ASTM C1601-04

(Test Method)Standard Test Method for Field Determination of Water Penetration of Masonry Wall Surfaces

Standard Test Method for Field Determination of Water Penetration of Masonry Wall Surfaces

SCOPE

1.1 This test method covers the field determination of water penetration of a masonry wall surface under specific water flow rate and air pressure conditions. This test is intended for use on any masonry wall surface that can be properly instrumented and tested within the requirements of this standard.

1.2 This test method is not identical to and the results are not directly comparable with the laboratory standard Test Method E 514 "Test Method for Water Penetration and Leakage Through Masonry."

1.3 Surface penetration, as determined by this test method, is defined as the amount of water passing through the wall surface exposed to testing per unit time per unit area. This property is not directly comparable to water penetration and leakage, which are typically defined as the amount of water travelling completely through a masonry system.

1.4 This standard may involve hazardous materials, operations, or equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1601–04

Standard Test Method for

Field Determination of Water Penetration of Masonry Wall

Surfaces

This standard is issued under the fixed designation C 1601; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope ing, corrosion of embedded metal items, and water leakage.

This test is used to determine surface water penetration

1.1 This test method covers the field determination of water

quantitatively at any single location, and it may not accurately

penetrationofamasonrywallsurfaceunderspecificwaterflow

predict leakage quantities or locations.

rate and air pressure conditions.This test is intended for use on

3.2 This test may be used to evaluate masonry walls in-situ

any masonry wall surface that can be properly instrumented

or for field mock-up testing. Common applications of this

and tested within the requirements of this standard.

method have been comparison of water penetration rates of

1.2 This test method is not identical to and the results are

walls before and after repairs, and testing the efficacy of

not directly comparable with the laboratory standard Test

coatings. Alternative procedures are also provided to simulate

Method E 514 “Test Method for Water Penetration and Leak-

the effect of local climatology on water penetration of masonry

age Through Masonry.”

wall surfaces.

1.3 Surface penetration, as determined by this test method,

3.3 The outer surface of all masonry walls will experience

is defined as the amount of water passing through the wall

water penetration when subjected to wind-driven rain. The

surface exposed to testing per unit time per unit area. This

resistance to water penetration is dependent on materials,

property is not directly comparable to water penetration and

workmanship, design, and maintenance. Some wall types

leakage, which are typically defined as the amount of water

accommodate large volumes of water penetration, without

travelling completely through a masonry system.

deleterious effects, through the presence of properly designed

1.4 This standard may involve hazardous materials, opera-

and installed drainage systems including flashing and weep

tions, or equipment. This standard does not purport to address

holes. Use of this standard without consideration of the overall

all of the safety problems associated with its use. It is the

wall system may lead to incorrect conclusions regarding

responsibility of the user of this standard to establish appro-

performance.

priate safety and health practices and determine the applica-

3.4 It is the intent of this standard that a sheet of water be

bility of regulatory limitations prior to use.

developedandmaintainedonthewallsurfaceduringtesting.In

2. Referenced Documents

some cases, due to the surface texture of the masonry, the

application of a coating, or other factors, a sheet of water will

2.1 ASTM Standards:

not consistently form. In those cases, results of this test method

E 514 Test Method for Water Penetration and Leakage

will likely be inaccurate.

Through Masonry

3.5 This test method is similar to but distinct from the

3. Significance and Use

laboratory Test Method E 514. This field test method is

designed to test in-situ walls. E 514 laboratory test method is

3.1 This non-destructive test method contains procedures

designed to test laboratory wall specimens. This test method

andequipmentrequirementstodeterminethewaterpenetration

determines water penetration of the masonry at its surface.Test

of a masonry wall surface. In general, excessive water penetra-

Method E 514 measures the water that has penetrated into and

tion of masonry may degrade masonry wall performance with

through the masonry specimen and is collected. Direct com-

respect to thermal conductivity, durability, efflorescence, stain-

parison of results from this test method and Test Method E 514

are inappropriate.

This Test Method is under the jurisdiction of ASTM Committee C15 on

Manufactured Masonry Units and is the direct responsibility of Subcommittee

4. Apparatus

C15.04 on Research.

