ASTM D6371-05(2010)

(Test Method)Standard Test Method for Cold Filter Plugging Point of Diesel and Heating Fuels

Standard Test Method for Cold Filter Plugging Point of Diesel and Heating Fuels

SIGNIFICANCE AND USE

The CFPP of a fuel is suitable for estimating the lowest temperature at which a fuel will give trouble-free flow in certain fuel systems.

In the case of diesel fuel used in European light duty trucks, the results are usually close to the temperature of failure in service except when the fuel system contains, for example, a paper filter installed in a location exposed to the weather or if the filter plugging temperature is more than 12°C below the cloud point value in accordance with Test Method D2500, D5771, D5772, or D5773. Domestic heating installations are usually less critical and often operate satisfactorily at temperatures somewhat lower than those indicated by the test results.

The difference in results obtained from the sample as received and after heat treatment at 45°C for 30 min can be used to investigate complaints of unsatisfactory performance under low temperature conditions.

SCOPE

1.1 This test method covers the determination of the cold filter plugging point (CFPP) temperature of diesel and domestic heating fuels using either manual or automated apparatus.

Note 1—This test method is technically equivalent to test methods IP 309 and EN 116.

1.2 The manual apparatus and automated apparatus are both suitable for referee purposes.

1.3 This test method is applicable to distillate fuels, including those containing a flow-improving or other additive, intended for use in diesel engines and domestic heating installations.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 WARNINGMercury has been designated by many regulatory agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s websitehttp://www.epa.gov/mercury/faq.htmfor additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6371 − 05 (Reapproved 2010)

Standard Test Method for

Cold Filter Plugging Point of Diesel and Heating Fuels

This standard is issued under the fixed designation D6371; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers the determination of the cold

D2500Test Method for Cloud Point of Petroleum Products

filter plugging point (CFPP) temperature of diesel and domes-

D4057Practice for Manual Sampling of Petroleum and

tic heating fuels using either manual or automated apparatus.

Petroleum Products

NOTE 1—This test method is technically equivalent to test methods

D4177Practice for Automatic Sampling of Petroleum and

IP309 and EN116.

Petroleum Products

1.2 Themanualapparatusandautomatedapparatusareboth

D5771Test Method for Cloud Point of Petroleum Products

suitable for referee purposes.

(Optical Detection Stepped Cooling Method)

D5772Test Method for Cloud Point of Petroleum Products

1.3 This test method is applicable to distillate fuels, includ-

(Linear Cooling Rate Method)

ing those containing a flow-improving or other additive,

D5773Test Method for Cloud Point of Petroleum Products

intended for use in diesel engines and domestic heating

(Constant Cooling Rate Method)

installations.

E1Specification for ASTM Liquid-in-Glass Thermometers

2.2 IP Standards:

1.4 The values stated in SI units are to be regarded as

IP309Diesel and domestic heating fuels - Determination of

standard. No other units of measurement are included in this

cold filter plugging point

standard.

Specifications for IP Standard Thermometers

1.5 WARNING—Mercury has been designated by many

2.3 ISO Standards:

regulatory agencies as a hazardous material that can cause

IP3310Test sieves - Technical requirements and testing -

central nervous system, kidney and liver damage. Mercury, or

Part 1: Metal cloth

its vapor, may be hazardous to health and corrosive to

2.4 European Standards:

materials.Cautionshouldbetakenwhenhandlingmercuryand

EN116Diesel and domestic heating fuels - Determination

mercury containing products. See the applicable product Ma-

of cold filter plugging point

terial Safety Data Sheet (MSDS) for details and EPA’s

website—http://www.epa.gov/mercury/faq.htm—for addi-

tional information. Users should be aware that selling mercury

and/or mercury containing products into your state or country

may be prohibited by law.

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific

warning statements, see Section 7.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

1 3

This test method is under the jurisdiction of ASTM Committee D02 on Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of U.K., http://www.energyinst.org.uk.

