ASTM D2860/D2860M-90(1999)

(Test Method)Standard Test Method for Adhesion of Pressure-Sensitive Tape to Fiberboard at 90° Angle and Constant Stress

Standard Test Method for Adhesion of Pressure-Sensitive Tape to Fiberboard at 90° Angle and Constant Stress

SCOPE

1.1 This test method covers the determination of the property of adhesion of pressure-sensitive tape to a fiberboard surface. The user of this test method has the option of choosing the paper surface for the test. The test surface may be the standard linerboard, another linerboard (or paper) of individual interest, or a specific fiberboard.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1-A complete metric companion to Test Method D2860 has been developed-D2860M; therefore, no metric equivalents are presented in this method. Test Method D2860M uses a 24 by 24-mm tape area rather than the 1 by 1-in. (25.4 by 25.4-mm) area used in this method. This difference in test parameters will generally produce lower time to failure for Test Method D2860M than Test Method D2860 but not necessarily by a constant factor.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 2860/D 2860M – 90 (Reapproved 1999)

Standard Test Method for

Adhesion of Pressure-Sensitive Tape to Fiberboard at 90°

Angle and Constant Stress

This standard is issued under the fixed designation D 2860/D 2860M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4. Summary of Test Method

1.1 This test method covers the determination of the prop- 4.1 Procedure A—The pressure-sensitive tape is mounted

erty of adhesion of pressure-sensitive tape to a fiber-board on a rigid panel. The adhesive side is exposed. A strip of

surface. The user of this test method has the option of choosing linerboard, which represents the fiberboard, is placed against

the paper surface for the test. The test surface may be the the tape adhesive with controlled pressure. The area of contact

standard linerboard, another linerboard (or paper) of individual is specified. The panel is mounted in a horizontal position. A

interest, or a specific fiberboard. specified mass is fastened to one end of the linerboard. The

1.2 The values stated in either SI or inch-pound units are to mass acts to peel the linerboard away from the adhesive at an

be regarded separately as standard. The values stated in each angle of 90°. The time required to peel the linerboard from the

system are not exact equivalents; therefore, each system must tape is measured.

be used independently, without combining values in any way. 4.2 Procedure B—In this procedure, the fiberboard or the

1.3 This standard does not purport to address all of the linerboard representing it is adhered to a rigid panel and the

safety concerns, if any, associated with its use. It is the tape peeled from it. In all other respects, the procedure is the

responsibility of the user of this standard to establish appro- same as Procedure A.

priate safety and health practices and determine the applica-

5. Significance and Use

bility of regulatory limitations prior to use.

5.1 This test method is designed to show the adhesion of a

2. Referenced Documents

pressure-sensitive tape to fiberboard when the tape is under a

2.1 ASTM Standards: constant stress. Test data from this test method for some types

D 996 Terminology of Packaging and Distribution Environ- of packaging tape relates to tape performance on fiberboard

ments box closure.

D 2904 Practice for Interlaboratory Testing of a Textile Test 5.2 Procedure A should be used when comparing tapes to an

Method that Produces Normally Distributed Data established requirement. The requirement may be established

D 2906 Practice for Statements on Precision and Bias for using either the standard linerboard or another linerboard

Textiles representing a specific fiberboard.

D 3715/D3715M Practice for Quality Assurance of 5.3 Procedure B should be used to rank tapes as to their

Pressure-Sensitive Tapes ability to adhere to fiberboard.

D 4332 Practice for Conditioning Containers, Packages, or

2 6. Apparatus and Materials

Packaging Components for Testing

6.1 Tape, pressure-sensitive, double-coated, 48-mm [2-in.]

3. Terminology

width. The tape shall exhibit sufficient adhesion to the panel

3.1 Definitions: Terminology found in Terminology D 996 and test specimen or fiberboard to avoid the failures cited in

shall apply. 10.1.9 and 10.2.14.

