ASTM D721-17

(Test Method)Standard Test Method for Oil Content of Petroleum Waxes

Standard Test Method for Oil Content of Petroleum Waxes

SIGNIFICANCE AND USE

4.1 The oil content of a wax may have significant effects on several of its properties, such as strength, hardness, flexibility, scuff resistance, coefficient of friction, coefficient of expansion, melting point, and oil straining. The importance of these effects may be dependent upon the ultimate use of the wax.

SCOPE

1.1 This test method covers the determination of oil in petroleum waxes having a congealing point of 30 °C (86 °F) or higher as determined in accordance with Test Method D938, and containing not more than 15 % of oil.2

Note 1: With some types of waxes, of oil contents greater than 5 %, there may be an incompatibility with MEK resulting in the formation of two liquid phases. If this occurs, the test method is not applicable to the material under test.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

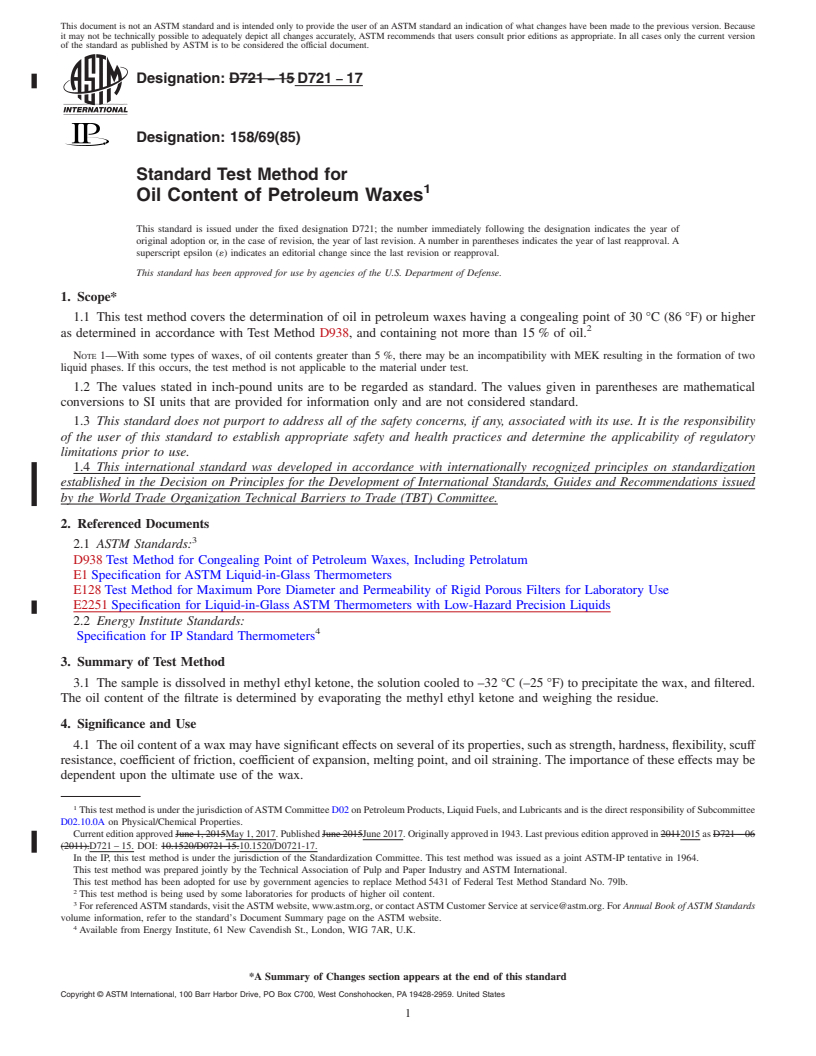

Designation: D721 − 17

Designation: 158/69(85)

Standard Test Method for

1

Oil Content of Petroleum Waxes

This standard is issued under the fixed designation D721; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

3

2.1 ASTM Standards:

1.1 This test method covers the determination of oil in

D938 Test Method for Congealing Point of Petroleum

petroleum waxes having a congealing point of 30 °C (86 °F) or

Waxes, Including Petrolatum

higher as determined in accordance with Test Method D938,

2

E1 Specification for ASTM Liquid-in-Glass Thermometers

and containing not more than 15 % of oil.

E128 Test Method for Maximum Pore Diameter and Perme-

NOTE 1—With some types of waxes, of oil contents greater than 5 %,

ability of Rigid Porous Filters for Laboratory Use

there may be an incompatibility with MEK resulting in the formation of

E2251 Specification for Liquid-in-Glass ASTM Thermom-

two liquid phases. If this occurs, the test method is not applicable to the

eters with Low-Hazard Precision Liquids

material under test.

2.2 Energy Institute Standards:

1.2 The values stated in inch-pound units are to be regarded

4

Specification for IP Standard Thermometers

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

3. Summary of Test Method

and are not considered standard.

