ASTM G7-97

(Practice)Standard Practice for Atmospheric Environmental Exposure Testing of Nonmetallic Materials

Standard Practice for Atmospheric Environmental Exposure Testing of Nonmetallic Materials

SCOPE

1.1 This practice covers procedures to be followed for direct exposure of nonmetallic materials to the environment. When originators of a weathering test have the actual exposure conducted by a separate agency, the specific conditions for the exposure of test and control specimens should be clearly defined and mutually agreed upon between all parties.

1.2 For exposures behind glass, refer to Practice G 24.

1.3 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.4 This practice is technically equivalent to the parts of ISO 877 that describe direct exposures of specimens to the environment.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G7–97

Standard Practice for

Atmospheric Environmental Exposure Testing of

Nonmetallic Materials

ThisstandardisissuedunderthefixeddesignationG7;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope AdjunctNo.12-700070-00 A Test Rack

2.3 ISO Standards:

1.1 Thispracticecoversprocedurestobefollowedfordirect

ISO877 Plastics—Methods of Exposure to DirectWeather-

exposure of nonmetallic materials to the environment. When

ing; to Weathering Using Glass-Filtered Daylight, and to

originators of a weathering test have the actual exposure

Intensified Weathering by Daylight Using Fresnel Mir-

conducted by a separate agency, the specific conditions for the

rors

exposure of test and control specimens should be clearly

defined and mutually agreed upon between all parties.

3. Terminology

1.2 For exposures behind glass, refer to Practice G24.

3.1 Definitions—The definitions given inTerminology E41

1.3 The values stated in SI units are to be regarded as the

and Terminology G113 are applicable to this practice.

standard. The inch-pound units given in parentheses are for

information only.

4. Significance and Use

1.4 This practice is technically equivalent to the parts of

4.1 The relative durability of materials in natural exposures

ISO 877 that describe direct exposures of specimens to the

canbeverydifferentdependingonthelocationoftheexposure

environment.

because of differences in ultraviolet (UV) radiation, time of

1.5 This standard does not purport to address all of the

wetness, temperature, pollutants, and other factors. Therefore,

safety concerns, if any, associated with its use. It is the

it cannot be assumed that results from one exposure in a single

responsibility of the user of this standard to establish appro-

location will be useful for determining relative durability in a

priate safety and health practices and determine the applica-

different location. Exposures in several locations with different

bility of regulatory limitations prior to use.

climates which represent a broad range of anticipated service

conditions are recommended.

2. Referenced Documents

4.2 Because of year-to-year climatological variations, re-

2.1 ASTM Standards:

2 sults from a single exposure test cannot be used to predict the

E41 Terminology Relating to Conditioning

absolute rate at which a material degrades. Several years of

E824 Test Method for Transfer of Calibration from Refer-

3 repeat exposures are needed to get an “average” test result for

ence to Field Pyranometers

a given location.

E913 Test Method for Calibration of Reference Pyranom-

3 4.3 Solar ultraviolet radiation varies considerably as a

eters with Axis Vertical by the Shading Method

functionoftimeofyear.Thiscancauselargedifferencesinthe

E941 Test Method for Calibration of Reference Pyranom-

3 apparent rate of degradation in many polymers. Comparing

eters with Axis Tilted by the Shading Method

results for materials exposed for short periods (less than one

G24 Practice for Conducting Exposures to Daylight Fil-

2 year) is not recommended unless materials are exposed at the

tered Through Glass

same time in the same location.

G 113 Terminology Relating to Natural and Artificial

2 4.4 Defining cxposure periods in terms of total solar or

Weathering Tests of Nonmetallic Materials

solar-ultraviolet radiant energy can reduce variability in results

2.2 ASTM Adjunct:

from separate exposures. Solar ultraviolet measurements may

be made using instruments which record broadband UV (e.g.

