ASTM F2380-04(2016)

(Test Method)Standard Test Method for Performance of Conveyor Toasters

Standard Test Method for Performance of Conveyor Toasters

SIGNIFICANCE AND USE

5.1 The energy input rate test is used to confirm that the conveyor toaster is operating properly prior to further testing.

5.2 Preheat energy and time can be useful to food service operators to manage power demands and to know how quickly the conveyor toaster can be ready for operation.

5.3 Idle energy rate and pilot energy rate can be used to estimate energy consumption during non-cooking periods. In addition, a power saving mode (if applicable) will demonstrate energy savings during idle periods.

5.4 Production capacity information can help an end user to better understand the production capabilities of a conveyor toaster as it is used to cook a typical food product and this could help in specifying the proper size and quantity of equipment. If production information is desired using a food product other than the specified test food, the test method could be adapted and applied.

SCOPE

1.1 This test method evaluates the energy consumption and cooking performance of conveyor toasters. The food service operator can use this evaluation to select a conveyor toaster and understand its energy consumption.

1.2 This test method is applicable to gas and electric conveyor toasters.

1.3 The conveyor toaster can be evaluated with respect to the following (where applicable):

1.3.1 Energy input rate and preheat temperature profile (10.2),

1.3.2 Preheat energy consumption and time (10.3),

1.3.3 Idle energy rate (10.4),

1.3.4 Pilot energy rate (if applicable, 10.5),

1.3.5 Cooking energy rate (10.8), and

1.3.6 Production capacity (10.8).

1.4 The values stated in inch-pound units are to be regarded as standard. The SI units given in parentheses are for information only.

1.5 This test method may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2380 − 04 (Reapproved 2016) An American National Standard

Standard Test Method for

Performance of Conveyor Toasters

This standard is issued under the fixed designation F2380; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ASHRAE Document:

ASHRAE Guideline 2 (RA90)Engineering Analysis of Ex-

1.1 This test method evaluates the energy consumption and

perimental Data

cooking performance of conveyor toasters. The food service

2.3 UL Document:

operatorcanusethisevaluationtoselectaconveyortoasterand

UL 1026Electric Household Cooking and Food Service

understand its energy consumption.

Appliances

1.2 This test method is applicable to gas and electric

conveyor toasters. 3. Terminology

3.1 Definitions:

1.3 The conveyor toaster can be evaluated with respect to

3.1.1 conveyor toaster, n—an appliance for caramelizing

the following (where applicable):

bread products that carries the bread product on a belt or chain

1.3.1 Energy input rate and preheat temperature profile

into and through a heated chamber. The chamber may be

(10.2),

heated by gas or electric forced convection, radiants, or quartz

1.3.2 Preheat energy consumption and time (10.3),

tubes. Top and bottom heat may be independently controlled.

1.3.3 Idle energy rate (10.4),

3.1.2 cooking energy rate, n—average rate of energy con-

1.3.4 Pilot energy rate (if applicable, 10.5),

sumption (Btu/h or kW) during the production capacity tests.

1.3.5 Cooking energy rate (10.8), and

3.1.3 energy input rate, n—peak rate at which a conveyor

1.3.6 Production capacity (10.8).

toaster consumes energy (Btu/h or kW).

1.4 The values stated in inch-pound units are to be regarded

3.1.4 idle energy rate, n—the conveyor toaster’s rate of

as standard. The SI units given in parentheses are for informa-

energy consumption (kW or Btu/h), when empty, required to

tion only.

maintain its cavity temperature at the predetermined tempera-

ture set point.

1.5 This test method may involve hazardous materials,

operations, and equipment. This standard does not purport to 3.1.5 toaster cavity, n—that portion of the conveyor toaster

address all of the safety concerns, if any, associated with its in which bread products are heated or toasted.

use. It is the responsibility of the user of this standard to

3.1.6 pilot energy rate, n—rate of energy consumption

establish appropriate safety and health practices and deter-

(Btu/h)byaconveyortoaster’scontinuouspilot(ifapplicable).

mine the applicability of regulatory limitations prior to use.

3.1.7 preheat energy, n—amount of energy consumed (Btu

or kWh), by the conveyor toaster while preheating its cavity

2. Referenced Documents

from ambient temperature to the determined steady state

temperature.

