ASTM F512-12(2017)

(Specification)Standard Specification for Smooth-Wall Poly(Vinyl Chloride) (PVC) Conduit and Fittings for Underground Installation

Standard Specification for Smooth-Wall Poly(Vinyl Chloride) (PVC) Conduit and Fittings for Underground Installation

ABSTRACT

This specification covers the dimensional, design, and performance requirements for five types (Types EB-20, EB-35, DB-60, DB-100, and DB-120) of smooth-wall poly(vinyl chloride) (PVC) conduits and fittings for underground communication and electrical power wires and cables. Conduits and fittings shall be evaluated on impact resistance and strength, joint tightness, pipe stiffness, and extrusion quality.

SCOPE

1.1 This specification covers the requirements for single wall and coextruded cellular core smooth-wall poly(vinyl chloride) conduit and fittings for underground communication and electrical power wire and cables. Plastics which does not meet the material requirements specified in Section 5 is excluded from single layer and all coextruded layers.

1.2 The values given in parentheses are for information only.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F512 −12 (Reapproved 2017) An American National Standard

Standard Specification for

Smooth-Wall Poly(Vinyl Chloride) (PVC) Conduit and

Fittings for Underground Installation

ThisstandardisissuedunderthefixeddesignationF512;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope moplastic Pipe and Fittings

D2152 Test Method for Adequacy of Fusion of Extruded

1.1 This specification covers the requirements for single

Poly(Vinyl Chloride) (PVC) Pipe and Molded Fittings by

wall and coextruded cellular core smooth-wall poly(vinyl

Acetone Immersion

chloride) conduit and fittings for underground communication

D2412 Test Method for Determination of External Loading

and electrical power wire and cables. Plastics which does not

Characteristics of Plastic Pipe by Parallel-Plate Loading

meet the material requirements specified in Section 5 is

D2444 Test Method for Determination of the Impact Resis-

excluded from single layer and all coextruded layers.

tance of Thermoplastic Pipe and Fittings by Means of a

1.2 The values given in parentheses are for information

Tup (Falling Weight)

only.

D2466 Specification for Poly(Vinyl Chloride) (PVC) Plastic

1.3 The following safety hazards caveat pertains only to the

Pipe Fittings, Schedule 40

test method portion, Section 8, of this specification: This D2564 Specification for Solvent Cements for Poly(Vinyl

standard does not purport to address all of the safety concerns,

Chloride) (PVC) Plastic Piping Systems

if any, associated with its use. It is the responsibility of the user D2855 Practice for the Two-Step (Primer and Solvent Ce-

of this standard to establish appropriate safety and health

ment) Method of Joining Poly (Vinyl Chloride) (PVC) or

practices and determine the applicability of regulatory limita- Chlorinated Poly (Vinyl Chloride) (CPVC) Pipe and

tions prior to use.

Piping Components with Tapered Sockets

1.4 This international standard was developed in accor- F412 Terminology Relating to Plastic Piping Systems

dance with internationally recognized principles on standard-

3. Terminology

ization established in the Decision on Principles for the

3.1 Definitions are in accordance with Terminology F412

Development of International Standards, Guides and Recom-

and abbreviations are in accordance with Terminology D1600,

mendations issued by the World Trade Organization Technical

unless otherwise specified. The abbreviation for poly(vinyl

Barriers to Trade (TBT) Committee.

chloride) is PVC.

2. Referenced Documents

3.2 Definitions of Terms Specific to This Standard:

2.1 ASTM Standards: 3.2.1 cellular plastic—a plastic containing numerous cells,

D618 Practice for Conditioning Plastics for Testing intentionally introduced, interconnecting or not, distributed

D1600 Terminology forAbbreviatedTerms Relating to Plas- throughout the mass.

tics

3.2.2 coextruded pipe—pipe consisting of two or more

D1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

concentric layers of material bonded together in processing by

Compounds and Chlorinated Poly(Vinyl Chloride)

any combination of temperature, pressure, grafting, cross-

(CPVC) Compounds

linking or adhesion.

D2122 Test Method for Determining Dimensions of Ther-

3.2.3 coextrusion—a process whereby two or more heated

or unheated plastic material streams, forced through one or

more shaping orifice(s), become one continuously formed

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

piece.

Piping Systems and is the direct responsibility of Subcommittee F17.25 on Vinyl

Based Pipe.

