ASTM A524-96(2012)

(Specification)Standard Specification for Seamless Carbon Steel Pipe for Atmospheric and Lower Temperatures

Standard Specification for Seamless Carbon Steel Pipe for Atmospheric and Lower Temperatures

ABSTRACT

This specification covers seamless carbon steel pipe intended primarily service at atmospheric and lower temperatures. The steel shall be killed steel made by one or more of the following processes: open-hearth, electric-furnace, or basic-oxygen. The steel shall be made to fine grain practice and may be cast in ingots or may be strand cast. All hot-finished and cold-drawn pipe shall be heat treated and be cooled in air or in the cooling chamber of a controlled atmosphere furnace. The steel shall be subjected to flattening, hydrostatic, bend, and tensile tests. A retest shall be conducted if a specimen breaks in an inside or outside surface flaw.

SCOPE

1.1 This specification2 covers seamless carbon steel pipe intended primarily for service at atmospheric and lower temperatures, NPS 1/8 to 26 inclusive, with nominal (average) wall thickness as given in ANSI B36.10. Pipe having other dimensions may be furnished, provided such pipe complies with all other requirements of this specification. Pipe ordered to this specification shall be suitable both for welding, and for bending, flanging, and similar forming operations.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. Note 1—The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as “nominal diameter,” “size,” and “nominal size.”

1.3 The following hazard caveat applies to the test methods portion, Section 16, only. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A524 −96 (Reapproved 2012)

Standard Specification for

Seamless Carbon Steel Pipe for Atmospheric and Lower

Temperatures

This standard is issued under the fixed designation A524; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 American National Standards Institute Standard:

B36.10Welded and Seamless Wrought Steel Pipe

1.1 This specification covers seamless carbon steel pipe

intended primarily for service at atmospheric and lower

3. Ordering Information

temperatures, NPS ⁄8 to 26 inclusive, with nominal (average)

3.1 Orders for material under this specification should

wall thickness as given in ANSI B36.10. Pipe having other

include the following, as required, to describe the desired

dimensions may be furnished, provided such pipe complies

material adequately:

with all other requirements of this specification. Pipe ordered

3.1.1 Quantity (feet or number of lengths),

to this specification shall be suitable both for welding, and for

3.1.2 Name of material (seamless carbon steel pipe),

bending, flanging, and similar forming operations.

3.1.3 Grade (Table 1 and Table 2),

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

3.1.4 Manufacture (hot finished or cold drawn),

as standard. The values given in parentheses are mathematical

3.1.5 Size(eithernominalwallthicknessandweightclassor

conversions to SI units that are provided for information only

schedule number, or both, or outside diameter and nominal

and are not considered standard.

wall thickness, ANSI B36.10),

3.1.6 Length (17),

NOTE 1—The dimensionless designator NPS (nominal pipe size) has

3.1.7 Optional requirements ( Section 8 and Section 11 of

been substituted in this standard for such traditional terms as “nominal

diameter,” “size,” and “nominal size.” Specification A530/A530M),

3.1.8 Test report required (Certification Section of Specifi-

1.3 The following hazard caveat applies to the test methods

cation A530/A530M),

portion, Section 16, only. This standard does not purport to

3.1.9 Specification designation,

address all of the safety concerns, if any, associated with its

3.1.10 End use of material, and

use. It is the responsibility of the user of this standard to

3.1.11 Special requirements.

establish appropriate safety and health practices and deter-

mine the applicability of regulatory limitations prior to use.

4. General Requirements

4.1 Material furnished to this specification shall conform to

2. Referenced Documents

the applicable requirements of the current edition of Specifi-

2.1 ASTM Standards:

cation A530/A530M unless otherwise provided herein.

A530/A530MSpecification for General Requirements for

Specialized Carbon and Alloy Steel Pipe

5. Materials and Manufacture

E29Practice for Using Significant Digits in Test Data to

5.1 Process:

Determine Conformance with Specifications

5.1.1 The steel shall be killed steel made by one or more of

the following processes: open-hearth, electric-furnace, or

basic-oxygen.

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

5.1.2 The steel shall be made to fine grain practice.

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

5.1.3 Steel may be cast in ingots or may be strand cast.

A01.09 on Carbon Steel Tubular Products.

When steel of different grades are sequentially strand cast,

Current edition approved March 1, 2012. Published November 2012. Originally

approved in 1965. Last previous edition approved in 2005 as A524–96 (2005). identification of the resultant transition material is required.

DOI: 10.1520/A0524-96R12.

