ASTM B464-99

(Specification)Standard Specification for Welded UNS N08020, N08024, and N08026 Alloy Pipe

Standard Specification for Welded UNS N08020, N08024, and N08026 Alloy Pipe

SCOPE

1.1 This specification covers welded UNS N08020, N08024, and N08026 alloy pipe for general corrosion-resisting and low- or high-temperature service.

1.2 The pipe covered is nominal pipe sizes up to and including Size 6, with the nominal wall thicknesses given as Schedules 5S, 10S, and 40S and nominal pipe sizes up to and including Size 2, also including Schedule 80S. Table 2 of Specification B775 is based on Table A1 of ANSI B36.19 and gives the nominal dimensions of these sizes. Table 3 of Specification B775 lists the dimensional requirements of these sizes. Pipe having other dimensions may be furnished provided such pipe complies with all other requirements of this specification.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 464 – 99

Standard Specification for

Welded UNS N08020, N08024, and N08026 Alloy Pipe

This standard is issued under the fixed designation B 464; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

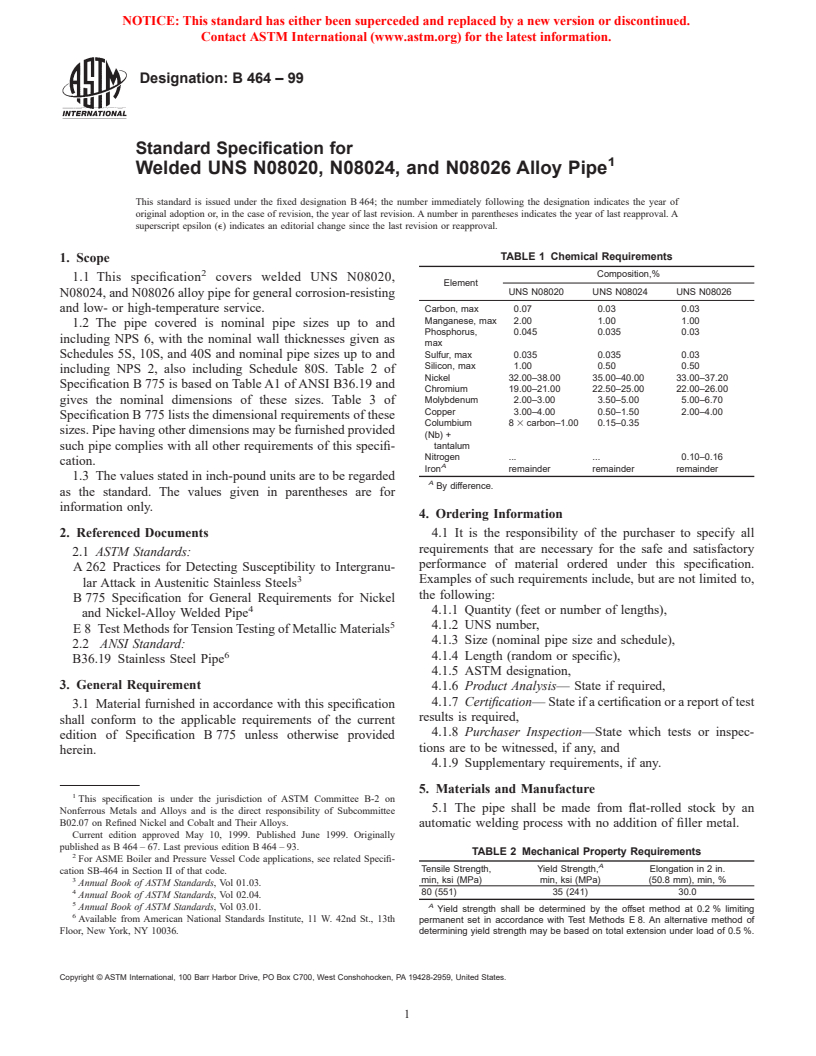

TABLE 1 Chemical Requirements

1. Scope

Composition,%

1.1 This specification covers welded UNS N08020,

Element

UNS N08020 UNS N08024 UNS N08026

N08024, and N08026 alloy pipe for general corrosion-resisting

and low- or high-temperature service.

