ASTM F888-06(2011)

(Test Method)Standard Test Method for Measuring Maximum Function Volume of the Primary Dirt Receptacle in a Vacuum Cleaner

Standard Test Method for Measuring Maximum Function Volume of the Primary Dirt<brk> Receptacle in a Vacuum Cleaner

SIGNIFICANCE AND USE

This test method covers a procedure to determine the maximum functional volume of the primary dirt receptacle when installed in the vacuum cleaner.

This test method provides the maximum amount of test media that the primary dirt receptacle will hold and may be more than the volume obtained when filled to the manufacturer's recommended fill line.

SCOPE

1.1 This test method covers household types of upright, canister, and combination vacuum cleaners.

1.2 This test method provides a measurement in dry quarts or litres of the maximum functional volume of the primary dirt receptacle when installed in the vacuum cleaner.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazards statements see 7.2 and 8.5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F888 − 06 (Reapproved 2011) An American National Standard

Standard Test Method for

Measuring Maximum Function Volume of the Primary Dirt

Receptacle in a Vacuum Cleaner

ThisstandardisissuedunderthefixeddesignationF888;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope rated frequency 61 Hz having a wave form that is essentially

sinusoidal with 3% maximum harmonic distortion for the

1.1 This test method covers household types of upright,

duration of the test.

canister, and combination vacuum cleaners.

4.3 Temperature Measuring Equipment, to provide mea-

1.2 This test method provides a measurement in dry quarts

surements accurate to within 61°F (0.5°C).

or litres of the maximum functional volume of the primary dirt

receptacle when installed in the vacuum cleaner. 4.4 Humidity Measuring Equipment, to provide measure-

ments accurate to within 62% relative humidity.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

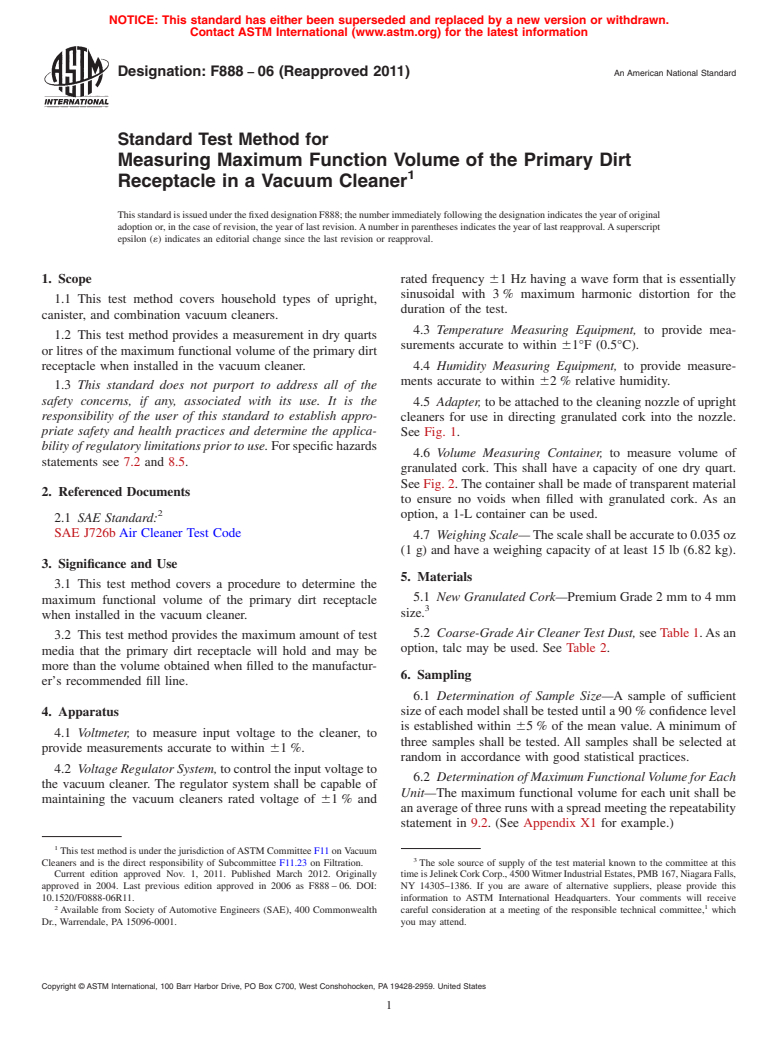

4.5 Adapter, to be attached to the cleaning nozzle of upright

responsibility of the user of this standard to establish appro-

cleaners for use in directing granulated cork into the nozzle.

