ASTM C997-83(1993)e1

(Test Method)Test Methods for Chemical and Instrumental Analysis of Nuclear-Grade Sodium and Cover Gas (Withdrawn 1999)

Test Methods for Chemical and Instrumental Analysis of Nuclear-Grade Sodium and Cover Gas (Withdrawn 1999)

SCOPE

1.1 These test methods provide instructions for performing chemical, radiochemical, and instrumental analyses of sodium metal and for determining impurities in cover gas.

1.2 The analytical procedures appear in the following order: Sections Bypass Sampling 6 to 12 Overflow Sampling 13 to 18 Wire and Foil Equilibration Sampling 19 to 24 Laboratory Distillation of Sodium 25 to 31 Hydrogen by Hydrogen-Diffusion Meter 32 to 37 Carbon by Oxyacidic-Flux Method 38 to 46 Carbonaceous Gases Released by Acid 47 to 54 Cyanide by Spectrophotometry 55 to 64 Oxygen by the Equilibration Method Using Vanadium Wires 65 to 74 Fluoride by Selective Ion Electrode 75 to 83 Chloride by Selective Ion Electrode 84 to 92 Trace Metals by Atomic Absorption or Flame Emission 93 to 101 Spectrophotometry Cadmium and Zinc by Atomic Absorption Spectrophotometry 102 to 111 Potassium by Atomic Absorption Spectrophotometry 112 to 121 Rubidium and Cesium by Flame Spectrometry 122 to 131 Silicon by Spectrophotometry 132 to 140 Boron by Spectrophotometry 141 to 149 Uranium by Fluorimetry 150 to 157 Oxygen by Oxygen Meter 158 to 164 Carbon by Equilibration Method 165 to 172 Hydrogen by Equilibration Method 173 to 180 Sulfur by Spectrophotometry 181 to 189 Sodium Purity By Titration 190 to 199 Plutonium by Alpha Assay 200 to 209 Gamma Assay of Distillation Residue 210 to 217 Gamma Assay of Sodium Solution 218 to 226 Radioactive Iodine by Gamma Counting 227 to 235 Tritium by Liquid Scintillation Counting 236 to 245 Particles by Filtration 246 to 254 Gaseous Impurities in Cover Gas by Gas Chromatography 255 to 263

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

ϵ1

Designation: C 997 – 83 (Reapproved 1993)

Standard Test Methods for

Chemical and Instrumental Analysis of Nuclear-Grade

Sodium and Cover Gas

This standard is issued under the fixed designation C997; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

ϵ NOTE—Section 264, Keywords, was added editorially in April 1993.

1. Scope D1193 Specification for Reagent Water

E146 Methods for Chemical Analysis of Zirconium and

1.1 These test methods provide instructions for performing

Zirconium Alloys

chemical, radiochemical, and instrumental analyses of sodium

metal and for determining impurities in cover gas.

3. Significance and Use

1.2 Theanalyticalproceduresappearinthefollowingorder:

3.1 Sodium metal is used as a coolant (heat-transfer me-

Sections

dium) in nuclear reactors, particularly in fast breeder reactors.

Bypass Sampling 6-12

Overflow Sampling 13-18

An inert gas (argon, nitrogen, or helium) is used to cover

Wire and Foil Equilibration Sampling 19-24

sodium within a reactor and during transfer and shipping

Laboratory Distillation of Sodium 25-31

operations to protect it from oxygen and water. To be suitable

Hydrogen by Hydrogen-Diffusion Meter 32-37

Carbon by Oxyacidic-Flux Method 38-46

for use, the metal and gas must meet specified criteria for

Carbonaceous Gases Released by Acid 47-54

purity as determined by analysis.

Cyanide by Spectrophotometry 55-64

3.2 During reactor operation, chemical and radiochemical

Oxygen by the Equilibration Method Using Vanadium Wires 65-74

Fluoride by Selective Ion Electrode 75-83

impuritiesresultingfromcorrosionandneutronactivationmust

Chloride by Selective Ion Electrode 84-92

be maintained within specification levels established for the

Trace Metals by Atomic Absorption or Flame Emission 93-101

reactor system. The sodium and cover gas must be analyzed

Spectrophotometry

Cadmium and Zinc by Atomic Absorption Spectrophotometry 102-111

periodically to monitor buildup of those impurities.