This practice is under the jurisdiction ofASTM Committee G-3 on Durability

ofNonmetallicMaterialsandisthedirectresponsibilityofSubcommitteeG03.02on

Natural Environmental Testing.

Current edition approved Dec. 10, 1997. Published February 1998. Originally Available from ASTM Headquarters, 100 Barr Harbor Dr., West Consho-

published as G7–69T. Last previous editionG7–96. hocken, PA 19428. Request ADJG0007.

2 5

Annual Book of ASTM Standards, Vol 14.02. Available from the American National Standards Institute (ANSI), 1430

Annual Book of ASTM Standards, Vol 12.02. Broadway, New York, NY 10018.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G7

295 6385nm)ornarrowbandUV,asdefinedinSections7.2.4 5.4 Exposure Orientation—Unless otherwise specified, ex-

and 7.2.5. An inherent limitation in solar-radiation measure- posure racks shall be oriented so that specimens face the

ments is that they do not reflect the effects of temperature and equator. Specimens can be exposed at a number of different

moisture, which are often as important as solar radiation. orientations or “exposure angles” in order to simulate end-use

conditions of the material being evaluated. Typical exposure

4.5 The design of the exposure rack, the location of the

angles are as follows:

specimen on the exposure rack, and the type or color of

5.4.1 Latitude Angle—Exposure rack is positioned so that

adjacent specimens can affect specimen temperature and time

the exposed surface of specimens are at an angle from the

of wetness. In order to minimize variability caused by these

horizontal that is equal to the geographical latitude of the

factors, it is recommended that test specimens, control speci-

exposure site.

mens, and any applicable weathering reference material be

5.4.2 45°—Exposure rack is positioned so that the exposed

placed on a single test panel or on test panels placed adjacent

specimens are at an angle of 45° from the horizontal. This is

to each other during exposure.

the most commonly used exposure orientation.

4.6 It is strongly recommended that at least one control

5.4.3 90°—Exposure rack is positioned so that the exposed

material be part of any exposure evaluation. The control

specimens are at an angle of 90° from the horizontal.

material should meet the requirements of Terminology G113,

5.4.4 5°—Exposure rack is positioned so that the exposed

and should be of similar composition and construction com-

specimens are at an angle of 5° from the horizontal.This angle

pared to test specimens. It is preferable to use two control

is preferred over horizontal exposure to avoid standing water

materials, one with relatively good durability and one with

on specimens being exposed. This exposure angle typically

relatively poor durability. Unless otherwise specified, use at

receives the highest levels of solar radiation during mid-

least two replicate specimens of each test and control material

summer and is used to test materials that would normally be

beingexposed.Controlmaterialsincludedaspartofatestshall

used in horizontal or nearly horizontal applications.

be used for the purpose of comparing the performance of test

materials relative to the controls.

NOTE 1—Exposures conducted at less than the site latitude typically

receive more ultraviolet radiation than exposures conducted at larger

5. Test Sites, Location of Test Fixtures, and Exposure angles.

Orientation

5.4.5 Any other angle that is mutually agreed on by all

5.1 Test Sites—Exposures can be conducted in any type of interested parties may be used. In some instances, exposures

facing directly away from the equator or some other specific

climate. However, in order to get more rapid indications of

outdoor durability, exposures are often conducted in locations directionmaybedesired.Thetestreportshallcontaintheexact

angle and specimen orientation of any exposure condition

that receive high levels of solar radiation, temperature, and

moisture. Typically, these conditions are found in hot desert outside of those described in 5.4.1-5.4.4.

and subtropical or tropical climates. Known attributes of the 5.5 Specimen Backing—Three types of specimen backing

use environment should be represented by the locations se- can be used. Comparisons between materials should only be

lectedforoutdoordurabilityevaluation.Forexample,iftheuse made with exposures conducted with the same specimen

environment for the product being evaluated will include backing.

freeze/thawcycling,specimenexposureinanortherntempera- 5.5.1 Unbacked Exposures—Specimens are exposed so that

ture climate is recommended. In addition, exposures are often the portion of the test specimen being evaluated is subjected to

conducted in areas where specimens are subjected to salt air the effects of the weather on all sides.