priate safety and health practices and determine the applica-

See Fig. 1.

bilityofregulatorylimitationspriortouse.Forspecifichazards

4.6 Volume Measuring Container, to measure volume of

statements see 7.2 and 8.5.

granulated cork. This shall have a capacity of one dry quart.

See Fig. 2.The container shall be made of transparent material

2. Referenced Documents

to ensure no voids when filled with granulated cork. As an

option, a 1-L container can be used.

2.1 SAE Standard:

SAE J726bAir Cleaner Test Code

4.7 WeighingScale—Thescaleshallbeaccurateto0.035oz

(1 g) and have a weighing capacity of at least 15 lb (6.82 kg).

3. Significance and Use

5. Materials

3.1 This test method covers a procedure to determine the

5.1 New Granulated Cork—Premium Grade 2 mm to 4 mm

maximum functional volume of the primary dirt receptacle

size.

when installed in the vacuum cleaner.

5.2 Coarse-GradeAir Cleaner Test Dust,seeTable1.Asan

3.2 This test method provides the maximum amount of test

option, talc may be used. See Table 2.

media that the primary dirt receptacle will hold and may be

more than the volume obtained when filled to the manufactur-

6. Sampling

er’s recommended fill line.

6.1 Determination of Sample Size—A sample of sufficient

sizeofeachmodelshallbetesteduntila90%confidencelevel

4. Apparatus

is established within 65% of the mean value. A minimum of

4.1 Voltmeter, to measure input voltage to the cleaner, to

three samples shall be tested. All samples shall be selected at

provide measurements accurate to within 61%.

random in accordance with good statistical practices.

4.2 VoltageRegulatorSystem,tocontroltheinputvoltageto

6.2 DeterminationofMaximumFunctionalVolumeforEach

the vacuum cleaner. The regulator system shall be capable of

Unit—The maximum functional volume for each unit shall be

maintaining the vacuum cleaners rated voltage of 61% and

anaverageofthreerunswithaspreadmeetingtherepeatability

statement in 9.2. (See Appendix X1 for example.)

ThistestmethodisunderthejurisdictionofASTMCommitteeF11onVacuum

Cleaners and is the direct responsibility of Subcommittee F11.23 on Filtration. The sole source of supply of the test material known to the committee at this

Current edition approved Nov. 1, 2011. Published March 2012. Originally timeisJelinekCorkCorp.,4500WitmerIndustrialEstates,PMB167,NiagaraFalls,

approved in 2004. Last previous edition approved in 2006 as F888–06. DOI: NY 14305–1386. If you are aware of alternative suppliers, please provide this

10.1520/F0888-06R11. information to ASTM International Headquarters. Your comments will receive

2 1

Available from Society of Automotive Engineers (SAE), 400 Commonwealth careful consideration at a meeting of the responsible technical committee, which

Dr., Warrendale, PA 15096-0001. you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F888 − 06 (2011)

FIG. 1 Adapter Plate for Uprights

FIG. 2 Volume Measuring Container

A

TABLE 1 Analysis of Coarse Grade Air Cleaner F11 Test Dust TABLE 2 Analysis of Unscented Commercial Grade Talcum

Particle Size Distribution by Volume

Particle Size Distribution

by Weight, %

Size, µm Coarse Grade (% less than)

0.5 % 44µ

5.5 13±3

12.5 % 20–43.9µ

11 24±3

27.0 % 10–19.9µ

22 37 ± 3

23.0 % 5–9.9µ

44 56 ± 3

20.0 % 2–4.9µ

88 84 ± 3

8.0 % 1–1.9µ

176 100

9.0 % 0.9µ

A

The information in Table 1 is contained in “Air Cleaner Test Code,”SAETechnical

Report J726b.

