ASTM F1409-16

(Test Method)Standard Test Method for Straight Line Movement of Vacuum Cleaners While Cleaning Carpets

Standard Test Method for Straight Line Movement of Vacuum Cleaners While Cleaning Carpets

SIGNIFICANCE AND USE

4.1 This test method measures the horizontal component of the relative work required by the user during the cleaning operation for the movement of a vacuum cleaner in the home or other cleaning location on standardized laboratory carpeting. Work is determined from the forces measured in the horizontal direction only by the mobility equipment.

4.2 This measurement is relative to the work performed by the user of vacuum cleaners and may be used for comparison between vacuum cleaners.

4.3 The relation between actual vacuum cleaner usage and the method of operation is valid only if the vacuum cleaner user operates the vacuum cleaner properly and in accordance with the manufacturer's instructions.

SCOPE

1.1 This test method covers a measurement of the relative work required to move an upright, canister, stick, or combination vacuum cleaner in a straight line with forward and backward stroking on a selection of typical carpeted surfaces.

1.1.1 This test method measures only the horizontal component of work required to move the vacuum cleaner on carpet.

1.2 This test method can be used in the testing of household and commercial vacuum cleaners.

1.3 This test method measures the relative work needed to move the vacuum cleaner with its motor or motors in operation.

1.4 This test method applies to the vacuum cleaning of carpets only.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1409 − 16

Standard Test Method for

Straight Line Movement of Vacuum Cleaners While Cleaning

1

Carpets

This standard is issued under the fixed designation F1409; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F884 Test Method for Motor Life Evaluation of a Built-In

(Central Vacuum) Vacuum Cleaner

1.1 This test method covers a measurement of the relative

F922 Test Method for Motor Life Evaluation of an Electric

work required to move an upright, canister, stick, or combina-

Motorized Nozzle

tion vacuum cleaner in a straight line with forward and

F1038 Test Method for Motor Life Evaluation of a Canister,

backward stroking on a selection of typical carpeted surfaces.

Hand-held, Stick, and Utility Type Vacuum Cleaner With-

1.1.1 This test method measures only the horizontal com-

out a Driven Agitator

ponentofworkrequiredtomovethevacuumcleaneroncarpet.

F1334 Test Method for Determining A-Weighted Sound

1.2 This test method can be used in the testing of household

Power Level of Vacuum Cleaners

and commercial vacuum cleaners.

