ASTM E982-94(2009)

(Specification)Standard Specification for Laboratory Glass Test Tubes

Standard Specification for Laboratory Glass Test Tubes

ABSTRACT

This specification covers glass test tubes suitable for laboratory use. The test tubes shall be of the following classification according to size: Type I, Type II, Type III, Type IV (Class A, Class B, and Class C), Type V, Type VI, and Type VII. Test tubes shall be made of the prescribed borosilicate glass (Type I glass) or of soda-lime glass (Type II glass) and shall be tubular, with one end having a rounded closure. The following are specified: (1) material requirements for screw caps, liners, and annealing and (2) design requirements for the test tube capacity, dimensions (OD, length, and wall thickness), and area for marking. Other dimensional requirements such as subdivision, stopper, and GPI thread finish are also specified.

SCOPE

1.1 This specification covers glass test tubes suitable for laboratory use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E982 −94(Reapproved 2009)

Standard Specification for

Laboratory Glass Test Tubes

This standard is issued under the fixed designation E982; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Classification

1.1 This specification covers glass test tubes suitable for

3.1 Test tubes shall be of the following sizes:

laboratory use.

Size Nominal OD × Length, mm

1 6×50

2. Referenced Documents

2 10×70

3 10×75

2.1 ASTM Standards:

4 12×75

C162 Terminology of Glass and Glass Products

5 12 × 100

D700 Specification for Phenolic Molding Compounds

6 13 × 100

7 14 × 100

(Withdrawn 1990)

8 14 × 150

D2146 Specification for Propylene Plastic Molding and

9 15 × 125

Extrusion Materials (Withdrawn 1986)

10 16 × 100

11 16 × 125

E438 Specification for Glasses in Laboratory Apparatus

12 16 × 150

E542 Practice for Calibration of Laboratory Volumetric

13 18 × 150

Apparatus

14 19 × 150

15 20 × 125

E671 Specification for Maximum Permissible Thermal Re-

16 20 × 150

sidual Stress in Annealed Glass Laboratory Apparatus

17 21 × 150

E675 Specification for Interchangeable Taper-Ground Stop-

18 22 × 175

19 25 × 150

cocks And Stoppers

20 25 × 200

E920 Specification for Commercially Packaged Laboratory

21 25 × 250

Apparatus

22 38 × 200

E921 Specification for Export Packaged Laboratory Appa-

3.1.1 Type I—General-Purpose, Beaded Rim:

ratus

Size Nominal OD × Length, mm

E1133 Practice for Performance Testing of Packaged Labo-

3 10×75

ratory Apparatus for United States Government Procure-

4 12×75

ments

6 13 × 100

9 15 × 125

E1157 Specification for Sampling and Testing of Reusable

11 16 × 125

Laboratory Glassware

12 16 × 150

2.2 Glass Packaging Institute Standard: 13 18 × 150

14 19 × 150

GPI Tall Continuous Thread Concealed Bead Finish, Glass

16 20 × 150

Finish Drawing Nos. 410, 415, and 430

19 25 × 150

20 25 × 200

This specification is under the jurisdiction of ASTM Committee E41 on

3.1.2 Type II—Beaded Rim, Graduated:

Laboratory Apparatus and is the direct responsibility of Subcommittee E41.01 on

Size Nominal OD × Length, mm

Apparatus.

Current edition approved Nov. 1, 2009. Published March 2010 . Originally

5 12 × 100

approved in 1984. Last previous edition approved in 2004 as E982–94 (2004). DOI:

8 14 × 150

10.1520/E0982-94R09.

11 16 × 125

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

12 16 × 150

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 16 20 × 150

Standards volume information, refer to the standard’s Document Summary page on 17 21 × 150

20 25 × 200

the ASTM website.

The last approved version of this historical standard is referenced on

3.1.3 Type III—Standard Taper, Glass-Stoppered:

www.astm.org.