Subcommittee D02.07 on Flow Properties. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Current edition approved Aug. 1, 2010. Published November 2010. Originally 4th Floor, New York, NY 10036, http://www.ansi.org.

approved in 1999. Last previous edition approved in 2005 as D6371–05. DOI: Available from European Committee for Standardization (CEN), 36 rue de

10.1520/D6371-05R10. Stassart, B-1050, Brussels, Belgium, http://www.cenorm.be.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6371 − 05 (2010)

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 certified reference material, n—a stable petroleum

product with a method-specific nominal CFPP value estab-

lished by a method-specific interlaboratory study following

6 4

RR:D02-1007 guidelines or ISO Guides 34 and 35.

3.1.2 cold filter plugging point, n—highest temperature,

expressed in multiples of 1°C, at which a given volume of fuel

fails to pass through a standardized filtration device in a

specified time when cooled under the conditions prescribed in

this test method.

4. Summary of Test Method

4.1 A specimen of the sample is cooled under specified

conditions and, at intervals of 1°C, is drawn into a pipet under

a controlled vacuum through a standardized wire mesh filter.

The procedure is repeated, as the specimen continues to cool,

for each 1°C below the first test temperature. Testing is

continued until the amount of wax crystals that have separated

out of solution is sufficient to stop or slow down the flow so

thatthetimetakentofillthepipetexceeds60sorthefuelfails

NOTE 1—All dimensions are in millimetres, and the comma (,) is used

toreturncompletelytothetestjarbeforethefuelhascooledby

as the decimal point.

a further 1°C.

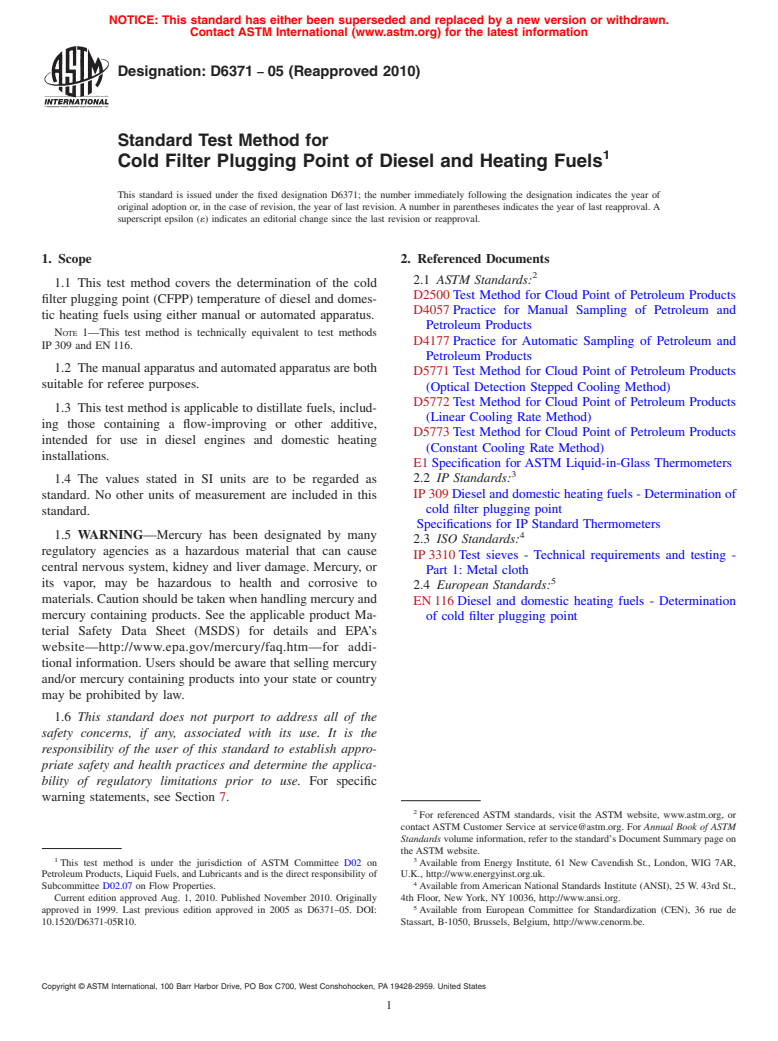

FIG. 1 Arrangement of Manual CFPP Apparatus

4.2 The indicated temperature at which the last filtration

was commenced is recorded as the CFPP.

selection from jars conforming to Test Method D2500, which specifies a

wider diameter tolerance.

