ASTM F1504-14(2021)e1

(Specification)Standard Specification for Folded Poly(Vinyl Chloride) (PVC) Pipe for Existing Sewer and Conduit Rehabilitation

Standard Specification for Folded Poly(Vinyl Chloride) (PVC) Pipe for Existing Sewer and Conduit Rehabilitation

ABSTRACT

This specification covers the material, dimensional, and requirements and corresponding test methods for folded poly(vinyl chloride) (PVC) pipes suitable for the rehabilitation of existing nonpressure sewers and conduits, wherein the folded PVC pipe is inserted into, and then expanded to conform to the wall of, the original conduit forming a new pipe-within-a-pipe structure. This specification does not include pipes manufactured from reprocessed, recycled, or reclaimed PVC. Appropriately sampled specimens shall be tested, and shall thereby conform accordingly to specified requirements for flattening resistance, impact strength, stiffness, extrusion quality by acetone immersion and heat reversion, flexural modulus of elasticity, and rounded pipe diameter and wall thickness.

SCOPE

1.1 This specification covers requirements and test methods for materials, dimensions, workmanship, flattening resistance, impact resistance, pipe stiffness, extrusion quality, and a form of marking for folded (vinyl chloride) (PVC) pipe for existing sewer and conduit rehabilitation.

1.2 Pipe produced to this specification is for use in non-pressure sewer and conduit rehabilitation where the folded PVC pipe is inserted into and then expanded to conform to the wall of the original conduit forming a new structural pipe-within-a-pipe.

Note 1: For installation procedures refer to Practice F1947.

1.3 This specification includes pipe made only from materials specified in Section 6. This specification does not include pipe manufactured from reprocessed, recycled, or reclaimed PVC.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 The following precautionary statement pertains to the test method portion only, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:F1504 −14 (Reapproved 2021)

Standard Specification for

Folded Poly(Vinyl Chloride) (PVC) Pipe for Existing Sewer

and Conduit Rehabilitation

This standard is issued under the fixed designation F1504; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Figure 1 was editorially corrected in March 2021.

1. Scope* mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This specification covers requirements and test methods

for materials, dimensions, workmanship, flattening resistance,

2. Referenced Documents

impact resistance, pipe stiffness, extrusion quality, and a form

2.1 ASTM Standards:

of marking for folded (vinyl chloride) (PVC) pipe for existing

D618 Practice for Conditioning Plastics for Testing

sewer and conduit rehabilitation.

D790 Test Methods for Flexural Properties of Unreinforced

1.2 Pipe produced to this specification is for use in non-

and Reinforced Plastics and Electrical Insulating Materi-

pressure sewer and conduit rehabilitation where the folded

als

PVC pipe is inserted into and then expanded to conform to the

D1600 TerminologyforAbbreviatedTermsRelatingtoPlas-

wall of the original conduit forming a new structural pipe-

tics

within-a-pipe.

D1784 Classification System and Basis for Specification for

NOTE 1—For installation procedures refer to Practice F1947.

Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlo-

rinated Poly(Vinyl Chloride) (CPVC) Compounds

1.3 This specification includes pipe made only from mate-

F1947 Practice for Installation of Folded Poly (Vinyl Chlo-

rials specified in Section 6. This specification does not include

ride) (PVC) Pipe into Existing Sewers and Conduits

pipe manufactured from reprocessed, recycled, or reclaimed

D2122 Test Method for Determining Dimensions of Ther-

PVC.

moplastic Pipe and Fittings

1.4 The values stated in inch-pound units are to be regarded

D2152 Test Method for Adequacy of Fusion of Extruded

as standard. The values given in parentheses are mathematical

Poly(Vinyl Chloride) (PVC) Pipe and Molded Fittings by

conversions to SI units that are provided for information only

Acetone Immersion

and are not considered standard.

D2412 Test Method for Determination of External Loading

1.5 The following precautionary statement pertains to the

Characteristics of Plastic Pipe by Parallel-Plate Loading

test method portion only, Section 11, of this specification: This

D2444 Practice for Determination of the Impact Resistance

standard does not purport to address all of the safety concerns,

of Thermoplastic Pipe and Fittings by Means of a Tup

if any, associated with its use. It is the responsibility of the user

(Falling Weight)

of this standard to establish appropriate safety, health, and

F412 Terminology Relating to Plastic Piping Systems

environmental practices and determine the applicability of

F1057 Practice for Estimating the Quality of Extruded Poly

regulatory limitations prior to use.