3. Summary of Test Method

1.3 This test method measures the relative work needed to

move the vacuum cleaner with its motor or motors in opera-

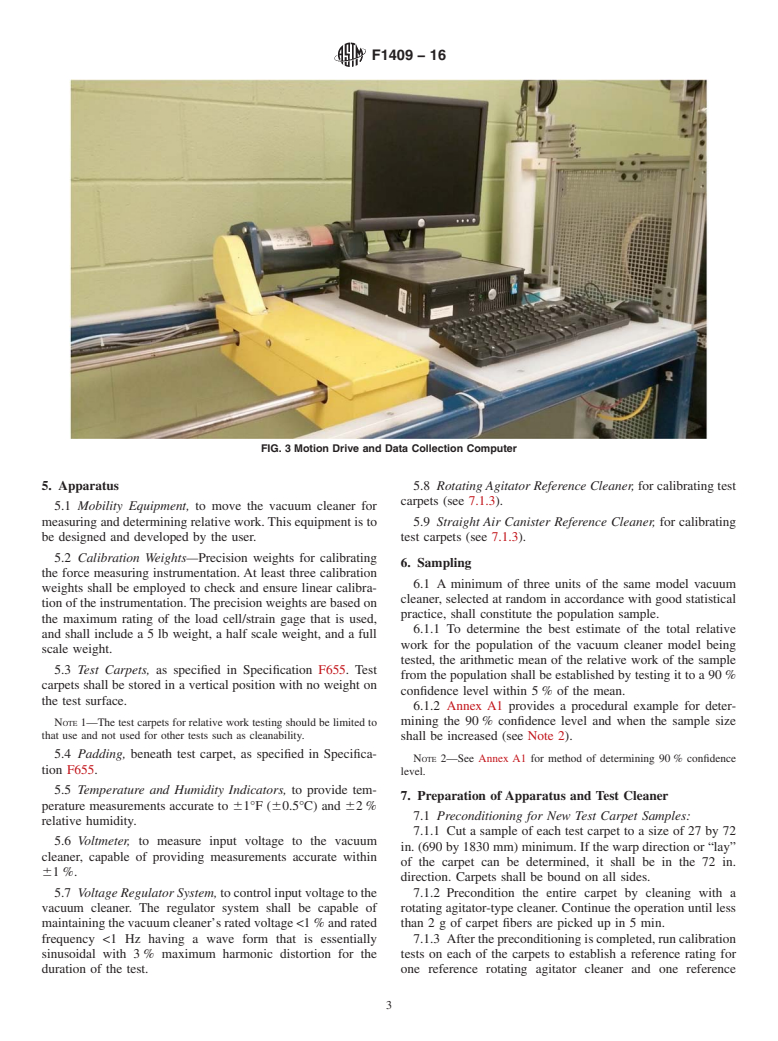

3.1 Mobility equipment is to be constructed and used to

tion.

push the vacuum cleaner back and forth on the test carpet in a

prescribed manner during the test. The mobility equipment is

1.4 This test method applies to the vacuum cleaning of

to employ a handle clamp assembly with a strain gage, to be

carpets only.

attached to the vacuum cleaner handle. This strain gage

1.5 The values stated in inch-pound units are to be regarded

measures the horizontal forces involved in moving only the

as standard. The values given in parentheses are mathematical

vacuum on the test carpet.

conversions to SI units that are provided for information only

3.2 Simultaneously, the incremental distance that the

and are not considered standard.

vacuum cleaner moves is also monitored and collected. The

1.6 This standard does not purport to address all of the

force and distance measurements are then used for calculating

safety concerns, if any, associated with its use. It is the

the work required to push and pull the vacuum on the test

responsibility of the user of this standard to establish appro-

carpet.

priate safety and health practices and determine the applica-

3.3 The design of the mobility equipment used in this

bility of regulatory limitations prior to use.

method is left to the user to develop and construct as there are

2. Referenced Documents numerous design approaches that may be employed for this

2

evaluation. The mobility equipment may be designed to move

2.1 ASTM Standards:

the vacuum automatically or manually. Photographs of one

F608 Test Method for Evaluation of Carpet Embedded Dirt

design used in the industry to move the vacuum without the

Removal Effectiveness of Household/Commercial

assistance of a technician is provided in Figs. 1-3. It is highly

Vacuum Cleaners

recommendedthatdataacquisitionandcomputerization,witha

F655 Specification for Test Carpets and Pads for Vacuum

data sampling rate of at least ten samples per second, be

Cleaner Testing

utilized to improve the speed and accuracy of data measure-

ments.

1

This test method is under the jurisdiction ofASTM Committee F11 on Vacuum

4. Significance and Use

Cleaners and is the direct responsibility of Subcommittee F11.20 on Performance

(Test Methods).

4.1 This test method measures the horizontal component of

Current edition approved Nov. 1, 2016. Published December 2016. Originally

the relative work required by the user during the cleaning

approved in 1992. Last previous edition approved in 2010 as F1409 – 00 (2010).

DOI: 10.1520/F1409-16.

operation for the movement of a vacuum cleaner in the home

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

orothercleaninglocationonstandardizedlaboratorycarpeting.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Work is determined from the forces measured in the horizontal

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. direction only by the mobility equipment.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1409 − 16

FIG. 1 ASTM Mobility Equipment

FIG. 2 Strain

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1409 − 00 (Reapproved 2010) F1409 − 16 An American National Standard

Standard Test Method for

Straight Line Movement of Vacuum Cleaners While Cleaning

1

Carpets

This standard is issued under the fixed designation F1409; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers thea measurement of the relative work required to move the carpet cleaning mechanism of an

upright, canister, stick, or combination vacuum cleaner in a straight line with forward and backward stroking on a selection of

typical carpeted surfaces.

1.1.1 This test method measures only the horizontal component of work required to move the vacuum cleaner on carpet.

1.2 This test method can be used in the testing of household and commercial vacuum cleaners.

1.3 This test method measures the relative work needed to move the vacuum cleaner with its motor or motors in operation.

1.4 This test method applies to the vacuum cleaning of carpets only.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

F608 Test Method for Evaluation of Carpet Embedded Dirt Removal Effectiveness of Household/Commercial Vacuum Cleaners

F655 Specification for Test Carpets and Pads for Vacuum Cleaner Testing

F884 Test Method for Motor Life Evaluation of a Built-In (Central Vacuum) Vacuum Cleaner

F922 Test Method for Motor Life Evaluation of an Electric Motorized Nozzle

F1038 Test Method for Motor Life Evaluation of a Canister, Hand-held, Stick, and Utility Type Vacuum Cleaner Without a

Driven Agitator

F1334 Test Method for Determining A-Weighted Sound Power Level of Vacuum Cleaners