2.1 ASTM Standards:

D3588Practice for Calculating Heat Value, Compressibility

3.1.8 preheat time, n—time (min) required for the conveyor

Factor, and Relative Density of Gaseous Fuels

toaster cavity to preheat from ambient temperature to the

specified set point.

3.1.9 production capacity, n—maximum rate (slices/h) at

This test method is under the jurisdiction of ASTM Committee F26 on Food

which a conveyor toaster can bring the specified bread product

Service Equipment and is the direct responsibility of Subcommittee F26.06 on

to a specified “toasted” condition.

Productivity and Energy Protocol.

Current edition approved Oct. 1, 2016. Published November 2016. Originally

approved in 2004. Last previous edition approved in 2010 as F2380– 04 (2010).

DOI: 10.1520/F2380-04R16. Available from American Society of Heating, Refrigerating, and Air-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 30329, http://www.ashrae.org.

Standards volume information, refer to the standard’s Document Summary page on Available from Underwriters Laboratories (UL), 333 Pfingsten Rd.,

the ASTM website. Northbrook, IL 60062-2096, http://www.ul.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2380 − 04 (2016)

3.1.10 production rate, n—rate (slices/h) at which a con- 6.5 Stop Watch, with a 1-s resolution.

veyor toaster brings the specified food product to a specified

6.6 Temperature Sensor, for measuring natural gas tempera-

“toasted” condition. This does not necessarily refer to maxi-

ture in the range of 50 to 100°F with an uncertainty of 61°F.

mumrate.Productionratevarieswiththeamountoffoodbeing

6.7 Thermocouple, high temperature glass insulated, 24

toasted.

gage,typeKthermocouplewire,connectedattheexposedends

3.1.11 uncertainty, n—measure of systematic and precision

by tightly twisting or soldering the two wires together.

errors in specified instrumentation or measure of repeatability

6.8 Watt-Hour Meter, for measuring the electrical energy

of a reported test result.

consumptionofaconveyortoaster,shallhavearesolutionofat

4. Summary of Test Method

least 10Wh and a maximum uncertainty no greater than 1.5%

4.1 Energy input rate is determined to confirm that the of the measured value for any demand greater than 100W. For

any demand less than 100 W, the meter shall have a resolution

conveyor toaster is operating within 5% of the nameplate

energy input rate. For gas conveyor toaster, the pilot energy of at least 10 Wh and a maximum uncertainty no greater than

10%.

rate and the fan and control energy rates are also determined.

4.2 Preheat energy and time are determined.

7. Reagents and Materials

4.3 Idle energy rate is determined.

7.1 Bread for Toasting, shall be a generic grocery store

brand, 1.5 6 0.1 lb white loaf with a crown, consisting of 20

4.4 Production rate is determined using sliced bread as a

slices(notincludingtheends)measuringapproximately4.5by

food product.

4.5by0.5in.perslice.Eachslicemustweigh0.065 60.01lb.

5. Significance and Use

The bread shall be stored at room temperature 75 6 5°F.

NOTE 1—The bread is not to have any type of topping such as a butter

5.1 The energy input rate test is used to confirm that the

top, flour top, or any seed/nut topping. Sandwich type bread is not to be

conveyor toaster is operating properly prior to further testing.

used because it does not have a crown. In addition, loaves of bread that

5.2 Preheat energy and time can be useful to food service only have 19 slices (not including the heals) typically have too high of

individual slice weight.The 1.5 lb of generic store brand white bread that

operators to manage power demands and to know how quickly

has 20 slices (not including the heals) more often than not consists of

the conveyor toaster can be ready for operation.

individual slices that weigh approximately 0.065 lb which is specified for

5.3 Idle energy rate and pilot energy rate can be used to this test method.

estimate energy consumption during non-cooking periods. In

8. Sampling and Test Units

addition,apowersavingmode(ifapplicable)willdemonstrate

8.1 Conveyor Toaster—Select a representative production

energy savings during idle periods.

model for performance testing.

5.4 Production capacity information can help an end user to

better understand the production capabilities of a conveyor 9. Preparation of Apparatus

toaster as it is used to cook a typical food product and this

9.1 Install the appliance according to the manufacturer’s

could help in specifying the proper size and quantity of

instructions. The associated heating or cooling system shall be

equipment. If production information is desired using a food

capable of maintaining an ambient temperature of 75 6 5°F

productotherthanthespecifiedtestfood,thetestmethodcould

(24 6 3°C) within the testing environment when the exhaust

be adapted and applied.

ventilation system is operating.