(Vinyl Chloride) (PVC) Pipe by the Heat Reversion

1.6 This international standard was developed in accor-

Technique

dance with internationally recognized principles on standard-

2.2 Federal Standard:

ization established in the Decision on Principles for the

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

Development of International Standards, Guides and Recom-

1 2

This specification is under the jurisdiction ofASTM Committee F17 on Plastic For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Piping Systems and is the direct responsibility of Subcommittee F17.67 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Trenchless Plastic Pipeline Technology. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Feb. 15, 2021. Published February 2021. Originally the ASTM website.

approved in 1994. Last previous edition approved in 2014 as F1504 –14. DOI: Available from DLA Document Services Building 4/D 700 Robbins Avenue

10.1520/F1504-14R21E01. Philadelphia, PA 19111-5094 http://quicksearch.dla.mil/

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F1504−14 (2021)

the specific approval of the cognizant code authority since chemicals not

2.3 Military Standard:

commonly found in drains and sewers and temperatures in excess of

MIL-STD-129 Marking for Shipment and Storage

140 °F (60 °C) may be encountered.

3. Terminology

5. Application of Materials

3.1 General—Abbreviations used in this specification are in

accordance with Terminology D1600 and definitions are in 5.1 The nominal folded PVC pipe sizes specified in Section

accordancewithTerminologyF412unlessotherwiseindicated. 8 are applicable for a range of original pipe inside diameters.

Table 1 lists the recommended ranges for each nominal size.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 folded pipe—pipe that has been manufactured in a

6. Materials and Manufacture

folded shape or that is subsequently folded for use in existing

sewer and conduit rehabilitation. See Fig. 1.

6.1 Basic Materials—The pipe shall be made from virgin

PVC compound meeting all the requirements for cell classifi-

3.2.2 rounded pipe—A rounded pipe is a sample for test

cations 12334, 13223, 32334, or 33223 as defined in Specifi-

purposes formed when the folded pipe has been inserted into a

cation D1784.

circular casing pipe and expanded with heat and pressure to fit

tightly to the casing pipe taking a circular cross section, in

6.2 Rework Material—Clean rework material, generated

accordance with Section 10. See Fig. 1.

from the manufacturer’s own PVC sewer pipe production may

be used by the same manufacturer provided that the rework

4. Significance and Use

material meets the requirements of 6.1 and that the pipe

4.1 The requirements of this specification are intended to

produced meets all the requirements of this specification.

provide folded pipe suitable for the rehabilitation of existing

Reworked material of intermixed cell classifications shall be

pipelines and conduits conveying sewage, process flow, and

labeled as the minimum cell classification of this specification,

storm water, under non–pressure conditions, through the

and labeled in accordance with 15.1.3.1. Reworked material

heating, insertion, and expansion of the folded pipe.

containing any copolymer materials shall be labeled as copo-

NOTE 2—Industrial waste disposal lines should be installed only with lymer material.

NOTE 1—This figure is intended only for clarification of terms specific to this specification and shows a representative folded pipe shape. Other folded

pipe shapes may meet the requirements of this specification.

FIG. 1Folded Pipe and Rounded Pipe—Clarification of Terms

´1

F1504−14 (2021)

