ASTM D6381-03b

(Test Method)Standard Test Method for Measurement of Asphalt Shingle Mechanical Uplift Resistance

Standard Test Method for Measurement of Asphalt Shingle Mechanical Uplift Resistance

SIGNIFICANCE AND USE

Uplift resistance is one of the properties of an applied shingle that relates to its ability to withstand wind forces. The mechanical tests described are laboratory methods to measure that resistance at a designated temperature after the shingles have been sealed under designated conditions.

5.1.1 No quantitative relationship has been established between the mechanical uplift resistance and uplift forces due to the wind.

Many factors influence the sealing characteristics of shingles in the field; for example, temperature, time, contamination by dirt and debris, roof slope, and interference by misplaced fasteners. It is not the objective of this test method to address all of these influences. This test method is designed to determine the mechanical uplift resistance when representative specimens of shingles are sealed under selected conditions prior to testing.

Procedure A produces lower results than Procedure B. Procedure A provides an edge-lift load value and Procedure B provides a perpendicular load value. The procedure applicable to a specific product depends on the specific product design, geometry, and rigidity. It is the responsibility of the user of this test method to determine the appropriate procedure with reference to the specific product and application. It is possible that engineering calculations would require both procedures to be employed, and for both results to be used in the calculation of the resistance of that specific product to the effects of wind.

SCOPE

1.1 This test method covers measuring the uplift resistance of asphalt roofing shingles by mechanical means. It is applicable to shingles that use a factory-applied or field-applied sealant.

1.2 There are several types of shingles designed for service without a factory-applied or field-applied sealant. These shingles, when applied in accordance with the manufacturers' application instructions, employ other means to provide resistance against the forces generated by the action of wind such as geometry and shingle construction. Field experience has shown that these types of shingles function satisfactorily in service. Because there are a variety of these shingle designs, it is not practical to describe in this test method how to test these shingles for uplift resistance. The testing of these types of shingles, therefore, goes beyond the scope of this test method.

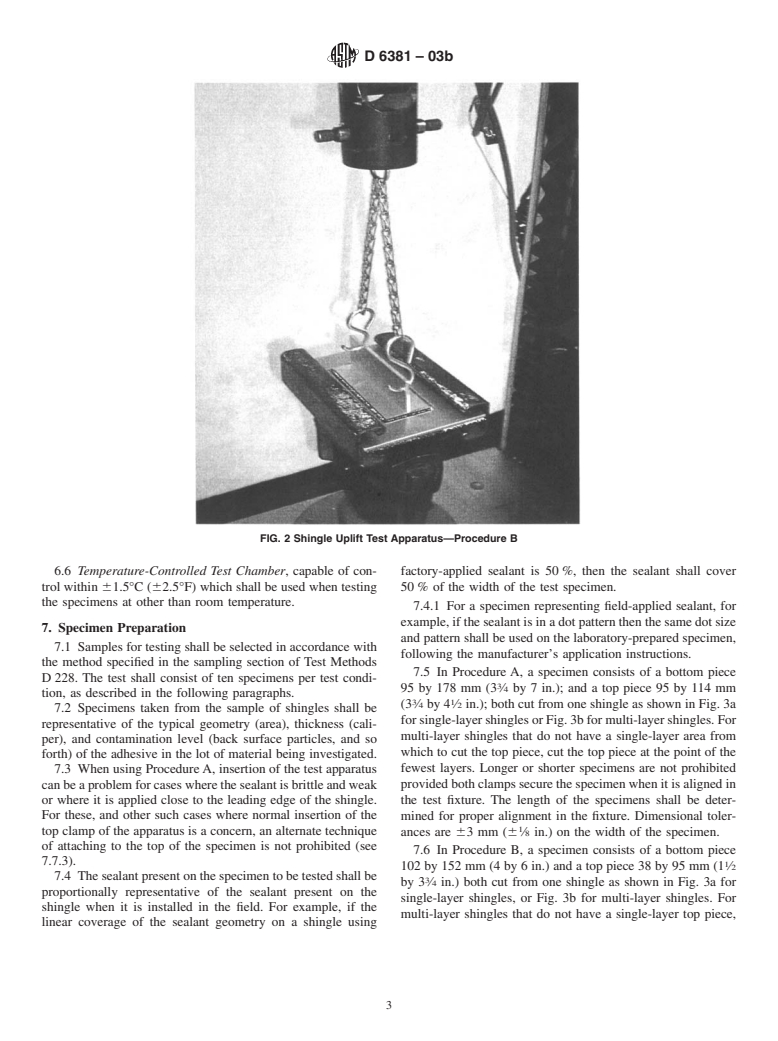

1.3 This test method describes two procedures for measuring shingle uplift resistance. Procedure A employs a specially designed apparatus with a clamping device which facilitates lifting of the edge of the shingle and measuring the force required to break the seal. Procedure B employs a metal "T" section adhered to the weather surface of the shingle to facilitate application and measurement of a perpendicular force to break the seal.