3.1 The sample is dissolved in methyl ethyl ketone, the

1.3 This standard does not purport to address all of the

solution cooled to –32 °C (–25 °F) to precipitate the wax, and

safety concerns, if any, associated with its use. It is the

filtered. The oil content of the filtrate is determined by

responsibility of the user of this standard to establish appro-

evaporating the methyl ethyl ketone and weighing the residue.

priate safety and health practices and determine the applica-

4. Significance and Use

bility of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

4.1 The oil content of a wax may have significant effects on

dance with internationally recognized principles on standard-

several of its properties, such as strength, hardness, flexibility,

ization established in the Decision on Principles for the

scuff resistance, coefficient of friction, coefficient of expansion,

Development of International Standards, Guides and Recom-

melting point, and oil straining. The importance of these effects

mendations issued by the World Trade Organization Technical

may be dependent upon the ultimate use of the wax.

Barriers to Trade (TBT) Committee.

5. Apparatus

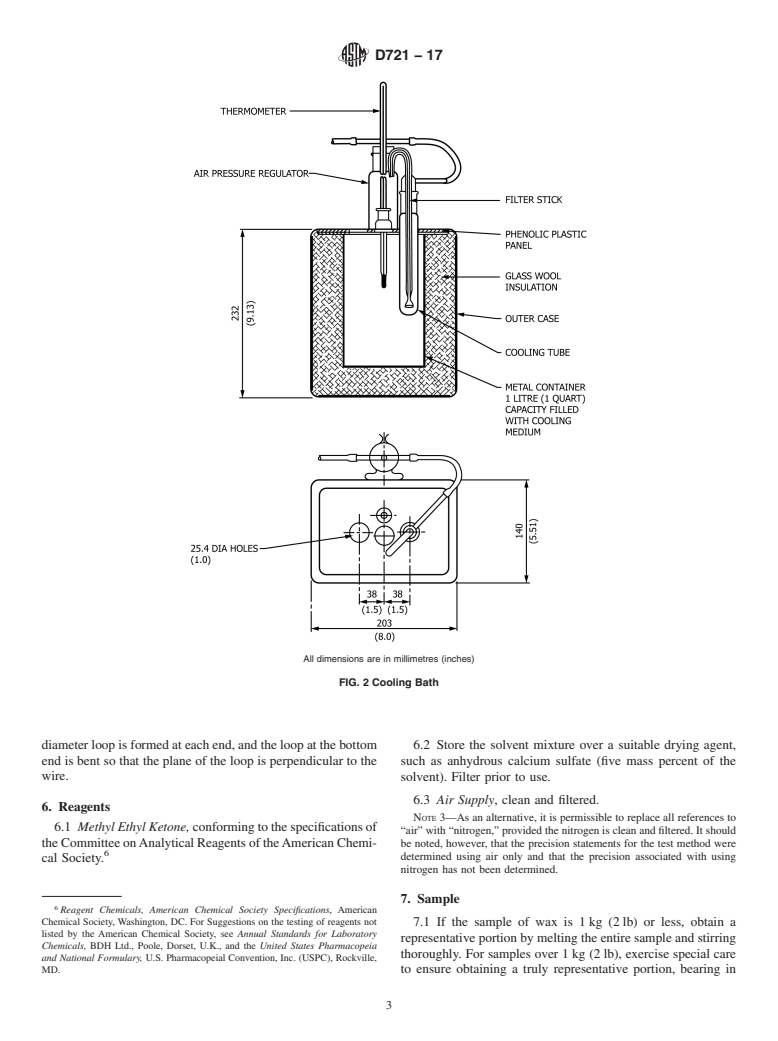

5.1 Filter Stick and Assembly, consisting of a 10 mm diam-

1 eter sintered glass filter stick of 10 μm to 15 μm maximum pore

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of diameter as determined by the method in Appendix X1,

Subcommittee D02.10 on Properties of Petroleum Waxes and Alternative Wax-like

provided with an air pressure inlet tube and delivery nozzle. It

Materials.

is provided with a ground-glass joint to fit a 25 mm by 170 mm

Current edition approved May 1, 2017. Published June 2017. Originally

test tube. The dimensions for a suitable filtration assembly are

approved in 1943. Last previous edition approved in 2015 as D721 – 15. DOI:

10.1520/D0721-17.

shown in Fig. 1.

In the IP, this test method is under the jurisdiction of the Standardization

Committee. This test method was issued as a joint ASTM-IP tentative in 1964.

3

This test method was prepared jointly by the Technical Association of Pulp and For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Paper Industry and ASTM International. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This test method has been adopted for use by government agencies to replace Standards volume information, refer to the standard’s Document Summary page on

Method 5431 of Federal Test Method Standard No. 79lb. the ASTM website.

