ASTM E907-96

(Test Method)Standard Test Method for Field Testing Uplift Resistance of Adhered Membrane Roofing Systems

Standard Test Method for Field Testing Uplift Resistance of Adhered Membrane Roofing Systems

SCOPE

1.1 This test method covers the determination of the resistance of adhered membrane roofing systems to uplift pressure. It applies to roof systems with or without rigid board insulation or base ply, which are either adhered or mechanically fastened, and fully adhered membranes.

1.2 This test method is intended to be used as a measure of the uplift resistance of the roofing system. Systems containing cold adhesive shall be in place for the cure time specified by the adhesive manufacturer to obtain optimum adhesion before conducting the test. Hot-applied systems shall be permitted to cool to normal prevailing surface temperatures before conducting the test.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: E 907 – 96

Standard Test Method for

Field Testing Uplift Resistance of Adhered Membrane

Roofing Systems

This standard is issued under the fixed designation E 907; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope edges of the chamber to be in complete contact with the roof

surface so that a negative pressure is developed inside the

1.1 This test method covers the determination of the resis-

chamber. Other methods are not to be used to prepare the test

tance of adhered membrane roofing systems to uplift pressure.

area unless the method used will produce a tight seal and is

It applies to roof systems with or without rigid board insulation

compatible so as not to damage the roof membrane. Examples

or base ply, which are either adhered or mechanically fastened,

are the use of wet sand, duct tape, water, or polythene film.

and fully adhered membranes.

1.2 This test method is intended to be used as a measure of

4. Significance and Use

the uplift resistance of the roofing system. Systems containing

4.1 This field test method is suitable for determining the

cold adhesive shall be in place for the cure time specified by

uplift resistance of the roofing system as stated in applicable

the adhesive manufacturer to obtain optimum adhesion before

specifications, bid documents, or when required by other

conducting the test. Hot-applied systems shall be permitted to

authorities having jurisdiction. This field test method is also

cool to normal prevailing surface temperatures before conduct-

intended to supplement measurement of the uplift resistance

ing the test.

performance of roofing systems as determined under laboratory

1.3 This standard does not purport to address all of the

conditions.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Apparatus

priate safety and health practices and determine the applica-

5.1 Square Chamber, 1500 6 15 mm (60 6 ⁄2 in.) in size,

bility of regulatory limitations prior to use.

sufficiently strong to withstand the necessary negative pressure

without collapsing.