(seashore) or industrial pollutants. 5.5.2 Backed Exposures—Specimens are attached to a solid

substrate so that only the front surface is exposed. Surface

5.1.1 Unless otherwise specified, test fixtures or racks shall

temperatures of specimens in backed exposures will be higher

belocatedinclearedareas.Theareabeneathandinthevicinity

than for specimens subjected to unbacked exposures. In some

of the test fixtures should be characterized by low reflectance

cases,thesubstrateispaintedblack,whichproducessignificant

and by ground cover typical of the climatological area where

differences in surface temperature compared to exposures

the exposures are being conducted. In desert areas, the ground

conducted on unpainted substrate. This can cause large differ-

is often gravel to control dust and in most temperate areas, the

encesindegradationrateswhencomparedtobackedexposures

ground cover should be low-cut grass. The type of ground

conducted on unpainted substrates.

cover at the exposure site shall be indicated in the test report.

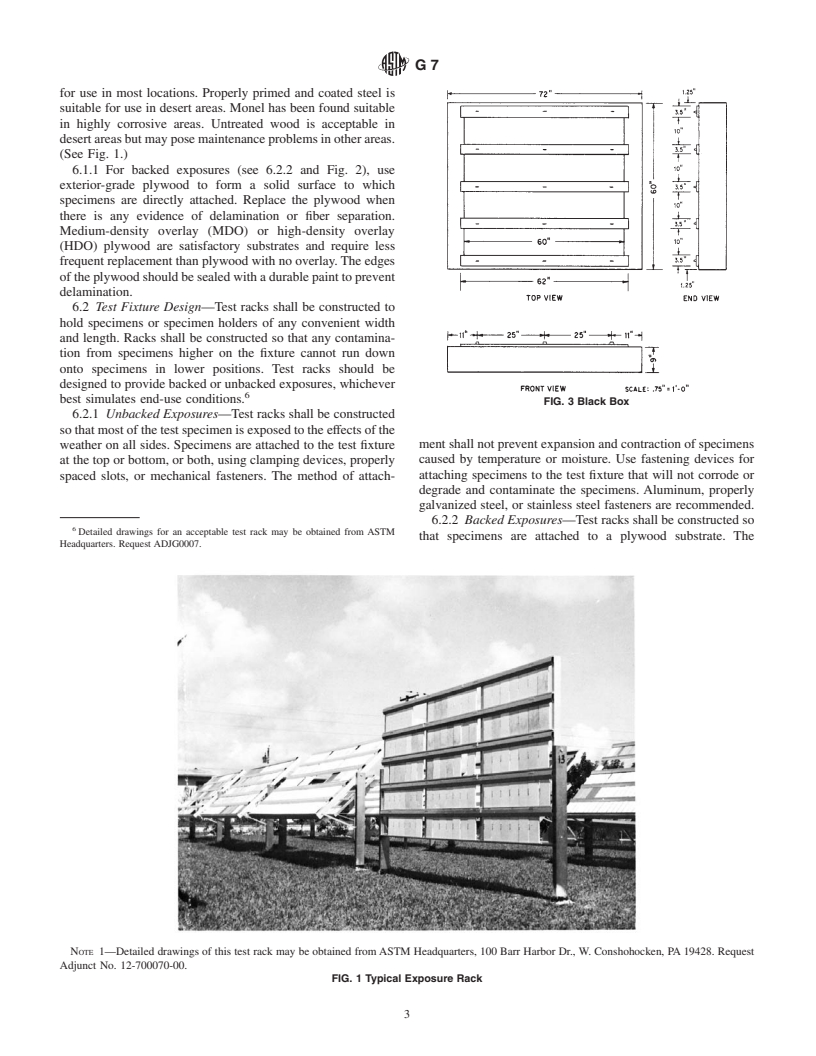

5.5.3 Black Box Exposure—Specimens are attached to the

If test fixtures are placed on a rooftop, specimens may be

front face of a black painted aluminum box (see 6.2.3). The

subjected to different environmental conditions than at ground

specimens form the top surface of the box. If there are not

level. These differences may affect test results.

