ASTM B605-95a(2009)

(Specification)Standard Specification for Electrodeposited Coatings of Tin-Nickel Alloy

Standard Specification for Electrodeposited Coatings of Tin-Nickel Alloy

ABSTRACT

This specification establishes the requirements for electrodeposited tin-nickel alloy coatings from aqueous solutions intended for the corrosion protection of fabricated articles of iron, steel, zinc-base alloys, copper, and copper alloys. This specification does not apply to sheets, strips, or wires in the fabricated form. It also may not be applicable to finely threaded articles, but the decision to use the coating on such components may be made by the purchaser. Coating grades shall be designated by a service condition number, which indicates the severity of exposure for which the coating is intended, and a coating thickness notation. Iron and steel specimens shall undergo pre- and post-coating treatments for reducing the risk of hydrogen embrittlement. Coatings shall be sampled, tested, and conform to specified requirements as to appearance (visible defects), composition, thickness (assessed either by microscopical, magnetic, coulometric, beta backscatter, or X-ray spectrometry), adhesion (determined either by burnishing, or heat-quench test), and integrity (including gross defects, mechanical damage, and porosity).

SCOPE

1.1 This specification covers the requirements for electrodeposited tin-nickel alloy coatings from aqueous solutions intended for the corrosion protection of fabricated articles of iron, steel, zinc-base alloys, copper, and copper alloys. The composition of the alloy remains constant at 65/35 tin-nickel in spite of wide fluctuations in both composition and operating conditions. The composition corresponds quite closely to an equiatomic ratio, and the process favors the co-deposition of tin and nickel atoms at identical rates.

1.2 This specification does not apply to sheet, strip, or wire in the fabricated form. It also may not be applicable to threaded articles having basic major diameters up to and including 19 mm because of the nonuniformity of thickness that can be expected on fine threads. However, a decision to use the coating on such components may be made by the purchaser.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B605 −95a(Reapproved2009)

StandardSpecification for

Electrodeposited Coatings of Tin-Nickel Alloy

This standard is issued under the fixed designation B605; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B252Guide for Preparation of Zinc Alloy Die Castings for

Electroplating and Conversion Coatings

1.1 Thisspecificationcoverstherequirementsforelectrode-

B281Practice for Preparation of Copper and Copper-Base

posited tin-nickel alloy coatings from aqueous solutions in-

Alloys for Electroplating and Conversion Coatings

tended for the corrosion protection of fabricated articles of

B322Guide for Cleaning Metals Prior to Electroplating

iron, steel, zinc-base alloys, copper, and copper alloys. The

B374Terminology Relating to Electroplating

compositionofthealloyremainsconstantat65/35tin-nickelin

B487Test Method for Measurement of Metal and Oxide

spite of wide fluctuations in both composition and operating

Coating Thickness by Microscopical Examination of

conditions. The composition corresponds quite closely to an

Cross Section

equiatomic ratio, and the process favors the co-deposition of

B499Test Method for Measurement of CoatingThicknesses

tin and nickel atoms at identical rates.

by the Magnetic Method: Nonmagnetic Coatings on

1.2 This specification does not apply to sheet, strip, or wire

Magnetic Basis Metals

inthefabricatedform.Italsomaynotbeapplicabletothreaded

B504Test Method for Measurement of Thickness of Metal-

articles having basic major diameters up to and including 19

lic Coatings by the Coulometric Method

mm because of the nonuniformity of thickness that can be

B507Practice for Design ofArticles to Be Electroplated on

expected on fine threads. However, a decision to use the

Racks

coating on such components may be made by the purchaser.

B567Test Method for Measurement of Coating Thickness

by the Beta Backscatter Method

1.3 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this B568Test Method for Measurement of Coating Thickness

by X-Ray Spectrometry

standard.

B571Practice for Qualitative Adhesion Testing of Metallic

1.4 This standard does not purport to address all of the

Coatings

safety concerns, if any, associated with its use. It is the

B602Test Method for Attribute Sampling of Metallic and

responsibility of the user of this standard to establish appro-

Inorganic Coatings

priate safety and health practices and determine the applica-

B634Specification for Electrodeposited Coatings of Rho-

bility of regulatory limitations prior to use.

dium for Engineering Use

B697Guide for Selection of Sampling Plans for Inspection

2. Referenced Documents

of Electrodeposited Metallic and Inorganic Coatings

2.1 ASTM Standards:

B762Test Method of Variables Sampling of Metallic and

B183Practice for Preparation of Low-Carbon Steel for

Inorganic Coatings

Electroplating

B765GuideforSelectionofPorosityandGrossDefectTests

B242Guide for Preparation of High-Carbon Steel for Elec-

for Electrodeposits and Related Metallic Coatings

troplating

B809Test Method for Porosity in Metallic Coatings by

B246Specification for Tinned Hard-Drawn and Medium-

Humid Sulfur Vapor (“Flowers-of-Sulfur”)

