ASTM F924-90(1999)

(Test Method)Standard Test Method for Resistance to Puncture of Cushioned Resilient Floor Coverings

Standard Test Method for Resistance to Puncture of Cushioned Resilient Floor Coverings

SCOPE

1.1 This test method covers the laboratory procedure for determining the resistance of cushioned resilient floor coverings to punctures from dropped pointed objects such as dinner forks.

1.2 This test method employs a 35-g cylindrical dart with a flat, small-diameter tip that is dropped onto a specimen of flooring. The dart represents the weight of a typical fork and the tip produces a similar puncture to those which result from dropped forks.

1.3 Flooring with thick wear layers may not puncture under even the most severe drop. Although data can be obtained by increasing the drop height or the weight of the dart, values of this magnitude have no practical application.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability and regulatory limitations prior to use. For specific precaution statement see 8.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 924 – 90 (Reapproved 1999)

Standard Test Method for

Resistance to Puncture of Cushioned Resilient Floor

Coverings

This standard is issued under the fixed designation F 924; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions of Terms Specific to This Standard:

3.2.1 puncture—a break in the wear layer of the specimen.

1.1 This test method covers the laboratory procedure for

An indentation at the point of impact shall be considered a

determining the resistance of cushioned resilient floor cover-

puncture only if the wear layer is broken completely through at

ings to punctures from dropped pointed objects such as dinner

some point.

forks.

3.2.2 wicking—the presence of ink below the wear layer of

1.2 This test method employs a 35-g cylindrical dart with a

the specimen in areas adjacent to a puncture. This can be seen

flat, small-diameter tip that is dropped onto a specimen of

next to the actual cut, and appears either as spots on the pattern

flooring. The dart represents the weight of a typical fork and

layer or as a general discoloration.

the tip produces a similar puncture to those which result from

dropped forks.

4. Significance and Use

1.3 Flooring with thick wear layers may not puncture under

4.1 Much of the cushioned resilient flooring in use today is

even the most severe drop. Although data can be obtained by

in household kitchens. Kitchen flooring is frequently subjected

increasing the drop height or the weight of the dart, values of

to the hazard of dropped tableware and cutting knives, that can

this magnitude have no practical application.

puncture the wear layer of cushioned resilient flooring. Food

1.4 This standard does not purport to address all of the

and soil that become embedded in these punctures often can

safety concerns, if any, associated with its use. It is the

not be removed by ordinary maintenance, resulting in unsightly

responsibility of whoever uses this standard to consult and

marks. Moisture, grease, or oils that penetrate to the cushion

establish appropriate safety and health practices and deter-

layer can be wicked into the foam and cause permanent

mine the applicability and regulatory limitations prior to use.

discoloration. Ultimately, the service life of the material is

For specific precaution statement see 8.2.

shortened.