5. Significance and Use

6.1.3 Jacket, brass, watertight, cylindrical, flat bottomed, to

5.1 The CFPPof a fuel is suitable for estimating the lowest

be used as an air bath. It shall have an inside diameter of 45 6

temperature at which a fuel will give trouble-free flow in

0.25 mm, outside diameter of 48 6 0.25 mm, and a height of

certain fuel systems.

115 6 3 mm (see Fig. 2).

5.2 In the case of diesel fuel used in European light duty

6.1.4 Insulating Ring, made from oil-resistant plastics or

trucks,theresultsareusuallyclosetothetemperatureoffailure

other suitable material, to be placed in the bottom of the jacket

in service except when the fuel system contains, for example,

(see 6.1.3) to provide insulation for the bottom of the test jar.

a paper filter installed in a location exposed to the weather or

It shall fit closely inside the jacket and have a thickness of 6 +

if the filter plugging temperature is more than 12°C below the

0.3 - 0.0 mm.

cloud point value in accordance with Test Method D2500,

6.1.5 Spacers (two) , approximately 5-mm thick, made of

D5771, D5772,or D5773. Domestic heating installations are

oil-resistant plastics or other suitable material, to be placed as

usually less critical and often operate satisfactorily at tempera-

shown in Fig. 1 around the test jar (see 6.1.2) to provide

tures somewhat lower than those indicated by the test results.

insulation for the test jar from the sides of the jacket. The

spacers shall fit closely to the test jar and closely inside the

5.3 The difference in results obtained from the sample as

jacket. The use of incomplete rings, each with a 2-mm

received and after heat treatment at 45°C for 30 min can be

circumferential gap, will accommodate variations in test jar

used to investigate complaints of unsatisfactory performance

diameter. The spacers and insulating ring may be made as a

under low temperature conditions.

single part as shown in Fig. 3.

6. Apparatus

6.1.6 Supporting Ring, of oil resistant plastics or other

suitable non-metallic, non-absorbent, oil-resistant material,

6.1 Manual Apparatus:

used to suspend the jacket (see 6.1.3) in a stable and upright

6.1.1 The apparatus, as detailed in 6.1.2 – 6.1.13, shall be

position in the cooling bath and to provide a concentric

arranged as shown in Fig. 1.

location for the stopper (see 6.1.7). A design is shown in Fig.

6.1.2 Test Jar,cylindrical,ofclearglass,flatbottomed,with

4 for guidance, but this design may be modified to suit the

aninternaldiameterof31.5 60.5mm,awallthicknessof1.25

cooling bath.

60.25 mm and a height of 120 6 5 mm. The jar shall have a

6.1.7 Stopper, of oil-resistant plastics or other suitable

permanent mark at the 45 6 1 mL level.

nonmetallic, nonabsorbent, oil-resistant material, to fit the test

NOTE 2—Test jars of the required dimensions may be obtained by

jar and the support ring as shown in Fig. 5. It shall have three

holes to accommodate the pipet (see 6.1.8) and the thermom-

eter(see6.1.9)andtoallowventingofthesystem.Ifnecessary,

Supporting data have been filed atASTM International Headquarters and may

be obtained by requesting Research Report RR:D02-1007. when using the high-range thermometer (see 6.1.9), the upper

D6371 − 05 (2010)