NOTE 2—The ambient temperature requirements are designed to simu-

6. Apparatus

laterealworldkitchentemperaturesandaremeanttoprovideareasonable

6.1 Analytical Balance Scale, for measuring weights up to

guideline for the temperature requirements during testing. If a facility is

not able to maintain the required temperatures, then it is reasonable to

20lb,witharesolutionof0.01lbandanuncertaintyof0.01lb.

expectthattheapplicationoftheproceduremaydeviatefromthespecified

6.2 Barometer, for measuring absolute atmospheric

requirements(ifitcannotbeavoided)aslongasthosedeviationsarenoted

pressure, to be used for adjustment of measured natural gas

on the Results Reporting Sheets.

volume to standard conditions. It shall have a resolution of 0.2

9.2 Connect the conveyor toaster to a calibrated energy test

in. Hg and an uncertainty of 0.2 in. Hg.

meter. For gas installations, install a pressure regulator down-

6.3 Gas Meter, for measuring the gas consumption of a stream from the meter to maintain a constant pressure of gas

for all tests. Install instrumentation to record both the pressure

conveyor toaster, shall be a positive displacement type with a

resolution of at least 0.01 ft and a maximum uncertainty no andtemperatureofthegassuppliedtotheconveyortoasterand

the barometric pressure during each test so that the measured

greaterthan1%ofthemeasuredvalueforanydemandgreater

than 2.2 ft /h. If the meter is used for measuring the gas gas flow can be corrected to standard conditions. For electric

installations,avoltageregulatormayberequiredduringtestsif

consumed by the pilot lights, it shall have a resolution of at

least 0.01 ft and a maximum uncertainty no greater than 2% the voltage supply is not within 62.5% of the manufacturer’s

nameplate voltage.

of the measured value.

6.4 Pressure Gage, for monitoring natural gas pressure. It 9.3 For an electric conveyor toaster, confirm (while the

shallhavearangeofzeroto10in.water,aresolutionof0.5in. conveyor toaster elements are energized) that the supply

water, and a maximum uncertainty of 1% of the measured voltage is within 62.5% of the operating voltage specified by

value. the manufacturer. Record the test voltage for each test.

F2380 − 04 (2016)

NOTE 3—It is the intent of the testing procedure herein to evaluate the

10.1.3 For electric conveyor toasters, record the following

performance of a conveyor toaster at its rated gas pressure or electric

for each test run:

voltage.Ifanelectricunitisrateddualvoltage(thatis,designedtooperate

10.1.3.1 Voltage while elements are energized,

ateither240or480Vwithnochangeincomponents),thevoltageselected

10.1.3.2 Energy input rate during or immediately prior to

by the manufacturer or tester, or both, shall be reported. If a conveyor

test(forexample,duringthepreheatforthatday’stesting),and

toaster is designed to operate at two voltages without a change in the

resistance of the heating elements, the performance of the unit (for

10.1.3.3 Ambient temperature.

example, preheat time) may differ at the two voltages.

10.1.4 For each test run, confirm that the peak input rate is

9.4 For a gas conveyor toaster, adjust (during maximum

within 65% of the rated nameplate input. If the difference is

energy input) the gas supply pressure downstream from the

greater than 5%, terminate testing and contact the manufac-

appliance’s pressure regulator to within 62.5% of the operat-

turer. The manufacturer may make appropriate changes or

ing manifold pressure specified by the manufacturer. Make adjustments to the conveyor toaster.

adjustments to the appliance following the manufacturer’s

10.2 Energy Input Rate and Preheat Temperature Profile:

recommendations for optimizing combustion.

10.2.1 Install a thermocouple ⁄4 in. above the conveyor, at

the center of the toaster cavity (side to side and front to back).