2

4

This test method is being used by some laboratories for products of higher oil Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

content. U.K.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

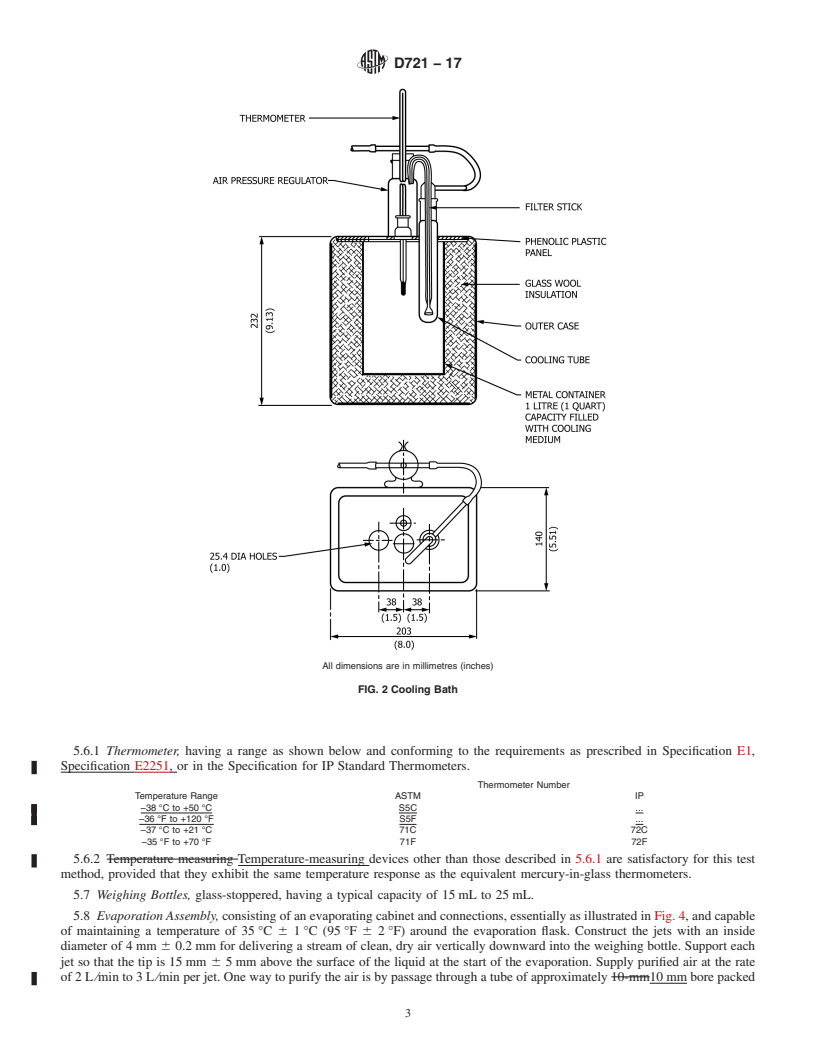

Designation: D721 − 15 D721 − 17

Designation: 158/69(85)

Standard Test Method for

1

Oil Content of Petroleum Waxes

This standard is issued under the fixed designation D721; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This test method covers the determination of oil in petroleum waxes having a congealing point of 30 °C (86 °F) or higher

2

as determined in accordance with Test Method D938, and containing not more than 15 % of oil.

NOTE 1—With some types of waxes, of oil contents greater than 5 %, there may be an incompatibility with MEK resulting in the formation of two

liquid phases. If this occurs, the test method is not applicable to the material under test.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

D938 Test Method for Congealing Point of Petroleum Waxes, Including Petrolatum

E1 Specification for ASTM Liquid-in-Glass Thermometers

E128 Test Method for Maximum Pore Diameter and Permeability of Rigid Porous Filters for Laboratory Use

E2251 Specification for Liquid-in-Glass ASTM Thermometers with Low-Hazard Precision Liquids

2.2 Energy Institute Standards:

4

Specification for IP Standard Thermometers

3. Summary of Test Method

3.1 The sample is dissolved in methyl ethyl ketone, the solution cooled to –32 °C (–25 °F) to precipitate the wax, and filtered.

The oil content of the filtrate is determined by evaporating the methyl ethyl ketone and weighing the residue.

4. Significance and Use

4.1 The oil content of a wax may have significant effects on several of its properties, such as strength, hardness, flexibility, scuff

resistance, coefficient of friction, coefficient of expansion, melting point, and oil straining. The importance of these effects may be

dependent upon the ultimate use of the wax.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.10.0A on Physical/Chemical Properties.

Current edition approved June 1, 2015May 1, 2017. Published June 2015June 2017. Originally approved in 1943. Last previous edition approved in 20112015 as D721 – 06

(2011).D721 – 15. DOI: 10.1520/D0721-15.10.1520/D0721-17.

In the IP, this test method is under the jurisdiction of the Standardization Committee. This test method was issued as a joint ASTM-IP tentative in 1964.

This test method was prepared jointly by the Technical Association of Pulp and Paper Industry and ASTM International.

This test method has been adopted for use by government agencies to replace Method 5431 of Federal Test Method Standard No. 79lb.

2

This test method is being used by some laboratories for products of higher oil content.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR, U.K.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D721 − 17

All dimensions are in millimetres

FIG. 1 Filter Stick

5. Apparatus

5.1 Filter Stick and Assembly, consisting of a 10 mm diameter sintered glass filter s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.