ASTM B983-21

(Specification)Standard Specification for Precipitation Hardened or Cold Worked, Seamless Nickel Alloy Pipe and Tube

Standard Specification for Precipitation Hardened or Cold Worked, Seamless Nickel Alloy Pipe and Tube

ABSTRACT

This specification covers high strength, seamless pipe and tube of nickel alloys (UNS N07022, UNS N07725, and UNS N07740). Pipe and tube shall be supplied in the cold worked or cold worked and precipitations hardened or solution annealed plus precipitation hardened and descaled conditions. When atmosphere control is used, descaling is not necessary. Each pipe or tube shall be tested by the manufacturer by either hydrostatic or a non-destructive electric test in accordance with Specification B829. This specification also describes chemical requirements, heat treatments, and mechanical properties, as well as calculation of mass or weight, sampling of chemical analysis, sampling for mechanical testing, specimen preparation, inspection, and certification. There shall be one test per lot for chemical analysis and one test per lot for tension test. If the specimen used in the mechanical test of any lot fails to meet the specified requirements, tow additional specimens shall be taken from different sample pieces and tested. The results of the tests on both of these specimens shall meet the specified requirements.

SCOPE

1.1 This specification covers high strength, seamless pipe and tube of nickel alloys (UNS N07022, UNS N07725, UNS N07740, UNS N09945, UNS N09925, UNS N07718, UNS N10276, UNS N06985)2 as shown in Table 1.

1.2 Pipe and tube shall be supplied in the cold worked or cold worked and precipitations hardened or solution annealed plus precipitation hardened and descaled conditions. When atmosphere control is used, descaling is not necessary.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Safety Data Sheet (SDS) for this product/material as provided by the manufacturer, to establish appropriate safety, health, and environmental practices, and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B983 −21

Standard Specification for

Precipitation Hardened or Cold Worked, Seamless Nickel

1

Alloy Pipe and Tube

This standard is issued under the fixed designation B983; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* B829 Specification for General Requirements for Nickel and

Nickel Alloys Seamless Pipe and Tube

1.1 This specification covers high strength, seamless pipe

B899 Terminology Relating to Non-ferrous Metals and Al-

and tube of nickel alloys (UNS N07022, UNS N07725, UNS

loys

N07740, UNS N09945, UNS N09925, UNS N07718, UNS

2 E8 Test Methods for Tension Testing of Metallic Materials

N10276, UNS N06985) as shown in Table 1.

[Metric] E0008_E0008M

1.2 Pipe and tube shall be supplied in the cold worked or

E527 Practice for Numbering Metals and Alloys in the

cold worked and precipitations hardened or solution annealed

Unified Numbering System (UNS)

plus precipitation hardened and descaled conditions. When

atmosphere control is used, descaling is not necessary.

3. Terminology

1.3 The values stated in inch-pound units are to be regarded

3.1 Terms shall be defined in accordance with Terminology

as standard. The values given in parentheses are mathematical

B899.

conversions to SI units that are provided for information only

3.2 Definitions of Terms Specific to This Standard:

and are not considered standard.

3.2.1 average diameter, n—See Terminology B899.

1.4 This standard does not purport to address all of the

3.2.2 pipe, n—See Terminology B899 and Specification

safety concerns, if any, associated with its use. It is the

B829.

responsibility of the user of this standard to become familiar

3.2.3 tube, n—See Terminology B899.

with all hazards including those identified in the appropriate

Safety Data Sheet (SDS) for this product/material as provided

4. General Requirements

by the manufacturer, to establish appropriate safety, health,

and environmental practices, and determine the applicability

4.1 Material furnished under this specification shall con-

of regulatory limitations prior to use.

form to the applicable requirements of Specification B829

1.5 This international standard was developed in accor-

unless otherwise provided herein.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

5. Ordering Information

Development of International Standards, Guides and Recom-

5.1 It is the responsibility of the purchaser to specify all

mendations issued by the World Trade Organization Technical

requirements that are necessary for the material ordered under

Barriers to Trade (TBT) Committee.

this specification. Examples of such requirements include, but

are not limited to the following:

2. Referenced Documents

5.1.1 Alloy—See Table 1.

3

2.1 ASTM Standards:

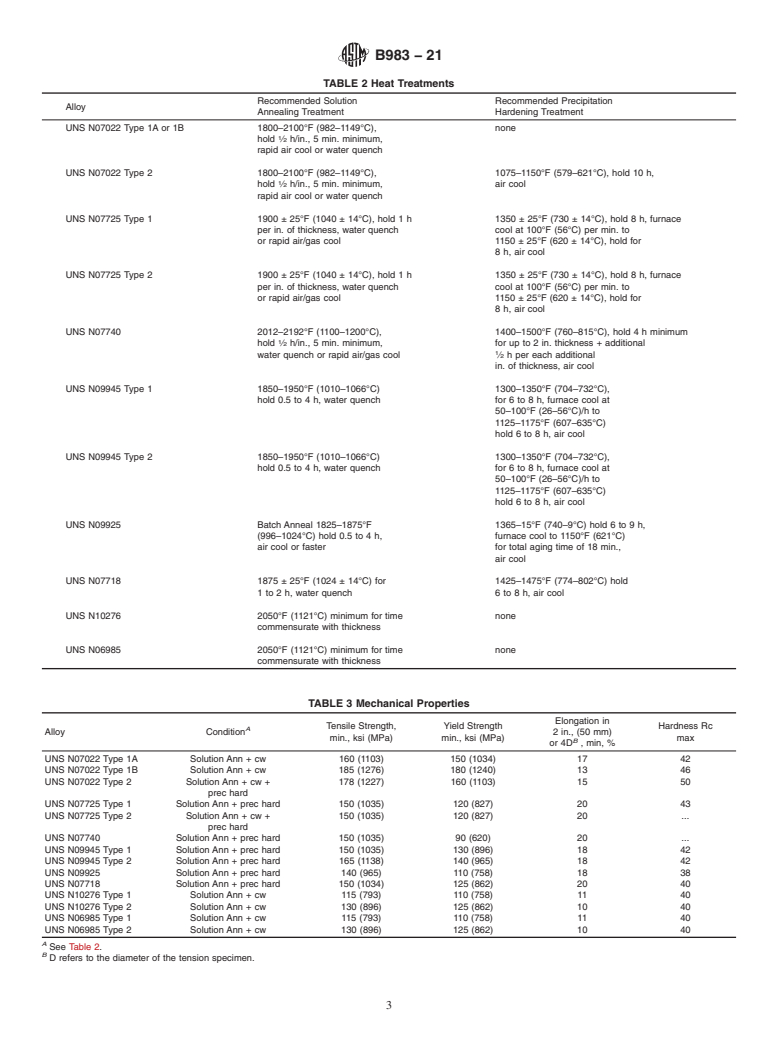

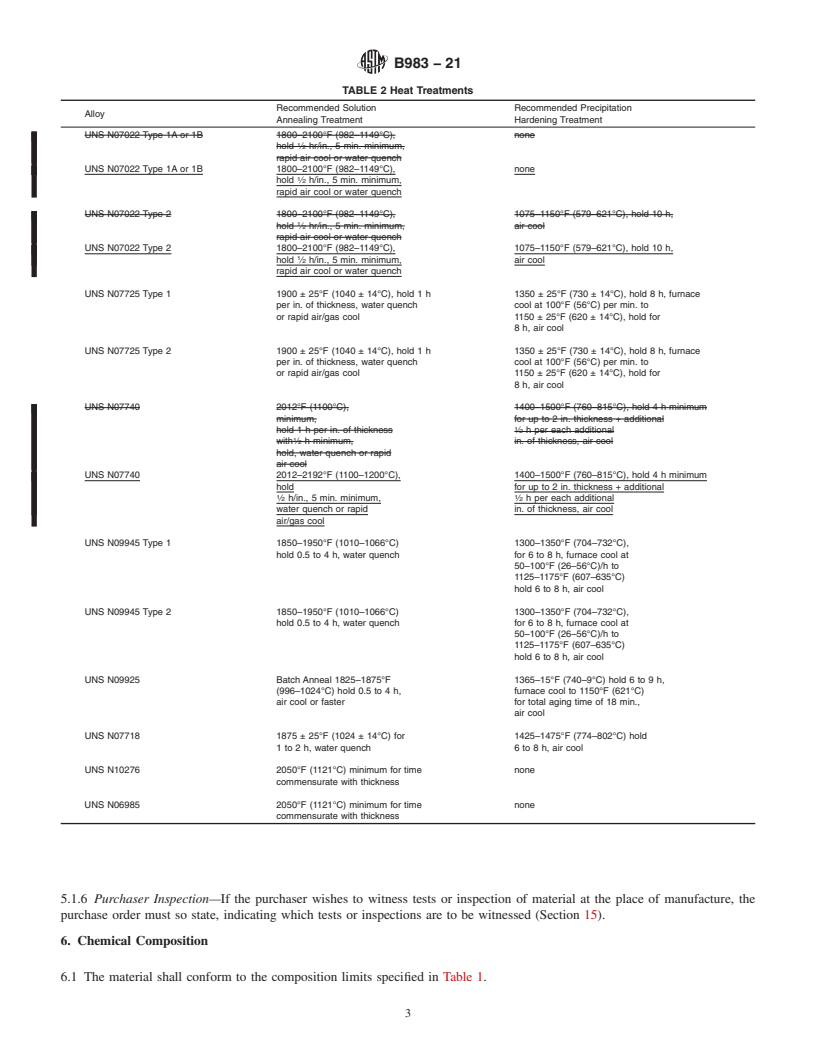

5.1.1.1 Heat Treatment or Cold Work or Type—See Table 2

and Table 3.