Hard-Drawn Copper Wire for Electrical Purposes

B849Specification for Pre-Treatments of Iron or Steel for

Reducing Risk of Hydrogen Embrittlement

B850GuideforPost-CoatingTreatmentsofSteelforReduc-

This specification is under the jurisdiction of ASTM Committee B08on

Metallic and Inorganic Coatingsand is the direct responsibility of Subcommittee ing the Risk of Hydrogen Embrittlement

B08.06 on Soft Metals.

D3951Practice for Commercial Packaging

Current edition approved Sept. 1, 2009. Published November 2009. Originally

approved in 1975. Last previous edition approved in 2004 as B605–95a(2004).

3. Terminology

DOI: 10.1520/B0605-95AR09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1 Definitions:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.1.1 Many terms used in this standard are defined in

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Terminology B374.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B605−95a(Reapproved2009)

TABLE 2 Tin-Nickel Coatings on Copper or Copper Alloys

3.1.2 significant surface—that portion of a coated article’s

surface where the coating is required to meet all the require- Service Minimum

Thickness

Condition Thickness,

ments of the coating specification for that article. Significant

Notation

Number µm

surfaces are those that are essential to the serviceability or

A B B

5 Cu/Sn-Ni as specified as specified

function of the article, or which can be a source of corrosion

(above 45) (above 45)

A

4 Cu/Sn-Ni 45 45

products or tarnish films that interfere with the function or

A

3 Cu/Sn-Ni 25 25

desirable appearance of the article. Significant surfaces are

A

2 Cu/Sn-Ni 15 15

A

those surfaces that are identified by the purchaser by, for

0 Cu/Sn-Ni 44

example, indicating them on an engineering drawing of the

A

An undercoating of copper 4.0 µm thick shall be applied on copper-zinc alloys to

product or marking a sample item of the product. serve as a zinc diffusion barrier.

B

Thickness of Sn-Ni shall be stated in a Thickness Notation. A statement of

3.1.3 undercoating—a metallic coating layer between the

Service Condition 5 is not sufficient.

basis metal or substrate and the topmost metallic coating. The

thickness of an undercoating is usually greater than 0.8 µm.

This is in contrast to strikes or flashes, whose thicknesses are TABLE 3 Tin-Nickel Coatings on Zinc Alloys

generally lower.

