ASTM D5385/D5385M-20

(Test Method)Standard Test Method for Hydrostatic Pressure Resistance of Waterproofing Membranes

Standard Test Method for Hydrostatic Pressure Resistance of Waterproofing Membranes

SIGNIFICANCE AND USE

3.1 This test method tests the hydrostatic resistance of a waterproofing membrane and can be used to compare the hydrostatic resistance of waterproofing membranes.

3.2 No correlation has been established between the performance in this test method and that in the field.

SCOPE

1.1 This test method measures the hydrostatic resistance of a waterproofing membrane under controlled laboratory conditions. This test method is not suitable for systems that rely on confinement of the seams by the backfill since backfill is not part of this test method.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D5385/D5385M −20

Standard Test Method for

Hydrostatic Pressure Resistance of Waterproofing

1

Membranes

This standard is issued under the fixed designation D5385/D5385M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 No correlation has been established between the perfor-

mance in this test method and that in the field.

1.1 This test method measures the hydrostatic resistance of

a waterproofing membrane under controlled laboratory condi-

4. Apparatus

tions. This test method is not suitable for systems that rely on

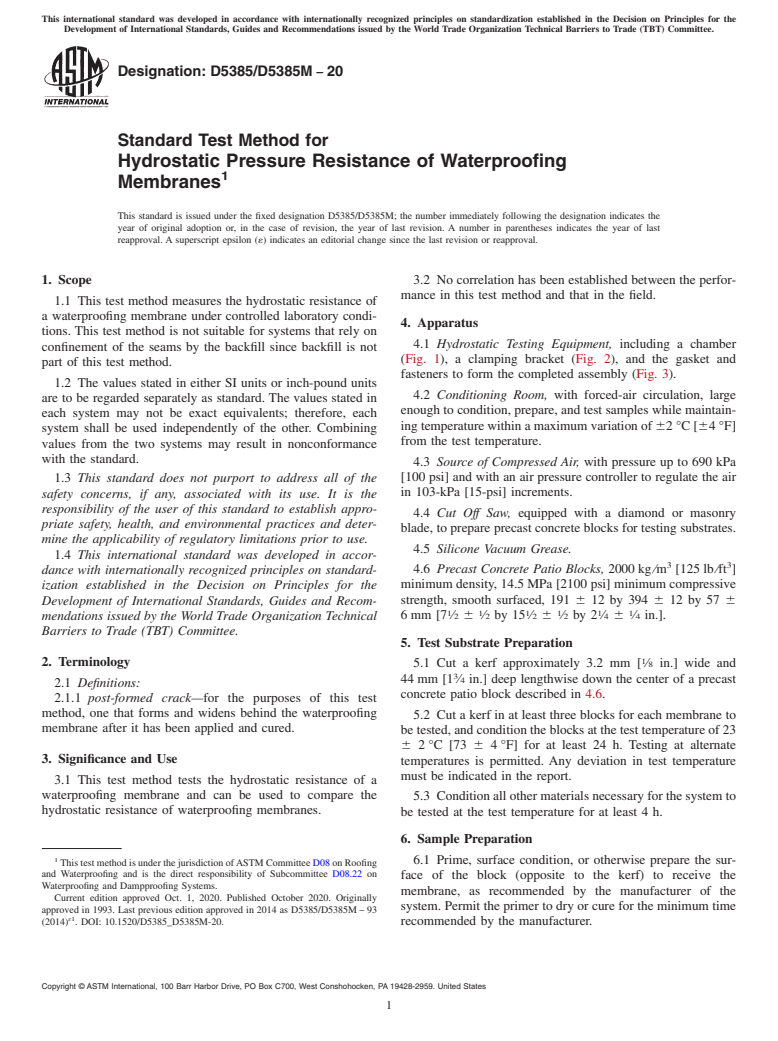