3.2.4 external recycled material—industrial rework gener-

Current edition approved April 1, 2017. Published April 2017. Originally

ated by a different company manufacturing to this specifica-

approved in 1977. Last previous edition approved in 2012 as F512–12. DOI:

tion. Composition is known by the industrial source of the

10.1520/F0512-12R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

material.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2.5 post-consumer recycled material—finished goods that

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. have been purchased by the public, then returned to industry

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F512−12 (2017)

and reprocessed into raw materials. Identity of finished goods blowing agent. The pipe produced shall meet all of the

is known by the reprocessing company. requirements of this specification.

3.2.6 certificate of composition—a certificate describing the

5.3 Recycled PVC Materials—RecycledPVCmaterialscon-

certain properties of an external recycled material of a post

forming to the cell classification of this specification may be

consumer recycled material.

used provided they are clean and free from foreign materials

and provided that the conduit or fittings produced meet all

3.2.7 composition disclosure—a document describing the

requirements of this specification.

formulation of an external recycled material.

5.4 Solvent Cement—The solvent cement shall meet the

4. Classification

requirements of Specification D2564.

4.1 This specification covers five types of underground

6. Requirements

conduit. There are two having lesser pipe stiffness values,

designed primarily for concrete encased burial (EB), and three

6.1 Workmanship—The conduit and fittings shall be homo-

with greater pipe stiffness values, designed primarily for direct

geneous throughout, and free from visible cracks, holes,

burial (DB). The complete designations follow:

foreign inclusions, or other injurious defects. The conduit and

Type EB-20 — Designed to be encased in concrete.

fittings shall be as uniform as is commercially practical in

Type EB-35 — Designed to be encased in concrete.

color, opacity, density, and other physical properties.

Type DB-60 — Designed for direct burial without encasement in concrete.

Type DB-100 — Designed for direct burial without encasement in concrete.

6.2 Dimensions:

Type DB-120 — Designed for direct burial without encasement in concrete.

6.2.1 Dimensions shall be determined in accordance with

4.2 This specification covers conduit with integral bells, or

Test Method D2122.

with either separate or attached couplings.

6.2.2 The dimensions and tolerances of the conduit shall be

as specified in Table 1.

4.3 This specification covers molded and fabricated fittings

6.2.3 Lengths—Conduit shall be supplied in lengths of 20 or

intended for use with all types of conduit.

25 ft, or as otherwise agreed upon between the purchaser and

5. Materials

the seller.Alength shall be considered to be the overall length

of the conduit, including integral bell, or coupling if attached,

5.1 Basic Materials—The conduit shall be made of virgin

unless otherwise specified. Tolerance on length shall be 61 in.

homopolymer PVC compound having a cell classification of

(625 mm).

12254, 12164 (with a minimum tensile strength of 4000 psi

6.2.4 Integral Bell Dimensions:

(28 MPa)), or 12264(with a minimum tensile modulus of

6.2.4.1 Two systems of fit for integral bells are in common

500 000 psi) as defined in Specification D1784. Molded

use. Unless otherwise specified, the manufacturer may employ

fittings shall be made from PVC compound having a cell

either of them.

classification of 12234 or 13343 as defined in Specification

6.2.4.2 Interference Fit System—The dimensions and toler-

D1784. Homopolymer PVC compounds must equal or exceed

ances listed in Columns A and B of Table 1 in Specification

the requirements of the listed cell classification numbers.

D2466 provide a satisfactory interference fit system between

5.2 Rework Materials—Rework material from the manufac-

pipe and socket.