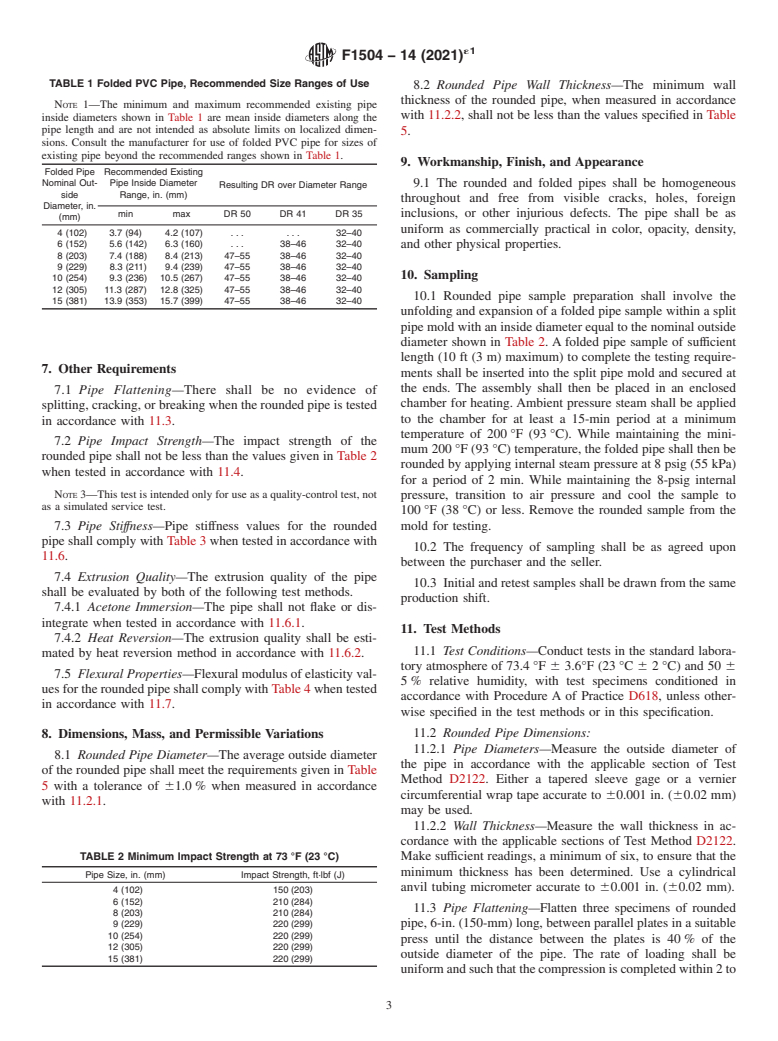

TABLE 1 Folded PVC Pipe, Recommended Size Ranges of Use

8.2 Rounded Pipe Wall Thickness—The minimum wall

thickness of the rounded pipe, when measured in accordance

NOTE 1—The minimum and maximum recommended existing pipe

with 11.2.2, shall not be less than the values specified in Table

inside diameters shown in Table 1 are mean inside diameters along the

pipe length and are not intended as absolute limits on localized dimen-

5.

sions. Consult the manufacturer for use of folded PVC pipe for sizes of

existing pipe beyond the recommended ranges shown in Table 1.

9. Workmanship, Finish, and Appearance

Folded Pipe Recommended Existing

Nominal Out- Pipe Inside Diameter 9.1 The rounded and folded pipes shall be homogeneous

Resulting DR over Diameter Range

side Range, in. (mm)

throughout and free from visible cracks, holes, foreign

Diameter, in.

min max DR 50 DR 41 DR 35

inclusions, or other injurious defects. The pipe shall be as

(mm)

uniform as commercially practical in color, opacity, density,

4 (102) 3.7 (94) 4.2 (107) . . . . . . 32–40

6 (152) 5.6 (142) 6.3 (160) . . . 38–46 32–40

and other physical properties.

8 (203) 7.4 (188) 8.4 (213) 47–55 38–46 32–40

9 (229) 8.3 (211) 9.4 (239) 47–55 38–46 32–40

10. Sampling

10 (254) 9.3 (236) 10.5 (267) 47–55 38–46 32–40

12 (305) 11.3 (287) 12.8 (325) 47–55 38–46 32–40

10.1 Rounded pipe sample preparation shall involve the

15 (381) 13.9 (353) 15.7 (399) 47–55 38–46 32–40

unfolding and expansion of a folded pipe sample within a split

pipe mold with an inside diameter equal to the nominal outside

diameter shown in Table 2. A folded pipe sample of sufficient

length (10 ft (3 m) maximum) to complete the testing require-

7. Other Requirements

ments shall be inserted into the split pipe mold and secured at

the ends. The assembly shall then be placed in an enclosed

7.1 Pipe Flattening—There shall be no evidence of

chamber for heating. Ambient pressure steam shall be applied

splitting, cracking, or breaking when the rounded pipe is tested

to the chamber for at least a 15-min period at a minimum

in accordance with 11.3.

temperature of 200 °F (93 °C). While maintaining the mini-

7.2 Pipe Impact Strength—The impact strength of the

mum 200 °F (93 °C) temperature, the folded pipe shall then be

rounded pipe shall not be less than the values given in Table 2

rounded by applying internal steam pressure at 8 psig (55 kPa)

when tested in accordance with 11.4.

for a period of 2 min. While maintaining the 8-psig internal

NOTE 3—This test is intended only for use as a quality-control test, not

pressure, transition to air pressure and cool the sample to

as a simulated service test.

