ASTM A1094/A1094M-20

(Specification)Standard Specification for Continuous Hot-Dip Galvanized Steel Bars for Concrete Reinforcement

Standard Specification for Continuous Hot-Dip Galvanized Steel Bars for Concrete Reinforcement

ABSTRACT

This specification covers requirements for steel reinforcing bars, with protective zinc or zinc-alloy coatings applied by the continuous hot-dip process. Continuous hot-dip galvanizing refers to the process of uninterrupted passage of long lengths of steel products through a molten bath of zinc or zinc-alloy. To control alloy formation and promote adhesion of the zinc or zinc-alloy coating with the steel base metal, the molten coating metal composition typically contains a percentage of aluminum ranging from 0.05 to 0.25. This aluminum is purposely supplied to the molten coating bath, either as a specified ingredient in the zinc spelter or by the addition of a master alloy containing aluminum.

This specification prescribes ordering information (including specification for reinforcing bars to be coated, quantity of bars, and size and grade of bars) as well as requirements for steel reinforcing bars and coating bath metal; minimum average coating thickness grade and equivalent weight [mass]; finish and adherence of coating; inspection and certification; and permissible amount of damaged coating and repair of damaged coating.

SCOPE

1.1 This specification covers steel reinforcing bars, with protective zinc or zinc-alloy coatings applied by the continuous hot-dip process.

Note 1: The galvanizer is identified throughout this specification as the manufacturer.

1.2 Guidelines for construction practices at the job-site are presented in Appendix X1.

1.3 Guidelines for use of continuous hot-dip galvanized reinforcing bars with non-galvanized steel forms are presented in Appendix X2.

1.4 The text of this specification references notes and footnotes which provide explanatory material. These notes and footnotes shall not be considered requirements of the specification.

1.5 This specification is applicable for orders in either inch-pound units (as Specification A1094) or SI units (as Specification A1094M).

1.6 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with this specification.

1.7 This specification does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this specification to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A1094/A1094M −20

Standard Specification for

Continuous Hot-Dip Galvanized Steel Bars for Concrete

1

Reinforcement

This standard is issued under the fixed designation A1094/A1094M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

1.1 This specification covers steel reinforcing bars, with

Barriers to Trade (TBT) Committee.

protectivezincorzinc-alloycoatingsappliedbythecontinuous

hot-dip process.

2. Referenced Documents

2

NOTE 1—The galvanizer is identified throughout this specification as

2.1 ASTM Standards:

the manufacturer.

A90/A90M Test Method for Weight [Mass] of Coating on

1.2 Guidelines for construction practices at the job-site are

Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

presented in Appendix X1.

A615/A615M SpecificationforDeformedandPlainCarbon-

Steel Bars for Concrete Reinforcement

1.3 Guidelines for use of continuous hot-dip galvanized

A706/A706M Specification for Deformed and Plain Low-

reinforcing bars with non-galvanized steel forms are presented

Alloy Steel Bars for Concrete Reinforcement

in Appendix X2.

A780/A780M PracticeforRepairofDamagedandUncoated

1.4 The text of this specification references notes and

Areas of Hot-Dip Galvanized Coatings

footnotes which provide explanatory material. These notes and

A996/A996M Specification for Rail-Steel and Axle-Steel

footnotes shall not be considered requirements of the specifi-

Deformed Bars for Concrete Reinforcement

cation.

A1035/A1035M Specification for Deformed and Plain,

1.5 This specification is applicable for orders in either

Low-Carbon, Chromium, Steel Bars for Concrete Rein-

inch-pound units (as Specification A1094) or SI units (as

forcement

Specification A1094M).

B6 Specification for Zinc

B487 Test Method for Measurement of Metal and Oxide

1.6 The values stated in either inch-pound units or SI units

Coating Thickness by Microscopical Examination of

are to be regarded separately as standard. Within the text, the

Cross Section

SI units are shown in brackets. The values stated in each

B852 Specification for Continuous Galvanizing Grade

system may not be exact equivalents; therefore, each system

(CGG) Zinc Alloys for Hot-Dip Galvanizing of Sheet

shall be used independently of the other. Combining values

Steel

from the two systems may result in non-conformance with this

E376 Practice for Measuring Coating Thickness by

specification.

Magnetic-Field or Eddy Current (Electromagnetic) Test-

1.7 This specification does not purport to address all of the

ing Methods

safety concerns, if any, associated with its use. It is the

responsibility of the user of this specification to establish

3. Terminology

appropriate safety, health, and environmental practices and

3.1 Definitions of Terms Specific to This Specification:

determine the applicability of regulatory limitations prior to

3.1.1 continuous hot-dip galvanizing, n—the process of

use.

uninterrupted passage of long lengths of steel products through

1.8 This international standard was developed in accor-

a molten bath of zinc or zinc-alloy.

dance with internationally recognized principles on standard-

3.1.1.1 Discussion—Tocontrolalloyformationandpromote

ization established in the Decision on Principles for the

adhesion of the zinc or zinc-alloy coating with the steel base

metal, the molten coating metal composition normally contains

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

2

A01.05 on Steel Reinforcement. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2020. Published September 2020. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2015. Last previous edition approved in 2018 as A1094/A1094M – 18. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/A1094_A1094M-20. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A1094/A1094M−20