turer’s own conduit or fittings production may be used by the

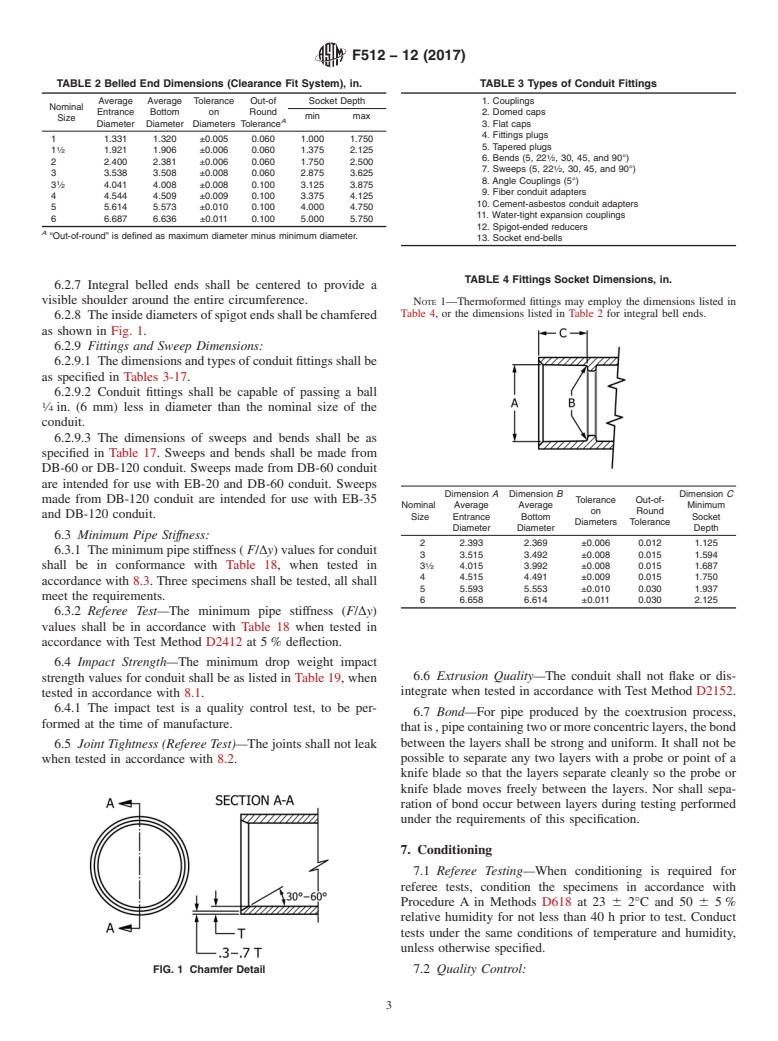

6.2.4.3 Clearance Fit System—The dimensions and toler-

same manufacturer, provided that the conduit or fittings pro-

ances listed in Table 2 of this specification provide a satisfac-

duced meet all of the requirements of this specification.

tory clearance fit system.

Rework material from the manufacture’s coextruded cellular

6.2.5 The wall thickness of integral bells and sweeps shall

core conduit shall be used in the core if it contains any residual

be considered satisfactory if formed from conduit which meets

the minimum requirements of this specification.

6.2.6 Socket depths for integral bells shall conform to the

Supporting data have been filed at ASTM International Headquarters and may

requirements listed in Table 2.

be obtained by requesting Research Report RR:F17-1002.

TABLE 1 Conduit Dimensions and Tolerances, in.

A

Tolerance on Minimum Wall Thickness

Average

Nominal

Outside Minimum Modulus 400 000 psi Minimum Modulus 500 000 psi

Out-of

Size

Average

B

Diameter

Round

EB-20 EB-35 DB-60 DB-100 DB-120 EB-20 EB-35 DB-60 DB-100 DB-120

1 1.315 ±0.005 0.060 — — — — 0.060 — — — — 0.060

1 ⁄2 1.900 ±0.006 0.060 — — 0.060 — 0.065 — — — — 0.060

2 2.375 ±0.006 0.060 — 0.060 0.065 — 0.083 0.060 — 0.060 — 0.077

3 3.500 ±0.008 0.060 0.067 0.082 0.100 0.121 0.127 0.061 0.076 0.092 0.112 0.118

3 ⁄2 4.000 ±0.008 0.100 0.078 0.095 0.115 0.138 0.147 0.072 0.088 0.107 0.128 0.136

4 4.500 ±0.009 0.100 0.089 0.109 0.131 0.155 0.166 0.082 0.100 0.121 0.145 0.154

5 5.563 ±0.010 0.100 0.112 0.136 0.164 0.192 0.205 0.103 0.126 0.152 0.179 0.191

6 6.625 ±0.011 0.100 0.135 0.164 0.196 0.229 0.244 0.125 0.152 0.182 0.213 0.227

A

Tolerance on wall thickness is +12, −0 % or +0.030, −0.000 in. whichever is greater.

B

“Out-of-round” is defined as maximum diameter minus minimum diameter.