100 °F (38 °C) or less. Remove the rounded sample from the

7.3 Pipe Stiffness—Pipe stiffness values for the rounded mold for testing.

pipe shall comply with Table 3 when tested in accordance with

10.2 The frequency of sampling shall be as agreed upon

11.6.

between the purchaser and the seller.

7.4 Extrusion Quality—The extrusion quality of the pipe

10.3 Initial and retest samples shall be drawn from the same

shall be evaluated by both of the following test methods.

production shift.

7.4.1 Acetone Immersion—The pipe shall not flake or dis-

integrate when tested in accordance with 11.6.1.

11. Test Methods

7.4.2 Heat Reversion—The extrusion quality shall be esti-

11.1 Test Conditions—Conduct tests in the standard labora-

mated by heat reversion method in accordance with 11.6.2.

tory atmosphere of 73.4 °F 6 3.6°F (23 °C 6 2 °C) and 50 6

7.5 Flexural Properties—Flexural modulus of elasticity val-

5 % relative humidity, with test spec

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: F1504 − 14 (Reapproved 2021) F1504 − 14 (Reapproved 2021)

Standard Specification for

Folded Poly(Vinyl Chloride) (PVC) Pipe for Existing Sewer

and Conduit Rehabilitation

This standard is issued under the fixed designation F1504; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Figure 1 was editorially corrected in March 2021.

1. Scope*

1.1 This specification covers requirements and test methods for materials, dimensions, workmanship, flattening resistance, impact

resistance, pipe stiffness, extrusion quality, and a form of marking for folded (vinyl chloride) (PVC) pipe for existing sewer and

conduit rehabilitation.

1.2 Pipe produced to this specification is for use in non-pressure sewer and conduit rehabilitation where the folded PVC pipe is

inserted into and then expanded to conform to the wall of the original conduit forming a new structural pipe-within-a-pipe.

NOTE 1—For installation procedures refer to Practice F1947.

1.3 This specification includes pipe made only from materials specified in Section 6. This specification does not include pipe

manufactured from reprocessed, recycled, or reclaimed PVC.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 The following precautionary statement pertains to the test method portion only, Section 11, of this specification: This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory

limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.67 on Trenchless

Plastic Pipeline Technology.

Current edition approved Feb. 15, 2021. Published February 2021. Originally approved in 1994. Last previous edition approved in 2014 as F1504 –14. DOI:

10.1520/F1504-14R21.10.1520/F1504-14R21E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F1504 − 14 (2021)

D1600 Terminology for Abbreviated Terms Relating to Plastics

D1784 Classification System and Basis for Specification for Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlorinated

Poly(Vinyl Chloride) (CPVC) Compounds

F1947 Practice for Installation of Folded Poly (Vinyl Chloride) (PVC) Pipe into Existing Sewers and Conduits

D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

D2152 Test Method for Adequacy of Fusion of Extruded Poly(Vinyl Chloride) (PVC) Pipe and Molded Fittings by Acetone

Immersion

D2412 Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

D2444 Practice for Determination of the Impact Resistance of Thermoplastic Pipe and Fittings by Means of a Tup (Falling

Weight)

F412 Terminology Relating to Plastic Piping Systems

F1057 Practice for Estimating the Quality of Extruded Poly (Vinyl Chloride) (PVC) Pipe by the Heat Reversion Technique

2.2 Federal Standard:

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

2.3 Military Standard:

MIL-STD-129 Marking for Shipment and Storage

3. Terminology

3.1 General—Abbreviations used in this specification are in accordance with Terminology D1600 and definitions are in

accordance with Terminology F412 unless otherwise indicated.

3.2 Definitions of Terms Specific to This Standard:

NOTE 1—This figure is intended only for clarification of terms specific to this specification and shows a representative folded pipe shape. Other folded

pipe shapes may meet the requirements of this specification.

