ASTM C1464-06(2011)

(Specification)Standard Specification for Bent Glass

Standard Specification for Bent Glass

ABSTRACT

This specification covers the standard for bent glass proposed for use in general building construction, furniture, display, and various other non-automotive applications. When the glass is specified as chemically strengthened, heat-strengthened, or fully tempered, the fabrication processes must be completed prior to the strengthening. The glass specimen shall also undergo impact testing for safety glazing.

SCOPE

1.1 This specification covers the requirements for bent glass used in general building construction, furniture, display, and various other non-automotive applications.

1.2 The dimensional values, stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 7, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1464 −06(Reapproved 2011)

Standard Specification for

Bent Glass

This standard is issued under the fixed designation C1464; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 Refer to Terminology C162, Specifications C1036,

C1422, and C1172, as appropriate.

1.1 This specification covers the requirements for bent glass

3.1.2 Blemishes in Flat Glass—Refer to Specifications

used in general building construction, furniture, display, and

C1036, C1048, C1422, and C1172, as appropriate.

various other non-automotive applications.

3.2 Definitions of Terms Specific to This Standard:

1.2 The dimensional values, stated in SI units are to be

3.2.1 bent glass, n—flatglassthathasbeenshapedwhilehot

regarded as the standard. The values given in parentheses are

into a body having curved surfaces.

provided for information only.

3.2.2 chord, n—a straight line segment that joins two points

1.3 The following safety hazards caveat pertains only to the

of an arc.

test method portion, Section 7, of this specification. This

standard does not purport to address all of the safety concerns,

3.2.3 compound bend, n—a profile shape composed of

if any, associated with its use. It is the responsibility of the user

curvature of one or more radii, curved on two or more axes.

of this standard to establish appropriate safety and health

3.2.4 crossbend, n—deviation from a straight edge along a

practices and determine the applicability of regulatory limita-

line perpendicular to the curvature measured on the concave

tions prior to use.

side.

3.2.5 cylindrical bend, n—a profile shape composed of a

2. Referenced Documents

singlecurvaturewithaconstantradiusandnostraightsections,

2.1 ASTM Standards:

all curved on a single axis.

C162 Terminology of Glass and Glass Products

3.2.6 degree of angle, n—the angular measurement of a

C1036 Specification for Flat Glass

segment of a curve.

C1048 Specification for Heat-Strengthened and Fully Tem-

pered Flat Glass

3.2.7 depth, n—on a circular bend, the distance from the

C1172 Specification for Laminated Architectural Flat Glass

midpoint of a chord to the arc measured along its radius

C1422 Specification for Chemically Strengthened Flat Glass

perpendicular to the circumference.

2.2 Federal Document:

3.2.8 elliptical bend, n—a curved profile shape composed of

CPSC 16 CFR 1201 Consumer Product Safety Commission

two or more tangential radii on a single axis.

Safety Standard for Architectural Glazing Material

3.2.9 girth, n—the distance around the concave or convex

surface measured perpendicular to the height including any

3. Terminology

flats.

3.1 Definitions:

3.2.10 height, n—the length measurement of the edge per-

pendicular to the horizontal arc or girth.