10. Procedure

NOTE 5—When placing the thermocouple wire in the toaster cavity

10.1 General:

above the conveyor belt, it is highly suggested to feed the thermocouple

10.1.1 Forgasappliances,recordthefollowingforeachtest

wire in from the front of the unit, in the same direction as the belt travels.

run:

This will prevent the toast from fouling the thermocouple wire, which

10.1.1.1 Higher heating value,

could get tangled in the conveyor belt. In addition, having the thermo-

couple wire visible will serve as a reminder as not to place the bread over

10.1.1.2 Standard gas pressure and temperature used to

the thermocouple when loading the toaster during the testing.

correct measured gas volume to standard conditions,

10.1.1.3 Measured gas temperature, 10.2.2 Turntheconveyortoasteron,andsetthetemperature

10.1.1.4 Measured gas pressure, controls to their maximum settings (if applicable). Record the

10.1.1.5 Barometric pressure, time, temperature, and energy consumption for one hour. At

10.1.1.6 Energy input rate during or immediately prior to this time the conveyor toaster should have reached a steady

test(forexample,duringthepreheatforthatday’stesting),and state temperature as described in Section 10.2.3.

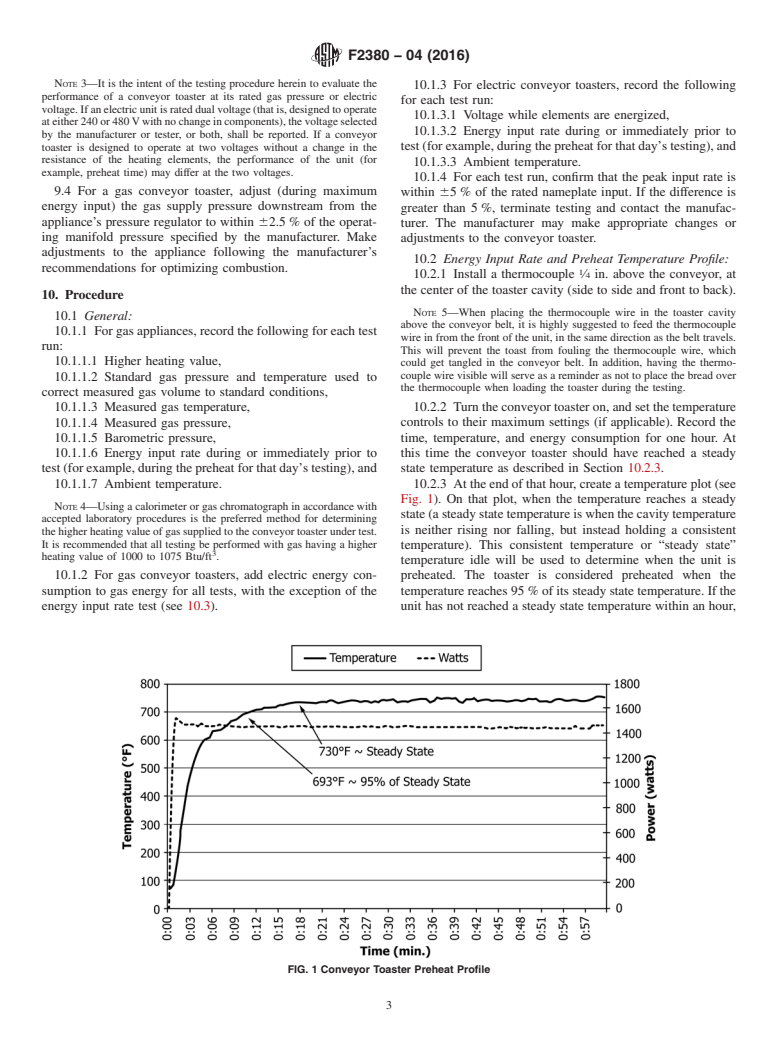

10.1.1.7 Ambient temperature. 10.2.3 Attheendofthathour,createatemperatureplot(see

Fig. 1). On that plot, when the temperature reaches a steady

NOTE 4—Using a calorimeter or gas chromatograph in accordance with

state(asteadystatetemperatureiswhenthecavitytemperature

accepted laboratory procedures is the preferred method for determining

is neither rising nor falling, but instead holding a consistent

thehigherheatingvalueofgassuppliedtotheconveyortoasterundertest.

