ASTM C955-18

(Specification)Standard Specification for Cold-Formed Steel Structural Framing Members

Standard Specification for Cold-Formed Steel Structural Framing Members

ABSTRACT

This specification covers steel studs, runners (tracks), and bracing or bridging for screw application of gypsum panel products and metal plaster bases in load-bearing construction assemblies. Steel of lesser thickness shall be permitted in additional engineered products. Members shall be manufactured from steel meeting the requirements specified. The properties and strength of members shall be computed in accordance with the given specification. The steel members shall be free of defects that interfere with the purpose for which they are intended. Penetration test method provides a procedure for evaluating the member's ability to pull the head of a screw below the surface of the gypsum panel product. Five specimens of members shall be tested. If more than one test specimen fails to meet the requirements, two more test specimens shall be chosen for retesting. Report shall indicate all specimens meeting the requirements of this specification if the screw penetrated the steel and the screw spin out; or shall indicate all specimens failing if the screw did not penetrate the steel, or the screw spun out.

SCOPE

1.1 This specification covers cold-formed steel structural framing members (with a base steel thickness of not less than 0.0329 in. (0.836 mm)) in load-bearing (transverse and axial) construction assemblies. Steel of lesser thickness shall be permitted in additional engineered products.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C955 −18

Standard Specification for

1

Cold-Formed Steel Structural Framing Members

This standard is issued under the fixed designation C955; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope* 2.2 AISI Standard:

S100 North American Specification for the Design of Cold-

1.1 This specification covers cold-formed steel structural

Formed Steel Structural Members

framing members (with a base steel thickness of not less than

S240 North American Standard for Cold-Formed Steel

0.0329 in. (0.836 mm)) in load-bearing (transverse and axial)

Structural Framing—2015 Edition

construction assemblies. Steel of lesser thickness shall be

permitted in additional engineered products.

3. Terminology

1.2 The values stated in inch-pound units are to be regarded 3.1 Definitions:

as standard. The values given in parentheses are mathematical 3.1.1 Definitions shall be in accordance with Terminology

C11.

conversions to SI units that are provided for information only

3.2 Definitions of Terms Specific to This Standard:

and are not considered standard.

3.2.1 members, n—studs, runners, tracks, bracing, bridging,

1.3 This international standard was developed in accor-

accessories, or other items manufactured in accordance with

dance with internationally recognized principles on standard-

this specification.

ization established in the Decision on Principles for the

3.2.2 structural member, n—a member in a steel framed

Development of International Standards, Guides and Recom-

system in which the loading exceeds any of the following

mendations issued by the World Trade Organization Technical

conditions: a transverse load of 20 lbf/ft (290 N/m) of member

Barriers to Trade (TBT) Committee.

length, or an axial load, exclusive of sheathing, of 200 lbf

(890 N) per member.

2. Referenced Documents

2

4. Materials and Manufacture

2.1 ASTM Standards:

A653/A653M Specification for Steel Sheet, Zinc-Coated

4.1 Members shall be manufactured from steel meeting the

(Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed)

requirements of Specification A1003/A1003M.

by the Hot-Dip Process

4.2 The minimum steel thickness (base steel) shall be not

A792/A792M Specification for Steel Sheet, 55 %

less than 0.0329 in. (0.84 mm).

Aluminum-Zinc Alloy-Coated by the Hot-Dip Process

4.3 Individual measurements before the application of pro-

A875/A875M Specification for Steel Sheet, Zinc-5 % Alu-

minum Alloy-Coated by the Hot-Dip Process tective coating shall be not less than 95 % of the specified

design thickness.

A1003/A1003M Specification for Steel Sheet, Carbon,

Metallic- and Nonmetallic-Coated for Cold-Formed

4.4 Members shall comply with the corrosion protection

Framing Members

requirements as listed in AISI S240, Section A4.

C11 Terminology Relating to Gypsum and Related Building

4.5 Edges of members shall be manufactured to minimize

Materials and Systems

burrs and sharp edges.

4.6 Factory punch-outs, when provided, shall be located

along the centerline of the webs of members and shall have

1

This specification is under the jurisdiction of ASTM Committee C11 on

center-to-center spacing of not less than 24 in. (610 mm). Web

Gypsum and Related Building Materials and Systems and is the direct responsibility

of Subcommittee C11.02 on Specifications and Test Methods for Accessories and

punch-outs maximum width shall be the lesser of 0.5 times the

Related Products.

1

member depth, d, or 2 ⁄2 in. (64 mm). Web punch-out length

Current edition approved June 1, 2018. Published June 2018. Originally

1

shall not exceed 4 ⁄2 in. (114 mm). Minimum distance between

approved in 1981. Last previous edition approved in 2017 as C955 – 17. DOI:

the end of the member and the near edge of the web punch-out

10.1520/C0955-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American Iron and Steel Institute (AISI), 1140 Connecticut

the ASTM website. Ave., NW, Suite 705, Washington, DC 20036, http://www.steel.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