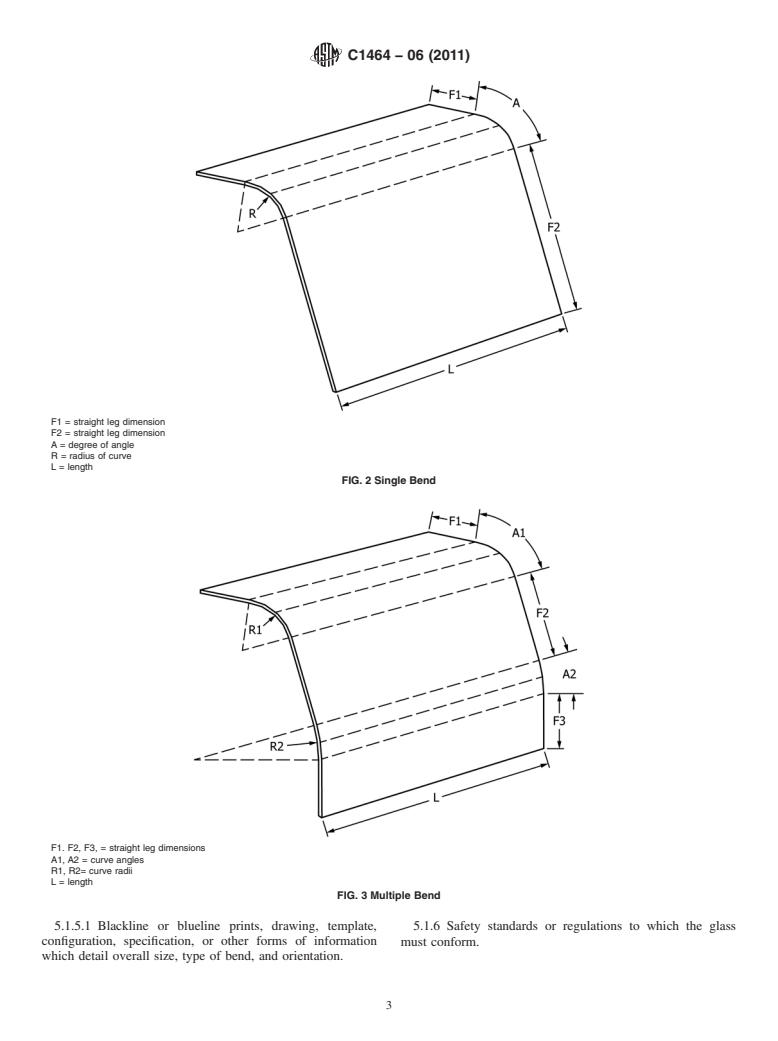

3.2.11 multiple bend, n—a profile shape composed of a

This specification is under the jurisdiction of ASTM Committee C14 on Glass

curvature of two or more radii, all curved on a single axis, with

and Glass Products and is the direct responsibility of Subcommittee C14.08 on Flat

Glass. at least two of the curvatures possibly separated by a flat

Current edition approved Oct. 1, 2011. Published October 2011. Originally

(plane) area, and with or without one or more additional flat

approved in 2000. Last previous edition approved in 2006 as C1464-06. DOI:

(plane) areas tangent to the curvatures.

10.1520/C1464-06R11.

Reference to these standards shall be the latest revision unless otherwise

3.2.12 pock marks, n—process surface blemishs that consist

specified by the authority applying this specification.

of small, shallow areas, circular in shape, on the surface of the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

glass.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

3.2.13 Ring marks—process surface blemishs that consist of

the ASTM website.

shallow marks typically running along the perimeter of the

Available from the Superintendent of Documents, U.S. Government Printing

Office, Washington, DC 20402. glass surface.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1464−06 (2011)

3.2.14 Rotation—a condition where vertical edges (perpen- fied for bent glass and in accordance with the applicable

dicular to arc) are not parallel to bending axis. requirements of Specification C1048 for fully tempered glass.

4.1.4 Kind BHS—Heat-strengthened bent glass shall be flat

3.2.15 Serpentine bend—profile shape composed of con-

glass, either transparent or patterned, in accordance with the

cave and convex curvatures of one or more radii on a single

applicable requirements of Specification C1036, as further

axis with or without flat areas tangent to the curvatures.

processed to conform with the requirements hereinafter speci-

3.2.16 Shape—contoured form including curvature, arc(s),

fied for bent glass and in accordance with the applicable

and even flats.