F512−12 (2017)

TABLE 2 Belled End Dimensions (Clearance Fit System), in. TABLE 3 Types of Conduit Fittings

Average Average Tolerance Out-of Socket Depth 1. Couplings

Nominal

Entrance Bottom on Round 2. Domed caps

min max

Size

A

Diameter Diameter Diameters Tolerance 3. Flat caps

4. Fittings plugs

1 1.331 1.320 ±0.005 0.060 1.000 1.750

5. Tapered plugs

1 ⁄2 1.921 1.906 ±0.006 0.060 1.375 2.125

6. Bends (5, 22 ⁄2, 30, 45, and 90°)

2 2.400 2.381 ±0.006 0.060 1.750 2.500

7. Sweeps (5, 22 ⁄2, 30, 45, and 90°)

3 3.538 3.508 ±0.008 0.060 2.875 3.625

8. Angle Couplings (5°)

3 ⁄2 4.041 4.008 ±0.008 0.100 3.125 3.875

9. Fiber conduit adapters

4 4.544 4.509 ±0.009 0.100 3.375 4.125

10. Cement-asbestos conduit adapters

5 5.614 5.573 ±0.010 0.100 4.000 4.750

11. Water-tight expansion couplings

6 6.687 6.636 ±0.011 0.100 5.000 5.750

12. Spigot-ended reducers

A

“Out-of-round” is defined as maximum diameter minus minimum diameter.

13. Socket end-bells

TABLE 4 Fittings Socket Dimensions, in.

6.2.7 Integral belled ends shall be centered to provide a

visible shoulder around the entire circumference. NOTE 1—Thermoformed fittings may employ the dimensions listed in

Table 4, or the dimensions listed in Table 2 for integral bell ends.

6.2.8 Theinsidediametersofspigotendsshallbechamfered

as shown in Fig. 1.

6.2.9 Fittings and Sweep Dimensions:

6.2.9.1 The dimensions and types of conduit fittings shall be

as specified in Tables 3-17.

6.2.9.2 Conduit fittings shall be capable of passing a ball

⁄4 in. (6 mm) less in diameter than the nominal size of the

conduit.

6.2.9.3 The dimensions of sweeps and bends shall be as

specified in Table 17. Sweeps and bends shall be made from

DB-60 or DB-120 conduit. Sweeps made from DB-60 conduit

are intended for use with EB-20 and DB-60 conduit. Sweeps

Dimension A Dimension B Dimension C

made from DB-120 conduit are intended for use with EB-35 Tolerance Out-of-

Nominal Average Average Minimum

on Round

and DB-120 conduit.

Size Entrance Bottom Socket

Diameters Tolerance

Diameter Diameter Depth

6.3 Minimum Pipe Stiffness:

2 2.393 2.369 ±0.006 0.012 1.125

6.3.1 The minimum pipe stiffness ( F/∆y) values for conduit

3 3.515 3.492 ±0.008 0.015 1.594

shall be in conformance with Table 18, when tested in 3 ⁄2 4.015 3.992 ±0.008 0.015 1.687

4 4.515 4.491 ±0.009 0.015 1.750

accordance with 8.3. Three specimens shall be tested, all shall

5 5.593 5.553 ±0.010 0.030 1.937

meet the requirements.

6 6.658 6.614 ±0.011 0.030 2.125

6.3.2 Referee Test—The minimum pipe stiffness (F/∆y)

values shall be in accordance with Table 18 when tested in

accordance with Test Method D2412 at 5 % deflection.

6.4 Impact Strength—The minimum drop weight impact

6.6 Extrusion Quality—The conduit shall not flake or dis-

strength values for conduit shall be as listed in Table 19, when

integrate when tested in accordance with Test Method D2152.

tested in accordance with 8.1.

6.4.1 The impact test is a quality control test, to be per-

6.7 Bond—For pipe produced by the coextrusion process,

formed at the time of manufacture.

thatis,pipecontainingtwoormoreconcentriclayers,thebond

between the layers shall be strong and uniform. It shall not be

6.5 Joint Tightness (Referee Test)—The joints shall not leak

possible to separate any two layers with a probe or point of a

when tested in accordance with 8.2.

knife blade so that the layers separate cleanly so the probe or

knife blade moves freely between the layers. Nor shall sepa-

ration of bond occur between layers during testing performed

under the requirements of this specification.

7. Conditioning

7.1 Referee Testing—When conditioning is required for

referee tests, condition the specimens in accordance with

Procedure A in Methods D618 at 23 6 2°C and 50 6 5%

relative humidity for not less than 40 h prior to test. Conduct

tests under the same conditions of temperature and humidity,

unless otherwise specified.

FIG. 1 Chamfer Detail 7.2 Quality Control:

F512−12 (2017)

TABLE 5 Coupling Dimensions, in. TABLE 7 Domed Cap Dimensions, in.