Potassium by Atomic Absorption Spectrophotometry 112-121

3.3 These methods are applicable to the analysis of sodium

Rubidium and Cesium by Flame Spectrometry 122-131

and cover gas for the above purposes.

Silicon by Spectrophotometry 132-140

Boron by Spectrophotometry 141-149

Uranium by Fluorimetry 150-157

4. Reagents

Oxygen by Oxygen Meter 158-164

4.1 Purity of Reagents—Reagent grade chemicals shall be

Carbon by Equilibration Method 165-172

Hydrogen by Equilibration Method 173-180

used in all tests. Unless otherwise indicated, it is intended that

Sulfur by Spectrophotometry 181-189

all reagents shall conform to the specifications of the Commit-

Sodium Purity By Titration 190-199

tee onAnalytical Reagents of theAmerican Chemical Society,

Plutonium by Alpha Assay 200-209

6,7

Gamma Assay of Distillation Residue 210-217

wheresuchspecificationsareavailable. Othergradesmaybe

Gamma Assay of Sodium Solution 218-226

used, provided it is first ascertained that the reagent is of

Radioactive Iodine by Gamma Counting 227-235

sufficiently high purity to permit its use without lessening the

Tritium by Liquid Scintillation Counting 236-245

Particles by Filtration 246-254

accuracy of the determination.

Gaseous Impurities in Cover Gas by Gas Chromatography 255-263

5. Safety Precautions

2. Referenced Documents

5.1 Sodium is a reactive metal. It reacts vigorously with

2.1 ASTM Standards:

water and alcohol to form hydrogen, which is easily ignited

A370 TestMethodsandDefinitionsforMechanicalTesting

of Steel Products

C859 Terminology Relating to Nuclear Materials

Annual Book of ASTM Standards, Vol 11.01.

Discontinued; see 1991 Annual Book of ASTM Standards, Vol 03.05.

1 6

These test methods are under the jurisdiction of ASTM Committee C-26 on “ReagentChemicals,AmericanChemicalSocietySpecifications,”Am.Chemi-

Nuclear Fuel Cycle and is the direct responsibility of Subcommittee C26.05 onTest cal Soc., Washington, D.C. For suggestions on the testing of reagents not listed by

Methods. theAmericanChemicalSociety,see“ReagentChemicalsandStandards,”byJoseph

Current edition approved May 27, 1983. Published August 1983. Rosin, D. Van Nostrand Co., Inc., New York, NY, and the “United States

Annual Book of ASTM Standards, Vol 01.03. Pharmacopeia.”

3 7

Annual Book of ASTM Standards, Vol 12.01. Met-L-X is a tradename for a NaCl-based powder.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

ϵ1

C 997 – 83 (1993)

and which can cause an explosion. Take care when dissolving 10. Precautions

a sodium sample, and it is recommended to use a safety shield

10.1 An important safety consideration in sampling is the

and fume hood. The proper type of fire extinguisher shall be

modeofconnectionofthesamplertothesystem.Threemodes

readilyavailable,andlocallyestablishedsafetyprecautionsfor

of connection for the bypass sampler are by welding, by

handling sodium shall be followed.

Swagelok fittings, and by Conoseal fittings. In general, expe-

5.2 Radioactive sodium must be handled in fume hoods or

rience has shown that fewer sodium leaks are experienced

other protective facilities, depending upon the degree of

when connections are welded. This is especially true at

radiation exposure involved. Locally established radiation

temperatures above approximately 400°C (750°F). At low

protection and monitoring regulations shall be followed.

pressures,SwagelokandConosealfittingscanbeusedsuccess-

fully at temperatures moderately above 400°C (750°F). The

BYPASS SAMPLING

fittings must be installed, maintained, and monitored in accor-

dance with locally approved safety practices.

6. Scope

6.1 This method is required to obtain a sample for the

11. Procedure

determination of carbon by the oxyacidic flux method. In

11.1 Rinse the sampling vessel successively with 1+5

addition, it may be used for those procedures in which the

nitric acid, water, and methanol. Dry, cap, and store until used.

sodium is dissolved directly out of the container, whether the

11.2 Attach the sampling vessel to the system in a manner

solvent is water, alcohol, or mercury.

consistent with local safety practices.

7. Summary of Method

11.3 Check the system as follows:

11.3.1 Check the sampling system for leaks according to

7.1 Asodiumsampleiscollectedinacontainerthat,through

locally approved operating and safety practices. Use helium-

extended treatment in flowing sodium, has been cleaned and

leak testing whenever possible. In that case, a helium-leak rate

equilibrated isothermally with the bulk sodium.