5.1.2 Dimensions:

1

This specification is under the jurisdiction of ASTM Committee B02 on

5.1.2.1 Tube—Outside diameter, minimum or average wall

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.07 on Refined Nickel and Cobalt and Their Alloys.

thickness, and length.

Current edition approved April 1, 2021. Published April 2021. Originally

5.1.2.2 Pipe—Standard pipe size and schedule (Specifica-

ɛ1

approved in 2012. Last previous edition approved in 2016 as B983 – 16 . DOI:

tion B829).

10.1520/B0983-21.

2

5.1.3 Ends—Plain ends cut and deburred will be furnished.

New designation established in accordance with Practice E527 and SAE J1086,

Practice for Numbering Metals and Alloys (UNS).

5.1.4 Certification—State if certification or a report of test

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

results is required (Section 16).

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1.5 Samples for Check Analysis—State whether samples

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. for check analysis should be furnished.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B983−21

TABLE 1 Chemical Requirements

UNS UNS UNS UNS UNS UNS UNS UNS

Element

N07022 N07725 N07740 N09945 N09925 N07718 N10276 N06985

Carbon 0.010 max 0.03 max 0.005-0.08 0.005-0.04 0.03 ma

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: B983 − 16 B983 − 21

Standard Specification for

Precipitation Hardened or Cold Worked, Seamless Nickel

1

Alloy Pipe and Tube

This standard is issued under the fixed designation B983; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Table 1 was editorially corrected in October 2017.

1. Scope*

1.1 This specification covers high strength, seamless pipe and tube of nickel alloys (UNS N07022, UNS N07725, UNS N07740,

2

UNS N09945, UNS N09925, UNS N07718, UNS N10276, UNS N06985) as shown in Table 1.

1.2 Pipe and tube shall be supplied in the cold worked or cold worked and precipitations hardened or solution annealed plus

precipitation hardened and descaled conditions. When atmosphere control is used, descaling is not necessary.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to become familiar with all hazards including those identified in the appropriate Safety Data Sheet

(SDS) for this product/material as provided by the manufacturer, to establish appropriate safety, health, and environmental

practices, and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

B829 Specification for General Requirements for Nickel and Nickel Alloys Seamless Pipe and Tube

B899 Terminology Relating to Non-ferrous Metals and Alloys

E8 Test Methods for Tension Testing of Metallic Materials [Metric] E0008_E0008M

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

3. Terminology

3.1 Terms shall be defined in accordance with Terminology B899.

1

This specification is under the jurisdiction of ASTM Committee B02 on Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee B02.07 on Refined

Nickel and Cobalt and Their Alloys.

Current edition approved Oct. 1, 2016April 1, 2021. Published October 2016April 2021. Originally approved in 2012. Last previous edition approved in 20152016 as B983

ɛ1

– 15.16 . DOI: 10.1520/B0983-16E01.10.1520/B0983-21.

2

New designation established in accordance with Practice E527 and SAE J1086, Practice for Numbering Metals and Alloys (UNS).

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B983 − 21

TABLE 1 Chemical Requirements

UNS UNS UNS UNS UNS UNS UNS UNS

Element

N07022 N07725 N07740 N09945 N09925 N07718 N10276 N06985

Carbon 0.010 max 0.03 max 0.005-0.08 0.005-0.04 0.03 max 0.08 max 0.02 max 0.015 max

Manganese 0.5 max 0.35 max 1.0 max 1.0 max 1.00 max 0.35 max 1.0 max 1.0 max

Silicon 0.08 max 0.20 max 1.0 max 0.5 max 0.50 max 0.35 max 0.08 max 1.0 max

Phosphorous 0.025 max 0.015 max 0.030 max 0.03 max . 0.015 max 0.030 max 0.04 max

Sulfur 0.015 max 0.010 max 0.030 max 0.03 max 0.030 max 0.015 max 0.030 max 0.03 max

Chromium 20.0-21.4 19.0-22.5 23.5-25.5 19.5-23.0 19.5-23.5 17.0-21.0 14.5-16.5 21.0-23.5

Cobalt 1.0 max . 15.0-22.0 . . 1.0 max 2.5 max 5.0 max

Molybdenum 15.5-17.4 7.00-9.50 2.0 max 3.0-4.0 2.50-3.50 2.80-3.30 15.0-17.0 6.0-8.0

Columbium . 2.75-4.00 . 2.4-4.5 0.50 max 4.75-5.50 . .

Titanium . 1.00-1.70 0.5-2.5 0.5-2.5 1.90-2.40 0.65-1.15 . .

Aluminum 0.5 max 0.35 max 0.2-2.0 0.01-0.7 0.10-0.50 0.20-0.80† . .

Aluminum 0.5 max 0.35 max 0.2-2.0 0.01-0.7 0.10-0.50 0.20-0.80 . .

Zirconium .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.