ASTM B131-22

(Specification)Standard Specification for Copper Alloy Bullet Jacket Cups

Standard Specification for Copper Alloy Bullet Jacket Cups

ABSTRACT

This specification covers bullet jacket preform cups made from UNS C22000 wrought copper alloy used for processing Types I-IV and Classes I-II bullet jackets. This standard contains information on chemical composition, grain size and testing requirements for the preform cups.

SIGNIFICANCE AND USE

15.1 For the purpose of determining compliance with the specified limits for requirements of the properties listed in the following table and for dimensional tolerances, an observed value or a calculated value shall be rounded as indicated in accordance with the rounding method of Practice E29.

Property

Rounded Unit for Observed or Calculated Value

Chemical Composition

Nearest unit in the last right-hand significant digit used in expressing the limiting value

Grain size

Nearest multiple of 0.005 mm

SCOPE

1.1 This specification establishes the requirements for bullet jacket preform cups produced of Copper Alloy UNS No. C22000 for processing into bullet jackets of the following types and classes:

1.1.1 Type I—Caliber 0.30.

1.1.2 Type II—Caliber 0.45.

1.1.3 Type III—Caliber 0.50.

1.1.4 Type IV—As specified in the contract or order.

1.1.5 Class I—Not annealed.

1.1.6 Class II—Annealed.

1.2 Units—The values stated in inch-pound units are to be regarded as standard, except for grain size, which is given in SI units. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B131 −22

Standard Specification for

1

Copper Alloy Bullet Jacket Cups

This standard is issued under the fixed designation B131; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* the Determination of Chemical Composition

E478 Test Methods for ChemicalAnalysis of CopperAlloys

1.1 This specification establishes the requirements for bullet

jacket preform cups produced of Copper Alloy UNS No.

3. Terminology

C22000 for processing into bullet jackets of the following

types and classes:

3.1 For definitions of terms related to copper and copper

1.1.1 Type I—Caliber 0.30.

alloys, refer to Terminology B846.

1.1.2 Type II—Caliber 0.45.

3.2 Definitions of Terms Specific to This Standard:

1.1.3 Type III—Caliber 0.50.

3.2.1 cup (cupping), n—a shallow cylindrical shell closed at

1.1.4 Type IV—As specified in the contract or order.

one end, normally intended for further fabrication, formed

1.1.5 Class I—Not annealed.

from a blank.

1.1.6 Class II—Annealed.

1.2 Units—The values stated in inch-pound units are to be

4. Ordering Information

regarded as standard, except for grain size, which is given in SI

4.1 Include the following specified choices when placing

units. The values given in parentheses are mathematical

orders for product under this specification, as applicable:

conversions to SI units that are provided for information only

and are not considered standard. 4.1.1 ASTM designation and year of issue,

4.1.2 Type and class (Section 1),

1.3 This international standard was developed in accor-

dance with internationally recognized principles on standard- 4.1.3 Grain size (Section 8),

ization established in the Decision on Principles for the

4.1.4 Dimensions and tolerances (Subsection 9.1),

Development of International Standards, Guides and Recom-

4.1.5 Drawing number to which order applies (Subsection

mendations issued by the World Trade Organization Technical

9.1),

Barriers to Trade (TBT) Committee.

4.1.6 Work test requirements, if required (Section 12), and

4.1.7 If product is purchased for agencies of the U.S.

2. Referenced Documents

Government (see the Supplementary Requirements section of

2

2.1 ASTM Standards:

this specification for additional requirements, if specified).

B601 Classification forTemper Designations for Copper and

Copper Alloys—Wrought and Cast

5. Materials and Manufacture

B846 Terminology for Copper and Copper Alloys

5.1 Materials:

E3 Guide for Preparation of Metallographic Specimens

5.1.1 The material of manufacture shall be annealed plate,

E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications sheet, strip, or disks of wrought Copper Alloy UNS No.

C22000 processed to produce even-topped cups.

E112 Test Methods for Determining Average Grain Size

E255 Practice for Sampling Copper and Copper Alloys for

5.2 Manufacture:

5.2.1 The product shall be manufactured by such blanking

and cupping to meet the cup dimensions specified, and subse-

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

quently annealed, if required. The annealed cups shall be

andCopperAlloysandisthedirectresponsibilityofSubcommitteeB05.01onPlate,

Sheet, and Strip. cleaned to provide a surface suitable for subsequent redrawing

Current edition approved Oct. 1, 2022. Published October 2022. Originally

into bullet jackets.

approved in 1940. Last previous edition approved in 2017 as B131-17. DOI:

10.1520/B0131-22.

2

6. Chemical Composition

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1 The product shall conform to the chemical composition

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. requirements in Table 1.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B131−22

