ASTM C1036-16

(Specification)Standard Specification for Flat Glass

Standard Specification for Flat Glass

ABSTRACT

This specification covers the quality requirements of flat, transparent, clear, and tinted glass. This glass is intended to be used primarily for architectural glazing products including: coated glass, insulating glass units, laminated glass, mirrors, spandrel glass, or similar uses. The monolithic flat glass shall be supplied as cut sizes or stock sheets. Two types of glasses shall be used: Type I which is a transparent flat glass and Type II which is a patterned and wired flat glass. Type II glass shall have clear and tinted classes while Type I glass shall only have the clear class. Different test methods for Type I glass shall be performed in order to determine the following properties: point blemish and linear blemish content, ream distortion, string distortion, line distortion, dimension, squareness, reflectance, and transmittance. As for the type II glass the following properties shall be determined after different tests: associated distortion and blemish appraisal, dimension, point blemish, reflectance, and transmittance.

SCOPE

1.1 This specification covers the requirements for annealed, monolithic flat soda-lime glass supplied as cut sizes or stock sheets.

1.2 This specification is applicable for laboratory and field evaluation only to the extent that such evaluation can be carried out in accordance with the test method(s) prescribed herein.

1.3 This specification covers the quality requirements of flat, transparent, clear, and tinted glass. This glass is intended to be used primarily for architectural glazing products including: coated glass, insulating glass units, laminated glass, mirrors, spandrel glass, or similar uses.

Note 1: Reflective distortion is not addressed in this specification.

1.4 This specification covers the quality requirements of patterned or wired glasses intended to be used primarily for decorative and general glazing applications.

1.5 The values given in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1036 −16

Standard Specification for

1

Flat Glass

This standard is issued under the fixed designation C1036; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3. Terminology

1.1 This specification covers the requirements for annealed,

3.1 Definitions—For additional definitions of terms, refer to

monolithic flat soda-lime glass supplied as cut sizes or stock Terminology C162.

sheets.

3.2 Definitions of Terms Specific to This Standard:

1.2 This specification is applicable for laboratory and field

3.2.1 associated distortion, n—alteration of viewed images

evaluationonlytotheextentthatsuchevaluationcanbecarried

caused by variations in glass flatness or inhomogeneous

out in accordance with the test method(s) prescribed herein.

portions within the glass.

1.3 This specification covers the quality requirements of

3.2.2 bevel, n—angled surface at the edge of a lite of glass.

flat, transparent, clear, and tinted glass. This glass is intended

3.2.3 blemish, n—imperfectioninthebodyoronthesurface

to be used primarily for architectural glazing products includ-

oftheglass;forthepurposeofthisspecification,blemishesare

ing: coated glass, insulating glass units, laminated glass,

divided into two categories:

mirrors, spandrel glass, or similar uses.

3.2.3.1 linear blemish, n—scratches, rubs, digs, and other

NOTE 1—Reflective distortion is not addressed in this specification.

similar imperfections, which may be straight or curved in

1.4 This specification covers the quality requirements of

nature. If curved, the length of such a blemish is to be

patterned or wired glasses intended to be used primarily for

measured from end to end along the curve.

decorative and general glazing applications.

3.2.3.2 point blemish, n—crush, knots, dirt, stones, gaseous

1.5 The values given in SI units are to be regarded as the

inclusions, and other similar imperfections.

standard. The values given in parentheses are for information

3.2.4 bow, n—aconditioninwhichaliteofflatglassdeparts

only.

from a true plane.

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.2.5 chip depth, n—measured distance of a chip from the

responsibility of the user of this standard to establish appro- face of the glass into the thickness.

priate safety and health practices and determine the applica-

3.2.6 chip length , n—maximum distance parallel to the

bility of regulatory limitations prior to use.

edge of the glass from one edge of a chip to the other.

2. Referenced Documents

3.2.7 chip width, n—maximum perpendicular distance from

2

the edge of the glass to the inner edge of the chip.

2.1 ASTM Standards:

C162Terminology of Glass and Glass Products

3.2.8 clear glass, n—glass formulated to have transmittance

3

2.2 NFRC Standard: in the visible spectrum greater than 82% (reference to NFRC

NFRC 300Test Method for Determining the Solar Optical

300 measurement method) at a standard thickness of 6mm

1

Properties of Glazing Materials and Systems

( ⁄4in.) with lack of color as compared to tinted glass of the

same thickness.

1

This specification is under the jurisdiction ofASTM Committee C14 on Glass

3.2.9 crush, n—pitted condition with a dull appearance.

and Glass Products and is the direct responsibility of Subcommittee C14.08 on Flat

Glass.

3.2.10 cut size, n—glass ordered cut to its final intended

Current edition approved Nov. 1, 2016. Published November 2016. Originally

size.

ε1

approved in 1985. Last previous edition approved in 2011 as C1036–11 . DOI:

10.1520/C1036-16.

3.2.11 dig, n—a deep scratch in the glass surface.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.2.12 dirt, n—small particle of foreign matter embedded in

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the surface of flat glass.

the ASTM website.