enough test specimens to completely cover the top surface,

5.2 The lowest row of specimens on a test fixture or rack

open areas shall be filled with black painted sheet metal panels

shall be positioned at a height above the ground to avoid

so that the box is completely closed.

contactwithvegetationandtopreventdamagethatmightoccur

duringareamaintenance.Aminimumheightof0.45m(18in.)

6. Construction of Test Fixtures (Exposure Racks)

above the ground is recommended.

5.3 Test fixtures shall be placed in a location so that there is 6.1 Materials of Construction—All materials used for test

no shadow on any specimen when the sun’s angle of elevation fixtures shall be noncorrodible without surface treatment.

is greater than 20°. AluminumAlloys6061T6or6063T6havebeenfoundsuitable

G7

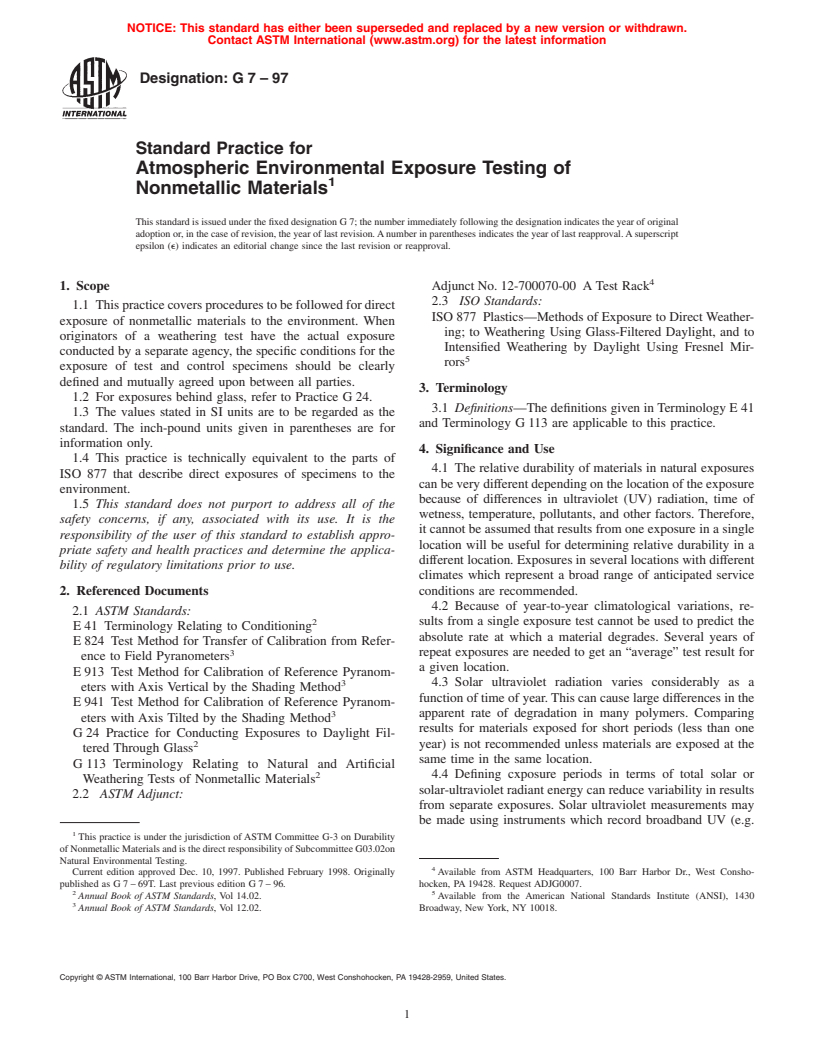

for use in most locations. Properly primed and coated steel is

suitable for use in desert areas. Monel has been found suitable

in highly corrosive areas. Untreated wood is acceptable in

desertareasbutmayposemaintenanceproblemsinotherareas.