2. Referenced Documents

5. Apparatus

2.1 ASTM Standards:

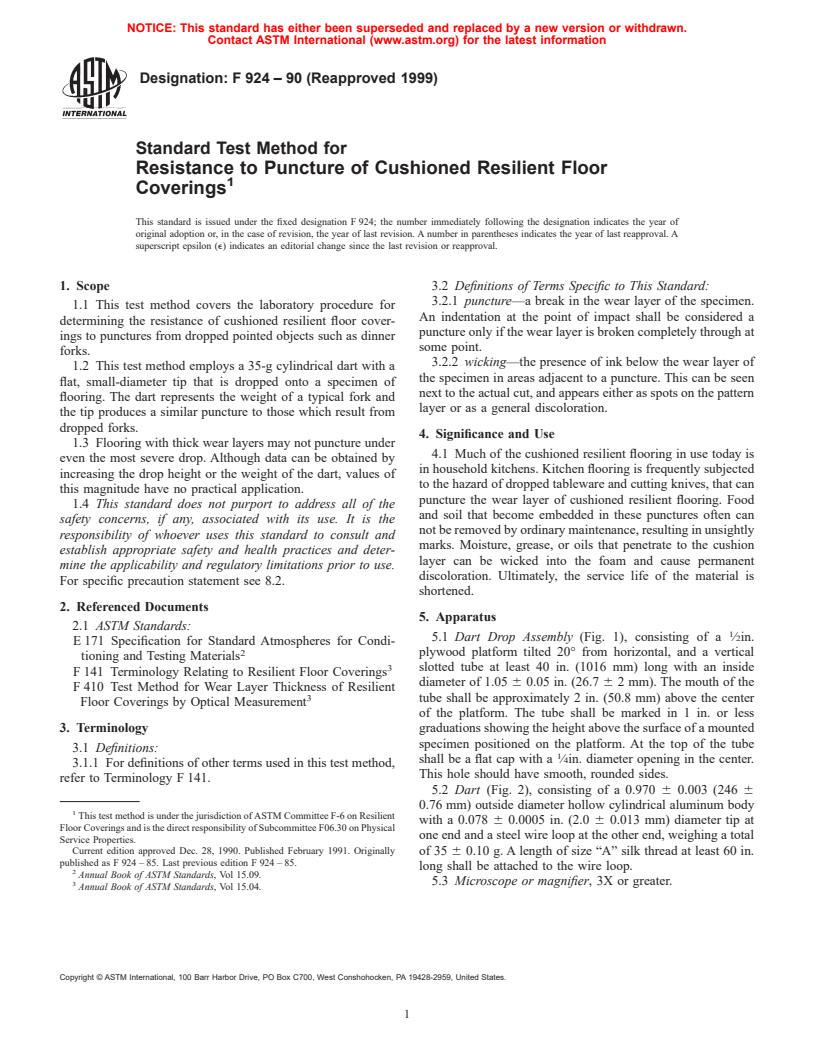

5.1 Dart Drop Assembly (Fig. 1), consisting of a ⁄2in.

E 171 Specification for Standard Atmospheres for Condi-

2 plywood platform tilted 20° from horizontal, and a vertical

tioning and Testing Materials

3 slotted tube at least 40 in. (1016 mm) long with an inside

F 141 Terminology Relating to Resilient Floor Coverings

diameter of 1.05 6 0.05 in. (26.7 6 2 mm). The mouth of the

F 410 Test Method for Wear Layer Thickness of Resilient

3 tube shall be approximately 2 in. (50.8 mm) above the center

Floor Coverings by Optical Measurement

of the platform. The tube shall be marked in 1 in. or less

3. Terminology graduations showing the height above the surface of a mounted

specimen positioned on the platform. At the top of the tube

3.1 Definitions:

shall be a flat cap with a ⁄4in. diameter opening in the center.

3.1.1 For definitions of other terms used in this test method,

This hole should have smooth, rounded sides.

refer to Terminology F 141.

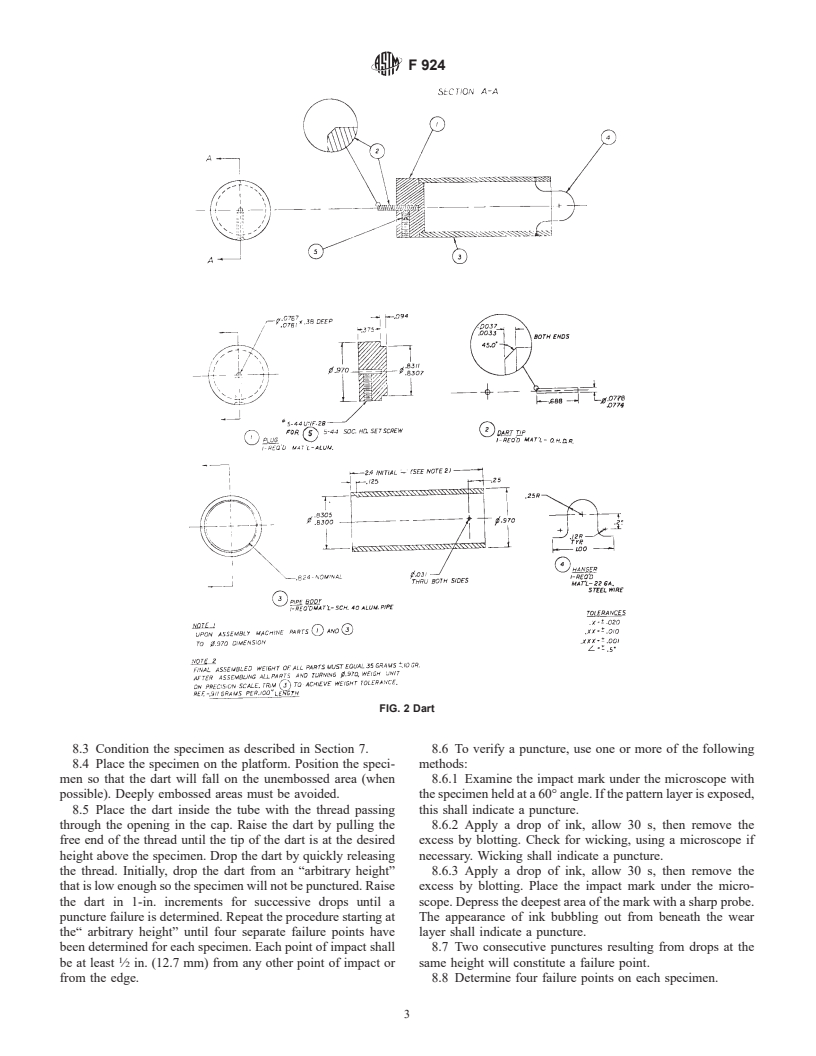

5.2 Dart (Fig. 2), consisting of a 0.970 6 0.003 (246 6

0.76 mm) outside diameter hollow cylindrical aluminum body

This test method is under the jurisdiction of ASTM Committee F-6 on Resilient

with a 0.078 6 0.0005 in. (2.0 6 0.013 mm) diameter tip at

Floor Coverings and is the direct responsibility of Subcommittee F06.30 on Physical

one end and a steel wire loop at the other end, weighing a total

Service Properties.

Current edition approved Dec. 28, 1990. Published February 1991. Originally

of 35 6 0.10 g. A length of size “A” silk thread at least 60 in.

published as F 924 – 85. Last previous edition F 924 – 85.

long shall be attached to the wire loop.

Annual Book of ASTM Standards, Vol 15.09.

5.3 Microscope or magnifier, 3X or greater.

Annual Book of ASTM Standards, Vol 15.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 924

FIG. 1 Dart Drop Assembly

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.