7.2 Expose all components involved in the test to the

controlled environment for at least 16 h prior to the start of the

7. Conditioning

test.(Warning—Storesufficient100qtor100-Lincrementsof

7.1 Maintain the test room at 70 6 5°F (216 3°C) and 45 granulated cork in such a manner that when used they are in a

to 55% relative humidity. state of constant mass/unit volume. )

F888 − 06 (2011)

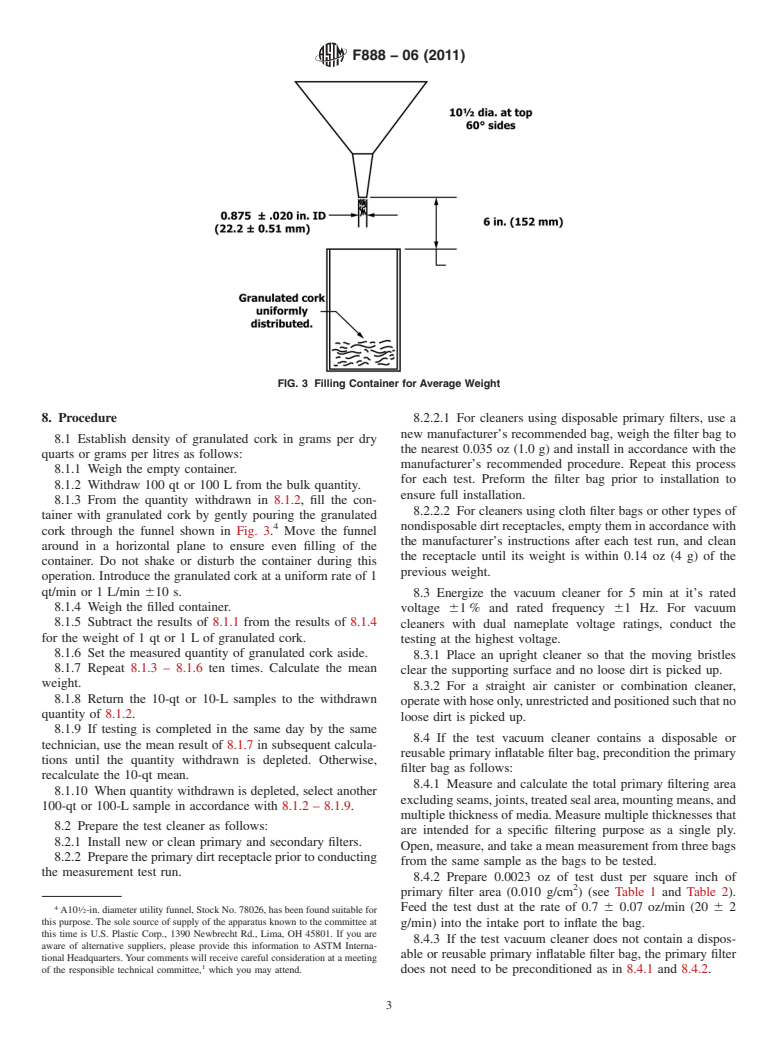

FIG. 3 Filling Container for Average Weight

8. Procedure 8.2.2.1 For cleaners using disposable primary filters, use a

new manufacturer’s recommended bag, weigh the filter bag to

8.1 Establish density of granulated cork in grams per dry

the nearest 0.035 oz (1.0 g) and install in accordance with the

quarts or grams per litres as follows:

manufacturer’s recommended procedure. Repeat this process

8.1.1 Weigh the empty container.

for each test. Preform the filter bag prior to installation to

8.1.2 Withdraw 100 qt or 100 L from the bulk quantity.

ensure full installation.

8.1.3 From the quantity withdrawn in 8.1.2, fill the con-

8.2.2.2 For cleaners using cloth filter bags or other types of

tainer with granulated cork by gently pouring the granulated

4 nondisposable dirt receptacles, empty them in accordance with

cork through the funnel shown in Fig. 3. Move the funnel

the manufacturer’s instructions after each test run, and clean

around in a horizontal plane to ensure even filling of the

the receptacle until its weight is within 0.14 oz (4 g) of the

container. Do not shake or disturb the container during this

previous weight.

operation. Introduce the granulated cork at a uniform rate of 1

qt/min or 1 L/min 610 s.