requirements of Specification C1048 for heat-strengthened

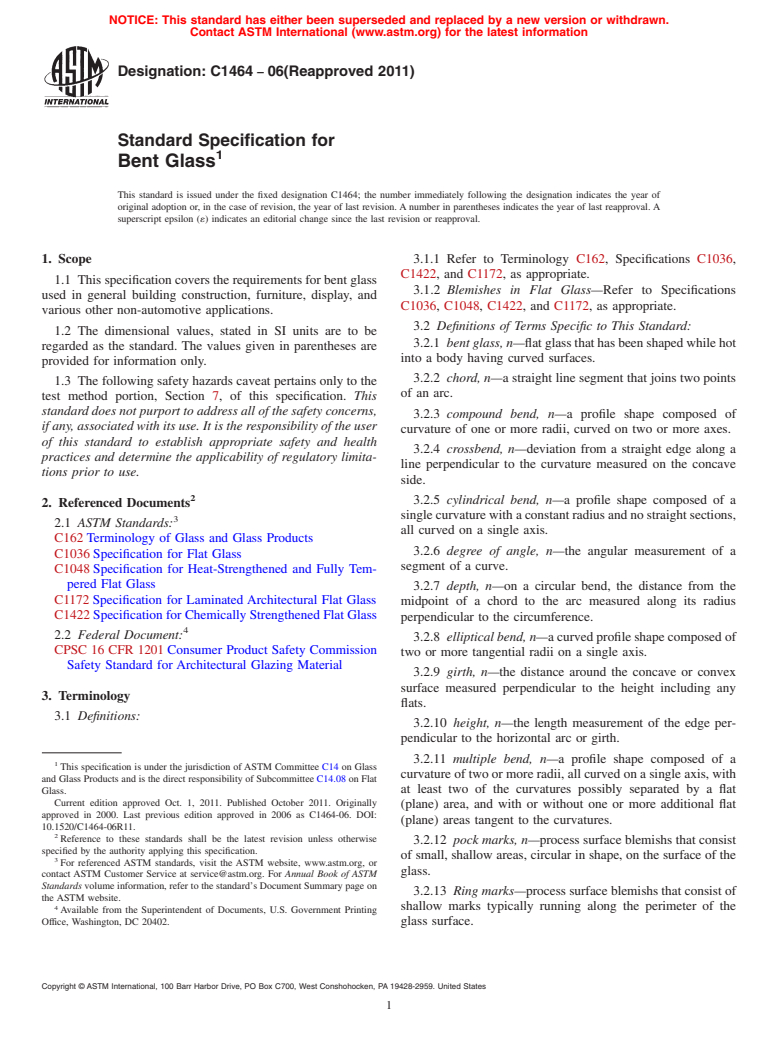

3.2.17 Single bend—a profile composed of a single radius

glass.

curved on a single axis, possibly with one or two flat (plane)

4.1.5 Kind BL—Laminated bent glass shall be flat glass,

areas tangent to the curvature.

either transparent or patterned, in accordance with the appli-

3.2.18 Twist—one or more of the corners of the glass are not

cablerequirementsofSpecificationC1036asfurtherprocessed

in the same plane.

withtherequirementshereinafterspecifiedforbentglassandin

accordance with the applicable requirements of Specification

4. Classification

C1172 for laminated glass.

4.1 Kinds—Bent glass furnished under this specification

4.1.6 Kind BX—Bent glass with miscellaneous combina-

shall be of the following kinds, as specified:

tions not previously combined.

4.1.1 Kind BA—Bent glass shall be annealed flat glass,

either transparent, patterned, or wired glass in accordance with

5. Ordering Information

the applicable requirements of Specification C1036, as further

5.1 Purchasers should include the following information in

processed to conform with the requirements hereinafter speci-

procurement documents:

fied for bent glass.

5.1.1 Title, number, and date of this specification.

4.1.2 Kind BCS—Chemically strengthened bent glass shall

be flat glass, either transparent or patterned, in accordance with 5.1.2 Kind of bent glass as referred to in this specification

the applicable requirements of Specification C1036, as further (see Section 4).

processed to conform with the requirements hereinafter speci-

5.1.3 Fabrication requirements (see Section 6).

fied for bent glass and in accordance with the applicable

5.1.4 Thickness Requirements:

requirements of Specification C1422 for chemically strength-

5.1.4.1 Overall thickness designation.

ened flat glass.

5.1.4.2 Thickness of individual lites in the laminate.

4.1.3 Kind BFT—Fully tempered bent glass shall be flat

5.1.4.3 Interlayer thickness and type.

glass, either transparent or patterned, in accordance with the

applicable requirements of Specification C1036, as further 5.1.5 Nominal height, width, radius (see definitions and

processed to conform with the requirements hereinafter speci- Figs. 1-3).

A = outside radius

B = chord

C = height

D = girth

E = depth

FIG. 1Cylindrical Be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.