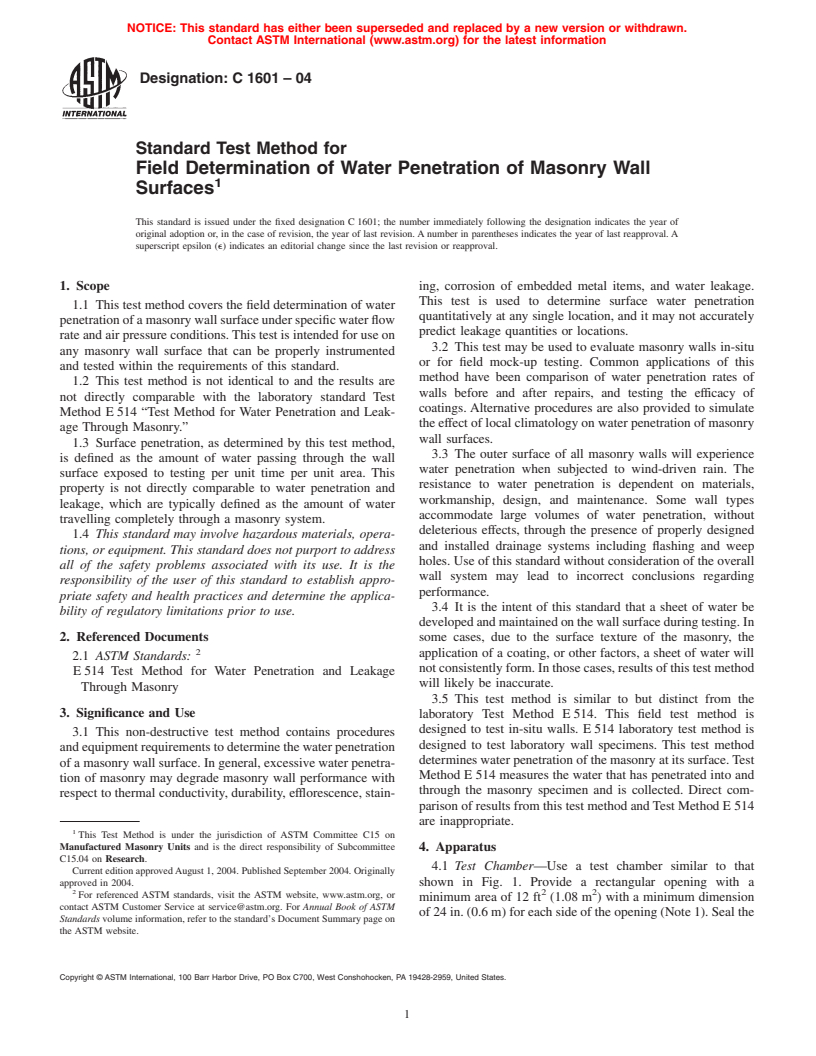

4.1 Test Chamber—Use a test chamber similar to that

Current edition approvedAugust 1, 2004. Published September 2004. Originally

approved in 2004. shown in Fig. 1. Provide a rectangular opening with a

2 2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

minimum area of 12 ft (1.08 m ) with a minimum dimension

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

of 24 in. (0.6 m) for each side of the opening (Note 1). Seal the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1601–04

FIG. 1 Water Surface Penetration Test System

mately 4 to 8 inches (100 to 200 mm) in diameter by 5 ft. (1.5 m) or taller

contact surface between the frame of the chamber and the test

is common.

area to prevent loss of water and maintain air pressure. Cover

the face of the chamber with a tough, transparent material

4.3 Other equipment includes devices for handling and

capable of withstanding the test pressure (Note 2). Provide a

mounting the chamber and measuring time, water quantities,

⁄4-in. (19-mm) diameter, corrosion-resistant, water spray pipe

and ambient temperature.

with a single line of 0.04-in. (1.0-mm) diameter holes spaced 1

in. (25 mm) apart, starting within 1 in. (25 mm) of each end

5. Hazards

(Note 3). Position the water spray pipe within the chamber so

5.1 The use of this test method requires careful design of

that the water impinges the wall perpendicular to the wall not

both air chamber and support of the wall system to avoid

more than 1.5 in. (40 mm) below the interior top of the test

possible injury due to equipment or masonry failure. Assure

chamber.

that the chamber and its attachment to the wall are adequate for

the applied pressures during testing.

NOTE 1—A size of 36 in. (0.9 m) wide and 48 in. (1.2 m) high is

common.

5.2 Water penetration resulting from this test can cause

3 1

NOTE 2—Clear acrylic sheets ⁄16 to ⁄4 inch (5 to 6 mm) thick have been

saturation of adjacent materials and leakage into occupied

shown to perform well. Plexiglast and Lexant are two sources of clear

spaces of the buildings. Take into consideration the effects of

acrylic sheets.

potential water infiltration and leakage.

NOTE 3—Clean-outs at the end of the spray bar to facilitate cleaning the

spray bar are common.