3

2.2 ASTM Adjunct:

Mobility fixture book

3. Summary of Test Method

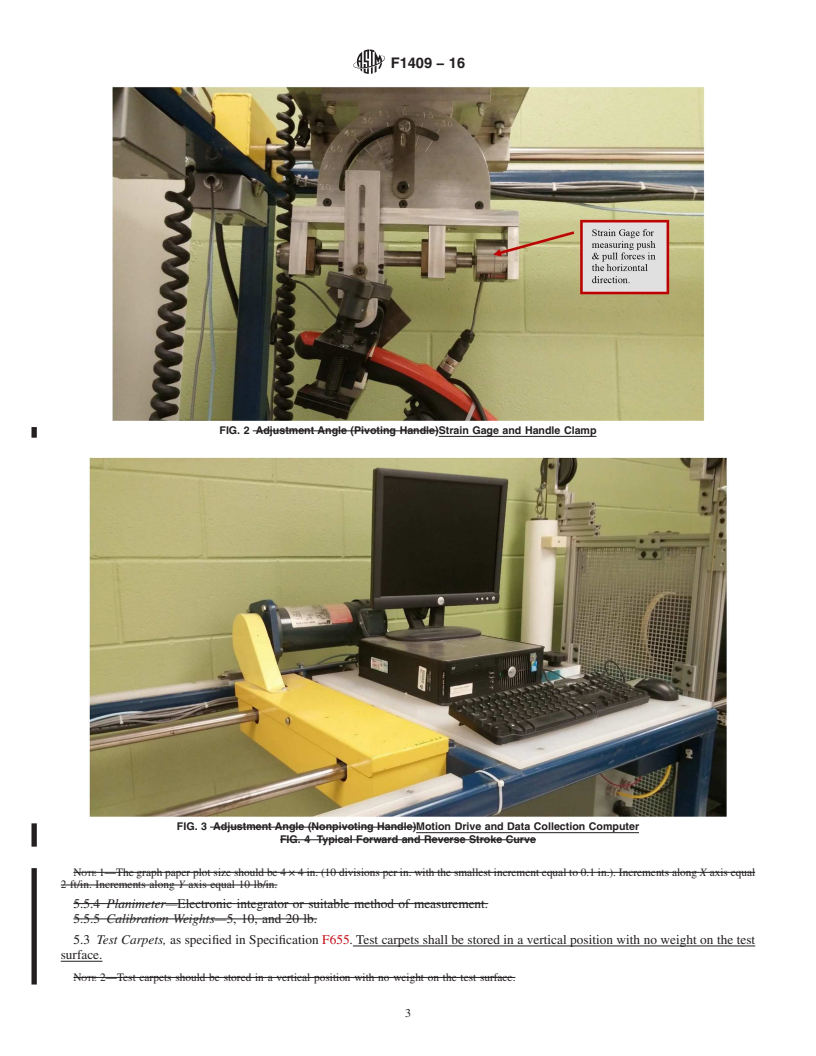

3.1 The carpet cleaning mechanism of Mobility equipment is to be constructed and used to push the vacuum cleaner is moved

back and forth on the test carpet in a prescribed manner during the test. A The mobility equipment is to employ a handle clamp

assembly with a strain gage is gage, to be attached to the vacuum cleaner at the location where the user’s working hand usually

grips the carpet cleaning mechanism. This handle. This strain gage measures the force horizontal forces involved in moving only

the carpet cleaning mechanism. vacuum on the test carpet.

3.2 Simultaneously, by means of a rod pivotally mounted to the test fixture, the the incremental distance that the vacuum cleaner

moves is monitored. also monitored and collected. The force and distance signalsmeasurements are then introduced into anused

1

This test method is under the jurisdiction of ASTM Committee F11 on Vacuum Cleaners and is the direct responsibility of Subcommittee F11.20 on Performance (Test

Methods).

Current edition approved Oct. 1, 2010Nov. 1, 2016. Published December 2010December 2016. Originally approved in 1992. Last previous edition approved in 20052010

as F1409 – 00 (2005).(2010). DOI: 10.1520/F1409-00R10.10.1520/F1409-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1409 − 16

for calculating X-Ythe recorder that produces a plot from which relative work is determined. Alternate data acquisition and

computing methods are acceptable.work required to push and pull the vacuum on the test carpet.

3.3 The design of the mobility equipment used in this method is left to the user to develop and construct as there are numerous

design approaches that may be employed for this evaluation. The mobility equipment may be designed to move the vacuum

automatically or manually. Pho

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.