2. Referenced Documents

2.1 ASTM Standards:

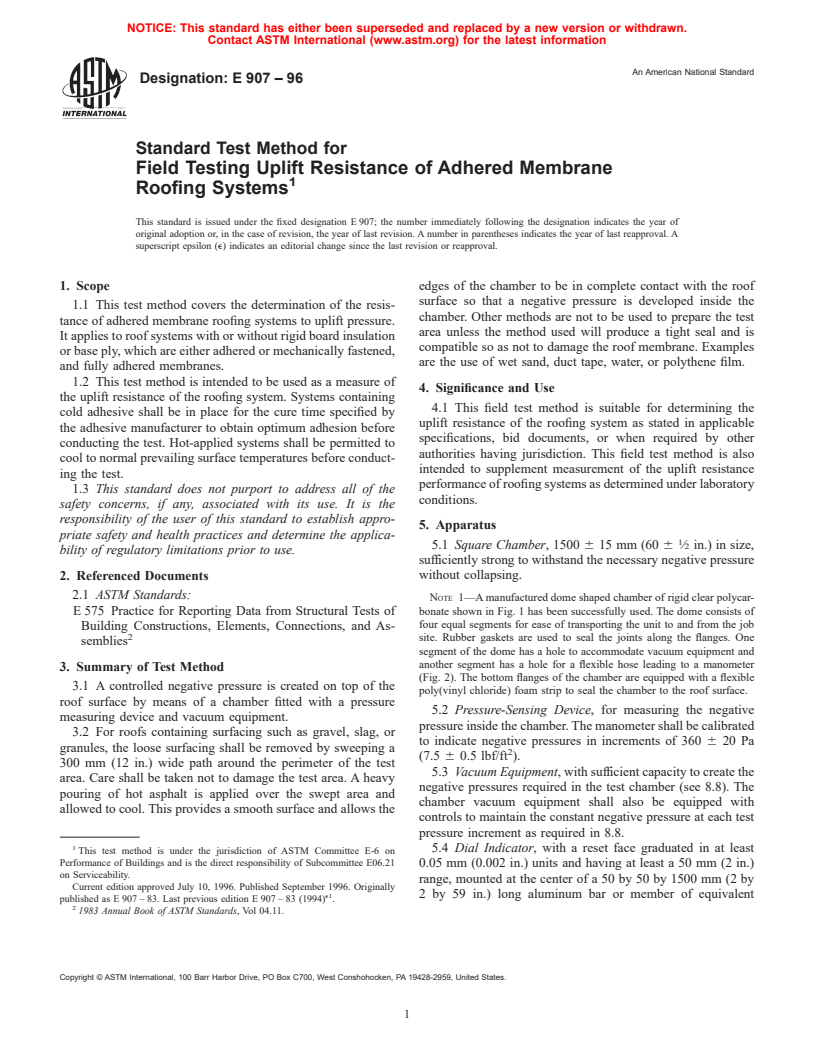

NOTE 1—A manufactured dome shaped chamber of rigid clear polycar-

E 575 Practice for Reporting Data from Structural Tests of bonate shown in Fig. 1 has been successfully used. The dome consists of

four equal segments for ease of transporting the unit to and from the job

Building Constructions, Elements, Connections, and As-

2 site. Rubber gaskets are used to seal the joints along the flanges. One

semblies

segment of the dome has a hole to accommodate vacuum equipment and

another segment has a hole for a flexible hose leading to a manometer

3. Summary of Test Method

(Fig. 2). The bottom flanges of the chamber are equipped with a flexible

3.1 A controlled negative pressure is created on top of the

poly(vinyl chloride) foam strip to seal the chamber to the roof surface.

roof surface by means of a chamber fitted with a pressure

5.2 Pressure-Sensing Device, for measuring the negative

measuring device and vacuum equipment.

pressure inside the chamber. The manometer shall be calibrated

3.2 For roofs containing surfacing such as gravel, slag, or

to indicate negative pressures in increments of 360 6 20 Pa

granules, the loose surfacing shall be removed by sweeping a

(7.5 6 0.5 lbf/ft ).

300 mm (12 in.) wide path around the perimeter of the test

5.3 Vacuum Equipment, with sufficient capacity to create the

area. Care shall be taken not to damage the test area. A heavy

negative pressures required in the test chamber (see 8.8). The

pouring of hot asphalt is applied over the swept area and

chamber vacuum equipment shall also be equipped with

allowed to cool. This provides a smooth surface and allows the

controls to maintain the constant negative pressure at each test

pressure increment as required in 8.8.

5.4 Dial Indicator, with a reset face graduated in at least

This test method is under the jurisdiction of ASTM Committee E-6 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.21

0.05 mm (0.002 in.) units and having at least a 50 mm (2 in.)

on Serviceability.

range, mounted at the center of a 50 by 50 by 1500 mm (2 by

Current edition approved July 10, 1996. Published September 1996. Originally

e1 2 by 59 in.) long aluminum bar or member of equivalent

published as E 907 – 83. Last previous edition E 907 – 83 (1994) .

1983 Annual Book of ASTM Standards, Vol 04.11.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 907

FIG. 1 View of Chamber over Roof Test Area During Test

stiffness. Feet on each end of the bar provide support and give considerations, tests shall not be conducted when the wind

a clear distance of 50 mm (2 in.) above the roof surface. This

speed at the roof level is over 6.5 m/s (15 mph). When

allows measurement of roof surface deflections in the test area

necessary to measure and record wind speed, a portable

(see Fig. 3).

anemometer shall be used.

5.4.1 All persons not involved in the test shall be kept far

8.3 Place the bar with attached dial indicator so that the tip

enough away from the test area to ensure that the dial gage

of the dial indicator is in contact with the roof membrane near

indicator is not affected by movement and influence the

the center of the test area.

readings.

8.4 Place the assembled chamber over the roof test area so

that the deflection bar with attached dial indicator is centered

6. Hazards

within the chamber and is perpendicular to two sides of the

6.1 The manometer shall be designed to serve as a safety

chamber. The edges of the chamber shall be sealed to the roof

device to prevent negative pressures that will cause the plastic

surface. Orient the chamber on the roof so that the edges are

dome to shatter. The design of the manometer or safety features

parallel with the direction of the structural framing of the

of other pressure sensing devices shall not be changed to

building.

increase negative pressures above the design or allowable

values of the chamber. 8.5 Install the pressure measuring device. If a manometer is

6.2 Safety goggles or face shield shall be worn by persons

used, fill it with water to zero calibration level.

operating the equipment or observing its operation as a

8.6 Connect the vacuum equipment to the hole provided for

precaution against injury caused by a sudden failure of the test

it in the chamber. Make sure that the bypass valve on the

chamber or roofing

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.