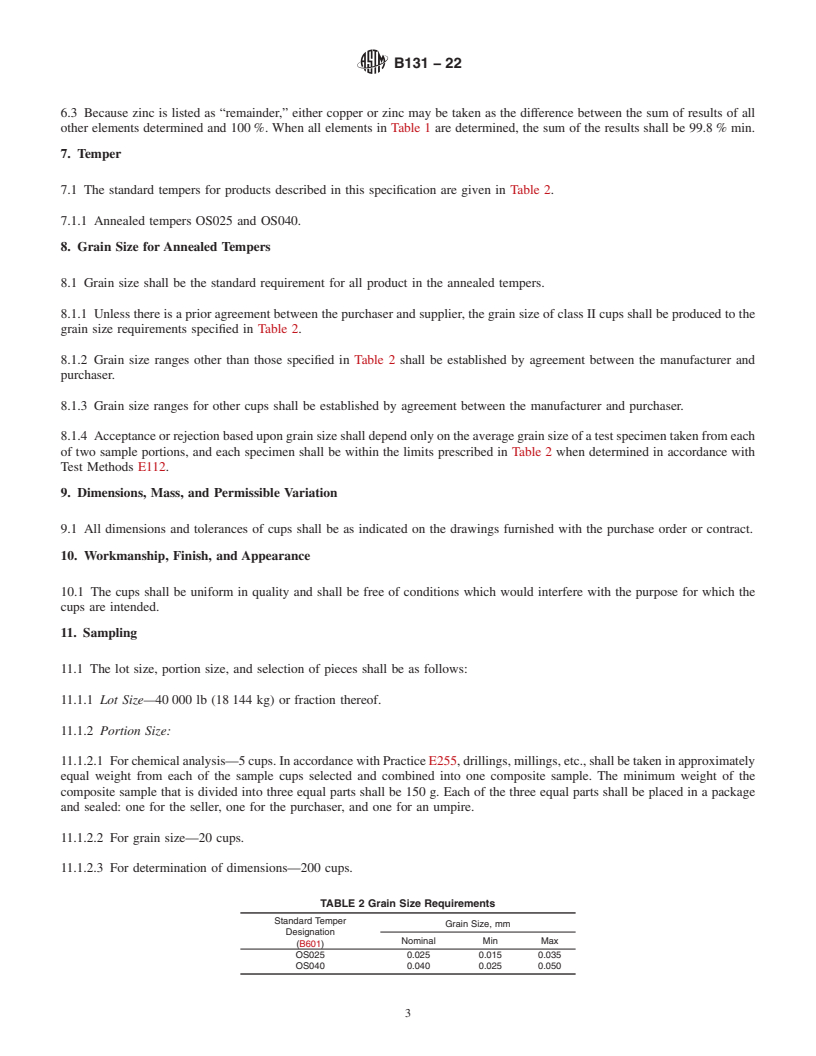

TABLE 1 Chemical Requirements

11. Sampling

Element Composition, %

11.1 The lot size, portion size, and selection of pieces shall

Copper 89.0–91.0

be as follows:

Lead, max 0.05

Iron, max 0.05 11.1.1 Lot Size—40 000 lb (18 144 kg) or fraction thereof.

Bismuth, max 0.006

11.1.2 Portion Size:

Zinc remainder

11.1.2.1 For chemical analysis—5 cups. In accordance with

Practice E255, drillings, millings, etc., shall be tak

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B131 − 17 B131 − 22

Standard Specification for

1

Copper Alloy Bullet Jacket Cups

This standard is issued under the fixed designation B131; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification establishes the requirements for bullet jacket preform cups produced of Copper Alloy UNS No. C22000 for

processing into bullet jackets of the following types and classes:

1.1.1 Type I—Caliber 0.30.

1.1.2 Type II—Caliber 0.45.

1.1.3 Type III—Caliber 0.50.

1.1.4 Type IV—As specified in the contract or order.

1.1.5 Class I—Not annealed.

1.1.6 Class II—Annealed.

1.2 Units—The values stated in inch-pound units are to be regarded as standard, except for grain size, which is given in SI units.

The values given in parentheses are mathematical conversions to SI units, whichunits that are provided for information only and

are not considered standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B601 Classification for Temper Designations for Copper and Copper Alloys—Wrought and Cast

B846 Terminology for Copper and Copper Alloys

E3 Guide for Preparation of Metallographic Specimens

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E112 Test Methods for Determining Average Grain Size

E255 Practice for Sampling Copper and Copper Alloys for the Determination of Chemical Composition

1

This specification is under the jurisdiction of ASTM Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.01 on Plate,

Sheet, and Strip.

Current edition approved April 1, 2017Oct. 1, 2022. Published April 2017October 2022. Originally approved in 1940. Last previous edition approved in 20122017 as

B131-12.-17. DOI: 10.1520/B0131-17.10.1520/B0131-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B131 − 22

E478 Test Methods for Chemical Analysis of Copper Alloys

3. Terminology

3.1 For definitions of terms related to copper and copper alloys, see refer to Terminology B846.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 cup (cupping), n—a shallow cylindrical shell closed at one end, normally intended for further fabrication, formed from a

blank.

4. Ordering Information

4.1 Include the following specified choices when placing orders for product under this specification, as applicable:

4.1.1 ASTM designation and year of issue.issue,

4.1.2 Type and class (Section 1),

4.1.3 Grain size (Section 8),

4.1.4 Dimensions and tolerances (see(Subsection 9.1),

4.1.5 Drawing number to which order applies (see(Subsection 9.1),

4.1.6 Work test requirements, if required (Section 12), and

4.1.7 If product is purchased for agencies of the U.S. Government (see the Supplementary Requirements section of this

specification for additional requirements, if specified).

5. Materials and Manufacture

5.1 Materials:

5.1.1 The material of manufacture shall be annealed plate, sheet, strip, or disks of wrought Copper Alloy UNS No. C22000

processed to produce even-topped cups.

5.2 Manufacture:

5.2.1 The product shall be manufactured by such blanking and cupping to meet the cup dimensions specified, and subsequently

annealed, if required. The annealed cups shall be cleaned to provide a surface suitable for subsequent redrawing into bullet jackets.

6. Chemical Composition

6.1 The product shall conform to the chemical composition requirements prescribed in Table 1.

6.2 These composition limits do not preclude the presence of other elements. By agreement between the manufacturer and

purchaser, limits may be established and analysis requi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.