(See Fig. 1.)

6.1.1 For backed exposures (see 6.2.2 and Fig. 2), use

exterior-grade plywood to form a solid surface to which

specimens are directly attached. Replace the plywood when

there is any evidence of delamination or fiber separation.

Medium-density overlay (MDO) or high-density overlay

(HDO) plywood are satisfactory substrates and require less

frequentreplacementthanplywoodwithnooverlay.Theedges

oftheplywoodshouldbesealedwithadurablepainttoprevent

delamination.

6.2 Test Fixture Design—Test racks shall be constructed to

hold specimens or specimen holders of any convenient width

and length. Racks shall be constructed so that any contamina-

tion from specimens higher on the fixture cannot run down

onto specimens in lower positions. Test racks should be

designed to provide backed or unbacked exposures, whichever

best simulates end-use conditions.

FIG. 3 Black Box

6.2.1 Unbacked Exposures—Test racks shall be constructed

sothatmostofthetestspecimenisexposedtotheeffectsofthe

mentshallnotpreventexpansionandcontractionofspecimens

weather on all sides. Specimens are attached to the test fixture

caused by temperature or moisture. Use fastening devices for

at the top or bottom, or both, using clamping devices, properly

attaching specimens to the test fixture that will not corrode or

spaced slots, or mechanical fasteners. The method of attach-

degrade and contaminate the specimens. Aluminum, properly

galvanized steel, or stainless steel fasteners are recommended.

6.2.2 Backed Exposures—Test racks shall be constructed so

Detailed drawings for an acceptable test rack may be obtained from ASTM

that specimens are attached to a plywood substrate. The

Headquarters. Request ADJG0007.

NOTE 1—Detailed drawings of this test rack may be obtained fromASTM Headquarters, 100 Barr Harbor Dr., W. Conshohocken, PA19428. Request

Adjunct No. 12-700070-00.

FIG. 1 Typical Exposure Rack

G7

FIG. 2 Backed Exposure Rack

FIG. 4 Black Box in Use

this type produce higher specimen temperatures than those that would be

thickness of the plywood and type of coating used shall be

seen on backed exposures conducted according to this practice.

agreed upon by all interested parties and must be reported.

6.2.3 Black Box Exposures—An aluminum box 0.23 m (9

NOTE 2—Backed exposures as described in this standard are not

in.) deep with the outside surface painted black. The top

insulatedexposures.Forsomeapplicationssuchasoutdoorexposuretests

surface is open and fitted with mounting strips to hold

for roofing products, a layer of insulation material is attached behind the

solid substrate to which specimens are attached. Insulated exposures of specimens firmly in place. Two types of black boxes are in

G7

common usage. One measures approximately 1.5 m (5 ft) high −1). If requested, a certificate of calibration shall be provided

and1.8m(6ft)wideandtheothermeasures1.7m(5.5ft)high with all total solar ultraviolet irradiance measurements.

and3.7m(12ft)wide.Fig.3showsthedesignanddimensions

7.2.5 Narrow-Band Solar Ultraviolet Radiation—

for an acceptable black box. Fig. 4 shows a black box in use. Narrowband radiometers can be used to measure specific

wavelength bands of solar ultraviolet radiation. Unless other-

, ,

7 8 9

7. Instrumentation

wise specified, (for example, when measuring solar UV radia-

tion with a wavelength greater than 315 nm), narrow-band UV

7.1 Instruments for determining climatological data during

radiometers shall, when used to time or monitor outdoor

the exposure period should be operated in the immediate

exposure testing, have response functions in the UV-B region

vicinity of the test racks. Data obtained shall be reported if

defined as 280

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.