Available from Glass Packaging Institute, 6845 Elm Street, Suite 209, McLean,

Size Nominal OD × Length, mm

VA 22101.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

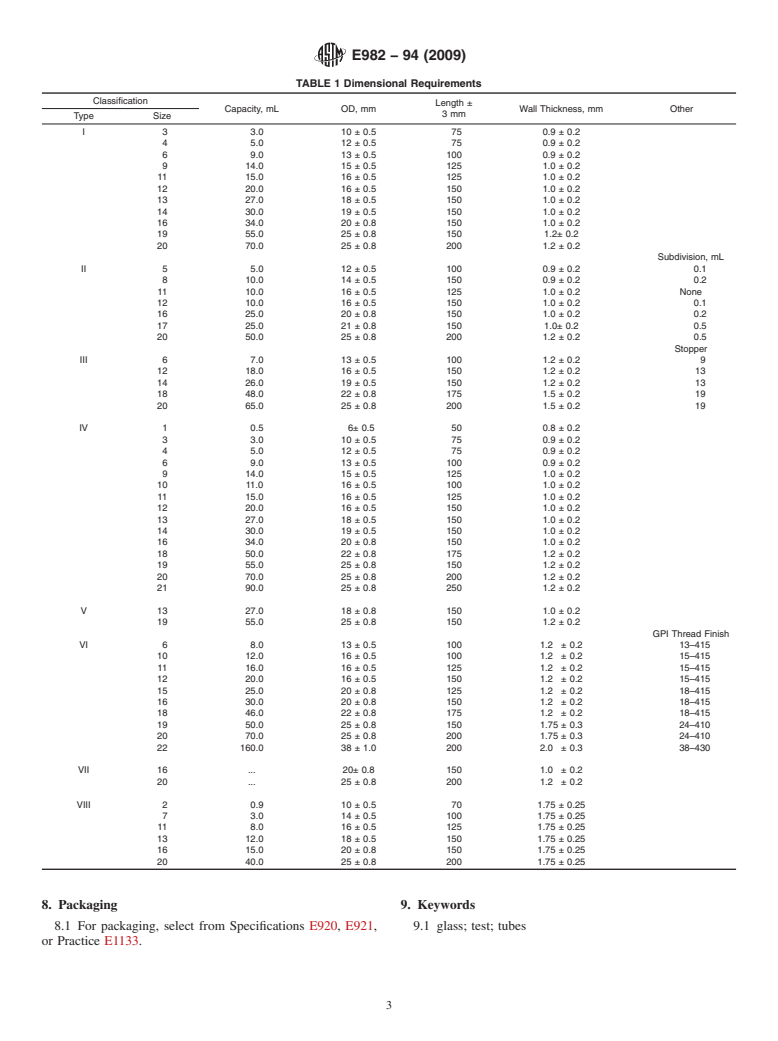

E982−94 (2009)

4.2 Screw Caps—ClassAand B screw caps shall be molded

6 13 × 100

12 16 × 150

of phenol-formaldehyde type resin, which is free of cellulose

14 19 × 150

acetate and urea, in accordance with Specification D700. Class

18 22 × 175

C screw cap shall be molded of polypropylene resin in

20 25 × 200

accordance with Specification D2146. Screw caps shall not

3.1.4 Type IV—Culture Tubes, Rimless:

deform, crack, turn color, or become tacky; and liners shall not

Size Nominal OD × Length, mm

detach or become tacky when autoclaved the first time.

1 6×50

3 10×75

4.3 Liners—Liners for Class A screw caps shall be fabri-

4 12×75

cated of resilient white rubber. Class B caps shall have a

6 13 × 100

polytetrafluoroethylene liner interface firmly bonded to the

9 15 × 125

10 16 × 100

glued-in white rubber liner as described for Class A caps.

11 16 × 125

12 16 × 150

4.4 Annealing—Maximum thermal residual stress shall be

13 18 × 150

in accordance with Specification E671.

14 19 × 150

16 20 × 150

18 22 × 125

5. Design

19 25 × 150

20 25 × 200

5.1 Shape—Test tubes covered by this specification shall be

21 25 × 250

tubular, with one end having a rounded closure.

3.1.5 Type V—Culture Tubes, Filtered for Wave Lengths in

5.2 Capacity—Capacities on ungraduated tubes are only

the 3000 to 5000-Å Range:

approximate, but any graduation onType II tubes shall indicate

Size Nominal OD × Length, mm

the contained capacity within 65 % of nominal tube capacity.

13 18 × 150

19 25 × 150

5.3 TypesIandII—TheopenendofTypesIandIItesttubes

shall have a beaded rim; dimensions shall be as specified in

3.1.6 Type VI—Culture Tubes, Screw Caps:

Table 1.

Size Nominal OD × Length, mm

6 13 × 100

5.4 Type III—The open end of Type III test tubes shall have

10 16 × 100

a standard taper stopper. The joint and stopper shall be in

11 16 × 125

accordance with Specification E675 and Table 1.

12 16 × 150

15 20 × 125

5.5 Types IV, V, and VIII—The open end of Types IV, V, and

16 20 × 150

18 22 × 175

VIII test tubes shall be rimless and fire polished, dimensions

19 25 × 150

shall be as specified in Table 1.

20 25 × 200

22 38 × 200

5.6 Type VI—The open end of Type VI test tubes shall have

3.1.6.1 Class A—Screw cap with whi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.