Service Minimum

Thickness

Condition Thickness,

Notation

Number µm

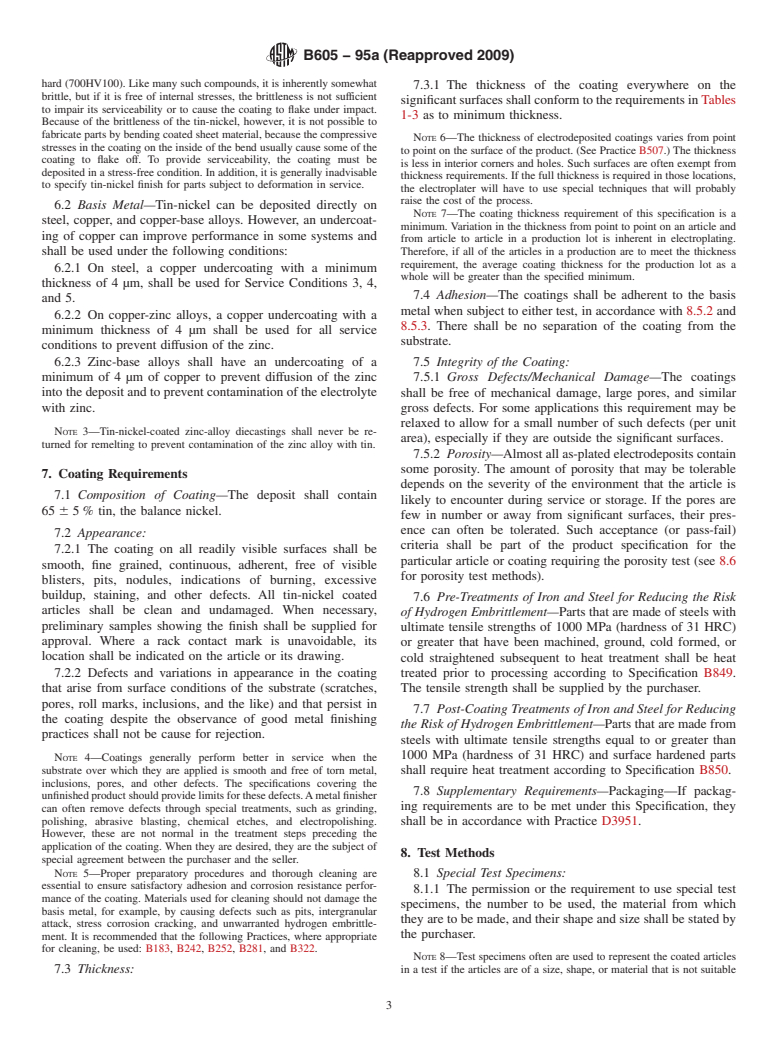

4. Classifications

A

4 Zn/Cu /Sn-Ni 45 45

4.1 Coating Grades—Six grades of coatings, designated by

A

3 Zn/Cu /Sn-Ni 25 25

A

service condition numbers, are covered by this specification.

2 Zn/Cu /Sn-Ni 15 15

A

1 Zn/Cu /Sn-Ni 8 8

For each coating grade a coating thickness grade is specified

A

An undercoating of copper 4.0 µm thick shall be applied to prevent zinc from

(see Tables 1-3).

contaminating the Sn-Ni plating bath and to serve as a diffusion barrier.

4.2 Service Condition Number—Theserviceconditionnum-

ber indicates the severity of exposure for which the grade of

coating is intended.

5.1.2 Location of significant surface(s) (see section 3.1.2),

SC5—extended severe service

5.1.3 The service number or coating thickness notation (see

SC4—very severe service

SC3—severe service 4.2 and 4.3),

SC2—moderate service

5.1.4 Undercoating, if required (see 6.2 and Tables 1-3),

SC1—mild service

5.1.5 Any requirement for submission of sample coated

SC0—mild service (copper and copper alloys only)

articles (see 7.2.1),

NOTE 1—Typical service conditions for which the service condition

5.1.6 Whether or not location of rack marks is to be defined

numbers are appropriate are given in Appendix X1.

(see 7.2.1),

4.3 Coating Thickness Notation—The coating thickness is

5.1.7 Any requirement for porosity testing and the criteria

specified for each service condition in the following manner:

for acceptance (see 7.5.2),

Basis metal/Undercoating (thickness)/Sn-Ni (thickness). For

5.1.8 Heat treatment for stress relief, whether it has been

example, Fe/Cu4/Sn-Ni25 would indicate a 25 µm tin-nickel

performed by the purchaser, or is required (see 7.6),

coating over an iron or steel article with a 4-µm thick copper

5.1.9 Heat treatment after electroplating, if required (see

undercoating. All thickness notations are minimum thick-

7.7),

nesses.

5.1.10 Any packaging requirement (see section 7.8),

5.1.11 Inspection procedure to be used (see Section 9),

5. Ordering Information

5.1.12 Any requirement for certification (see Section 11),

5.1 To make the application of this standard complete, the

and

purchaser needs to supply the following information to the

5.1.13 Any requirement for test specimens (see 8.1.1).

seller in the purchase order or other government documents.

5.1.1 The name, designation, and date of issue of this

6. Material and Process

standard,

6.1 Composition of Coating—Electrolytes that have been

investigated for producing Sn-Ni alloy deposits include

TABLE 1 Tin-Nickel Coatings on Steel

cyanide, fluoborate, pyrophosphate, and acetate, but the only

Service Minimum

one in general commercial use is the fluoride-chloride formu-

Thickness

Condition Thickness,

Notation

lation. Thedepositcontains35 65%nickelwiththeremain-

Number µm

A B B der tin (see Note 2).

5 Fe/Cu /Sn-Ni as specified as specified

(above 45) (above 45)

NOTE 2—The electrodeposited tin-nickel coating is a single-phase,

A

4 Fe/Cu /Sn-Ni 45 45

A metastable compound, corresponding approximately to the formula SnNi.

3 Fe/Cu /Sn-Ni 25 25

It is stable at ordinary temperatures but starts to recrystallize at elevated

2 Fe/Sn-Ni 15 15

temperatures. The safe working temperature of the coating is 300°C,

1 Fe/Sn-Ni 8 8

although actual melting does not commence below 800°C. The coating is

A

Copper undercoat shall be at least 4.0 µm.

B

Thickness of Sn-Ni shall be stated in a Thickness Notation. A statement of

Service Condition 5 is not sufficient.

Lowenheim, F. A., Electroplating, McGraw-Hill Inc., 1978.

