ASTM F3508-21a

(Guide)Standard Guide for In-Situ Pipeline Renovation As Dual-Wall Composite Pipeline by Push/Pull Installation of Compressed-Fit Shape-Memory-Polymer Tubular (SMPT)

Standard Guide for In-Situ Pipeline Renovation As Dual-Wall Composite Pipeline by Push/Pull Installation of Compressed-Fit Shape-Memory-Polymer Tubular (SMPT)

SCOPE

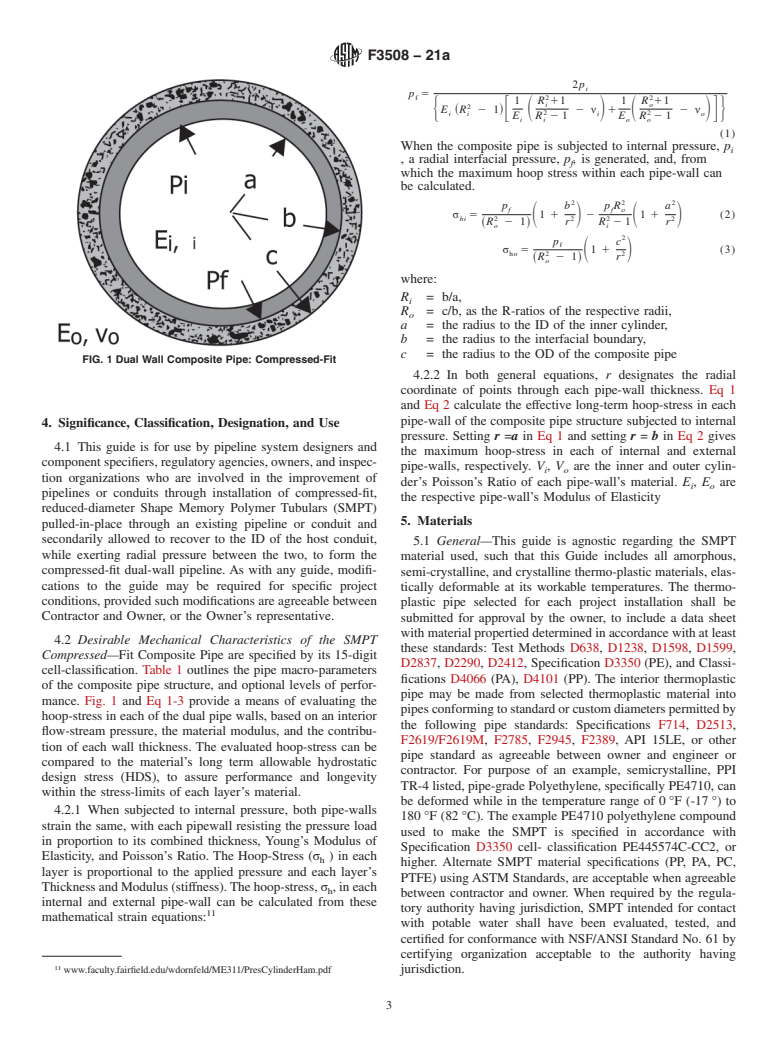

1.1 This guide describes the specification and re-construction of in-situ pipelines and conduits 2 in. to 63 in. (50 mm to 1600 mm) diameter) by the pulled-in-place installation, into an existing conduit, of circular, radially reduced, Shape-Memory-Polymer Tubular (SMPT) that after installation, re-expands (by “memory”) to press against the ID of the host pipe, thus coupling the interior pipe, by friction fit, as reinforcement to the host pipe. The added SMPT pipe wall restores leak tightness and adds its strength to the host pipe (Dual-Wall Composite-Pipe). It becomes a continuous compressed-fit dual-wall pipeline. Depending upon the SMPT compound used, the re-constructed pipelines or conduits are suitable for pressure and nonpressure pipeline applications such as process piping, raw and treated water transmission, water pipe systems, forced-mains, industrial and oil-patch gathering and transmission pipelines, sanitary sewers, storm sewers, and culverts.

Note 1: This standard guide covers circular SMPT tubulars which are radially reduced by mechanical means at the time of installation. This guide does not address “liners” that at the time of manufacture are deformed (folded) into U-shape, C-shape, H-shape, or other such configurations. This guide refers to dual-wall meaning two layers of pipe co-joined in the field, which is different from dual-wall factory-made co-extruded pipe or corrugated pipe. This guide does not provide a complete design basis covering the many variables required for design and construction of this field fabricated product; the advice of professional contractors and/or registered professional engineers may be incorporated as an adjunct to this guide.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

Note 2: There are no ISO standards covering the primary subject matter of this guide.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3508 − 21a

Standard Guide for

In-Situ Pipeline Renovation As Dual-Wall Composite

Pipeline by Push/Pull Installation of Compressed-Fit Shape-

1

Memory-Polymer Tubular (SMPT)

This standard is issued under the fixed designation F3508; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This guide describes the specification and re-

responsibility of the user of this standard to establish appro-

construction of in-situ pipelines and conduits 2 in. to 63 in. (50

priate safety, health, and environmental practices and deter-

mm to 1600 mm) diameter) by the pulled-in-place installation,

mine the applicability of regulatory limitations prior to use.

into an existing conduit, of circular, radially reduced, Shape-

1.4 This international standard was developed in accor-

Memory-Polymer Tubular (SMPT) that after installation, re-

dance with internationally recognized principles on standard-

expands (by “memory”) to press against the ID of the host

ization established in the Decision on Principles for the

pipe, thus coupling the interior pipe, by friction fit, as rein-

Development of International Standards, Guides and Recom-

forcement to the host pipe.The added SMPTpipe wall restores

mendations issued by the World Trade Organization Technical

leak tightness and adds its strength to the host pipe (Dual-Wall

Barriers to Trade (TBT) Committee.

