ASTM B427-02

(Specification)Standard Specification for Gear Bronze Alloy Castings

Standard Specification for Gear Bronze Alloy Castings

ABSTRACT

This specification establishes requirements for gear bronze alloy castings with Copper Alloy No. C90800, C91700, C90700, C91600, and C92900. The castings may be furnished as one of three types: static chill, centrifugal chill, or sand cast. The alloys shall be subject to tensile strength, yield strength, elongation, and Brinell hardness tests. The Brinell readings shall be taken on the grip end of the tension test bar as described in the specification.

SCOPE

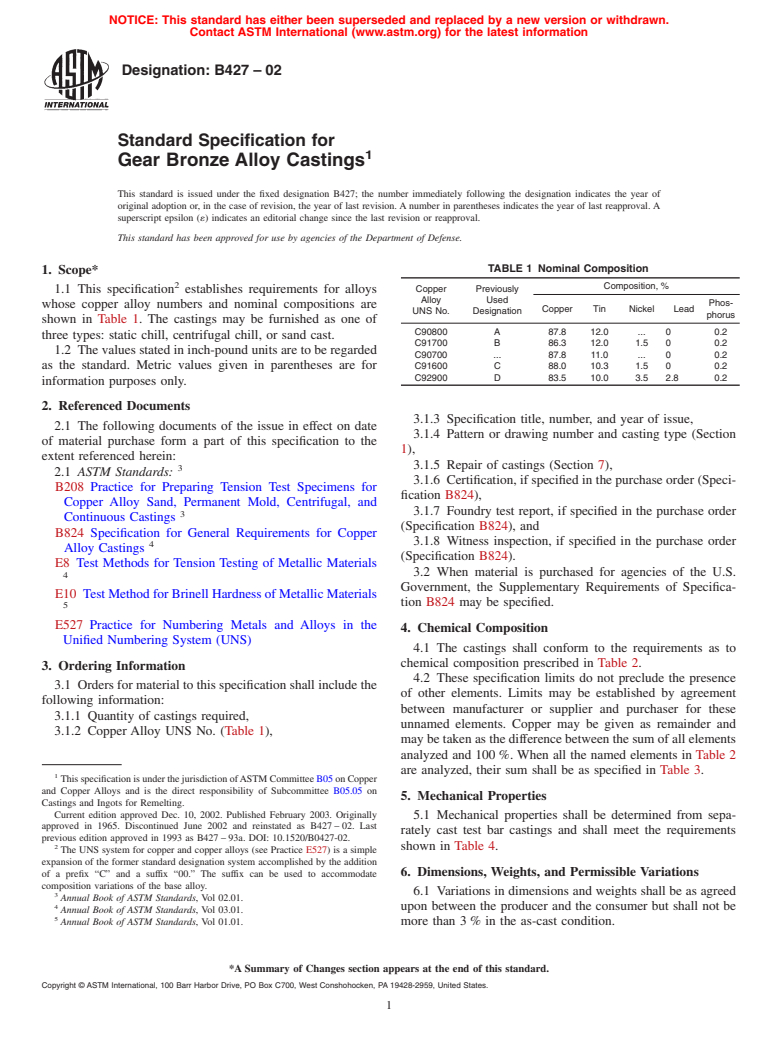

1.1 This specification establishes requirements for alloys whose copper alloy numbers and nominal compositions are shown in Table 1. The castings may be furnished as one of three types: static chill, centrifugal chill, or sand cast.

1.2 The values stated in inch-pound units are to be regarded as the standard. Metric values given in parentheses are for information purposes only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B427 – 02

Standard Specification for

1

Gear Bronze Alloy Castings

This standard is issued under the fixed designation B427; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

TABLE 1 Nominal Composition

1. Scope*

2

Composition, %

Copper Previously

1.1 This specification establishes requirements for alloys

Alloy Used

Phos-

whose copper alloy numbers and nominal compositions are

Copper Tin Nickel Lead

UNS No. Designation

phorus

shown in Table 1. The castings may be furnished as one of

C90800 A 87.8 12.0 . 0 0.2

three types: static chill, centrifugal chill, or sand cast.