Nominal Size M, max SH, max N,min

Nominal Size W, max M, max

13 1

11 ⁄64 0.070 ⁄16

3 13

22 ⁄32 2 ⁄16

1 9 1

1 ⁄2 2 ⁄32 0.070 ⁄16

334 ⁄32

47 3

22 ⁄64 0.075 ⁄32

1 1 5

3 ⁄2 3 ⁄8 4 ⁄8

31 7

33 ⁄32 0.076 ⁄64

31 13

43 ⁄64 5 ⁄64

1 1 7

3 ⁄2 4 ⁄2 0.087 ⁄64

27 1

54 ⁄64 6 ⁄4

1 7

45 ⁄32 0.097 ⁄64

7 25

65 ⁄32 7 ⁄64

1 9

56 ⁄4 0.118 ⁄64

1 9

67 ⁄2 0.140 ⁄64

TABLE 8 Flat Cap Dimensions, in.

TABLE 6 5° Angle Couplings, in.

Nominal Size F,min M, max

19 35

2 ⁄32 2 ⁄64

1 45

3 ⁄16 3 ⁄64

1 5 7

3 ⁄2 ⁄64 4 ⁄32

3 3

4 ⁄32 4 ⁄4

3 53

5 ⁄32 5 ⁄64

1 61

6 ⁄8 6 ⁄64

TABLE 9 Fitting Plug Dimensions, in.

Nominal Size M, max N,min X and Tolerance Y, min Bend R

22 ⁄16 1.50 2.375 ± 0.006 2.62 30

33 ⁄32 1.55 3.500 ± 0.008 3.14 36

44 ⁄64 1.39 4.500 ± 0.009 3.14 36

55 ⁄64 2.25 5.563 ± 0.010 4.19 48

67 ⁄64 3.12 6.625

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F512 − 12 F512 − 12 (Reapproved 2017) An American National Standard

Standard Specification for

Smooth-Wall Poly(Vinyl Chloride) (PVC) Conduit and

Fittings for Underground Installation

This standard is issued under the fixed designation F512; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*Scope

1.1 This specification covers the requirements for single wall and coextruded cellular core smooth-wall poly(vinyl chloride)

conduit and fittings for underground communication and electrical power wire and cables. Plastics which does not meet the

material requirements specified in Section 5 is excluded from single layer and all coextruded layers.

1.2 The values given in parentheses are for information only.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 8, of this specification:This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D1600 Terminology for Abbreviated Terms Relating to Plastics

D1784 Specification for Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlorinated Poly(Vinyl Chloride) (CPVC)

Compounds

D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

D2152 Test Method for Adequacy of Fusion of Extruded Poly(Vinyl Chloride) (PVC) Pipe and Molded Fittings by Acetone

Immersion

D2412 Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

D2444 Test Method for Determination of the Impact Resistance of Thermoplastic Pipe and Fittings by Means of a Tup (Falling

Weight)

D2466 Specification for Poly(Vinyl Chloride) (PVC) Plastic Pipe Fittings, Schedule 40

D2564 Specification for Solvent Cements for Poly(Vinyl Chloride) (PVC) Plastic Piping Systems

D2855 Practice for the Two-Step (Primer and Solvent Cement) Method of Joining Poly (Vinyl Chloride) (PVC) or Chlorinated

Poly (Vinyl Chloride) (CPVC) Pipe and Piping Components with Tapered Sockets

F412 Terminology Relating to Plastic Piping Systems

3. Terminology

3.1 Definitions are in accordance with Terminology F412 and abbreviations are in accordance with Terminology D1600, unless

otherwise specified. The abbreviation for poly(vinyl chloride) is PVC.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 cellular plastic—a plastic containing numerous cells, intentionally introduced, interconnecting or not, distributed

throughout the mass.

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.25 on Vinyl Based

Pipe.

Current edition approved Aug. 1, 2012April 1, 2017. Published September 2012April 2017. Originally approved in 1977. Last previous edition approved in 20062012 as

F51206.–12. DOI: 10.1520/F0512-12.10.1520/F0512-12R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F512 − 12 (2017)

3.2.2 coextruded pipe—pipe consisting of two or more concentric layers of material bonded together in processing by any

combination of temperature, pressure, grafting, cross-linking or adhesion.

3.2.3 coextrusion—a process whereby two or more heated or unheated plastic material streams, forced through one or more

shaping orifice(s), become one continuously formed piece.

3.2.4 external recycled material—industrial rework generated by a different company manufacturing to this specification.

Composition is known by the industrial source of the material.