Carbon, max 0.07 0.03 0.03

Manganese, max 2.00 1.00 1.00

1.2 The pipe covered is nominal pipe sizes up to and

Phosphorus, 0.045 0.035 0.03

including NPS 6, with the nominal wall thicknesses given as

max

Schedules 5S, 10S, and 40S and nominal pipe sizes up to and Sulfur, max 0.035 0.035 0.03

Silicon, max 1.00 0.50 0.50

including NPS 2, also including Schedule 80S. Table 2 of

Nickel 32.00–38.00 35.00–40.00 33.00–37.20

Specification B 775 is based on Table A1 of ANSI B36.19 and

Chromium 19.00–21.00 22.50–25.00 22.00–26.00

gives the nominal dimensions of these sizes. Table 3 of Molybdenum 2.00–3.00 3.50–5.00 5.00–6.70

Copper 3.00–4.00 0.50–1.50 2.00–4.00

Specification B 775 lists the dimensional requirements of these

Columbium 8 3 carbon–1.00 0.15–0.35

sizes. Pipe having other dimensions may be furnished provided

(Nb) +

tantalum

such pipe complies with all other requirements of this specifi-

Nitrogen . . 0.10–0.16

cation.

A

Iron remainder remainder remainder

1.3 The values stated in inch-pound units are to be regarded

A

By difference.

as the standard. The values given in parentheses are for

information only.

4. Ordering Information

2. Referenced Documents

4.1 It is the responsibility of the purchaser to specify all

requirements that are necessary for the safe and satisfactory

2.1 ASTM Standards:

performance of material ordered under this specification.

A 262 Practices for Detecting Susceptibility to Intergranu-

Examples of such requirements include, but are not limited to,

lar Attack in Austenitic Stainless Steels

the following:

B 775 Specification for General Requirements for Nickel

4.1.1 Quantity (feet or number of lengths),

and Nickel-Alloy Welded Pipe

4.1.2 UNS number,

E 8 Test Methods for Tension Testing of Metallic Materials

4.1.3 Size (nominal pipe size and schedule),

2.2 ANSI Standard:

4.1.4 Length (random or specific),

B36.19 Stainless Steel Pipe

4.1.5 ASTM designation,

3. General Requirement

4.1.6 Product Analysis— State if required,

4.1.7 Certification— State if a certification or a report of test

3.1 Material furnished in accordance with this specification

results is required,

shall conform to the applicable requirements of the current

4.1.8 Purchaser Inspection—State which tests or inspec-

edition of Specification B 775 unless otherwise provided

tions are to be witnessed, if any, and

herein.

4.1.9 Supplementary requirements, if any.

5. Materials and Manufacture

This specification is under the jurisdiction of ASTM Committee B-2 on

5.1 The pipe shall be made from flat-rolled stock by an

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.07 on Refined Nickel and Cobalt and Their Alloys.

automatic welding process with no addition of filler metal.

Current edition approved May 10, 1999. Published June 1999. Originally

published as B 464 – 67. Last previous edition B 464 – 93.

TABLE 2 Mechanical Property Requirements

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

A

Tensile Strength, Yield Strength, Elongation in 2 in.

cation SB-464 in Section II of that code.

min, ksi (MPa) min, ksi (MPa) (50.8 mm), min, %

Annual Book of ASTM Standards, Vol 01.03.

80 (551) 35 (241) 30.0

Annual Book of ASTM Standards, Vol 02.04.

A

Annual Book of ASTM Standards, Vol 03.01.

Yield strength shall be determined by the offset method at 0.2 % limiting

Available from American National Standards Institute, 11 W. 42nd St., 13th

permanent set in accordance with Test Methods E 8. An alternative method

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.