Composite-Pipe). It becomes a continuous compressed-fit

dual-wall pipeline. Depending upon the SMPT compound

2. Referenced Documents

used, the re-constructed pipelines or conduits are suitable for

2

2.1 ASTM Standards:

pressure and nonpressure pipeline applications such as process

D638 Test Method for Tensile Properties of Plastics

piping,rawandtreatedwatertransmission,waterpipesystems,

D1238 Test Method for Melt Flow Rates of Thermoplastics

forced-mains, industrial and oil-patch gathering and transmis-

by Extrusion Plastometer

sion pipelines, sanitary sewers, storm sewers, and culverts.

D1598 Test Method for Time-to-Failure of Plastic Pipe

NOTE 1—This standard guide covers circular SMPTtubulars which are

Under Constant Internal Pressure

radially reduced by mechanical means at the time of installation. This

D1599 Test Method for Resistance to Short-Time Hydraulic

guide does not address “liners” that at the time of manufacture are

Pressure of Plastic Pipe, Tubing, and Fittings

deformed (folded) into U-shape, C-shape, H-shape, or other such configu-

D1600 TerminologyforAbbreviatedTermsRelatingtoPlas-

rations. This guide refers to dual-wall meaning two layers of pipe

co-joined in the field, which is different from dual-wall factory-made tics

co-extruded pipe or corrugated pipe. This guide does not provide a

D2290 Test Method for Apparent Hoop Tensile Strength of

completedesignbasiscoveringthemanyvariablesrequiredfordesignand

Plastic or Reinforced Plastic Pipe

construction of this field fabricated product; the advice of professional

D2412 Test Method for Determination of External Loading

contractors and/or registered professional engineers may be incorporated

Characteristics of Plastic Pipe by Parallel-Plate Loading

as an adjunct to this guide.

D2513 Specification for Polyethylene (PE) Gas Pressure

1.2 The values stated in inch-pound units are to be regarded

Pipe, Tubing, and Fittings

as standard. The values given in parentheses are mathematical

D2837 Test Method for Obtaining Hydrostatic Design Basis

conversions to SI units that are provided for information only

forThermoplasticPipeMaterialsorPressureDesignBasis

and are not considered standard.

for Thermoplastic Pipe Products

D3035 SpecificationforPolyethylene(PE)PlasticPipe(DR-

NOTE 2—There are no ISO standards covering the primary subject

matter of this guide. PR) Based on Controlled Outside Diameter

D3350 Specification for Polyethylene Plastics Pipe and Fit-

tings Materials

1

This test method is under the jurisdiction of ASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.67 on

2

Trenchless Plastic Pipeline Technology. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2021. Published December 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2021. Last previous edition approved in 2021 as F3

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F3508 − 21 F3508 − 21a

Standard Guide for

In-Situ Pipeline Re-ConstructionRenovation As Coupled

Dual-Wall Composite Pipeline by Push/Pull Installation of

1

Compressed-Fit Shape-Memory-Polymer Tubular (SMPT)

This standard is issued under the fixed designation F3508; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide describes the the specification and re-construction of in-situ pipelines and conduits 2 in. to 63 in. (50 mm to 1600

mm) diameter) by the pulled-in-place installation, into an existing conduit, of circular, radially reduced, Shape-Memory-Polymer

Tubular (SMPT) that after installation, re-expands (by “memory”) to press against the ID of the host pipe, thus coupling the interior

pipe, by friction fit, as reinforcement to the host pipe. The added SMPT pipe wall restores leak tightness and adds its strength to

the host pipe (Dual-Wall Composite-Pipe). It becomes a continuous compressed-fit dual-wall pipeline. Depending upon the SMPT

compound used, the re-constructed pipelines or conduits are suitable for pressure and nonpressure pipeline applications such as

process piping, raw and treated water transmission, water pipe systems, forced-mains, industrial and oil-patch gathering and

transmission pipelines, sanitary sewers, storm sewers, and culverts.

NOTE 1— This standard guide covers circular SMPT tubulars which are radially reduced by mechanical means at the time of installation. This guide does

not address “liners” that at the time of manufacture are deformed (folded) into U-shape, C-shape, H-shape, or other such configurations. This guide refers

to dual-wall meaning two layers of pipe co-joined in the field, which is different from dual-wall factory-made co-extruded pipe or corrugated pipe. This

guide does not provide a complete design basis covering the many variables required for design and construction of this field fabricated product; the

advice of professional contractors and/or registered professional engineers may be incorporated as an adjunct to this guide.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

NOTE 2—There are no ISO standards covering the primary subject matter of this guide.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This test method is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.67 on Trenchless

Plastic Pipeline Technology.

Current edition approved Aug. 1, 2021Nov. 1, 2021. Published August 2021December 2021. Originally approved in 2021. Last previous edition approved in 2021 as

F3508–21. DOI: 10.1520/F3508–2110.1520/F3508–21A

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3508 − 21a

2. Referenced Documents

2

2.1 ASTM Standards:

D638 Test Method for Tensile Properties of Plastics

D1238 Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer

D1598 Test Method for Time-to-Failure of Plastic Pipe Under Constant Internal Pressure

D1599 Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittings

D1600 Terminology for Abbreviated Terms Relating to Plastics

D2290 Test Method for Apparent Hoop Tensile Strength of Plastic or Reinforced Plastic Pipe

D2412 Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

D2513 Specification for Polyethylene (PE) Gas Pressure Pipe, Tubing, and Fittings

D2837 Test Method for Obtaining Hy

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.