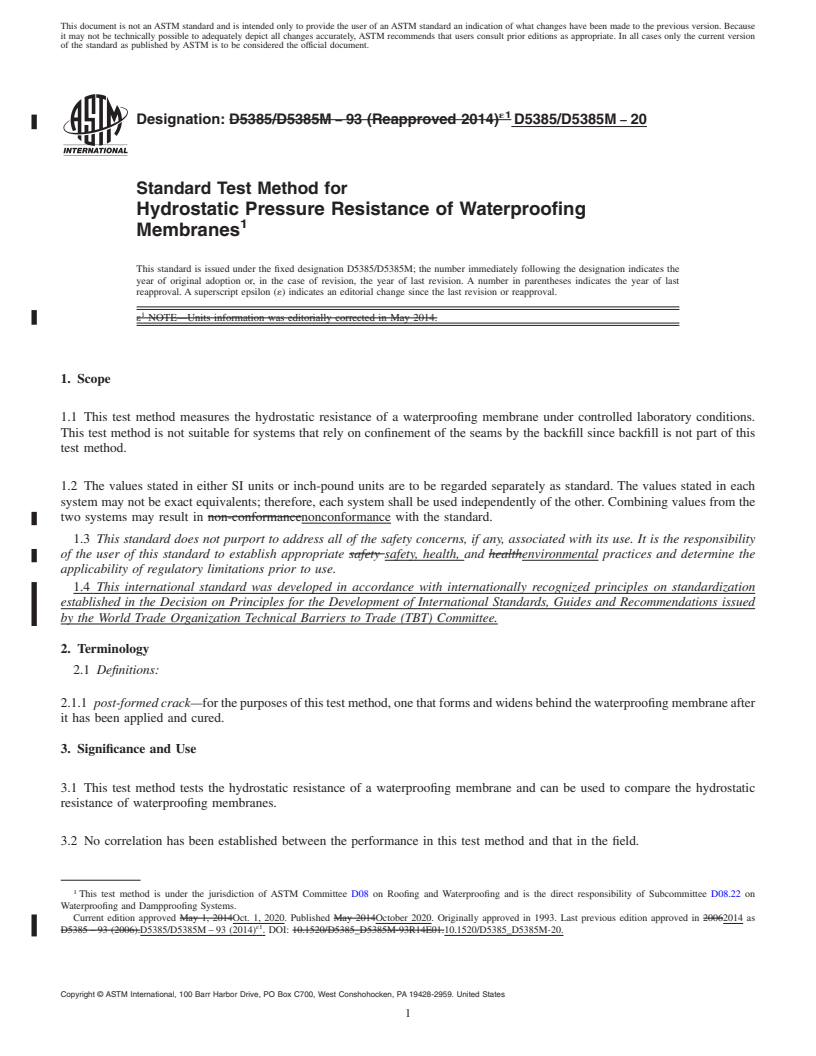

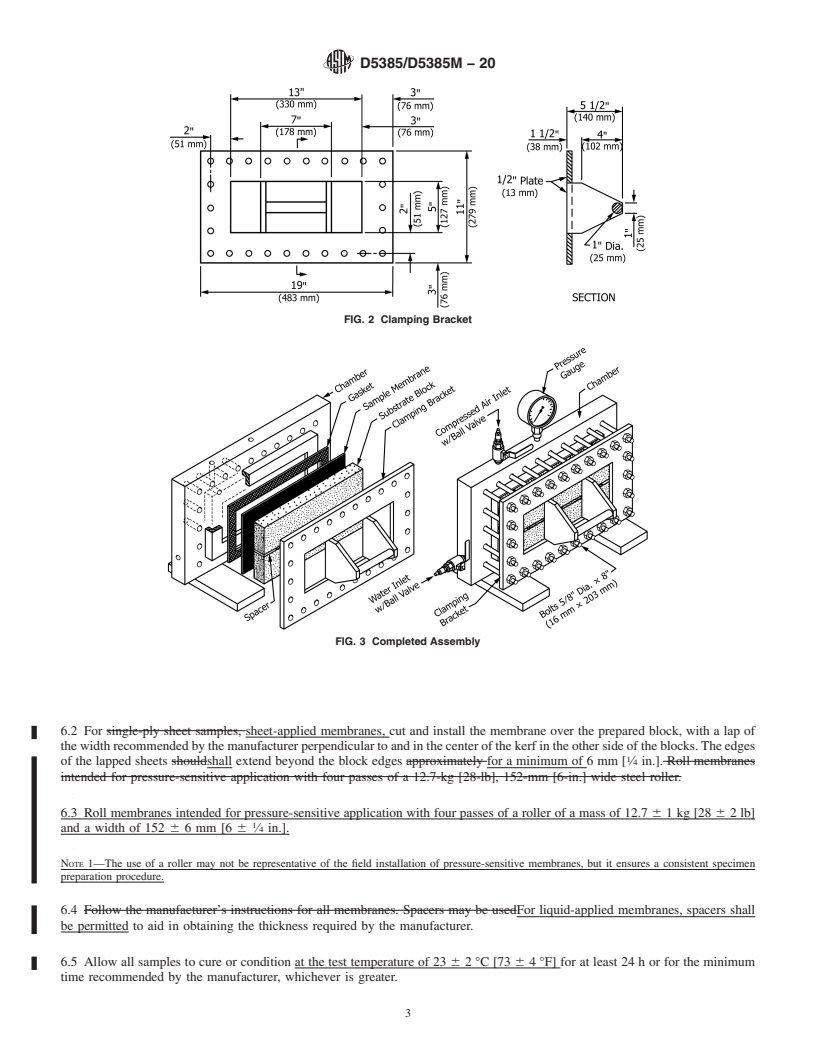

4.1 Hydrostatic Testing Equipment, including a chamber

confinement of the seams by the backfill since backfill is not

(Fig. 1), a clamping bracket (Fig. 2), and the gasket and

part of this test method.

fasteners to form the completed assembly (Fig. 3).

1.2 The values stated in either SI units or inch-pound units

4.2 Conditioning Room, with forced-air circulation, large

are to be regarded separately as standard. The values stated in

enough to condition, prepare, and test samples while maintain-

each system may not be exact equivalents; therefore, each

ing temperature within a maximum variation of 62°C[64 °F]

system shall be used independently of the other. Combining

from the test temperature.

values from the two systems may result in nonconformance

with the standard.

4.3 Source of Compressed Air, with pressure up to 690 kPa

[100 psi] and with an air pressure controller to regulate the air

1.3 This standard does not purport to address all of the

in 103-kPa [15-psi] increments.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.4 Cut Off Saw, equipped with a diamond or masonry

priate safety, health, and environmental practices and deter-

blade, to prepare precast concrete blocks for testing substrates.

mine the applicability of regulatory limitations prior to use.

4.5 Silicone Vacuum Grease.

