ASTM D5677-16

(Specification)Standard Specification for Fiberglass (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe and Pipe Fittings, Adhesive Bonded Joint Type, for Aviation Jet Turbine Fuel Lines

Standard Specification for Fiberglass (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe and Pipe Fittings, Adhesive Bonded Joint Type, for Aviation Jet Turbine Fuel Lines

ABSTRACT

This specification covers reinforced plastic pipe and fitting system made from epoxy resin and glass-fiber reinforcement, together with adhesive for joint assembly, intended for services in aviation jet turbine fuel lines installed below ground. The fiberglass pipe shall be round and straight, and the pipe and fittings shall be of uniform density, resin content, and surface finish. Tests shall be conducted on the specimen to determine compliance with the following performance requirements: joint strength; hydrostatic strength; impact resistance; boil resistance; external load resistance; and degradation resistance.

SCOPE

1.1 This specification covers a reinforced plastic pipe and fittings system made from epoxy resin and glass-fiber reinforcement, together with adhesive for joint assembly, intended for service up to 150°F (65.6°C) and 150-psig (1034-kPa) operating pressure and surges up to 275 psig (1896 kPa) in aviation jet turbine fuel lines installed below ground.

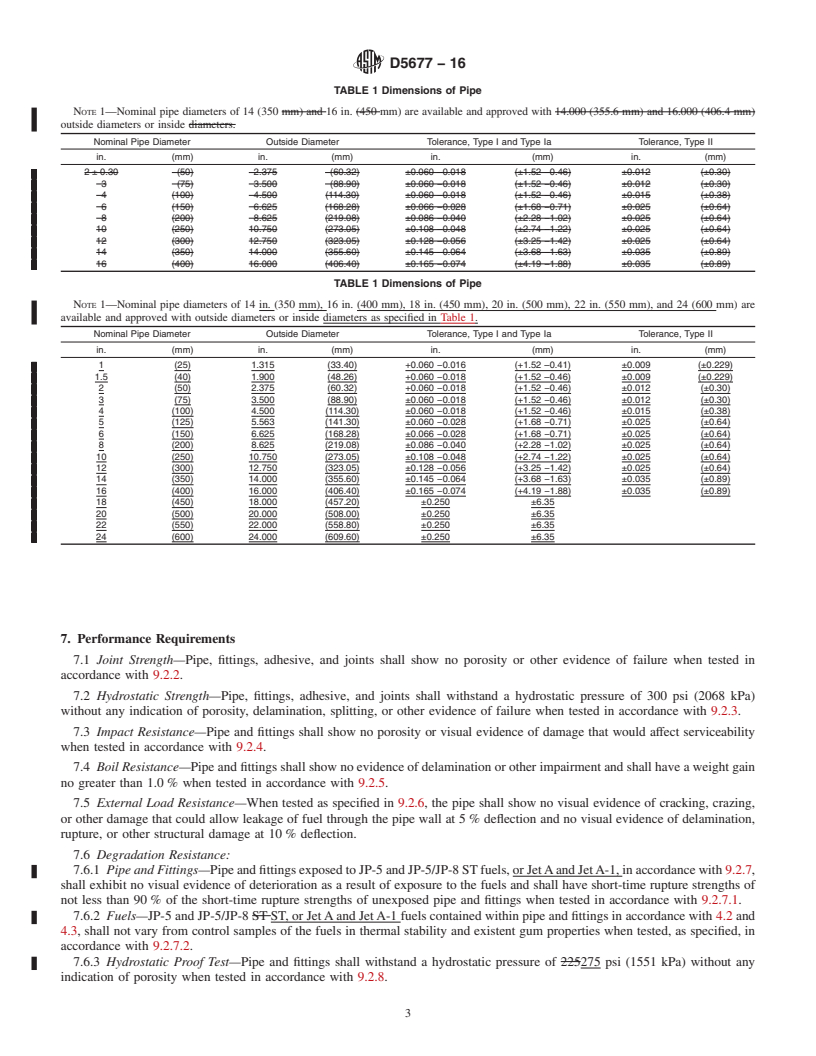

1.2 The dimensionless designator NPS has been substituted in this specification for such traditional terms as nominal diameter, size, and nominal size.

1.3 The values stated in inch-pound units are to be regarded as standard. The values in parentheses are for information only.

1.4 The following safety hazards caveat pertains only to the test method portion, Section 9, of this specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1: There is no known ISO equivalent to this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5677 −16 An American National Standard

Standard Specification for

Fiberglass (Glass-Fiber-Reinforced Thermosetting-Resin)

Pipe and Pipe Fittings, Adhesive Bonded Joint Type, for

1

Aviation Jet Turbine Fuel Lines

This standard is issued under the fixed designation D5677; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D1655Specification for Aviation Turbine Fuels

D2310 Classification for Machine-Made “Fiberglass”

1.1 This specification covers a reinforced plastic pipe and

(Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

fittings system made from epoxy resin and glass-fiber

D2412Test Method for Determination of External Loading

reinforcement, together with adhesive for joint assembly,

Characteristics of Plastic Pipe by Parallel-Plate Loading

intended for service up to 150°F (65.6°C) and 150-psig

D3241Test Method for Thermal Oxidation Stability of

(1034-kPa)operatingpressureandsurgesupto275psig(1896

Aviation Turbine Fuels

kPa) in aviation jet turbine fuel lines installed below ground.

D3567PracticeforDeterminingDimensionsof“Fiberglass”

1.2 The dimensionless designator NPS has been substituted

(Glass-Fiber-Reinforced Thermosetting Resin) Pipe and

in this specification for such traditional terms as nominal

Fittings

diameter, size, and nominal size.