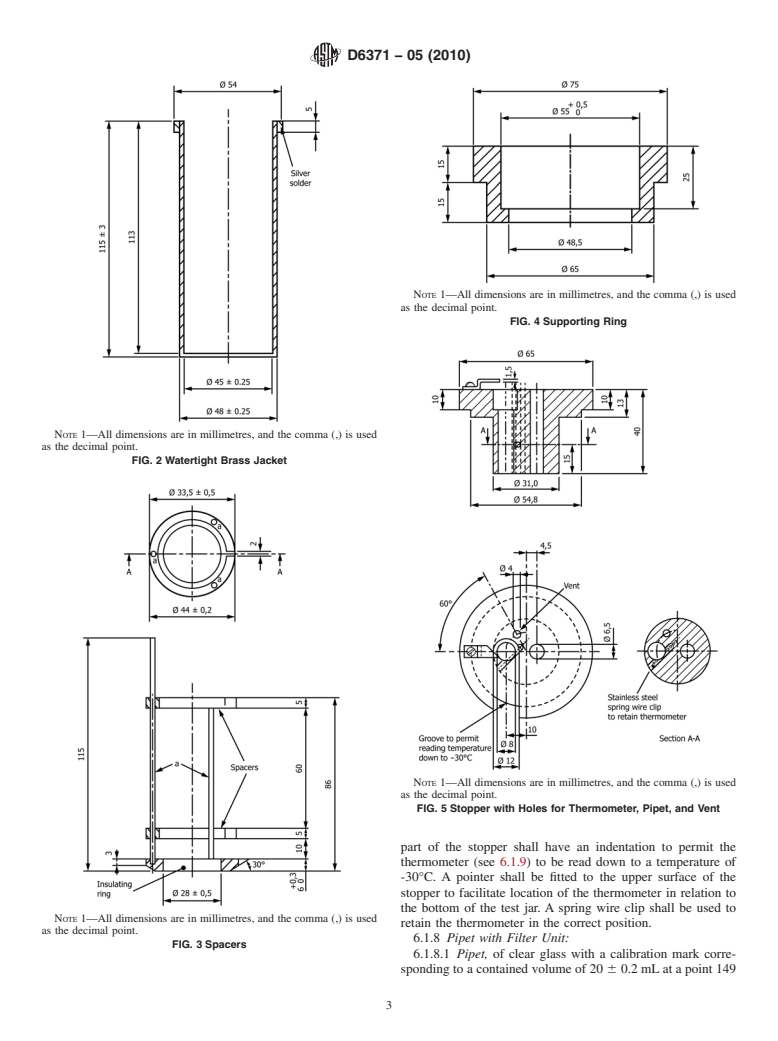

NOTE 1—All dimensions are in millimetres, and the comma (,) is used

as the decimal point.

FIG. 4 Supporting Ring

NOTE 1—All dimensions are in millimetres, and the comma (,) is used

as the decimal point.

FIG. 2 Watertight Brass Jacket

NOTE 1—All dimensions are in millimetres, and the comma (,) is used

as the decimal point.

FIG. 5 Stopper with Holes for Thermometer, Pipet, and Vent

part of the stopper shall have an indentation to permit the

thermometer (see 6.1.9) to be read down to a temperature of

-30°C. A pointer shall be fitted to the upper surface of the

stopper to facilitate location of the thermometer in relation to

the bottom of the test jar. A spring wire clip shall be used to

NOTE 1—All dimensions are in millimetres, and the comma (,) is used

retain the thermometer in the correct position.

as the decimal point.

6.1.8 Pipet with Filter Unit:

FIG. 3 Spacers

6.1.8.1 Pipet, of clear glass with a calibration mark corre-

sponding to a contained volume of 20 6 0.2 mLat a point 149

D6371 − 05 (2010)

NOTE 1—All dimensions are in millimetres, and the comma (,) is used

NOTE 1—All dimensions are in millimetres, and the comma (,) is used

as the decimal point.

as the decimal point.

FIG. 7 Filter Unit

FIG. 6 Pipet

pressed into the filter holder. The diameter of the exposed part

of the gauze shall be 12 + 0.1 - 0.0 mm (see Fig. 8).

(5) Brass Cylinder, threaded on the outside, that can be

6 0.5 mm from the bottom of the pipet (see Fig. 6). It shall be

screwed into the cavity of the body (see 6.1.8.2 (1)) to clamp

connected to the filter unit (see 6.1.8.2).

the filter holder (see 6.1.8.2 (4)) against the O-ring (6.1.8.2

6.1.8.2 Filter Unit (see Fig. 7), containing the following

(1)),The lower end shall have four slots to allow the specimen

elements:

to flow into the filter unit.

(1) Brass Body,withathreadedcavitythathousesthewire

mesh holder. The cavity shall be fitted with an O-ring of

NOTE 3—The requirements for the wire mesh are taken from

oil-resistant plastics. The internal diameter of the central tube

IP3310IP3310, to which reference may be made for methods for testing

the gauze.

shall be 4 6 0.1 mm.