The producer shall remove the transition material by any

For ASME Boiler and Pressure Vessel Code Applications see related Specifi-

established procedure that positively separates the grades.

cation SA-524 in Section II of that Code.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute, 11 West 42nd St., 13th

the ASTM website. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A524−96 (2012)

TABLE 1 Chemical Requirements

180° around a cylindrical mandrel, the diameter of which is

Element Grades I and II, Composition, % eight times the nominal diameter of the pipe, without failure.

Carbon, max 0.21

9.2.2 Forpipewhosediameterexceeds25in.(635mm)and

Manganese 0.90–1.35

whose diameter to wall thickness ratio is 7.0 or less, bend test

Phosphorus, max 0.035

specimens shall be bent at room temperature through 180°

Sulfur, max 0.035

Silicon 0.10–0.40 without cracking on the outside of the bent portion.The inside

diameterofthebendshallbe1in.(25.4mm).Thistestshallbe

in place of Section 10.

NOTE 3—Diameter to wall thickness ratio = specified outside diameter/

5.1.4 PipeNPS1 ⁄2 andundermaybeeitherhotfinishedor

nominal wall thickness.

cold drawn.

Example: For 28 in. diameter 5.000 in. thick pipe the diameter to wall

5.1.5 Unless otherwise specified, pipe NPS 2 and over shall thickness ratio = 28/5 = 5.6.

be furnished hot finished. When agreed upon between the

manufacturer and purchaser, cold-drawn pipe may be fur- 10. Flattening Test Requirements

nished.

10.1 ForpipeoverNPS2,asectionofpipenotlessthan2 ⁄2

5.2 Heat Treatment—All hot-finished and cold-drawn pipe in.(63.5mm)inlengthshallbeflattenedcoldbetweenparallel

shall be reheated to a temperature above 1550 °F (845°C) and platesuntiltheoppositewallsofthepipemeet.Flatteningtests

followed by cooling in air or in the cooling chamber of a shallbeinaccordancewithSpecificationA530/A530M,except

controlled atmosphere furnace. thatintheequationusedtocalculatetheHvalue,thefollowing

e constants shall be used:

6. Chemical Composition

0.07 for Grade I

0.08 for Grade II

6.1 The steel shall conform to the chemical requirements

prescribed in Table 1. 10.2 When low D-to-t ratio tubulars are tested, because the

strain imposed due to geometry is unreasonably high on the

7. Heat Analysis

insidesurfaceatthe6and12o’clocklocations,cracksatthese

locations shall not be cause for rejection if the D-to-t ratio is

7.1 An analysis of each heat of steel shall be made by the

less than ten.

steel manufacturer to determine the percentages of the ele-

ments specified in Section 6. The chemical composition thus

11. Hydrostatic Test Requirements

determined, or that determined from a product analysis made

by the manufacturer, if the latter has not manufactured the

11.1 Each length of pipe shall be subjected to the hydro-

steel, shall be reported to the purchaser or the purchaser’s

static pressure, except as provided in 11.2.

representative, and shall conform to the requirements specified

11.2 When specified in the order, pipe may be furnished

in Section 6.

without hydrostatic testing and each length so furnished shall

include with the mandatory marking the letters “NH.”

8. Product Analysis

11.3 When certification is required by the purchaser and the

8.1 At the request of the purchaser, analyses of two pipes

hydrostatic test has been omitted, the certification shall clearly

fromeachlot(Note2)shallbemadebythemanufacturerfrom

state “Not Hydrostatically Tested,” and the specification num-

the finished pipe. The chemical composition thus determined

ber and grade designation, as shown on the certification, shall

shall conform to the requirements specified in Section 6.

be followed by the letters “NH.”

NOTE2—Alotshallconsistof400lengths,orfractionthereof,foreach

size NPS 2 up to but not including NPS 6, and of 200 lengths, or fraction

12. Dimensions and Weights

thereof, for each size NPS 6 and over.

12.1 The dimensions and weights of plain-end pipe are

8.2 If the analysis of one of the tests specified in 8.1 does

included in ANSI B36.10. Sizes and wall thicknesses most

not conform to the requirements specified in 6, analyses shall

generally available are listed in Appendix X1.

bemadeonadditionalpipeofdoubletheoriginalnumberfrom

the same lot, each of which shall conform to requirements

13. Dimensions, Weight, and Permissible Variations

specified.

13.1 Weight—The weight of any length of pipe shall not

9. Physical Properties

vary more than 6.5% over and 3.5% under that specified for

pipe of Schedule 120 and lighter nor more than 10% over and

9.1 Tensile Properties—The material shall conform to the

requirements as to tensile properties prescribed in Table 2. 3.5% under that specified for pipe heavier than Schedule 120.