3.2.5 post-consumer recycled material—finished goods that have been purchased by the public, then returned to industry and

reprocessed into raw materials. Identity of finished goods is known by the reprocessing company.

3.2.6 certificate of composition—a certificate describing the certain properties of an external recycled material of a post

consumer recycled material.

3.2.7 composition disclosure—a document describing the formulation of an external recycled material.

4. Classification

4.1 This specification covers five types of underground conduit. There are two having lesser pipe stiffness values, designed

primarily for concrete encased burial (EB), and three with greater pipe stiffness values, designed primarily for direct burial (DB).

The complete designations follow:

Type EB-20 — Designed to be encased in concrete.

Type EB-35 — Designed to be encased in concrete.

Type DB-60 — Designed for direct burial without encasement in concrete.

Type DB-100 — Designed for direct burial without encasement in concrete.

Type DB-120 — Designed for direct burial without encasement in concrete.

4.2 This specification covers conduit with integral bells, or with either separate or attached couplings.

4.3 This specification covers molded and fabricated fittings intended for use with all types of conduit.

5. Materials

5.1 Basic Materials—The conduit shall be made of virgin homopolymer PVC compound having a cell classification of 12254,

12164 (with a minimum tensile strength of 4000 psi (28 MPa)), or 12264(with a minimum tensile modulus of 500 000 psi) as

defined in Specification D1784. Molded fittings shall be made from PVC compound having a cell classification of 12234 or 13343

as defined in Specification D1784. Homopolymer PVC compounds must equal or exceed the requirements of the listed cell

classification numbers.

5.2 Rework Materials—Rework material from the manufacturer’s own conduit or fittings production may be used by the same

manufacturer, provided that the conduit or fittings produced meet all of the requirements of this specification. Rework material

from the manufacture’s coextruded cellular core conduit shall be used in the core if it contains any residual blowing agent. The

pipe produced shall meet all of the requirements of this specification.

5.3 Recycled PVC Materials—Recycled PVC materials conforming to the cell classification of this specification may be used

provided they are clean and free from foreign materials and provided that the conduit or fittings produced meet all requirements

of this specification.

5.4 Solvent Cement—The solvent cement shall meet the requirements of Specification D2564.

6. Requirements

6.1 Workmanship—The conduit and fittings shall be homogeneous throughout, and free from visible cracks, holes, foreign

inclusions, or other injurious defects. The conduit and fittings shall be as uniform as is commercially practical in color, opacity,

density, and other physical properties.

6.2 Dimensions:

6.2.1 Dimensions shall be determined in accordance with Test Method D2122.

6.2.2 The dimensions and tolerances of the conduit shall be as specified in Table 1.

6.2.3 Lengths—Conduit shall be supplied in lengths of 20 or 25 ft, or as otherwise agreed upon between the purchaser and the

seller. A length shall be considered to be the overall length of the conduit, including integral bell, or coupling if attached, unless

otherwise specified. Tolerance on length shall be 61 in. (625 mm).

6.2.4 Integral Bell Dimensions:

6.2.4.1 Two systems of fit for integral bells are in common use. Unless otherwise specified, the manufacturer may employ either

of them.

Supporting data have been filed at ASTM International Headquarters and may be obtained by requesting Research Report RR:F17-1002.

F512 − 12 (2017)

