ASTM D7088-08

(Practice)Standard Practice for Resistance to Hydrostatic Pressure for Coatings Used in Below Grade Applications Applied to Masonry (Withdrawn 2017)

Standard Practice for Resistance to Hydrostatic Pressure for Coatings Used in Below Grade Applications Applied to Masonry (Withdrawn 2017)

SIGNIFICANCE AND USE

This test is meant to simulate the ability of a coating applied to a basement or other below grade masonry walls to prevent the intrusion of water through the coating caused by hydrostatic pressure from water on the outside of the structure.

SCOPE

1.1 This practice is for the evaluation of coatings used in below grade applications to resist the passage of water through concrete block.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

Formerly under the jurisdiction of Committee D01 on Paint and Related Coatings, Materials, and Applications, this practice was withdrawn in January 2017 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7088 − 08

Standard Practice for

Resistance to Hydrostatic Pressure for Coatings Used in

1

Below Grade Applications Applied to Masonry

This standard is issued under the fixed designation D7088; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope in outside dimensions with a hollow inside area (cell) of a

nominal 10 by 13 by 20 cm (4 by 5 by 8 in.) with a nominal

1.1 This practice is for the evaluation of coatings used in

1

wall thickness of 4 cm (1 ⁄2 in.) are coated on all four faces

below grade applications to resist the passage of water through

with the test paint and allowed to cure. Rubber gaskets are

concrete block.

sealed to the top and bottom of the test blocks typically with an

1.2 The values stated in SI units are to be regarded as the

epoxy or sealant. Water is then used to fill each coated test

standard. The values given in parentheses are for information

block. They are allowed to sit for seven days. Air pressure is

only.

then introduced and the face of the blocks is evaluated for the

1.3 This standard does not purport to address all of the

size and frequency of water droplets on the face of the coating,

safety concerns, if any, associated with its use. It is the any blistering, loss of adhesion, softening, discoloration or

responsibility of the user of this standard to establish appro-

other film irregularities.

priate safety and health practices and to determine the

applicability of regulatory limitations prior to use. 4. Significance and Use

4.1 This test is meant to simulate the ability of a coating

2. Referenced Documents

applied to a basement or other below grade masonry walls to

2

2.1 ASTM Standards:

prevent the intrusion of water through the coating caused by

D714 Test Method for Evaluating Degree of Blistering of

hydrostatic pressure from water on the outside of the structure.

Paints

D1475 Test Method For Density of Liquid Coatings, Inks,

5. Apparatus

and Related Products

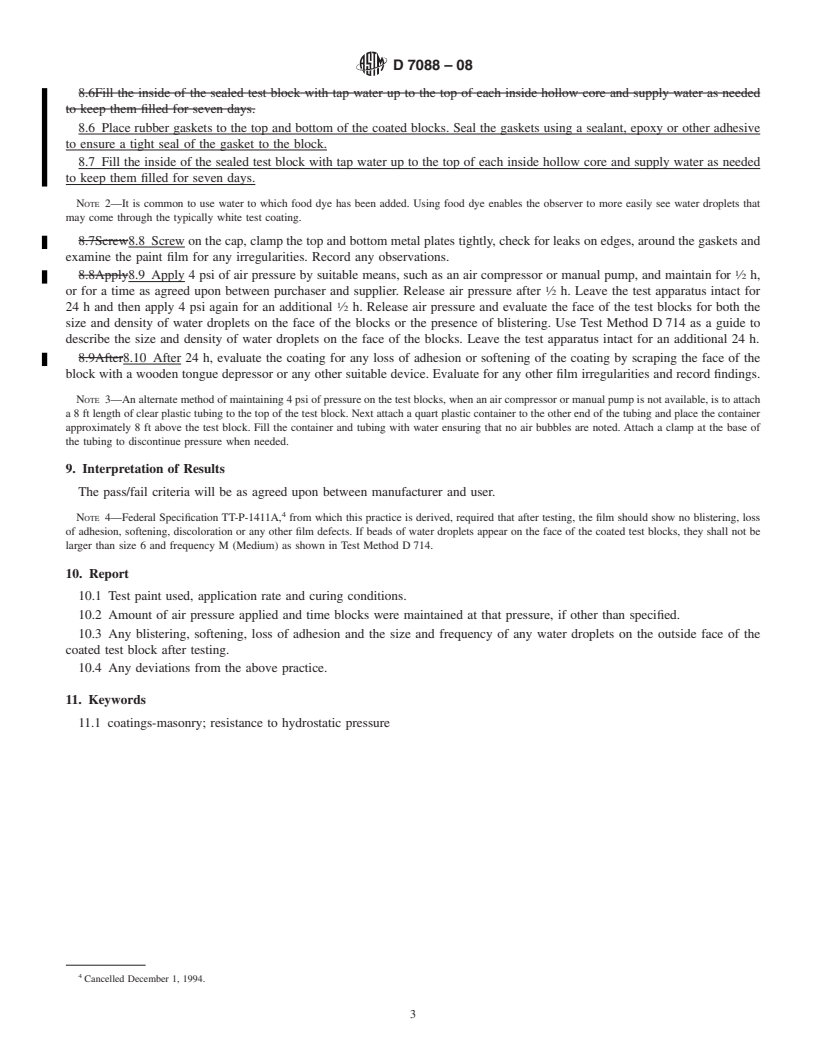

5.1 The metal frame test apparatus used in this practice (See

D3924 Specification for Environment for Conditioning and

Fig. 1) consists of a series of bolts and wing nuts used for

Testing Paint, Varnish, Lacquer, and Related Materials

clamping the plate tightly against the gasket and the test block.