FIG. 1 Folded Pipe and Rounded Pipe—Clarification of Terms

Available from DLA Document Services Building 4/D 700 Robbins Avenue Philadelphia, PA 19111-5094 http://quicksearch.dla.mil/

´1

F1504 − 14 (2021)

3.2.1 folded pipe—pipe that has been manufactured in a folded shape or that is subsequently folded for use in existing sewer and

conduit rehabilitation. See Fig. 1.

3.2.2 rounded pipe—A rounded pipe is a sample for test purposes formed when the folded pipe has been inserted into a circular

casing pipe and expanded with heat and pressure to fit tightly to the casing pipe taking a circular cross section, in accordance with

Section 10. See Fig. 1.

4. Significance and Use

4.1 The requirements of this specification are intended to provide folded pipe suitable for the rehabilitation of existing pipelines

and conduits conveying sewage, process flow, and storm water, under non–pressure conditions, through the heating, insertion, and

expansion of the folded pipe.

NOTE 2—Industrial waste disposal lines should be installed only with the specific approval of the cognizant code authority since chemicals not commonly

found in drains and sewers and temperatures in excess of 140 °F (60 °C) may be encountered.

5. Application of Materials

5.1 The nominal folded PVC pipe sizes specified in Section 8 are applicable for a range of original pipe inside diameters. Table

1 lists the recommended ranges for each nominal size.

6. Materials and Manufacture

6.1 Basic Materials—The pipe shall be made from virgin PVC compound meeting all the requirements for cell classifications

12334, 13223, 32334, or 33223 as defined in Specification D1784.

6.2 Rework Material—Clean rework material, generated from the manufacturer’s own PVC sewer pipe production may be used

by the same manufacturer provided that the rework material meets the requirements of 6.1 and that the pipe produced meets all

the requirements of this specification. Reworked material of intermixed cell classifications shall be labeled as the minimum cell

classification of this specification, and labeled in accordance with 15.1.3.1. Reworked material containing any copolymer materials

shall be labeled as copolymer material.

7. Other Requirements

7.1 Pipe Flattening—There shall be no evidence of splitting, cracking, or breaking when the rounded pipe is tested in accordance

with 11.3.

7.2 Pipe Impact Strength—The impact strength of the rounded pipe shall not be less than the values given in Table 2 when tested

in accordance with 11.4.