8.3 Energize the vacuum cleaner for 5 min at it’s rated

8.1.4 Weigh the filled container.

voltage 61% and rated frequency 61 Hz. For vacuum

8.1.5 Subtract the results of 8.1.1 from the results of 8.1.4

cleaners with dual nameplate voltage ratings, conduct the

for the weight of 1 qt or 1 L of granulated cork.

testing at the highest voltage.

8.1.6 Set the measured quantity of granulated cork aside.

8.3.1 Place an upright cleaner so that the moving bristles

8.1.7 Repeat 8.1.3 – 8.1.6 ten times. Calculate the mean

clear the supporting surface and no loose dirt is picked up.

weight.

8.3.2 For a straight air canister or combination cleaner,

8.1.8 Return the 10-qt or 10-L samples to the withdrawn

operatewithhoseonly,unrestrictedandpositionedsuchthatno

quantity of 8.1.2.

loose dirt is picked up.

8.1.9 If testing is completed in the same day by the same

8.4 If the test vacuum cleaner contains a disposable or

technician, use the mean result of 8.1.7 in subsequent calcula-

reusable primary inflatable filter bag, precondition the primary

tions until the quantity withdrawn is depleted. Otherwise,

filter bag as follows:

recalculate the 10-qt mean.

8.4.1 Measure and calculate the total primary filtering area

8.1.10 When quantity withdrawn is depleted, select another

excludingseams,joints,treatedsealarea,mountingmeans,and

100-qt or 100-L sample in accordance with 8.1.2 – 8.1.9.

multiplethicknessofmedia.Measuremultiplethicknessesthat

8.2 Prepare the test cleaner as follows:

are intended for a specific filtering purpose as a single ply.

8.2.1 Install new or clean primary and secondary filters.

Open, measure, and take a mean measurement from three bags

8.2.2 Preparetheprimarydirtreceptaclepriortoconducting

from the same sample as the bags to be tested.

the measurement test run.

8.4.2 Prepare 0.0023 oz of test dust per square inch of

primary filter area (0.010 g/cm ) (see Table 1 and Table 2).

Feed the test dust at the rate of 0.7 6 0.07 oz/min (20 6 2

A10 ⁄2-in.diameterutilityfunnel,StockNo.78026,hasbeenfoundsuitablefor

this purpose. The sole source of supply of the apparatus known to the committee at

g/min) into the intake port to inflate the bag.

this time is U.S. Plastic Corp., 1390 Newbrecht Rd., Lima, OH 45801. If you are

8.4.3 If the test vacuum cleaner does not contain a dispos-

aware of alternative suppliers, please provide this information to ASTM Interna-

able or reusable primary inflatable filter bag, the primary filter

tional Headquarters.Your comments will receive careful consideration at a meeting

of the responsible technical committee, which you may attend. does not need to be preconditioned as in 8.4.1 and 8.4.2.

F888 − 06 (2011)

FIG. 4 Test Set-up

8.5 Testing has shown that the test media, granulated cork, 8.7 De-energize the cleaner after it will accept no more

can be reused a maximum of ten times without affecting the granulated cork.

maximum functional volume measurement. (Warning—If

8.7.1 For bagless or hard dirt receptacle cleaners, de-

granulated cork is reused, the density in grams per dry quarts energize the cleaner after the granulated cork reaches the

or grams per litres must be reestablished (see 8.1 – 8.1.10).)

receptacle “full line.” If the receptacle has no “full line,”

continue the test until the cleaner will accept no more granu-

8.6 Introduce the granulated cork at a uniform rate of 1

lated cork. Do not include any granulated cork remaining

qt/minor1L/min 610sintothevacuumcleanerinaccordance

outside the dirt receptacle in the maximum functional volume

with 8.6.1, 8.6.2,or 8.6.3.

measurement.

8.6.1 For an upright cleaner, without attached hose or

attachment port, feed the granulated cork through the adapter

8.8 Carefully remove the primary dirt receptacle containing

on the nozzle. Use only adapter shown in Fig. 1 or equivalent.

the collected granulated cork. Do not include any granulated

The handle of the upright cleaner should be placed in the

cork remaining outside the primary dirt receptacle system,

position specified in the instruction book for above-the-floor

includingthedeliverytube,inthemaximumfunctionalvolume

cleaning.

measurement.

