ASTM B196/B196M-03

(Specification)Standard Specification for Copper-Beryllium Alloy Rod and Bar

Standard Specification for Copper-Beryllium Alloy Rod and Bar

SCOPE

1.1 This specification establishes the requirements for copper-beryllium alloy rod and bar in straight lengths. The following three alloys are included:Copper Alloy Previously UsedNominal BerylliumUNS No.DesignationsContent, %C17000 Alloy 1651.7C17200 Alloy 251.9C173001.9+0.4 lead

1.2 Unless otherwise required, Copper Alloy UNS No. C17200 shall be the alloy furnished whenever Specification B 196/B 196M is specified without any alloy designation.

1.3 The values stated in either inch-pounds or SI units are to be regarded separately as the standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 196/B 196M – 03

Standard Specification for

1

Copper-Beryllium Alloy Rod and Bar

This standard is issued under the fixed designation B 196/B 196M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* B 249/B 249M Specification for General Requirements for

Wrought Copper and Copper-Alloy Rod, Bar, Shapes, and

1.1 This specification establishes the requirements for

Forgings

copper-beryllium alloy rod and bar in straight lengths. The

B 601 Practice for Temper Designations for Copper and

following three alloys are included:

Copper Alloys—Wrought and Cast

Copper Alloy Previously Used Nominal Beryllium

B 846 Terminology for Copper and Copper Alloys

UNS No. Designations Content, %

E8 Test Methods of Tension Testing of Metallic Materials

C17000 Alloy 165 1.7

E8M Test Methods of Tension Testing of Metallic Materi-

C17200 Alloy 25 1.9

als [Metric]

C17300 1.9

+0.4 lead

3. General Requirements

1.2 Unless otherwise required, Copper Alloy UNS No.

3.1 The following sections of Specification B 249/B 249M

C17200 shall be the alloy furnished whenever Specification

constitute a part of this specification:

B 196/B 196M is specified without any alloy designation.

3.1.1 Terminology;

1.3 The values stated in either inch-pounds or SI units are to

3.1.2 Dimensions and Permissible Variations;

be regarded separately as the standard. Within the text, the SI

3.1.3 Workmanship, Finish, and Appearance;

units are shown in brackets. The values stated in each system

3.1.4 Sampling;

may not be exact equivalents; therefore, each system shall be

3.1.5 Number of Tests and Retests;

used independently of the other. Combining values from the

3.1.6 Specimen Preparation;

two systems may result in nonconformance with the specifi-

3.1.7 Test Methods;

cation.

3.1.8 Significance of Numerical Limits;

1.4 This standard does not purport to address all of the

3.1.9 Inspection;

safety concerns, if any, associated with its use. It is the

3.1.10 Rejection and Rehearing;

responsibility of the user of this standard to establish appro-

3.1.11 Certification;

priate safety and health practices and determine the applica-

3.1.12 Mill Test Report;

bility of regulatory limitations prior to use.

3.1.13 Packaging and Package Marking; and

2. Referenced Documents

3.1.14 Heat Identification

3.2 In addition, when a section with a title identical to that

2.1 The following documents in the current issue of the

referencedin3.1aboveappearsinthisspecification,itcontains

BookofStandardsformapartofthisspecificationtotheextent

additional requirements which supplement those appearing in

referenced herein:

Specification B 249/B 249M.

2.2 ASTM Standards:

B 194 Specification for Copper-Beryllium Alloy Plate,

4. Terminology

Sheet, Strip and Rolled Bar

4.1 For terms related to copper and copper alloys, refer to

Terminology B 846.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

4.2 Definitions of Terms Specific to This Standard:

and CopperAlloys and is the direct responsibility of Subcommittee B05.02 on Rod,

4.2.1 grain count—the number of grains per stock thick-

Bar, Wire, Shapes, and Forgings.

ness.