B605−95a(Reapproved2009)

hard (700HV100). Like many such compounds, it is inherently somewhat

7.3.1 The thickness of the coating everywhere on the

brittle, but if it is free of internal stresses, the brittleness is not sufficient

significantsurfacesshallconformtotherequirementsinTables

to impair its serviceability or to cause the coating to flake under impact.

1-3 as to minimum thickness.

Because of the brittleness of the tin-nickel, however, it is not possible to

fabricate parts by bending coated sheet material, because the compressive

NOTE 6—The thickness of electrodeposited coatings varies from point

stresses in the coating on the inside of the bend usually cause some of the

to point on the surface of the product. (See Practice B507.)The thickness

coating to flake off. To provide serviceability, the coating must be

is less in interior corners and holes. Such surfaces are often exempt from

depositedinastress-freecondition.Inaddition,itisgenerallyinadvisable

thickness requirements. If the full thickness is required in those locations,

to specify tin-nickel finish for parts subject to deformation in service.

the electroplater will have to use special techniques that will probably

raise the cost of the process.

6.2 Basis Metal—Tin-nickel can be deposited directly on

NOTE 7—The coating thickness requirement of this specification is a

steel, copper, and copper-base alloys. However, an undercoat-

minimum. Variation in the thickness from point to point on an article and

ing of copper can improve performance in some systems and

from article to article in a production lot is inherent in electroplating.

shall be used under the following conditions: Therefore, if all of the articles in a production are to meet the thickness

requirement, the average coating thickness for the production lot as a

6.2.1 On steel, a copper undercoating with a minimum

whole will be greater than the specified minimum.

thickness of 4 µm, shall be used for Service Conditions 3, 4,

7.4 Adhesion—The coatings shall be adherent to the basis

and 5.

metal when subject to either test, in accordance with 8.5.2 and

6.2.2 On copper-zinc alloys, a copper undercoating with a

8.5.3. There shall be no separation of the coating from the

minimum thickness of 4 µm shall be used for all service

substrate.

conditions to prevent diffusion of the zinc.

6.2.3 Zinc-base alloys shall have an undercoating of a 7.5 Integrity of the Coating:

minimum of 4 µm of copper to prevent diffusion of the zinc 7.5.1 Gross Defects/Mechanical Damage—The coatings

intothedepositandtopreventcontaminationoftheelectrolyte shall be free of mechanical damage, large pores, and similar

with zinc. gross defects. For some applications this requirement may be

relaxed to allow for a small number of such defects (per unit

NOTE 3—Tin-nickel-coated zinc-alloy diecastings shall never be re-

area), especially if they are outside the significant surfaces.

turned for remelting to prevent contamination of the zinc alloy with tin.

7.5.2 Porosity—Almostallas-platedelectrodepositscontain

some porosity. The amount of porosity that may be tolerable

7. Coating Requirements

depends on the severity of the environment that the article is

7.1 Composition of Coating—The deposit shall contain

likely to encounter during service or storage. If the pores are

65 65% tin, the balance nickel.

few in number or away from significant surfaces, their pres-

ence can often be tolerated. Such acceptance (or pass-fail)

7.2 Appearance:

criteria shall be part of the product specification for the

7.2.1 The coating on all readily visible surfaces shall be

particular article or coating requiring the porosity test (see 8.6

smooth, fine grained, continuous, adherent, free of visible

for porosity test methods).

blisters, pits, nodules, indications of burning, excessive

buildup, staining, and other defects. All tin-nickel coated

7.6 Pre-Treatments of Iron and Steel for Reducing the Risk

articles shall be clean and undamaged. When necessary,

of Hydrogen Embrittlement—Parts that are made of steels with

preliminary samples showing the finish shall be supplied for

ultimate tensile strengths of 1000 MPa (hardness of 31 HRC)

approval. Where a rack contact mark is unavoidable, its

or greater that have been machined, ground, cold formed, or

location shall be indicated on the article or its drawing.

cold straightened subsequent to heat treatment shall be heat

7.2.2 Defects and variations in appearance in the coating treated prior to processing according to Specification B849.

that arise from surface conditions of the substrate (scratches, The tensile strength shall be supplied by the purchaser.

pores, roll marks, inclusions, and the like) and that persist in

7.7 Post-Coating Treatments of Iron and Steel for Reducing

the coating despite the observance of good metal finishing

the Risk of Hydrogen Embrittlement—Partsthataremadefrom

practices shall not be cause for rejection.

steels with ultimate tensile strengths equal to or greater than

1000 MPa (hardness of 31 HRC) and surface hardened parts

NOTE 4—Coatings generally perform better in service when the

substrate over which they are applied is smooth and free of torn metal, shall require heat treatment according t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.