6. Procedure

4.2 Fixtures and Appurtenances to Chamber—Fixtures and

6.1 Mounting Chamber—Attach the test chamber with me-

appurtenances to the chamber include an air line with manom-

chanical fasteners using sufficient pressure to form an air- and

eter or pressure gauge able to read air pressure to within 0.50

water-resistant seal (Note 5).

lb/ft (24 Pa), a water line with valves, a flow meter in the

water supply line able to read flow within 0.02 gpm (4.5 L/h),

NOTE 5—Use of a gasket or sealant at the contact surface is common.

and a water drain pipe at the bottom of the chamber. The water

6.2 Sealing—If needed, apply a perimeter sealant between

is stored in a calibrated reservoir with a minimum volume of 3

the chamber and wall surface to ensure that leakage does not

gal. (13 L), with graduations to allow readings within 0.015 gal

occur at the interface. Allow the sealant to cure sufficiently to

(0.055 L) (Note 4). Pump water from the reservoir to the spray

ensure adequate bond and water resistance.

bar. Return water which drains from the bottom of the chamber

6.3 Application of Air Pressure and Water Flow—Adjust

directly to the reservoir. 2 2

the water flow rate to 3.4 gal/ft /h (138 L/m /h) times the area

NOTE 4—Use of a cylindrical reservoir having dimensions of approxi- of the chamber opening. Simultaneously, increase the air

C1601–04

pressure within the chamber to 10 lb/ft (500 Pa). Check for which the water and air pressures are held constant.Atest may

leakage from the perimeter of the chamber. If leakage occurs, consist of one or more time periods.

stop the test, reseal, and re-start the procedure.

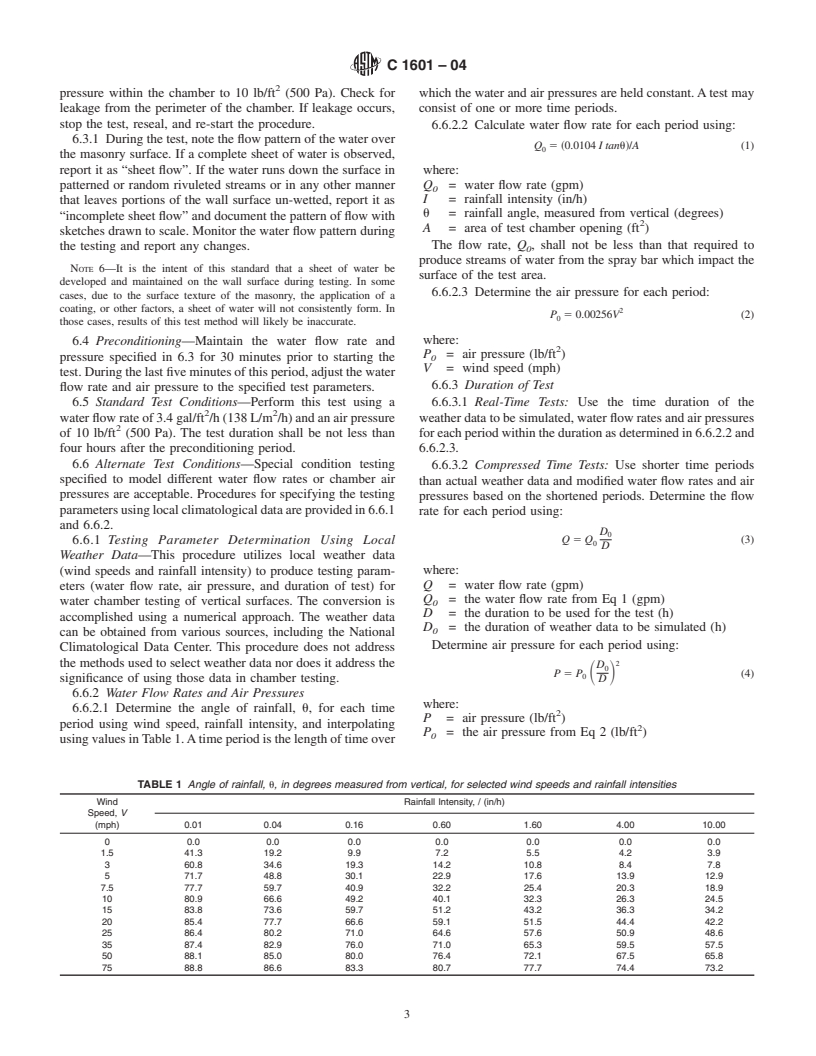

6.6.2.2 Calc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.