Unless otherwise agreed upon between the manufacturer and

9.2 Bending Properties:

purchaser, pipe in sizes NPS 4 and smaller may be weighed in

9.2.1 For pipe NPS 2 and under, a sufficient length of pipe

convenient lots; pipe in sizes larger than NPS 4 shall be

shall stand being bent cold through 90° around a cylindrical

weighed separately.

mandrel, the diameter of which is twelve times the nominal

diameterofthepipe,withoutdevelopingcracks.Whenordered 13.2 Diameter—Variations in outside diameter shall not

for close coiling, the pipe shall stand being bent cold through exceed those specified in Table 3.

A524−96 (2012)

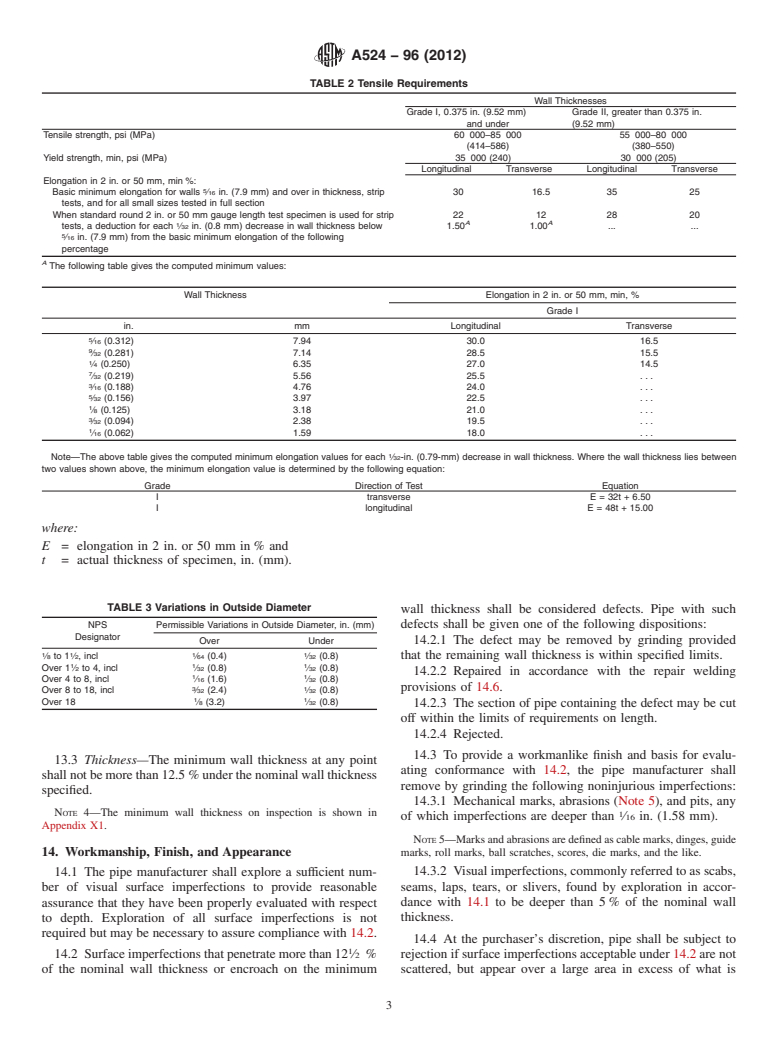

TABLE 2 Tensile Requirements

Wall Thicknesses

Grade I, 0.375 in. (9.52 mm) Grade II, greater than 0.375 in.

and under (9.52 mm)

Tensile strength, psi (MPa) 60 000–85 000 55 000–80 000

(414–586) (380–550)

Yield strength, min, psi (MPa) 35 000 (240) 30 000 (205)

Longitudinal Transverse Longitudinal Transverse

Elongation in 2 in. or 50 mm, min %:

Basic minimum elongation for walls ⁄16 in. (7.9 mm) and over in thickness, strip 30 16.5 35 25

tests, and for all small sizes tested in full section

When standard round 2 in. or 50 mm gauge length test specimen is used for strip 22 12 28 20

A A

tests, a deduction for each ⁄32 in. (0.8 mm) decrease in wall thickness below 1.50 1.00 . .

⁄16 in. (7.9 mm) from the basic minimum elongation of the following

percentage

A

The following table gives the computed minimum values:

Wall Thickness Elongation in 2 in. or 50 mm, min, %

Grade I

in. mm Longitudinal Transverse

⁄16 (0.312) 7.94 30.0 16.5

⁄32 (0.281) 7.14 28.5 15.5

⁄4 (0.250) 6.35 27.0 14.5

⁄32 (0.219) 5.56 25.5 . . .