It is recommended that all testing be performed with gas having a higher

temperature). This consistent temperature or “steady state”

heating value of 1000 to 1075 Btu/ft .

temperature idle will be used to determine when the unit is

10.1.2 For gas conveyor toasters, add electric energy con- preheated. The toaster is considered preheated when the

sumption to gas energy for all tests, with the exception of the temperaturereaches95%ofitssteadystatetemperature.Ifthe

energy input rate test (see 10.3). unit has not reached a steady state temperature within an hour,

FIG. 1 Conveyor Toaster Preheat Profile

F2380 − 04 (2016)

repeat 10.2.2 and increase the monitoring time from1hto2h, 10 ⁄2-in. (267-mm) wide can be divided into two sections,

or until a steady state temperature is reached. allowing two standard slices of bread to fit side-by-side on the

conveyor.

NOTE 6—Research at the Food Service Technology Center indicates

10.6.2 Based on the conveyor toaster belt width (two slice,

that a conveyor toaster is sufficiently preheated and ready to cook/toast

three slice toaster, and so

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2380 − 04 (Reapproved 2010) F2380 − 04 (Reapproved 2016)An American National Standard

Standard Test Method for

Performance of Conveyor Toasters

This standard is issued under the fixed designation F2380; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method evaluates the energy consumption and cooking performance of conveyor toasters. The food service

operator can use this evaluation to select a conveyor toaster and understand its energy consumption.

1.2 This test method is applicable to gas and electric conveyor toasters.

1.3 The conveyor toaster can be evaluated with respect to the following (where applicable):

1.3.1 Energy input rate and preheat temperature profile (10.2),

1.3.2 Preheat energy consumption and time (10.3),

1.3.3 Idle energy rate (10.4),

1.3.4 Pilot energy rate (if applicable, 10.5),

1.3.5 Cooking energy rate (10.8), and

1.3.6 Production capacity (10.8).

1.4 The values stated in inch-pound units are to be regarded as standard. The SI units given in parentheses are for information

only.

1.5 This test method may involve hazardous materials, operations, and equipment. This standard does not purport to address

all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate

safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D3588 Practice for Calculating Heat Value, Compressibility Factor, and Relative Density of Gaseous Fuels

2.2 ASHRAE Document:

ASHRAE Guideline 2 (RA90) Engineering Analysis of Experimental Data

2.3 UL Document:

UL 1026 Electric Household Cooking and Food Service Appliances

3. Terminology

3.1 Definitions:

3.1.1 conveyor toaster, n—an appliance for caramelizing bread products that carries the bread product on a belt or chain into

and through a heated chamber. The chamber may be heated by gas or electric forced convection, radiants, or quartz tubes. Top and

bottom heat may be independently controlled.

3.1.2 cooking energy rate, n—average rate of energy consumption (Btu/h or kW) during the production capacity tests.

3.1.3 energy input rate, n—peak rate at which a conveyor toaster consumes energy (Btu/h or kW).

3.1.4 idle energy rate, n—the conveyor toaster’s rate of energy consumption (kW or Btu/h), when empty, required to maintain

its cavity temperature at the predetermined temperature set point.

This test method is under the jurisdiction of ASTM Committee F26 on Food Service Equipment and is the direct responsibility of Subcommittee F26.06 on Productivity

and Energy Protocol.

Current edition approved March 1, 2010Oct. 1, 2016. Published May 2010November 2016. Originally approved in 2004. Last previous edition approved in 20042010 as

F2380F2380 – 04. DOI: 10.1520/F2380-04R10. – 04 (2010). DOI: 10.1520/F2380-04R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA 30329,

http://www.ashrae.org.

Available from Underwriters Laboratories (UL), 333 Pfingsten Rd., Northbrook, IL 60062-2096, http://www.ul.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2380 − 04 (2016)

3.1.5 toaster cavity, n—that portion of the conveyor toaster in which bread products are heated or toasted.

3.1.6 pilot energy rate, n—rate of energy consumption (Btu/h) by a conveyor toaster’s continuous pilot (if applicable).

3.1.7 preheat energy, n—amount of energy consumed (Btu or kWh), by the conveyor toaster while preheating its cavity from

ambient temperature to the determined steady state temperature.

3.1.8 preheat time, n—time (min) required for the conveyor toaster cavity to preheat from ambient temperature to the specified

set point.

3.1.9 production capacity, n—maximum rate (slices/h) at which a conveyor toaster can bring the specified bread product to a

specified “toasted” condition.

3.1.10 production rate, n—rate (slices/h) at which a conveyor toaster brings the specified food product to a specified “toasted”

condition. This does not necessarily refer to maximum rate. Production rate varies with the amount of food being toasted.