D3925 Practice for Sampling Liquid Paints and Related

The top metal plate has an opening in the center into which a

Pigmented Coatings

pipe cap is drilled and tapped to receive an air supply from a

2.2 U. S. Federal Standards

compressor tank or hand pump to increase in inside pressure.

TT-P-1411A Paint, Copolymer-Resin, Cementitious (for

(See Fig. 2.)

3

Waterproofing Concrete and Masonry Walls)

5.2 The test apparatus typically consists of the following:

3. Summary of Practice

5.2.1 Galvanized Steel Top and Bottom Plates, measuring

1 1

28 by 28 by 0.3 cm (11 by 11 by ⁄8 in.), each with ⁄4 in. holes

3.1 Commercially available concrete blocks or concrete

drilled along the outer edges of the plates for insertion of

masonry units, typically 20 by 20 by 20 cm (8 by 8 by 8 in.)

screws and bolts to secure the blocks. There are typically three

holes on each side. In addition, the top plate should have a 2.5

1

This practice is under the jurisdiction of ASTM Committee D01 on Paint and

cm (1 in.) diameter hole in the center for insertion of the air

Related Coatings, Materials, and Applications and is the direct responsibility of

supply.

Subcommittee D01.47 on Concrete, Stone and Masonry Treatments.

1

Current edition approved June 1, 2008. Published June 1, 2008. Originally

5.2.2 Bolts(8), 12 by ⁄4 in. with accompanying washers and

approved in 2004. Last previous edition approved in 2004 as D7088 - 04. DOI:

wing nut screws to secure each block.

10.1520/D7088-08.

5.2.3 Air Compressor, capable of pressurizing the test

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

blocks to approximately 4 pounds per square inch (psi)

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

equipped with a pressure regulator to control the air pressure

the ASTM website.

being applied to the block.

3

Available from U.S. Government Printing Office Superintendent of Documents,

1

5.2.4 Rubber Gaskets (2), 20 by 20 by 0.5 cm (8 by 8 by ⁄4

732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.access.gpo.gov. in.) to be placed on top and bottom of the test block. The

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D7088–04 Designation:D7088–08

Standard Practice for

Resistance to Hydrostatic Pressure for Coatings Used in

1

Below Grade Applications Applied to Masonry

This standard is issued under the fixed designation D 7088; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice is for the evaluation of coatings used in below grade applications to resist the passage of water through

concrete block.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 714 Test Method for Evaluating Degree of Blistering of Paints

D 1475 Test Method forFor Density of Liquid Coatings, Inks, and Related Products

D 3924 Specification for Standard Environment for Conditioning and Testing Paint, Varnish, Lacquer, and Related Materials

D 3925 Practice for Sampling Liquid Paints and Related Pigmented Coatings

2.2 U. S. Federal Standards

3

TT-P-1411A Paint, Copolymer-Resin, Cementitious (for Waterproofing Concrete and Masonry Walls)

3. Summary of Practice

3.1 Commercially available concrete blocks or concrete masonry units, typically 20 by 20 by 20 cm (8 by 8 by 8 in.) in outside

dimensions with a hollow inside area (cell) of a nominal 10 by 13 by 20 cm (4 by 5 by 8 in.) with a nominal wall thickness of

1

4cm(1 ⁄2 in.) are coated on all four faces with the test paint and allowed to cure. Rubber gaskets are sealed to the top and bottom

of the test blocks typically with an epoxy or sealant. Water is then used to fill each coated test block. They are allowed to sit for

seven days.Air pressure is then introduced and the face of the blocks is evaluated for the size and frequency of water droplets on

the face of the coating, any blistering, loss of adhesion, softening, discoloration or other film irregularities.

4. Significance and Use

4.1 This test is meant to simulate the ability of a coating applied to a basement or other below grade masonry walls to prevent

the intrusion of water through the coating caused by hydrostatic pressure from water on the outside of the structure.

5. Apparatus

5.1 The metal frame test apparatus used in this practice (See Fig. 1) consists of a series of bolts and wing nuts used for clamping

the plate tightly against the gasket and the test block. The top metal plate has an opening in the center into which a pipe cap is

drilled and tapped to receive an air supply from a compressor tank or hand pump to increase in inside pressure. (See Fig. 2.)

5.2 The test apparatus typically consists of the following:

1

This practice is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.47 on Masonry Treatments.

Current edition approved Nov. 1, 2004. Published November 2004.

1

This practice is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.47 on Concrete, Stone and Masonry Treatments.

Current edition approved June 1, 2008. Published June 1, 2008. Originally approved in 2004. Last previous edition approved in 2004 as D 7088 - 04.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098.

3

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D7088–08

FIG. 1

1 1

5.2.1 Galvanized Steel Top and Bottom Plates, measuring 28 by 28

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.