C91700 B 86.3 12.0 1.5 0 0.2

1.2 The values stated in inch-pound units are to be regarded

C90700 . 87.8 11.0 . 0 0.2

as the standard. Metric values given in parentheses are for C91600 C 88.0 10.3 1.5 0 0.2

C92900 D 83.5 10.0 3.5 2.8 0.2

information purposes only.

2. Referenced Documents

3.1.3 Specification title, number, and year of issue,

2.1 The following documents of the issue in effect on date

3.1.4 Pattern or drawing number and casting type (Section

of material purchase form a part of this specification to the

1),

extent referenced herein:

3.1.5 Repair of castings (Section 7),

3

2.1 ASTM Standards:

3.1.6 Certification, if specified in the purchase order (Speci-

B208 Practice for Preparing Tension Test Specimens for

fication B824),

Copper Alloy Sand, Permanent Mold, Centrifugal, and

3.1.7 Foundry test report, if specified in the purchase order

3

Continuous Castings

(Specification B824), and

B824 Specification for General Requirements for Copper

3.1.8 Witness inspection, if specified in the purchase order

4

Alloy Castings

(Specification B824).

E8 Test Methods for Tension Testing of Metallic Materials

3.2 When material is purchased for agencies of the U.S.

4

Government, the Supplementary Requirements of Specifica-

E10 Test Method for Brinell Hardness of Metallic Materials

tion B824 may be specified.

5

E527 Practice for Numbering Metals and Alloys in the

4. Chemical Composition

Unified Numbering System (UNS)

4.1 The castings shall conform to the requirements as to

chemical composition prescribed in Table 2.

3. Ordering Information

4.2 These specification limits do not preclude the presence

3.1 Orders for material to this specification shall include the

of other elements. Limits may be established by agreement

following information:

between manufacturer or supplier and purchaser for these

3.1.1 Quantity of castings required,

unnamed elements. Copper may be given as remainder and

3.1.2 Copper Alloy UNS No. (Table 1),

may be taken as the difference between the sum of all elements

analyzed and 100 %. When all the named elements in Table 2

are analyzed, their sum shall be as specified in Table 3.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

and Copper Alloys and is the direct responsibility of Subcommittee B05.05 on

5. Mechanical Properties

Castings and Ingots for Remelting.

Current edition approved Dec. 10, 2002. Published February 2003. Originally

5.1 Mechanical properties shall be determined from sepa-

approved in 1965. Discontinued June 2002 and reinstated as B427 – 02. Last

rately cast test bar castings and shall meet the requirements

previous edition approved in 1993 as B427 – 93a. DOI: 10.1520/B0427-02.

2 shown in Table 4.

The UNS system for copper and copper alloys (see Practice E527) is a simple

expansion of the former standard designation system accomplished by the addition

6. Dimensions, Weights, and Permissible Variations

of a prefix “C” and a suffix “00.” The suffix can be used to accommodate

composition variations of the base alloy.

6.1 Variations in dimensions and weights shall be as agreed

3

Annual Book of ASTM Standards, Vol 02.01.

4

upon between the producer and the consumer but shall not be

Annual Book of ASTM Standards, Vol 03.01.

5

Annual Book of ASTM Standards, Vol 01.01. more than 3 % in the as-cast condition.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B427 – 02

TABLE 2 Chemical Requirements

Composition, max % (Unless Shown as a Range or Minimum) Copper Alloy UNS No.

Element

A A A A A

C90800 C91700 C90700 C91600 C92900

Copper remainder remainder remainder remainder remainder

Tin 11.0–13.0 11.3–12.5 10.0–12.0 9.7–10.8 9.0–11.0

Lead 0.25 0.25 0.50 0.25 2.0–3.2

Zinc 0.25 0.25 0.50 0.25 0.25

Iron 0.15 0.20 0.15 0.20 0.20

An

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.