3.1.11 uncertainty, n—measure of systematic and precision errors in specified instrumentation or measure of repeatability of a

reported test result.

4. Summary of Test Method

4.1 Energy input rate is determined to confirm that the conveyor toaster is operating within 5 % of the nameplate energy input

rate. For gas conveyor toaster, the pilot energy rate and the fan and control energy rates are also determined.

4.2 Preheat energy and time are determined.

4.3 Idle energy rate is determined.

4.4 Production rate is determined using sliced bread as a food product.

5. Significance and Use

5.1 The energy input rate test is used to confirm that the conveyor toaster is operating properly prior to further testing.

5.2 Preheat energy and time can be useful to food service operators to manage power demands and to know how quickly the

conveyor toaster can be ready for operation.

5.3 Idle energy rate and pilot energy rate can be used to estimate energy consumption during non-cooking periods. In addition,

a power saving mode (if applicable) will demonstrate energy savings during idle periods.

5.4 Production capacity information can help an end user to better understand the production capabilities of a conveyor toaster

as it is used to cook a typical food product and this could help in specifying the proper size and quantity of equipment. If production

information is desired using a food product other than the specified test food, the test method could be adapted and applied.

6. Apparatus

6.1 Analytical Balance Scale, for measuring weights up to 20 lb, with a resolution of 0.01 lb and an uncertainty of 0.01 lb.

6.2 Barometer, for measuring absolute atmospheric pressure, to be used for adjustment of measured natural gas volume to

standard conditions. It shall have a resolution of 0.2 in. Hg and an uncertainty of 0.2 in. Hg.

6.3 Gas Meter, for measuring the gas consumption of a conveyor toaster, shall be a positive displacement type with a resolution

3 3

of at least 0.01 ft and a maximum uncertainty no greater than 1 % of the measured value for any demand greater than 2.2 ft /h.

If the meter is used for measuring the gas consumed by the pilot lights, it shall have a resolution of at least 0.01 ft and a maximum

uncertainty no greater than 2 % of the measured value.

6.4 Pressure Gage, for monitoring natural gas pressure. It shall have a range of zero to 10 in. water, a resolution of 0.5 in. water,

and a maximum uncertainty of 1 % of the measured value.

6.5 Stop Watch, with a 1-s resolution.

6.6 Temperature Sensor, for measuring natural gas temperature in the range of 50 to 100°F with an uncertainty of 61°F.

6.7 Thermocouple, high temperature glass insulated, 24 gage, type K thermocouple wire, connected at the exposed ends by

tightly twisting or soldering the two wires together.

6.8 Watt-Hour Meter, for measuring the electrical energy consumption of a conveyor toaster, shall have a resolution of at least

10 Wh and a maximum uncertainty no greater than 1.5 % of the measured value for any demand greater than 100 W. For any

demand less than 100 W, the meter shall have a resolution of at least 10 Wh and a maximum uncertainty no greater than 10 %.

7. Reagents and Materials

7.1 Bread for Toasting, shall be a generic grocery store brand, 1.5 6 0.1 lb white loaf with a crown, consisting of 20 slices (not

including the ends) measuring approximately 4.5 by 4.5 by 0.5 in. per slice. Each slice must weigh 0.065 6 0.01 lb. The bread

shall be stored at room temperature 75 6 5°F.

F2380 − 04 (2016)

NOTE 1—The bread is not to have any type of topping such as a butter top, flour top, or any seed/nut topping. Sandwich type bread is not to be used

because it does not have a crown. In addition, loaves of bread that only have 19 slices (not including the heals) typically have too high of individual slice

weight. The 1.5 lb of generic store brand white bread that has 20 slices (not including the heals) more often than not consists of individual slices that

weigh approximately 0.065 lb which is specified for this test method.

8. Sampling and Test Units

8.1 Conveyor Toaster—Select a representative production model for performance testing.

9. Preparation of Apparatus

9.1 Install the appliance according to the manufacturer’s instructions. The associated heating or cooling system shall be capable

of maintaining an ambient temperature of 75 6 5°F (24 6 3°C) within the testing environment when the exhaust ventilation system

is operating.