⁄16 (0.188) 4.76 24.0 . . .

⁄32 (0.156) 3.97 22.5 . . .

⁄8 (0.125) 3.18 21.0 . . .

⁄32 (0.094) 2.38 19.5 . . .

⁄16 (0.062) 1.59 18.0 . . .

Note—The above table gives the computed minimum elongation values for each ⁄32-in. (0.79-mm) decrease in wall thickness. Where the wall thickness lies between

two values shown above, the minimum elongation value is determined by the following equation:

Grade Direction of Test Equation

I transverse E = 32t + 6.50

I longitudinal E = 48t + 15.00

where:

E = elongation in 2 in. or 50 mm in% and

t = actual thickness of specimen, in. (mm).

TABLE 3 Variations in Outside Diameter

wall thickness shall be considered defects. Pipe with such

NPS Permissible Variations in Outside Diameter, in. (mm) defects shall be given one of the following dispositions:

Designator

Over Under 14.2.1 The defect may be removed by grinding provided

1 1 1 1

⁄8 to 1 ⁄2, incl ⁄64 (0.4) ⁄32 (0.8)

that the remaining wall thickness is within specified limits.

1 1 1

Over 1 ⁄2 to 4, incl ⁄32 (0.8) ⁄32 (0.8)

14.2.2 Repaired in accordance with the repair welding

1 1

Over 4 to 8, incl ⁄16 (1.6) ⁄32 (0.8)

3 1 provisions of 14.6.

Over 8 to 18, incl ⁄32 (2.4) ⁄32 (0.8)

1 1

Over 18 ⁄8 (3.2) ⁄32 (0.8)

14.2.3 The section of pipe containing the defect may be cut

off within the limits of requirements on length.

14.2.4 Rejected.

14.3 To provide a workmanlike finish and basis for evalu-

13.3 Thickness—The minimum wall thickness at any point

ating conformance with 14.2, the pipe manufacturer shall

shallnotbemorethan12.5%underthenominalwallthickness

remove by grinding the following noninjurious imperfections:

specified.

14.3.1 Mechanical marks, abrasions (Note 5), and pits, any

NOTE 4—The minimum wall thickness on inspection is shown in

of which imperfections are deeper than ⁄16 in. (1.58 mm).

Appendix X1.

NOTE5—Marksandabrasionsaredefinedascablemarks,dinges,guide

14. Workmanship, Finish, and Appearance marks, roll marks, ball scratches, scores, die marks, and the like.

14.1 The pipe manufacturer shall explore a sufficient num- 14.3.2 Visualimperfections,commonlyreferredtoasscabs,

seams, laps, tears, or slivers, found by exploration in accor-

ber of visual surface imperfections to provide reasonable

assurance that they have been properly evaluated with respect dance with 14.1 to be deeper than 5% of the nominal wall

thickness.

to depth. Exploration of all surface imperfections is not

required but may be necessary to assure compliance with 14.2.

14.4 At the purchaser’s discretion, pipe shall be subject to

14.2 Surfaceimperfectionsthatpenetratemorethan12 ⁄2 % rejectionifsurfaceimperfectionsacceptableunder14.2arenot

of the nominal wall thickness or encroach on the minimum scattered, but appear over a large area in excess of what is

A524−96 (2012)

consideredaworkmanlikefinish.Dispositionofsuchpipeshall shallbetakeninatransversedirection.Onetestspecimenshall

be a matter of agreement between the manufacturer and the be taken as close to the outer surface as possible and another

purchaser. from as close to the inner surface as possible. The specimens

1 1 1

shall be either ⁄2 by ⁄2 in. (12.7 mm) in section or 1 by ⁄2 in.

14.5 When imperfections or defects are removed by

(25.4 by 12.7 mm) in section with the corners rounded to a

grinding, a smooth curved surface shall be maintained, and the

radius not over ⁄16 in. (1.6 mm) and need not exceed 6 in.

wall thickness shall not be decreased below that permitted by

(152mm) in length. The side of the samples placed in tension

thisspecification.Theoutsidediameteratthepointofgrinding

during the bend shall be the side closest to the inner and outer

may be reduced by the amount so removed.

surface of the pipe respectively.

14.5.1 Wall thickness measurements shall be made with a

mechanical caliper or with a properly calibrated nondestruc-

17. Lengths

tive testing device of appropriate accuracy. In case of dispute,

17.1 Pipe lengths shall be in accordance with the following

the measurement determined by use of the mechanical caliper

regular practice:

shall govern.

17.1.1 The lengths required shall be specified in the order,

14.6 Weld repair shall be permitted only subject to the

and

approvalo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.