−7 3 −8 3

of <1 310 cm ·atm/s (<1 310 m ·Pa/s) through the

8. Apparatus connectors or welds shall be attained. For systems that can

tolerate introduction of small amounts of gas, this step may be

8.1 Sampling Vessel, may be a section of seamless metal

replaced by 11.3.2.

tubing; for example, stainless-steel tubing having an inside

11.3.2 Purgethevesselwithaninertgas.Connectonefitting

diameter of > ⁄8 in. (>9.5 mm) and an internal finish of 32 µin.

to a sampling port while continuing the purge. Discontinue the

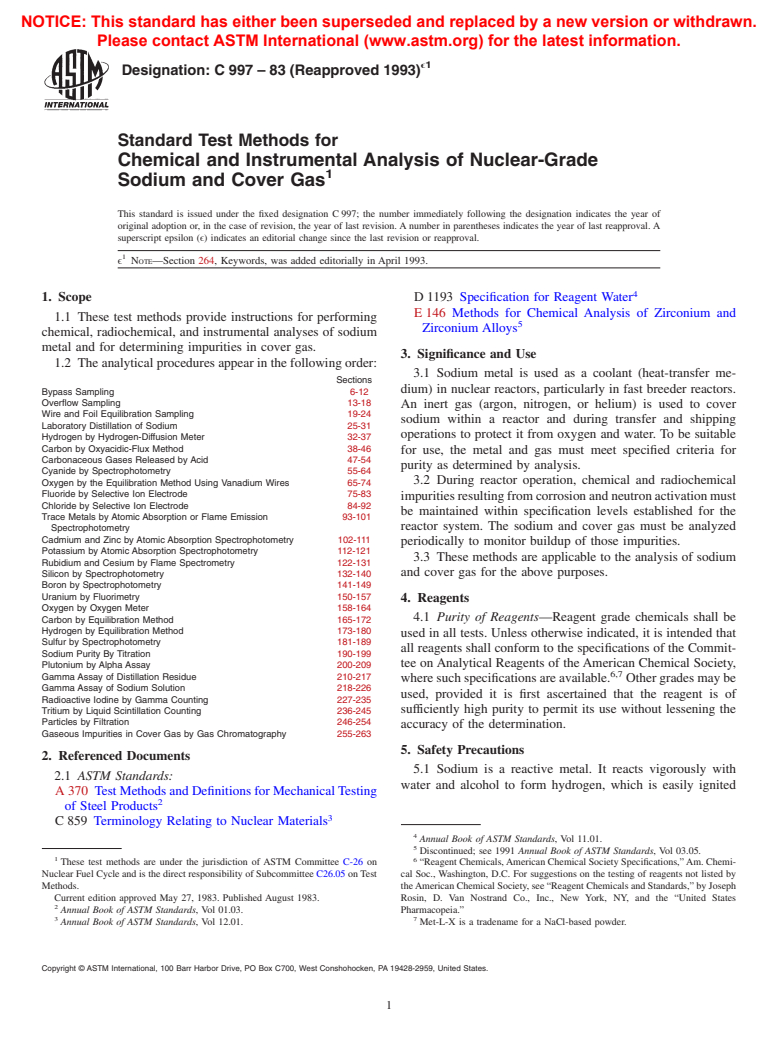

AA (0.81 mµ) or better, or a vessel as shown in Fig. 1. The

purge and immediately connect the second fitting to the other

vessel in Fig. 1 consists of two matching sections clamped

sampling port. Check the sampling system for leaks, in

together.Itsmainbody,thathasaninsidediameterof0.855in.

accordance with locally approved operating and safety prac-

(21.7mm),tapersateachendtoaninsidediameterof0.279in.

tices. Use helium-leak testing whenever possible. In that case,

(7.09 mm). Vessels may be made of either nickel or stainless

−7 3 −8 3

a leak rate of <1 310 cm ·atm/s (<1 310 m ·Pa/s)

steel.Attachment of the vessel to a system is done by coupling

through the connectors or welds should be attained.

consistent with locally approved safety practices. Provisions

11.4 Heat the entire sampling-vessel system to a tempera-

must be available to heat the vessel and maintain its tempera-

ture greater than 100°C (212°F), taking care to heat progres-

ture as required.

sivelyfromeitherthesolid-liquidorsolid-gasinterfacetoward

9. Reagents and Materials thecontrolvalves.Raisethetemperatureoftheentiresystemto

approximately 150°C (300°F).