Current edition approved Oct. 1, 2003. Published November 2003. Originally

approved in 1945 to replace portions of B 120 – 41 T. Last previous edition

approved in 2001 as B 196/B 196M – 01.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 196/B 196M – 03

5. Ordering Information 7.3 Copper is customarily given as remainder, but may be

taken as the difference between the sum of all elements

5.1 Orders for products should include the following infor-

analyzed and 100 %.

mation, as applicable:

7.4 When all the elements in Table 1 are determined, the

5.1.1 ASTM specification designation and year of issue,

sum of results shall be 99.5 % min.

5.1.2 Quantity,

5.1.3 Copper Alloy UNS No. designation (Section 1),

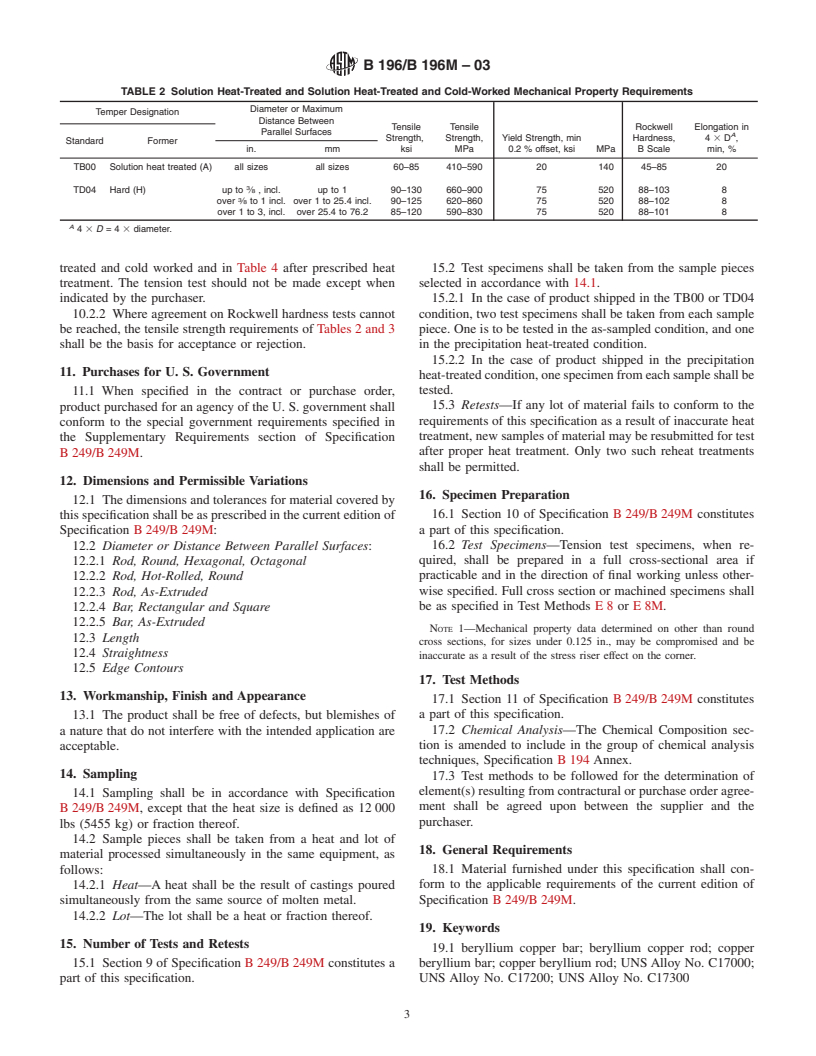

8. Temper

5.1.4 Form of material (rod or bar and cross section, such as

round, hexagonal, and so forth), 8.1 The standard temper designations available under this

5.1.5 Temper (Section 8), specification and as specified in Practice B 601 are solution

5.1.6 Dimensions (diameter or distance between parallel heat-treated TB00 (A), and cold-drawn hard TD04 (H), (see

surfaces, and length), Table 2) to be precipitation heat treated by the user. Also

5.1.7 How furnished (stock or specific lengths, with

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.