(2) Brass Screw Cap, to connect the upper part of the body

6.1.9 Thermometers, having ranges shown below and con-

of the filter unit (see 6.1.8.2) to the lower part of the pipet (see

forming to the requirements prescribed in Specification E1 or

6.1.8.1) to ensure a leak-free joint.An example of satisfactory

Specifications for IP Standard Thermometers.

connection is shown in Fig. 7.

Thermometer Number

(3) Disc,15 6 0.1-mm diameter, of plain weave stainless

Thermometer Temperature Range ASTM IP

High-range for CFPP down to −38°C to +50°C 5C 1C

steel wire mesh gauze with a nominal aperture size of 45 µm.

−30°C

The nominal diameter of the wire shall be 32 µm, and the

Low-range from CFPP below –80°C to +20°C 6C 2C

tolerance for the size of an individual aperture shall be as

−30°C

Cooling bath −80°C to +20°C 6C 2C

follows:

No aperture size shall exceed the nominal size by more 6.1.10 Cooling Bath:

than 22 µm. 6.1.10.1 The type of cooling bath is optional, but it shall be

Theaverageaperturesizeshallbewithin 63.1µmofthe ofashapeandsizesuitableforcontainingthejacket(see6.1.3)

nominal size. in a stable and upright position at the required depth.

Not more than 6% of the apertures shall be above the 6.1.10.2 The bath shall be fitted with a cover with one or

nominal size by more than 13 µm. more holes in it to accommodate the supporting ring (see

(4) Filter Holder of Brass, in which the disc of wire mesh 6.1.6). The jacket (see 6.1.3) may be permanently mounted in

gauze (see 6.1.8.2 (3)) is firmly clamped by a retaining ring the cover.

D6371 − 05 (2010)

TABLE 1 Cooling Bath Temperatures

Expected CFPP Required Cooling Bath Temperature(s)

Down to −20°C −34 ± 0.5°C

Between −20°C and −35°C −34 ± 0.5°C then −51 ± 1°C

Below −35°C −34 ± 0.5°C then –51 ± 1°C then −67 ± 2°C

for the duration of the test. For multi-position testers using the

same vacuum pump, the flow rate shall be checked when

several positions are operating simultaneously.

7. Reagents and Materials

7.1 Heptane, clean commercial or reagent grade.

(Warning—Flammable. Harmful if inhaled.)

NOTE 1—All dimensions are in millimetres, and the comma (,) is used

7.2 Acetone, clean commercial or reagent grade.

as the decimal point.

FIG. 8 Brass Filter Holder (Warning—Extremely flammable.)

7.3 Filter Paper, (approximately 4 to 6 µm retention).

7.4 Certified Reference Materials.

6.1.10.3 The bath temperature shall be maintained at the

required value and tolerance by a refrigeration unit or by the

8. Sampling

use of suitable freezing mixtures, ensuring a homogenous

8.1 Unless otherwise specified in the commodity

temperature in the bath by stirring or other means of agitation.

specification, samples shall be taken as described in Practice

Table 1 lists the bath temperature set-points required in the

CFPP procedure. If only one bath is utilized, it must have the D4057 or D4177 in accordance with the requirements of

nationalstandardsorregulationforthesamplingoftheproduct

ability to change down to the next lower set-point temperature

under test, or both.

in a time period not exceeding 2 min 30 s.

6.1.11 Stopcock, glass, with double oblique bore of 3-mm

9. Preparation of Test Specimen

diameter.

9.1 Filter approximately 50 mL of the sample (see 8.1)at

6.1.12 Vacuum Source, vacuum pump or water pump pow-

erful enough to ensure an air flow rate in the vacuum regulator laboratory ambient temperature, but in any case not at a

temperature less than 15°C, through dry filter paper (see 7.3).

of 15 6 1 L/h for the duration of the test.

6.1.13 Vacuum Regulator, consisting of a glass bottle, at

10. Preparation of Apparatus

least 350-mm high, not less than 5 L capacity, partially filled

with water. It shall be closed by a s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.