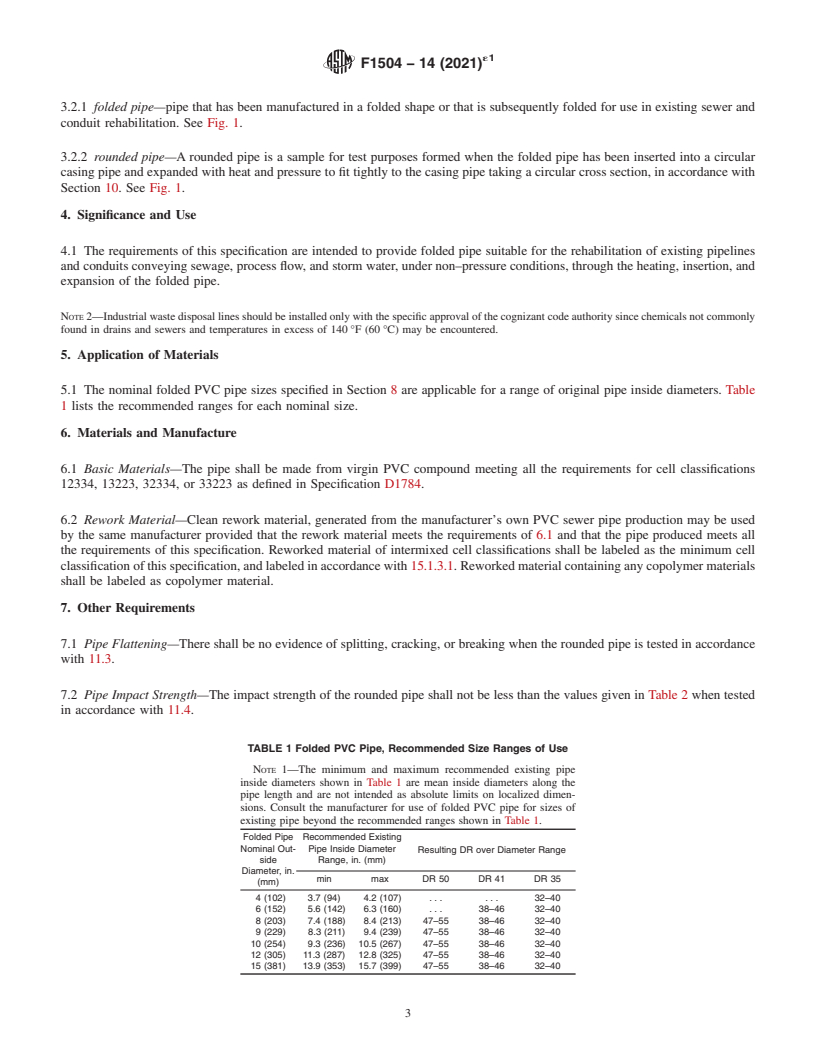

TABLE 1 Folded PVC Pipe, Recommended Size Ranges of Use

NOTE 1—The minimum and maximum recommended existing pipe

inside diameters shown in Table 1 are mean inside diameters along the

pipe length and are not intended as absolute limits on localized dimen-

sions. Consult the manufacturer for use of folded PVC pipe for sizes of

existing pipe beyond the recommended ranges shown in Table 1.

Folded Pipe Recommended Existing

Nominal Out- Pipe Inside Diameter

Resulting DR over Diameter Range

side Range, in. (mm)

Diameter, in.

min max DR 50 DR 41 DR 35

(mm)

4 (102) 3.7 (94) 4.2 (107) . . . . . . 32–40

6 (152) 5.6 (142) 6.3 (160) . . . 38–46 32–40

8 (203) 7.4 (188) 8.4 (213) 47–55 38–46 32–40

9 (229) 8.3 (211) 9.4 (239) 47–55 38–46 32–40

10 (254) 9.3 (236) 10.5 (267) 47–55 38–46 32–40

12 (305) 11.3 (287) 12.8 (325) 47–55 38–46 32–40

15 (381) 13.9 (353) 15.7 (399) 47–55 38–46 32–40

´1

F1504 − 14 (2021)

TABLE 2 Minimum Impact Strength at 73 °F (23 °C)

Pipe Size, in. (mm) Impact Strength, ft·lbf (J)

4 (102) 150 (203)

6 (152) 210 (284)

8 (203) 210 (284)

9 (229) 220 (299)

10 (254) 220 (299)

12 (305) 220 (299)

15 (381) 220 (299)

NOTE 3—This test is intended only for use as a quality-control test, not as a simulated service test.

7.3 Pipe Stiffness—Pipe stiffness values for the rounded pipe shall comply with Table 3 when tested in accordance with 11.6.

7.4 Extrusion Quality—The extrusion quality of the pipe shall be evaluated by both of the following test methods.

7.4.1 Acetone Immersion—The pipe shall not flake or disintegrate when tested in accordance with 11.6.1.

7.4.2 Heat Reversion—The extrusion quality shall be estimated by heat reversion method in accordance with 11.6.2.

7.5 Flexural Properties—Flexural modulus of elasticity values for the rounded pipe shall comply with Table 4 when tested in

accordance with 11.7.

8. Dimensions, Mass, and Permissible Variations

8.1 Rounded Pipe Diameter—The average outside diameter of the rounded pipe shall meet the requirements given in Table 5 with

a tolerance of 61.0 % when measured in accordance with 11.2.1.

8.2 Rounded Pipe Wall Thickness—The minimum wall thickness of the rounded pipe, when measured in accordance with 11.2.2,

shall not be less than the values specified in Table 5.

9. Workmanship, Finish, and Appearance

9.1 The rounded and folded pipes shall be homogeneous throughout and free from visible cracks, holes, foreign inclusions, or

other injurious defects. The pipe shall be as uniform as commercially practical in color, opacity, density, and other physical

properties.

10. Sampling

10.1 Rounded pipe sample preparation shall involve the unfolding and expansion of a folded pipe sample within a split pipe mold

with an inside diameter equal to the nominal outside diameter shown in Table 2. A folded pipe sample of sufficient length (10 ft

(3 m) maximum) to complete the testing requirements shall be inserted into the split pipe mold and secured at the ends. The

assembly shall then be placed in an enclosed chamber for heating. Ambient pressure steam shall be applied to the chamber for at

least a 15-min period at a minimum temperature of 200 °F (93 °C). While maintaining the minimum 200 °F

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.