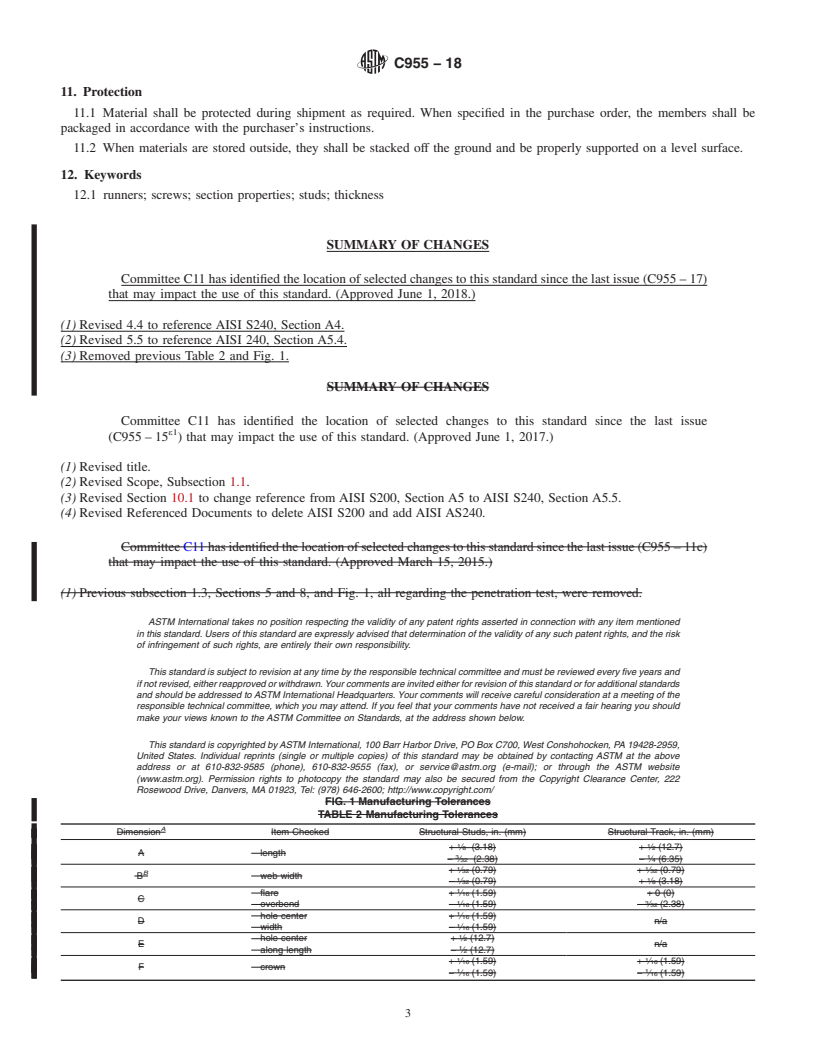

C955 − 18

TABLE 1 Coating Designations

Minimum Coating Requirements

Coating Coating

A B C D

Zinc-Coated Zinc Iron 55 % Al-Zinc Zinc-5 %

Classification Designator

2 2 2 2 2 2 2 2

oz/ft (g ⁄m ) oz/ft (g ⁄m ) oz/ft (g ⁄m ) oz/ft (g ⁄m )

Metal

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C955 − 17 C955 − 18

Standard Specification for

1

Cold-Formed Steel Structural Framing Members

This standard is issued under the fixed designation C955; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers cold-formed steel structural framing members (with a base steel thickness of not less than 0.0329

in. (0.836 mm)) in load-bearing (transverse and axial) construction assemblies. Steel of lesser thickness shall be permitted in

additional engineered products.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A653/A653M Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the

Hot-Dip Process

A792/A792M Specification for Steel Sheet, 55 % Aluminum-Zinc Alloy-Coated by the Hot-Dip Process

A875/A875M Specification for Steel Sheet, Zinc-5 % Aluminum Alloy-Coated by the Hot-Dip Process

A1003/A1003M Specification for Steel Sheet, Carbon, Metallic- and Nonmetallic-Coated for Cold-Formed Framing Members

C11 Terminology Relating to Gypsum and Related Building Materials and Systems

3

2.2 AISI Standard:

S100 North American Specification for the Design of Cold-Formed Steel Structural Members

S240 North American Standard for Cold-Formed Steel Structural Framing—2015 Edition

3. Terminology

3.1 Definitions:

3.1.1 Definitions shall be in accordance with Terminology C11.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 members, n—studs, runners, tracks, bracing, bridging, accessories, or other items manufactured in accordance with this

specification.

3.2.2 structural member, n—a member in a steel framed system in which the loading exceeds any of the following conditions:

a transverse load of 20 lbf/ft (290 N/m) of member length, or an axial load, exclusive of sheathing, of 200 lbf (890 N) per member.

4. Materials and Manufacture

4.1 Members shall be manufactured from steel meeting the requirements of Specification A1003/A1003M.

4.2 The minimum steel thickness (base steel) shall be not less than 0.0329 in. (0.84 mm).

4.3 Individual measurements before the application of protective coating shall be not less than 95 % of the specified design

thickness.

1

This specification is under the jurisdiction of ASTM Committee C11 on Gypsum and Related Building Materials and Systems and is the direct responsibility of

Subcommittee C11.02 on Specifications and Test Methods for Accessories and Related Products.

Current edition approved June 1, 2017June 1, 2018. Published June 2017June 2018. Originally approved in 1981. Last previous edition approved in 20152017 as

ε1

C955 – 15C955 – 17. . DOI: 10.1520/C0955-17.10.1520/C0955-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Iron and Steel Institute (AISI), 1140 Connecticut Ave., NW, Suite 705, Washington, DC 20036, http://www.steel.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C955 − 18

4.4 Members shall have a protective coating in accordance comply with Table 1, CP 60 minimum.the corrosion protection

requirements as listed in AISI S240, Section A4.

4.5 Edges of members shall be manufactured to minimize burrs and sharp edges.

4.6 Factory punch-outs, when provided, shall be located along the centerline of the webs of members and shall have

center-to-center spacing of not less than 24 in. (610 mm). Web punch-outs maximum width shall be the lesser of 0.5 times the

1 1

member dept

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.