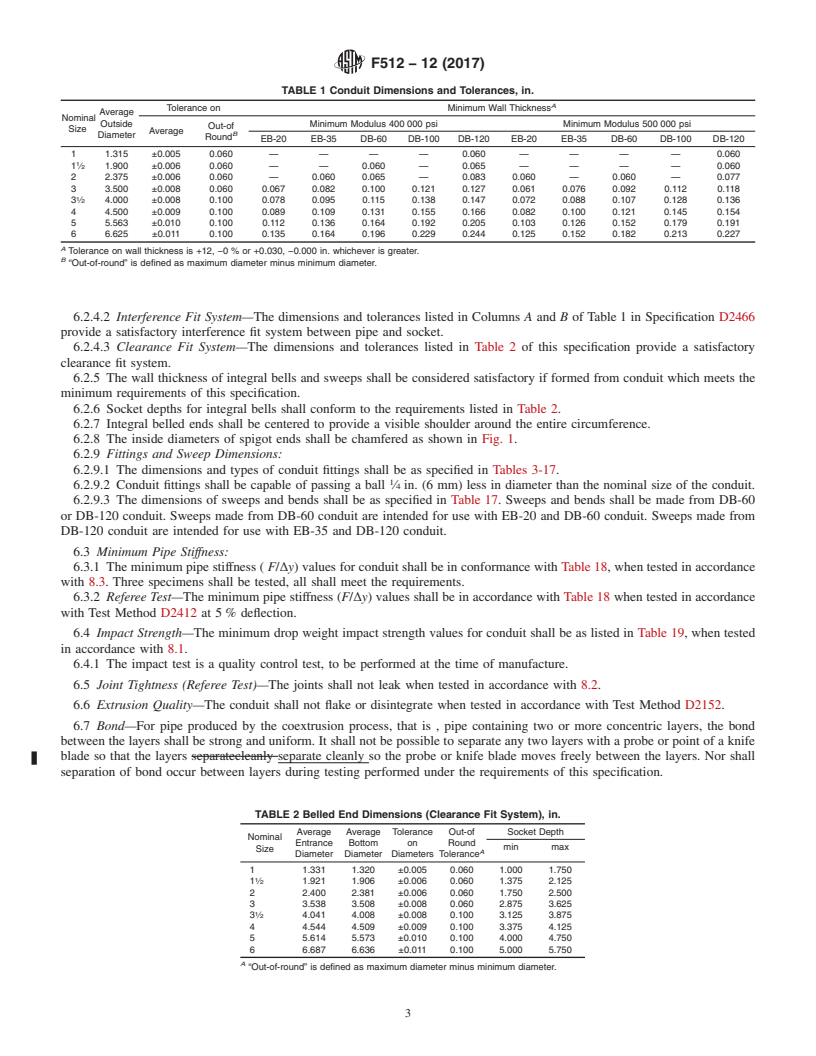

TABLE 1 Conduit Dimensions and Tolerances, in.

A

Tolerance on Minimum Wall Thickness

Average

Nominal

Outside Minimum Modulus 400 000 psi Minimum Modulus 500 000 psi

Out-of

Size

Average

B

Diameter

Round

EB-20 EB-35 DB-60 DB-100 DB-120 EB-20 EB-35 DB-60 DB-100 DB-120

1 1.315 ±0.005 0.060 — — — — 0.060 — — — — 0.060

1 ⁄2 1.900 ±0.006 0.060 — — 0.060 — 0.065 — — — — 0.060

2 2.375 ±0.006 0.060 — 0.060 0.065 — 0.083 0.060 — 0.060 — 0.077

3 3.500 ±0.008 0.060 0.067 0.082 0.100 0.121 0.127 0.061 0.076 0.092 0.112 0.118

3 ⁄2 4.000 ±0.008 0.100 0.078 0.095 0.115 0.138 0.147 0.072 0.088 0.107 0.128 0.136

4 4.500 ±0.009 0.100 0.089 0.109 0.131 0.155 0.166 0.082 0.100 0.121 0.145 0.154

5 5.563 ±0.010 0.100 0.112 0.136 0.164 0.192 0.205 0.103 0.126 0.152 0.179 0.191

6 6.625 ±0.011 0.100 0.135 0.164 0.196 0.229 0.244 0.125 0.152 0.182 0.213 0.227

A

Tolerance on wall thickness is +12, −0 % or +0.030, −0.000 in. whichever is greater.

B

“Out-of-round” is defined as maximum diameter minus minimum diameter.

6.2.4.2 Interference Fit System—The dimensions and tolerances listed in Columns A and B of Table 1 in Specification D2466

provide a satisfactory interference fit system between pipe and socket.

6.2.4.3 Clearance Fit System—The dimensions and tolerances listed in Table 2 of this specification provide a satisfactory

clearance fit system.

6.2.5 The wall thickness of integral bells and sweeps shall be considered satisfactory if formed from conduit which meets the

minimum requirements of this specification.

6.2.6 Socket depths for integral bells shall conform to the requirements listed in Table 2.

6.2.7 Integral belled ends shall be centered to provide a visible shoulder around the entire circumference.

6.2.8 The inside diameters of spigot ends shall be chamfered as shown in Fig. 1.

6.2.9 Fittings and Sweep Dimensions:

6.2.9.1 The dimensions and types of conduit fittings shall be as specified in Tables 3-17.

6.2.9.2 Conduit fittings shall be capable of passing a ball ⁄4 in. (6 mm) less in diameter than the nominal size of the conduit.