1.4 It is not prohibited to use this test method over a range of sealing time and temperature combinations and testing temperatures to simulate a variety of actual field use conditions. The times and temperatures used shall be stated in the report.

1.5 The values stated in SI units are to be regarded as the standard. The inch-pound values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6381–03b

Standard Test Method for

Measurement of Asphalt Shingle Mechanical Uplift

1

Resistance

This standard is issued under the fixed designation D 6381; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This test method covers measuring the uplift resistance 2.1 ASTM Standards:

of asphalt roofing shingles by mechanical means. It is appli- D 228 Test Methods for Sampling, Testing, andAnalysis of

cable to shingles that use a factory-applied or field-applied Asphalt Roll Roofing, Cap Sheets, and Shingles Used in

sealant. Roofing and Waterproofing

1.2 There are several types of shingles designed for service D 1079 Terminology Relating to Roofing, Waterproofing,

without a factory-applied or field-applied sealant. These and Bituminous Materials

shingles, when applied in accordance with the manufacturers’ D 3462 SpecificationforAsphaltShinglesMadefromGlass

application instructions, employ other means to provide resis- Felt and Surfaced with Mineral Granules

tanceagainsttheforcesgeneratedbytheactionofwindsuchas

3. Terminology

geometryandshingleconstruction.Fieldexperiencehasshown

that these types of shingles function satisfactorily in service. 3.1 Definitions—For definition of terms used in this test

method, refer to Terminology D 1079.

Because there are a variety of these shingle designs, it is not

practical to describe in this test method how to test these 3.2 Definitions of Terms Specific to This Standard:

3.2.1 seal—as it relates to steep roofing shingles,isthe

shingles for uplift resistance. The testing of these types of

shingles, therefore, goes beyond the scope of this test method. bonding that results from the activation of the sealant under the

action of time and temperature.

1.3 This test method describes two procedures for measur-

ing shingle uplift resistance. Procedure A employs a specially 3.2.2 sealant—as it relates to steep roofing shingles,is

defined as factory-applied or field-applied material designed to

designed apparatus with a clamping device which facilitates

lifting of the edge of the shingle and measuring the force seal the shingles to each other under the action of time and

temperature after the shingles are applied to a roof.

required to break the seal. Procedure B employs a metal “T”

3.2.3 sealed—as it relates to steep roofing shingles,isthe

section adhered to the weather surface of the shingle to

facilitate application and measurement of a perpendicular force condition of the shingles after the sealant has been activated by

the action of time and temperature.

to break the seal.

1.4 It is not prohibited to use this test method over a range

4. Summary of Test Method

of sealing time and temperature combinations and testing

4.1 The test specimens are constructed from pieces of

temperatures to simulate a variety of actual field use condi-

shingles, overlaid and sealed prior to testing.All specimens are

tions. The times and temperatures used shall be stated in the

then conditioned and tested at selected temperatures. Speci-

report.

mens are tested in ProcedureAby lifting the exposed edge and

1.5 The values stated in SI units are to be regarded as the

recording the uplift force required to break the seal, and in

standard. The inch-pound values given in parentheses are for

Procedure B, by recording the perpendicular force required to

information only.

break the seal.

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 Uplift resistance is one of the properties of an applied

priate safety and health practices and determine the applica-

shingle that relates to its ability to withstand wind forces. The

bility of regulatory limitations prior to use.

mechanical tests described are laboratory methods to measure

1

This test method is under the jurisdiction ofASTM Committee D08 on Roofing

2

and Waterproofing and is the direct responsibility of Subcommittee D08.02 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Prepared Roofings, Shingles and Siding Materials. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Dec. 1, 2003. Published January 2004. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1999. Last previous edition approved in 2003 as D 6381 – 03a. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United Sta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.