D3951Practice for Commercial Packaging

D5685 Specification for “Fiberglass” (Glass-Fiber-

1.3 Thevaluesstatedininch-poundunitsaretoberegarded

asstandard.Thevaluesinparenthesesareforinformationonly. Reinforced Thermosetting-Resin) Pressure Pipe Fittings

F412Terminology Relating to Plastic Piping Systems

1.4 The following safety hazards caveat pertains only to the

F1173SpecificationforThermosettingResinFiberglassPipe

test method portion, Section 9, of this specification:This

Systems to Be Used for Marine Applications

standard does not purport to address all of the safety concerns,

2.2 Military Specification:

if any, associated with its use. It is the responsibility of the user

MIL-T-5624Turbine Fuel, Aviation, Grades JP-4, JP-5 and

of this standard to establish appropriate safety and health

3

JP-5/JP-8 ST

practices and determine the applicability of regulatory limita-

2.3 ANSI Standard:

tions prior to use.

4

B16.5Steel Pipe Flanges and Flanged Fittings

NOTE 1—There is no known ISO equivalent to this standard.

3. Terminology

2. Referenced Documents

3.1 Definitions—Definitions are in accordance with Termi-

2

2.1 ASTM Standards:

nologies D883 and F412, and abbreviations are in accordance

D381Test Method for Gum Content in Fuels by Jet Evapo-

with Terminology D1600, unless otherwise indicated.

ration

3.2 Definitions of Terms Specific to This Standard:

D883Terminology Relating to Plastics

3.2.1 conductive—a pipe or fitting that meets the require-

D1599Test Method for Resistance to Short-Time Hydraulic

ments for conductivity listed in Section 6 of Specification

Pressure of Plastic Pipe, Tubing, and Fittings

F1173.

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

tics 3.3 Abbreviations:

3.3.1 RTRP, n—reinforced thermosetting resin pipe.

1

This specification is under the jurisdiction of ASTM Committee D20 on

4. Classification

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced

4.1 General:

Plastic Piping Systems and Chemical Equipment.

Current edition approved Sept. 1, 2016. Published September 2016. Originally

approved in 1995. Last previous edition approved in 2010 as D5677–05 (2010).

3

DOI: 10.1520/D5677-16. Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM dodssp.daps.dla.mil.

4

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5677−16

4.1.1 Pipe meeting this specification is classified by type, 5.3 Adhesive—Adhesive for joint assembly shall be a ma-

grade, and class similar to Classification D2310. terialsuitableforprovidingasealbetweenthepipeandfittings

4.1.2 Fittings meeting this specification are also classified

in continuous service up to 150°F (65°C) and 150 psig (1034

by type (method of manufa

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5677 − 05 (Reapproved 2010) D5677 − 16 An American National Standard

Standard Specification for

Fiberglass (Glass-Fiber-Reinforced Thermosetting-Resin)

Pipe and Pipe Fittings, Adhesive Bonded Joint Type, for

1

Aviation Jet Turbine Fuel Lines

This standard is issued under the fixed designation D5677; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This specification covers a reinforced plastic pipe and fittings system made from epoxy resin and glass-fiber reinforcement,

together with adhesive for joint assembly, intended for service up to 150°F (65.6°C) and 150-psig (1034-kPa) operating pressure

and surges up to 275 psig (1896 kPa) in aviation jet turbine fuel lines installed below ground.

1.2 The dimensionless designator NPS has been substituted in this specification for such traditional terms as nominal

diameter,size, and nominal size.

1.3 The values stated in inch-pound units are to be regarded as standard. The values in parentheses are for information only.

1.4 The following safety hazards caveat pertains only to the test method portion, Section 9, of this specification:This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D381 Test Method for Gum Content in Fuels by Jet Evaporation

D883 Terminology Relating to Plastics

D1599 Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittings

D1600 Terminology for Abbreviated Terms Relating to Plastics

D1655 Specification for Aviation Turbine Fuels

D2310 Classification for Machine-Made “Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

D2412 Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

D3241 Test Method for Thermal Oxidation Stability of Aviation Turbine Fuels

D3567 Practice for Determining Dimensions of “Fiberglass” (Glass-Fiber-Reinforced Thermosetting Resin) Pipe and Fittings

D3951 Practice for Commercial Packaging

D5685 Specification for “Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin) Pressure Pipe Fittings

F412 Terminology Relating to Plastic Piping Systems

F1173 Specification for Thermosetting Resin Fiberglass Pipe Systems to Be Used for Marine Applications

2.2 Military Specification:

3

MIL-T-5624 Turbine Fuel, Aviation, Grades JP-4, JP-5 and JP-5/JP-8 ST

2.3 ANSI Standard:

4

B16.5 Steel Pipe Flanges and Flanged Fittings

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced Plastic Piping

Systems and Chemical Equipment.

Current edition approved Nov. 1, 2010Sept. 1, 2016. Published March 2011September 2016. Originally approved in 1995. Last previous edition approved in 20052010

as D5677 – 05.D5677 – 05 (2010). DOI: 10.1520/D5677-05R10.10.1520/D5677-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://dodssp.daps.dla.mil.

4

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5677 − 16

3. Terminology

3.1 Definitions—Definitions are in accordance with Terminologies D883 and F412, and abbreviations are in accordance with

Terminology D1600, unless otherwise indicated.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 conductive—a pipe or fitting that meets the requirements for conductivity listed in Section 6 of Specification F1173.

3.3 Abbreviations:

3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.