6.2.9.3 The dimensions of sweeps and bends shall be as specified in Table 17. Sweeps and bends shall be made from DB-60

or DB-120 conduit. Sweeps made from DB-60 conduit are intended for use with EB-20 and DB-60 conduit. Sweeps made from

DB-120 conduit are intended for use with EB-35 and DB-120 conduit.

6.3 Minimum Pipe Stiffness:

6.3.1 The minimum pipe stiffness ( F/Δy) values for conduit shall be in conformance with Table 18, when tested in accordance

with 8.3. Three specimens shall be tested, all shall meet the requirements.

6.3.2 Referee Test—The minimum pipe stiffness (F/Δy) values shall be in accordance with Table 18 when tested in accordance

with Test Method D2412 at 5 % deflection.

6.4 Impact Strength—The minimum drop weight impact strength values for conduit shall be as listed in Table 19, when tested

in accordance with 8.1.

6.4.1 The impact test is a quality control test, to be performed at the time of manufacture.

6.5 Joint Tightness (Referee Test)—The joints shall not leak when tested in accordance with 8.2.

6.6 Extrusion Quality—The conduit shall not flake or disintegrate when tested in accordance with Test Method D2152.

6.7 Bond—For pipe produced by the coextrusion process, that is , pipe containing two or more concentric layers, the bond

between the layers shall be strong and uniform. It shall not be possible to separate any two layers with a probe or point of a knife

blade so that the layers separatecleanly separate cleanly so the probe or knife blade moves freely between the layers. Nor shall

separation of bond occur between layers during testing performed under the requirements of this specification.

TABLE 2 Belled End Dimensions (Clearance Fit System), in.

Average Average Tolerance Out-of Socket Depth

Nominal

Entrance Bottom on Round

min max

Size

A

Diameter Diameter Diameters Tolerance

1 1.331 1.320 ±0.005 0.060 1.000 1.750

1 ⁄2 1.921 1.906 ±0.006 0.060 1.375 2.125

2 2.400 2.381 ±0.006 0.060 1.750 2.500

3 3.538 3.508 ±0.008 0.060 2.875 3.625

3 ⁄2 4.041 4.008 ±0.008 0.100 3.125 3.875

4 4.544 4.509 ±0.009 0.100 3.375 4.125

5 5.614 5.573 ±0.010 0.100 4.000 4.750

6 6.687 6.636 ±0.011 0.100 5.000 5.750

A

“Out-of-round” is defined as maximum diameter minus minimum diameter.

F512 − 12 (2017)

FIG. 1 Chamfer Detail

TABLE 3 Types of Conduit Fittings

1. Couplings

2. Domed caps

3. Flat caps

4. Fittings plugs

5. Tapered plugs

6. Bends (5, 22 ⁄2, 30, 45, and 90°)

7. Sweeps (5, 22 ⁄2, 30, 45, and 90°)

8. Angle Couplings (5°)

9. Fiber conduit adapters

10. Cement-asbestos conduit adapters

11. Water-tight expansion couplings

12. Spigot-ended reducers

13. Socket end-bells

TABLE 4 Fittings Socket Dimensions, in.

NOTE 1—Thermoformed fittings may employ the dimensions listed in

Table 4, or the dimensions listed in Table 2 for integral bell ends.

Dimension A Dimension B Dimension C

Tolerance Out-of-

Nominal Average Average Minimum

on Round

Size Entrance Bottom Socket

Diameters Tolerance

Diameter Diameter Depth

2 2.393 2.369 ±0.006 0.012 1.125

3 3.515 3.492 ±0.008 0.015 1.594

3 ⁄2 4.015 3.992 ±0.008 0.015 1.687

4 4.515 4.491 ±0.009 0.015 1.750

5 5.593 5.553 ±0.010 0.030 1.937

6 6.658 6.614 ±0.011 0.030 2.125

7. Conditioning

7.1 Referee Testing—When conditioning is required for referee tests, condition the specimens in accordance with Procedure A

in Methods D618 at 23 6 2°C and 50 6 5 % relative humidity for not less than 40 h prior to test. Conduct tests under the same

conditions of temperature and humidity, unless otherwise specified.

7.2 Quality Control:

7.2.1 For quality control tests, condition specimens for a minimum of 3 h in air, or 1 h in liquid at 23 6 2°C (70 to 77°F). Test

the specimens at 23 6 2°C without regard to relative humidity.

7.2.2 For the impact test, condition specimens for at least 30 min at 0 to 1.6°C (32 to 35°F).

F512 − 12 (2017)

TABLE 5 Coupling Dimensions, in.

Nominal Size M, max SH,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.