8.6.2 For an upright cleaner with attached hose or attach-

8.9 Weigh the primary dirt receptacle and collected granu-

ment port, feed the granulated cork through hose attached or

lated cork.

the hose provided for the attachment port. The handle of the

uprightcleanershouldbeplacedinthepositionspecifiedinthe 8.10 Calculatetheweightofgranulatedcorkcollectedinthe

instruction book for above-the-floor cleaning. primary dirt receptacle by subtracting the dirt receptacle and

8.6.3 Forcanisterandcombinationcleaners,feedthegranu- test dust weight (if added) as described in 8.2.2 and 8.4.2 from

lated cork through the hose accompanying the model being the full dirt receptacle weight (see 8.9). Calculate the maxi-

tested. The hose and cleaner must be placed in such a manner mum functional volume by dividing the total weight of

that their position will allow a uniform pickup from the collected granulated cork by the average weight of granulated

container (see Fig. 4). cork per quart or litre in accordance with 8.1.

F888 − 06 (2011)

TABLE 3 Repeatability and Reproducibility

Type Standard Deviation Repeatability, Standard Deviation Reproducibility

Cleaner of Repeatability, S r of Reproducibility, S Limit, R

r R

Bagless Upright Vacuum 0.07 0.21 0.19 0.52

Bagged Vacuum 0.10 0.28 0.47 1.32

8.11 Record the maximum functional volume in dry quarts 9.2.2 With 95% confidence, it can be stated that within a

or litres to the nearest tenth. laboratory,asetofmeasuredresultsderivedfromtestingaunit

shouldbeconsideredsuspectifthedifferencebetweenanytwo

8.12 Themaximumfunctionalvolumeforasingletestisthe

of the three values is greater than the respective values of the

number of quarts or litres of granulated cork collected by the

repeatability limit, r, listed in Table 3.

primary dirt receptacle. The maximum functional volume of a

given vacuum cleaner is the mean value of three tests meeting

9.3 Reproducibility (multi-laboratory)—The expected stan-

therepeatabilitystatementsspecifiedin9.2.(SeeAppendixX1

dard deviation of reproducibility of the average of a set of

for example.)

measured results between multiple laboratories, S , has been

R

found to be the respective values listed in Table 3.

9. Precision and Bias

9.3.1 The 95% reproducibility limit within a laboratory, R,

9.1 Precision—For bagged vacuums, these statements are

has been found to be the respective values listed in Table 3,

based on an interlaboratory test involving twelve laboratories

where R= 2.8(S ).

R

and four units. The range of maximum functional volume of

9.3.2 With95%confidence,itcanbestatedthattheaverage

the units was from 0.90 to 9.4 dry quarts. For bagless upright

of the measured results from a set of three test runs performed

vacuumsonly,thesestatementsarebasedonaninterlaboratory

in one laboratory, as compared to a second laboratory, should

test involving twelve laboratories and four units. The range of

be considered suspect if the difference between those two

maximumfunctionalvolumeoftheunitswasfrom1.12to2.23

values is greater than the respective values of the reproducibil-

5,6

dryquarts. Nodataiscurrentlyavailabletomakestatements

ity limit, R, listed in Table 3.

concerning the precision of other types of bagless vacuums.

9.3.3 If the absolute value of the difference between the

9.2 Repeatability (single-operator-laboratory)—The ex- averageofthemeasuredresultsfromthetwolaboratoriesisnot

pected standard deviation of repeatability of the measured equal to or less than the respective reproducibility limit listed

results within a laboratory, S , has been found to be the

in Table 3, the set of results from both laboratories shall be

r

respective values listed in Table 3. considered suspect.

9.2.1 The95%repeatabilitylimitwithinalaboratory,r,has

9.4 Bias—No justifiable statement can be made on the bias

been found to be the respective values listed in Table 1, where

of this test method.The true values of the properties cannot be

r=2.8(S ).

r

established by acceptable referee met

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.