6.2 Panel—Any steel piece at least 50 by 125 mm [2 by 5

in.] and no less than 1.1 mm [0.043 in.] thick, having one face

This test method is under the jurisdiction of ASTM Committee D-10 on

(2 by 5 in.) that does not deviate from a plane by more than

Packaging, and is the direct responsibility of Subcommittee D 10.14 on Tape and

0.050 mm [0.002 in.].

Labels.

Current edition approved June 29, 1990. Published August 1990. Originally 6.3 Stop Watch.

published as D 2860 – 70. Last previous edition D 2860 – 87.

6.4 Razor Blade, single-edge.

Annual Book of ASTM Standards, Vol 15.09.

Annual Book of ASTM Standards, Vol 07.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 2860/D 2860M – 90 (1999)

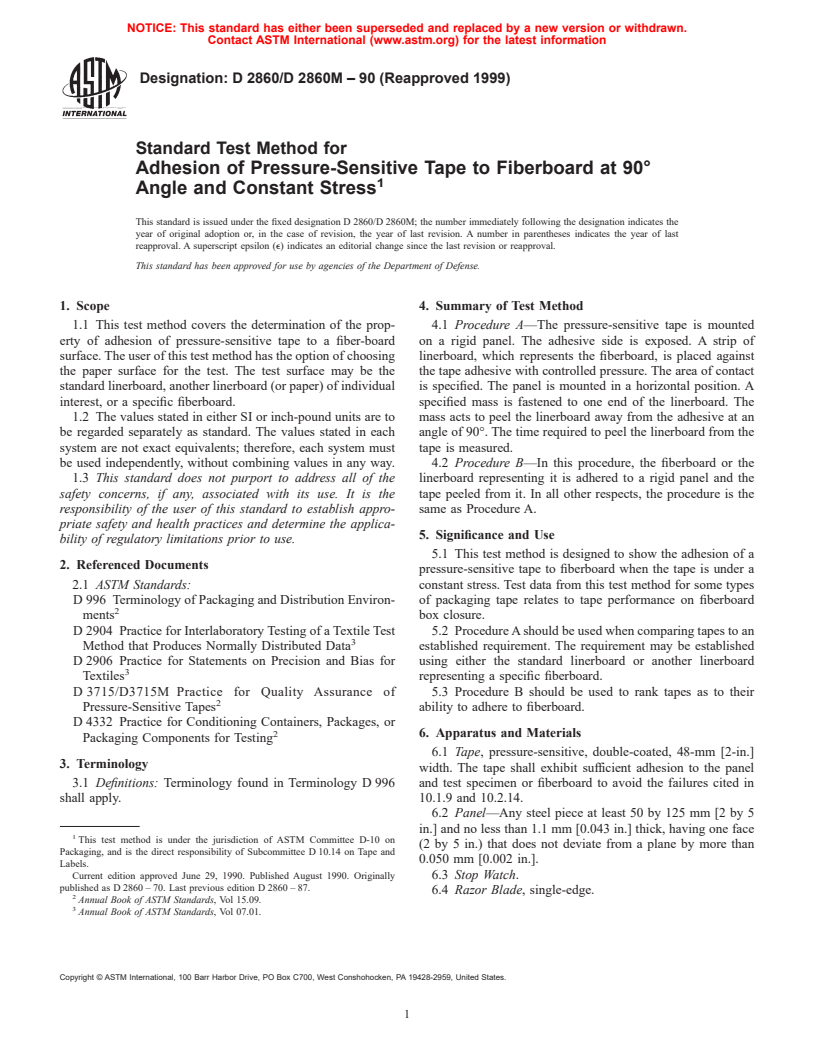

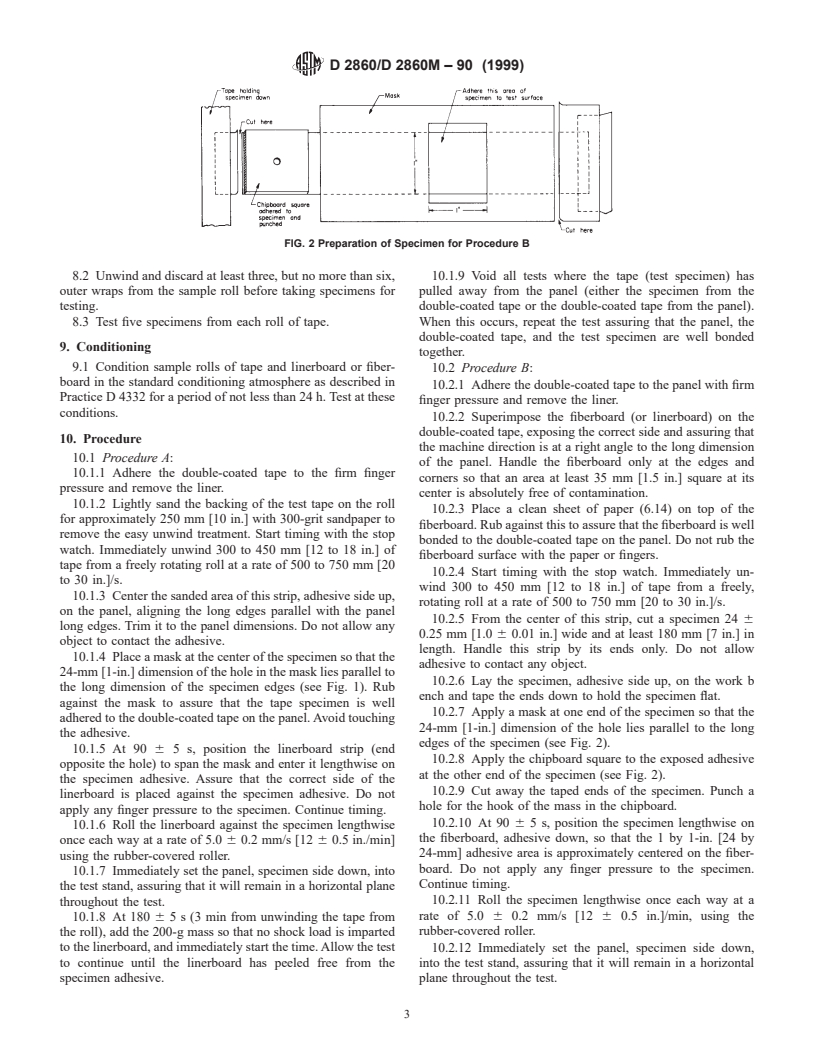

6.5 Mask—Any paper no more than 0.050 mm [0.002 in.] use. When comparing one roll of tape to another or one lot of

thick formed to a rectangle approximately 125 by 60 mm [5 by tape to another, the linerboard or fiberboard should be from a

2.5 in.] with a rectangular hole exactly 24 6 0.25 [1.0 6 0.01] single lot.

by 32 mm [1.25 in.] centered in the piece. The 24-mm [1-in.]

6.10 Steel Roller, 82.5 6 2.5 mm [3.25 6 0.1 in.] in

hole dimension shall be in the 125-mm [5-in.] direction (see

diameter and 45 6 1.5 mm [1.75 6 0.05 in.] in width, covered

Fig. 1 and Fig. 2).

with rubber approximately 6 mm [0.25 in.] in thickness having

6.6 Cutter, for preparing fiberboard or linerboard and tape

a Shore A durometer hardness of 80 6 5. The surface shall be

specimens.

a true cylinder void of any convex or concave deviations. The

6.7 Paperboard Piece, approximately 25 by 25 mm [1 by 1

mass of the roller shall be 2040 6 45 g [4.5 6 0.1 lb]. The

in.], for reinforcement.

mass of the handle shall not add to the mass of the roller during

6.8 Paper Punch, single-hole.

use.