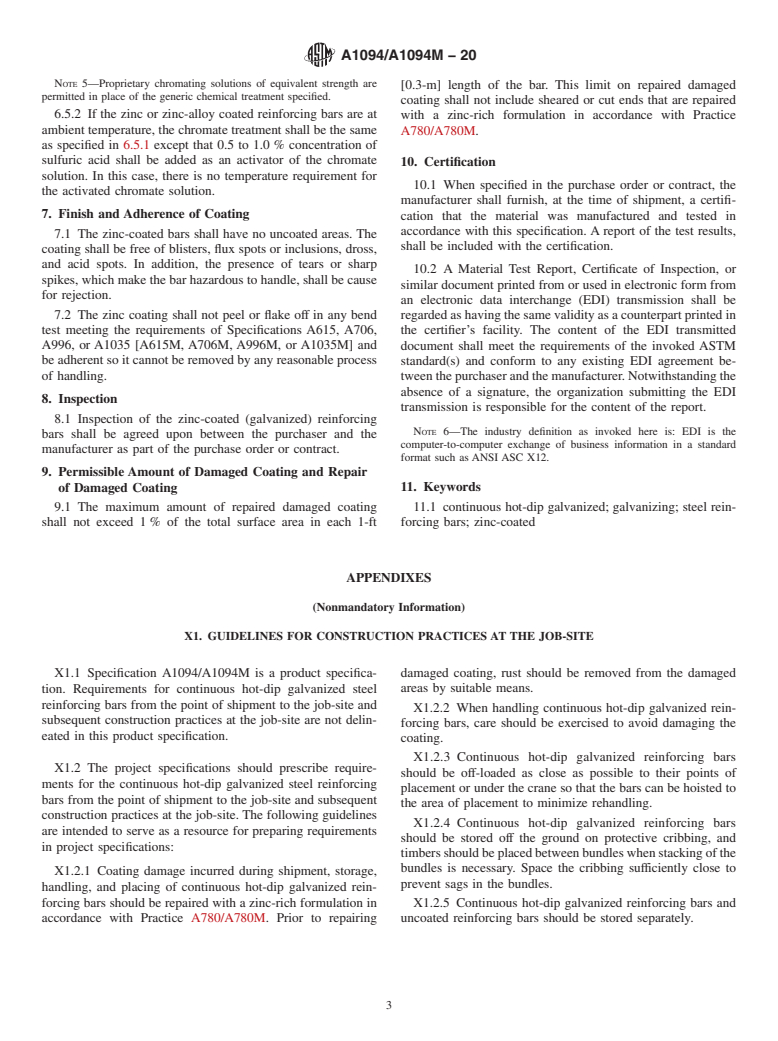

a percentage of aluminum usually in the range from 0.05 to 6.3 Thickness of Coating:

0.25. This aluminum is purpose

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A1094/A1094M − 18 A1094/A1094M − 20

Standard Specification for

Continuous Hot-Dip Galvanized Steel Bars for Concrete

1

Reinforcement

This standard is issued under the fixed designation A1094/A1094M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers steel reinforcing bars, with protective zinc or zinc-alloy coatings applied by the continuous hot-dip

process.

NOTE 1—The galvanizer is identified throughout this specification as the manufacturer.

1.2 Guidelines for construction practices at the job-site are presented in Appendix X1.

1.3 Guidelines for use of continuous hot-dip galvanized reinforcing bars with non-galvanized steel forms are presented in

Appendix X2.

1.4 The text of this specification references notes and footnotes which provide explanatory material. These notes and footnotes

shall not be considered requirements of the specification.

1.5 This specification is applicable for orders in either inch-pound units (as Specification A1094) or SI units (as Specification

A1094M).

1.6 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units

are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two systems may result in non-conformance with this specification.

1.7 This specification does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this specification to establish appropriate safety, health, and environmental practices and determine the applicability

of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.05

on Steel Reinforcement.

Current edition approved Nov. 1, 2018Sept. 1, 2020. Published November 2018September 2020. Originally approved in 2015. Last previous edition approved in 20162018

as A1094/A1094M – 16.18. DOI: 10.1520/A1094_A1094M-18.10.1520/A1094_A1094M-20.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A1094/A1094M − 20

2. Referenced Documents

2

2.1 ASTM Standards:

A90/A90M Test Method for Weight [Mass] of Coating on Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

A615/A615M Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement

A706/A706M Specification for Deformed and Plain Low-Alloy Steel Bars for Concrete Reinforcement

A780/A780M Practice for Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized Coatings

A996/A996M Specification for Rail-Steel and Axle-Steel Deformed Bars for Concrete Reinforcement

A1035/A1035M Specification for Deformed and Plain, Low-Carbon, Chromium, Steel Bars for Concrete Reinforcement

B6 Specification for Zinc

B487 Test Method for Measurement of Metal and Oxide Coating Thickness by Microscopical Examination of Cross Section

B852 Specification for Continuous Galvanizing Grade (CGG) Zinc Alloys for Hot-Dip Galvanizing of Sheet Steel

E376 Practice for Measuring Coating Thickness by Magnetic-Field or Eddy Current (Electromagnetic) Testing Methods

3. Terminology

3.1 Definitions of Terms Specific to This Specification:

3.1.1 continuous hot-dip galvanizing, n—the process of uninterrupted passage of long lengths of steel products through a molten

bath of zinc or zinc-alloy.

3.1.1.1 Discussion—

To control alloy formation and promote adhesion of the zinc or zinc-alloy coating with the steel base metal, the molten coating

metal composition normally contains a percentage of aluminum usually in the range from 0.05 to 0.25. This aluminum is purposely

supplied to the molten coating bath, either as a specified

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.