NOTE 2—The ambient temperature requirements are designed to simulate real world kitchen temperatures and are meant to provide a reasonable

guideline for the temperature requirements during testing. If a facility is not able to maintain the required temperatures, then it is reasonable to expect

that the application of the procedure may deviate from the specified requirements (if it cannot be avoided) as long as those deviations are noted on the

Results Reporting Sheets.

9.2 Connect the conveyor toaster to a calibrated energy test meter. For gas installations, install a pressure regulator downstream

from the meter to maintain a constant pressure of gas for all tests. Install instrumentation to record both the pressure and

temperature of the gas supplied to the conveyor toaster and the barometric pressure during each test so that the measured gas flow

can be corrected to standard conditions. For electric installations, a voltage regulator may be required during tests if the voltage

supply is not within 62.5 % of the manufacturer’s nameplate voltage.

9.3 For an electric conveyor toaster, confirm (while the conveyor toaster elements are energized) that the supply voltage is

within 62.5 % of the operating voltage specified by the manufacturer. Record the test voltage for each test.

NOTE 3—It is the intent of the testing procedure herein to evaluate the performance of a conveyor toaster at its rated gas pressure or electric voltage.

If an electric unit is rated dual voltage (that is, designed to operate at either 240 or 480 V with no change in components), the voltage selected by the

manufacturer or tester, or both, shall be reported. If a conveyor toaster is designed to operate at two voltages without a change in the resistance of the

heating elements, the performance of the unit (for example, preheat time) may differ at the two voltages.

9.4 For a gas conveyor toaster, adjust (during maximum energy input) the gas supply pressure downstream from the appliance’s

pressure regulator to within 62.5 % of the operating manifold pressure specified by the manufacturer. Make adjustments to the

appliance following the manufacturer’s recommendations for optimizing combustion.

10. Procedure

10.1 General:

10.1.1 For gas appliances, record the following for each test run:

10.1.1.1 Higher heating value,

10.1.1.2 Standard gas pressure and temperature used to correct measured gas volume to standard conditions,

10.1.1.3 Measured gas temperature,

10.1.1.4 Measured gas pressure,

10.1.1.5 Barometric pressure,

10.1.1.6 Energy input rate during or immediately prior to test (for example, during the preheat for that day’s testing), and

10.1.1.7 Ambient temperature.

NOTE 4—Using a calorimeter or gas chromatograph in accordance with accepted laboratory procedures is the preferred method for determining the

higher heating value of gas supplied to the conveyor toaster under test. It is recommended that all testing be performed with gas having a higher heating

value of 1000 to 1075 Btu/ft .

10.1.2 For gas conveyor toasters, add electric energy consumption to gas energy for all tests, with the exception of the energy

input rate test (see 10.3).

10.1.3 For electric conveyor toasters, record the following for each test run:

10.1.3.1 Voltage while elements are energized,

10.1.3.2 Energy input rate during or immediately prior to test (for example, during the preheat for that day’s testing), and

10.1.3.3 Ambient temperature.

10.1.4 For each test run, confirm that the peak input rate is within 65 % of the rated nameplate input. If the difference is greater

than 5 %, terminate testing and contact the manufacturer. The manufacturer may make appropriate changes or adjustments to the

conveyor toaster.

10.2 Energy Input Rate and Preheat Temperature Profile:

10.2.1 Install a thermocouple ⁄4 in. above the conveyor, at the center of the toaster cavity (side to side and front to back).

NOTE 5—When placing the thermocouple wire in the toaster cavity above the conveyor belt, it is highly suggested to feed the thermocouple wire in

from the front of the unit, in the same direction as the belt travels. This will prevent the toast from fouling the thermocouple wire, which could get tangled

in the conveyor belt. In addition, having the thermocouple wire visible will serve as a reminder as not to place the bread over the thermocouple when

loading the toaster during the testing.

F2380 − 04 (2016)

10.2.2 Turn the conveyor toaster on, and set the temperature controls to their maximum settings (if applicable). Record the time,

temperature, and energy consumption for one hour. At this time the conveyor toaster should have reached a steady state temperature

as described in Section 10.2.3.

10.2.3 At the end of that hour, create a temperature plot (see Fig. 1). On that plot, when the temperature reaches a steady state

(a steady state temperature is when the cavity temperature is neither rising nor falling, but instead holding a consistent

temperature). This consistent temperature or “steady state” temperature idle will be used to determine when the unit is preheated.

The toaster is considered preheated when

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.