6.9 Fiberboard or Linerboard Surface, against which the

NOTE 1—A simple check to determine if the rubber surface is cylindri-

test is made.

cal is to wrap the roller in a very thin paper (onionskin) and drag it across

6.9.1 For Procedure A, cut a rectangle exactly 24 6 0.25

a flat glass plate on which is placed a carbon paper, face up. The carbon

mm [1.0 6 0.01 in.] wide by at least 125 mm [5 in.] in length,

rubs off onto the thin paper wrapper to reveal high spots or hollows on the

from the linerboard representing the fiberboard on which the

rubber surface.

tape will be used. The long dimension shall lie at a right angle

6.11 Test Stand, to support the panel securely in a horizontal

to the machine direction of the linerboard. Reinforce one end

plane during the test period.

of the strip with a chipboard piece adhered with double-coated

6.12 Mass, 200 6 0.2 g, with a hook.

tape. Punch a hole at the center of the reinforcement.

6.9.2 For Procedure B, cut a rectangle, preferably 125 by 50 6.13 Timing System, for measuring test time in minutes.

mm [5 by 2 in.], but no less than 50 by 50 mm [2 by 2 in.], from

6.14 Paper, clean, unprinted, and without a coating of any

the fiberboard on which the tape will be used (or linerboard

kind, for use in adhering linerboard or fiberboard to the panel

representing it). The long test dimension shall lie at a right

(Procedure B).

angle to the machine direction of the linerboard.

6.9.3 For either procedure, prepare the linerboard or fiber-

7. Sampling

board in advance of testing and mark it to show which side to

7.1 Sampling shall be in accordance with Practice D 3715.

8. Test Specimens

8.1 A roll or rolls of tape for testing must be at least 36 mm

The linerboard accepted as the standard test surface, Standard Reference

[1.5 in.] in width.

Material 1810A, is available form the Office of Standard Reference Materials,

National Institute of Standards and Technology, Washington, DC 20234.

NOTE 1—Fix panel securely in a horizontal plane.

FIG. 1 Test Assembly for Procedure A

D 2860/D 2860M – 90 (1999)

FIG. 2 Preparation of Specimen for Procedure B

8.2 Unwind and discard at least three, but no more than six, 10.1.9 Void all tests where the tape (test specimen) has

outer wraps from the sample roll before taking specimens for pulled away from the panel (either the specimen from the

testing. double-coated tape or the double-coated tape from the panel).

8.3 Test five specimens from each roll of tape. When this occurs, repeat the test assuring that the panel, the

double-coated tape, and the test specimen are well bonded

9. Conditioning

together.

9.1 Condition sample rolls of tape and linerboard or fiber-

10.2 Procedure B:

board in the standard conditioning atmosphere as described in

10.2.1 Adhere the double-coated tape to the panel with firm

Practice D 4332 for a period of not less than 24 h. Test at these

finger pressure and remove the liner.

conditions.

10.2.2 Superimpose the fiberboard (or linerboard) on the

double-coated tape, exposing the correct side and assuring that

10. Procedure

the machine direction is at a right angle to the long dimension

10.1 Procedure A:

of the panel. Handle the fiberboard only at the edges and

10.1.1 Adhere the double-coated tape to the firm finger

corners so that an area at least 35 mm [1.5 in.] square at its

pressure and remove the liner.

center is absolutely free of contamination.

10.1.2 Lightly sand the backing of the test tape on the roll

10.2.3 Place a clean sheet of paper (6.14) on top of the

for approximately 250 mm [10 in.] with 300-grit sandpaper to

fiberboard. Rub against this to assure that the fiberboard is well

remove the easy unwind treatment. Start timing with the stop

bonded to the double-coated tape on the panel. Do not rub the

watch. Immediately unwind 300 to 450 mm [12 to 18 in.] of

fiberboard surface with the paper or fingers.

tape from a freely rotating roll at a rate of 500 to 750 mm [20

10.2.4 Start timing with the stop watch. Immediately un-

to 30 in.]/s.

wind 300 to 450 mm [12 to 18 in.] of tape from a freely,

10.1.3 Center the sanded area of this strip, adhesive side up,

rotating roll at a rate of 500 to 750 mm [20 to 30 in.]/s.

on the panel, aligning the long edges parallel with the panel

10.2.5 From the center of this strip, cut a specimen 24 6

long edges. Trim it to the panel dimensions. Do not allow any

0.25 mm [1.0 6 0.01 in.] wide and at least 180 mm [

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.