9.1 Methanol, redistilled using a quartz or borosilicate glass

11.5 Establish sodium flow by opening the outlet and inlet

still and stored in polyethylene bottles. Ethanol may be

valves in the proper sequence. If step 11.3.2 has been used, the

substituted for methanol.

sequence of opening first the outlet and then the inlet valve is

9.2 Nitric acid, diluted 1-part nitric acid with 5-parts dis-

desirablebecausethissequencerelievesthegaspressureinthe

tilled water.

vessel to the outlet line.

9.3 Water, distilled and passed through a high-quality

mixed-bed ion exchange column and stored in a polyethylene 11.6 Adjust the sodium-flow rate, if necessary.Aminimum

−6 3

bottle. flow rate of 0.1 g/m (6.3 310 m /s) should be maintained.

FIG. 1 Typical Sample Vessel

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

ϵ1

C 997 – 83 (1993)

11.7 Increase the heat input to the sampler system if 14. Summary of Method

necessary to maintain the sampling vessel at the sampling

14.1 A sodium sample is obtained in a cup or beaker by

temperature.

overflowing the container with sodium. The excess sodium

11.8 Maintain the temperature and flow rate until the vessel

returns to the system.

has equilibrated with the sodium. The time necessary for

15. Apparatus

equilibration varies with the temperature of the sampling

vessel. Table 1 gives the minimum equilibration time required

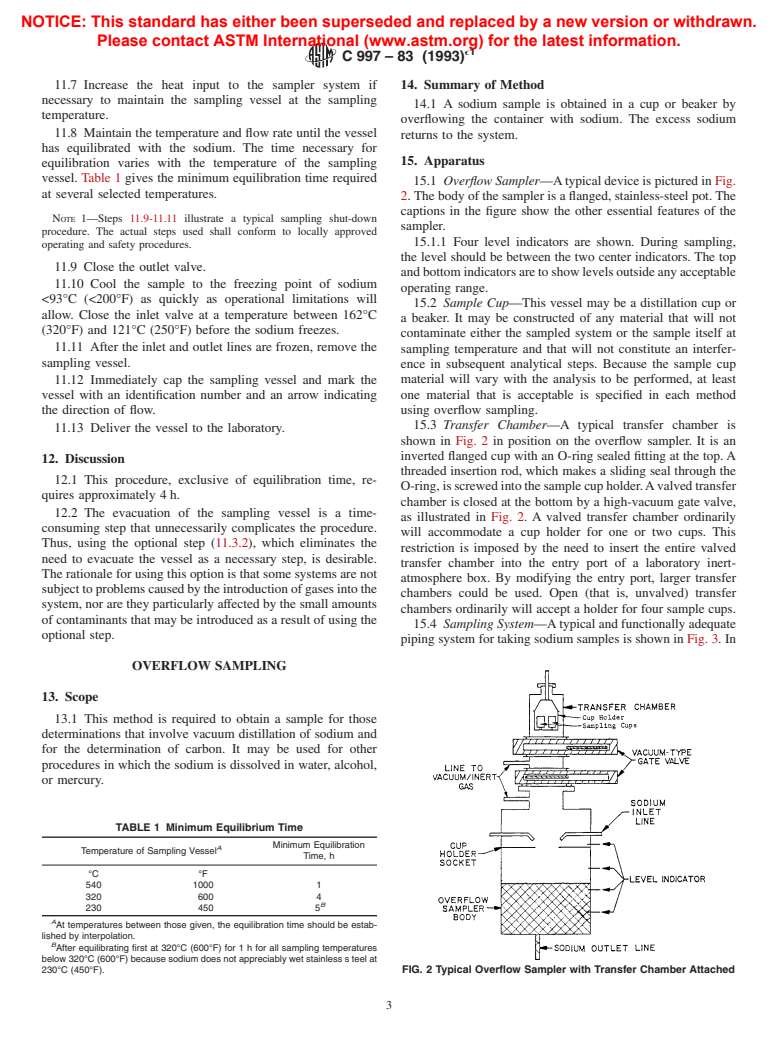

15.1 Overflow Sampler—AtypicaldeviceispicturedinFig.

at several selected temperatures.