1.4 This international standard was developed in accor-

3 3

4.6 Precast Concrete Patio Blocks, 2000 kg⁄m [125 lb⁄ft ]

dance with internationally recognized principles on standard-

minimum density, 14.5 MPa [2100 psi] minimum compressive

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- strength, smooth surfaced, 191 6 12 by 394 6 12 by 57 6

1 1 1 1 1 1

6mm[7 ⁄2 6 ⁄2 by 15 ⁄2 6 ⁄2 by 2 ⁄4 6 ⁄4 in.].

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

5. Test Substrate Preparation

1

2. Terminology

5.1 Cut a kerf approximately 3.2 mm [ ⁄8 in.] wide and

3

44 mm [1 ⁄4 in.] deep lengthwise down the center of a precast

2.1 Definitions:

concrete patio block described in 4.6.

2.1.1 post-formed crack—for the purposes of this test

method, one that forms and widens behind the waterproofing

5.2 Cut a kerf in at least three blocks for each membrane to

membrane after it has been applied and cured.

be tested, and condition the blocks at the test temperature of 23

6 2 °C [73 6 4 °F] for at least 24 h. Testing at alternate

3. Significance and Use

temperatures is permitted. Any deviation in test temperature

must be indicated in the report.

3.1 This test method tests the hydrostatic resistance of a

waterproofing membrane and can be used to compare the 5.3 Condition all other materials necessary for the system to

hydrostatic resistance of waterproofing membranes.

be tested at the test temperature for at least 4 h.

