).

2

The UNS System for copper and copper alloys (see Practice E 527) is a simple expansion of the former standard designation system accomplished by the addition of

a prefix “C” and a suffix “00”. The suffix can be used to accommodate composition variations of the base alloy.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

F 68–05

B 272 Specification for Copper Flat Products with Finished (Rolled or Drawn) Edges (Flat Wire and Strip)

B 372 Specification for Seamless Copper and Copper-Alloy Rectangular Waveguide Tube

B 577 Test Methods for Detection of Cuprous Oxide Hydrogen Embrittlement Susceptibility in Copper

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E112 Test Methods for Determining Average Grain Sizes

E 527 Practice for Numbering Metals and Alloys (UNS)

2.3

2.2 ASTM Adjunct:

4

Comparison Chart

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.