3

3.2.13 fire crack, n—small, sometimes microscopic fissure

National Fenestration Rating Council, 84884 Georgia Ave., Suite 320, Silver

Spring, MD 20910. in the edge of wired or patterned glass.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1036−16

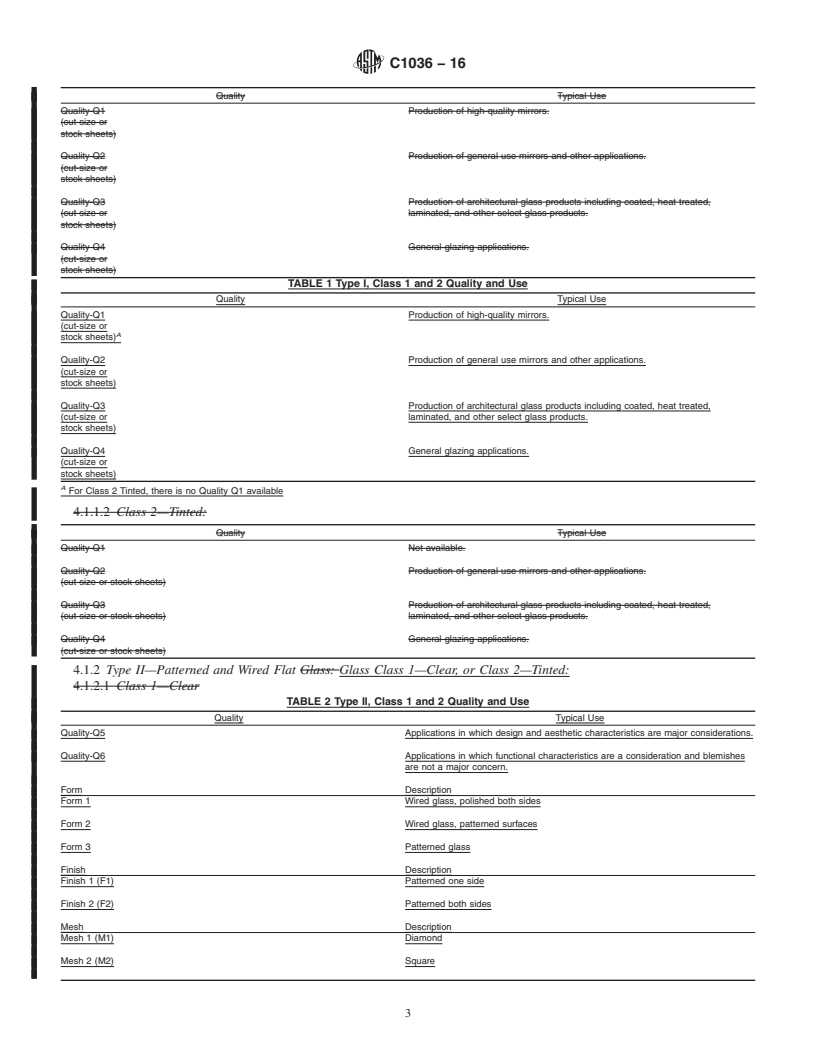

TABLE 1 Type I, Class 1 and 2 Quality and Use

3.2.14 flare, n—protrusion on the glass edge or corner of an

Quality Typical Use

otherwise rectangular surface.

Quality-Q1 Production of high-quality mirrors

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: C1036 − 11 C1036 − 16

Standard Specification for

1

Flat Glass

This standard is issued under the fixed designation C1036; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1

ε NOTE—Editorial changes were made in February 2012.

1. Scope

1.1 This specification covers the requirements for annealed, monolithic flat soda-lime glass supplied as cut sizes or stock sheets.

1.2 This specification is applicable for laboratory and field evaluation only to the extent that such evaluation can be carried out

in accordance with the test method(s) prescribed herein.

1.3 This specification covers the quality requirements of flat, transparent, clear, and tinted glass. This glass is intended to be used

primarily for architectural glazing products including: coated glass, insulating glass units, laminated glass, mirrors, spandrel glass,

or similar uses.

NOTE 1—Reflective distortion is not addressed in this specification.

1.4 This specification covers the quality requirements of patterned or wired glasses intended to be used primarily for decorative

and general glazing applications.

1.5 The values given in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C162 Terminology of Glass and Glass Products

3

2.2 NFRC Standard:

NFRC 300 Test Method for Determining the Solar Optical Properties of Glazing Materials and Systems

3. Terminology

3.1 Definitions—For additional definitions of terms, refer to Terminology C162.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 associated distortion, n—alteration of viewed images caused by variations in glass flatness or inhomogeneous portions

within the glass.

3.2.2 bevel, n—angled surface at the edge of a lite of glass.

3.2.3 blemish, n—imperfection in the body or on the surface of the glass; for the purpose of this specification, blemishes are

divided into two categories:

3.2.3.1 linear blemish, n—scratches, rubs, digs, and other similar imperfections, which may be straight or curved in nature. If

curved, the length of such a blemish is to be measured from end to end along the curve.

3.2.3.2 point blemish, n—crush, knots, dirt, stones, gaseous inclusions, and other similar imperfections.

1

This specification is under the jurisdiction of ASTM Committee C14 on Glass and Glass Products and is the direct responsibility of Subcommittee C14.08 on Flat Glass.

Current edition approved Oct. 1, 2011Nov. 1, 2016. Published October 2011November 2016. Originally approved in 1985. Last previous edition approved in 20062011

ε1

as C1036 – 06.C1036 – 11 . DOI: 10.1520/C1036-11E01.10.1520/C1036-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

National Fenestration Rating Council, 84884 Georgia Ave., Suite 320, Silver Spring, MD 20910.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1036 − 16

3.2.4 bow, n—a condition in which a lite of flat glass departs from a true plane.

3.2.5 chip depth, n—measured distance of a chip from the face of the glass into the thickness.

3.2.6 chip length , n—maximum distance parallel to the edge of the glass from one edge of a chip to the other.

3.2.7 chip width, n—maximum perpendicular distance from the edge of the glass to the inner edge of the chip.

3.2.8 clear glass, n—glass formulated to have transmittance in the visible spectrum greater than 82 % (reference to NFRC 300

1

measurement method) at a standard thickness of 6 mm ( ⁄4 in.) with lack of color as compared to tinted glass of the same thickness.

3.2.9 crush, n—lightly pitted condition with a dull gray appearance.

3.2.10 cut size, n—glass ordered cu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.