2.Thebodyofthesamplerisaflanged,stainless-steelpot.The

captions in the figure show the other essential features of the

NOTE 1—Steps 11.9-11.11 illustrate a typical sampling shut-down

sampler.

procedure. The actual steps used shall conform to locally approved

15.1.1 Four level indicators are shown. During sampling,

operating and safety procedures.

the level should be between the two center indicators. The top

11.9 Close the outlet valve.

andbottomindicatorsaretoshowlevelsoutsideanyacceptable

11.10 Cool the sample to the freezing point of sodium

operating range.

<93°C (<200°F) as quickly as operational limitations will

15.2 Sample Cup—This vessel may be a distillation cup or

allow. Close the inlet valve at a temperature between 162°C

a beaker. It may be constructed of any material that will not

(320°F) and 121°C (250°F) before the sodium freezes.

contaminate either the sampled system or the sample itself at

11.11 After the inlet and outlet lines are frozen, remove the

sampling temperature and that will not constitute an interfer-

sampling vessel.

ence in subsequent analytical steps. Because the sample cup

material will vary with the analysis to be performed, at least

11.12 Immediately cap the sampling vessel and mark the

vessel with an identification number and an arrow indicating one material that is acceptable is specified in each method

using overflow sampling.

the direction of flow.

15.3 Transfer Chamber—A typical transfer chamber is

11.13 Deliver the vessel to the laboratory.

shown in Fig. 2 in position on the overflow sampler. It is an

inverted flanged cup with an O-ring sealed fitting at the top.A

12. Discussion

threaded insertion rod, which makes a sliding seal through the

12.1 This procedure, exclusive of equilibration time, re-

O-ring,isscrewedintothesamplecupholder.Avalvedtransfer

quires approximately 4h.

chamber is closed at the bottom by a high-vacuum gate valve,

12.2 The evacuation of the sampling vessel is a time-

as illustrated in Fig. 2. A valved transfer chamber ordinarily

consuming step that unnecessarily complicates the procedure.

will accommodate a cup holder for one or two cups. This

Thus, using the optional step (11.3.2), which eliminates the

restriction is imposed by the need to insert the entire valved

need to evacuate the vessel as a necessary step, is desirable.

transfer chamber into the entry port of a laboratory inert-

The rationale for using this option is that some systems are not

atmosphere box. By modifying the entry port, larger transfer

subjecttoproblemscausedbytheintroductionofgasesintothe

chambers could be used. Open (that is, unvalved) transfer

system, nor are they particularly affected by the small amounts

chambers ordinarily will accept a holder for four sample cups.

of contaminants that may be introduced as a result of using the

15.4 Sampling System—Atypicalandfunctionallyadequate

optional step.

pipingsystemfortakingsodiumsamplesisshowninFig.3.In

OVERFLOW SAMPLING

13. Scope

13.1 This method is required to obtain a sample for those

determinations that involve vacuum distillation of sodium and

for the determination of carbon. It may be used for other

procedures in which the sodium is dissolved in water, alcohol,

or mercury.

TABLE 1 Minimum Equilibrium Time

Minimum Equilibration

A

Temperature of Sampling Vessel

Time, h

°C °F

540 1000 1

320 600 4

B

230 450 5

A

At temperatures between those given, the equilibration time should be estab-

lished by interpolation.

B

After equilibrating first at 320°C (600°F) for 1 h for all sampling temperatures

below320°C(600°F)becausesodiumdoesnotappreciablywetstainlesssteelat

230°C (450°F). FIG. 2 Typical Overflow Sampler with Transfer Chamber Attached

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

ϵ1

C 997 – 83 (1993)

FIG. 3 Typical Sampling System

this system, sodium enters through a normally closed pneu-

maticbellowsvalvewiththebellowsdownstream;itflowsfirst

through an electromagnetic pump and electromagnetic flow-

meterandthenthroughamanuallyoperatedbellowsvalveinto

themultiplespoutsoftheoverflowsampler.Sodiumleavesthe

sampler at the bottom; passing through another manually

FIG. 4 Multipurpose Sampler

operatedbellowsvalve,anoptionalfilter,andanoptionalsurge

tank;anditexitsthroughanormallyclosedpneumaticbellows

16.2.2 A fail-safe system of interlocks (if required by local

valve with the bellows upstream.

safety practices) to close the isolation valves

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.