6. Sample Preparation

1

6.1 Prime, surface condition, or otherwise prepare the sur-

This test method is under the jurisdiction ofASTM Committee D08 on Roofing

and Waterproofing and is the direct responsibility of Subcommittee D08.22 on

face of the block (opposite to the kerf) to receive the

Waterproofing and Dampproofing Systems.

membrane, as recommended by the manufacturer of the

Current edition approved Oct. 1, 2020. Published October 2020. Originally

system. Permit the primer to dry or cure for the minimum time

approved in 1993. Last previous edition approved in 2014 as D5385/D5385M – 93

ɛ1

(2014) . DOI: 10.1520/D5385_D5385M-20. recommended by the manufacturer.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5385/D5385M−20

FIG. 1 Chamber

FIG. 2 Clamping Bracket

FIG. 3 Completed Assembly

6.2 For sheet-applied membranes, cut and install the me

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D5385/D5385M − 93 (Reapproved 2014) D5385/D5385M − 20

Standard Test Method for

Hydrostatic Pressure Resistance of Waterproofing

1

Membranes

This standard is issued under the fixed designation D5385/D5385M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Units information was editorially corrected in May 2014.

1. Scope

1.1 This test method measures the hydrostatic resistance of a waterproofing membrane under controlled laboratory conditions.

This test method is not suitable for systems that rely on confinement of the seams by the backfill since backfill is not part of this

test method.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformancenonconformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Terminology

2.1 Definitions:

2.1.1 post-formed crack—for the purposes of this test method, one that forms and widens behind the waterproofing membrane after

it has been applied and cured.

3. Significance and Use

3.1 This test method tests the hydrostatic resistance of a waterproofing membrane and can be used to compare the hydrostatic

resistance of waterproofing membranes.

3.2 No correlation has been established between the performance in this test method and that in the field.

1

This test method is under the jurisdiction of ASTM Committee D08 on Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.22 on

Waterproofing and Dampproofing Systems.

Current edition approved May 1, 2014Oct. 1, 2020. Published May 2014October 2020. Originally approved in 1993. Last previous edition approved in 20062014 as

ɛ1

D5385 – 93 (2006).D5385/D5385M – 93 (2014) . DOI: 10.1520/D5385_D5385M-93R14E01.10.1520/D5385_D5385M-20.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5385/D5385M − 20

4. Apparatus

4.1 Hydrostatic Testing Equipment, including a chamber (Fig. 1), and a clamping bracket (Fig. 2), and the gasket and fasteners

to form the completed assembly (Fig. 3).

4.2 Conditioning Room, with forced air circulation to maintain a temperature of 2 to 7°C [35 to 45°F] for testing sheet systems,

18 to 24°C [65 to 75°F] for liquid-applied systems, and large enough to condition, prepare, and test samples.forced-air circulation,

large enough to condition, prepare, and test samples while maintaining temperature within a maximum variation of 62 °C [64 °F]

from the test temperature.

4.3 Source of Compressed Air, with pressure up to 690 kPa [100 psi] and with an air pressure controller to regulate the air in

103-kPa [15-psi] increments.

4.4 Cut Off Saw, equipped with a diamond or masonry blade, to prepare precast concrete blocks for testing substrates.

4.5 Clock—Either a common time piece or a 1-h interval timer.

4.5 Silicone Vacuum Grease.

3 3

4.6 Precast-Concrete Precast Concrete Patio Blocks, 125-lb/ft2000 kg ⁄m [125 lb ⁄ft ] minimum density, 2100-psi 14.5 MPa

1 1 1

[2100 psi] minimum compressive strength, smooth surfaced, 191 6 12 by 394 by 51 mm 6 12 by 57 6 6 mm [7 ⁄2 6 ⁄2 by 15 ⁄2

1 1 1

6 ⁄2 by 2 ⁄4 6 ⁄4 in.].

5. Test Substrate Preparation

1 3

5.1 Cut an approximately 3.2-mm a kerf approximately 3.2 mm [ ⁄8-in.] wide kerf 44 mm in.] wide and 44 mm [1 ⁄4 in.] deep

1 1

lengthwise down the center of a 191 by 394 by 51-mm [7precast concrete patio block described in ⁄2 4.6by 15. ⁄2 by 2-in.] concrete

block.

5.2 Cut a kerf in at least three blocks for each s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.