ASTM E636-14e1

(Guide)Standard Guide for Conducting Supplemental Surveillance Tests for Nuclear Power Reactor Vessels

Standard Guide for Conducting Supplemental Surveillance Tests for Nuclear Power Reactor Vessels

SIGNIFICANCE AND USE

3.1 Practices E185 and E2215 describe a minimum program for the surveillance of reactor vessel materials, specifically mechanical property changes that occur in service. This guide may be applied in order to generate additional information on radiation-induced property changes to better assist the determination of the optimum reactor vessel operation schemes.

SCOPE

1.1 This guide discusses test procedures that can be used in conjunction with, but not as alternatives to, those required by Practices E185 and E2215 for the surveillance of nuclear reactor vessels. The supplemental mechanical property tests outlined permit the acquisition of additional information on radiation-induced changes in mechanical properties of the reactor vessel steels.

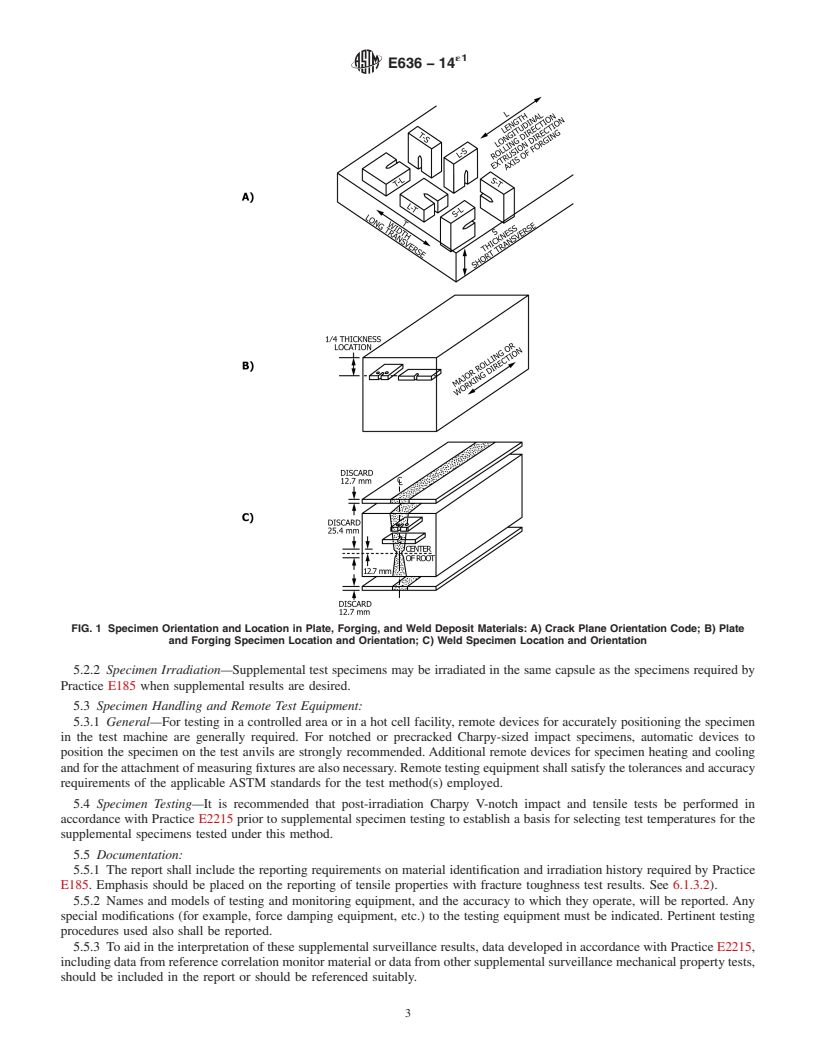

1.2 This guide provides recommendations for the preparation of test specimens for irradiation, and identifies special precautions and requirements for reactor surveillance operations and post-irradiation test planning. Guidance on data reduction and computational procedures is also given. Reference is made to other ASTM test methods for the physical conduct of specimen tests and for raw data acquisition.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: E636 − 14

Standard Guide for

Conducting Supplemental Surveillance Tests for Nuclear

1

Power Reactor Vessels

This standard is issued under the fixed designation E636; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—The title of this guide was updated editorially in May 2017.

1. Scope Light-Water Moderated Nuclear Power Reactor Vessels

E399Test Method for Linear-Elastic Plane-Strain Fracture

1.1 This guide discusses test procedures that can be used in

Toughness K of Metallic Materials

Ic

conjunction with, but not as alternatives to, those required by

E1253Guide for Reconstitution of Irradiated Charpy-Sized

Practices E185 and E2215 for the surveillance of nuclear

Specimens

reactor vessels. The supplemental mechanical property tests

E1820Test Method for Measurement of FractureToughness

outlined permit the acquisition of additional information on

E1921 Test Method for Determination of Reference

radiation-induced changes in mechanical properties of the

Temperature, T , for Ferritic Steels in the Transition

o

reactor vessel steels.

Range

1.2 This guide provides recommendations for the prepara-

E2215Practice for Evaluation of Surveillance Capsules

tion of test specimens for irradiation, and identifies special

from Light-Water Moderated Nuclear Power ReactorVes-

precautions and requirements for reactor surveillance opera-

sels

tions and post-irradiation test planning. Guidance on data

E2298Test Method for Instrumented Impact Testing of

reduction and computational procedures is also given. Refer-

Metallic Materials

ence is made to other ASTM test methods for the physical

3

2.2 ASME Standards:

conduct of specimen tests and for raw data acquisition.

ASME Boiler and PressureVessel Code, Section IIISubsec-

1.3 The values stated in SI units are to be regarded as the

tion NB (Class 1 Components)

standard. The values given in parentheses are for information

only.

3. Significance and Use

1.4 This international standard was developed in accor-

3.1 PracticesE185andE2215describeaminimumprogram

dance with internationally recognized principles on standard-

for the surveillance of reactor vessel materials, specifically

ization established in the Decision on Principles for the

mechanical property changes that occur in service. This guide

Development of International Standards, Guides and Recom-

may be applied in order to generate additional information on

mendations issued by the World Trade Organization Technical

radiation-induced property changes to better assist the deter-

Barriers to Trade (TBT) Committee.

mination of the optimum reactor vessel operation schemes.

2. Referenced Documents

4. Supplemental Mechanical Property Test

2

2.1 ASTM Standards:

4.1 Fracture Toughness Test—This test involves the dy-

E23Test Methods for Notched Bar Impact Testing of Me-

namicorstatictestingofafatigue-precrackedspecimenduring

tallic Materials

which a record of force versus displacement is used to

E185Practice for Design of Surveillance Programs for

determine material fracture toughness properties such as the

plane strain fracture toughness (K ), the J-integral fracture

Ic

1

toughness (J ), the J-R curve, and the reference temperature

This guide is under the jurisdiction of ASTM Committee E10 on Nuclear

Ic

Technology and Applications and is the direct responsibility of Subcommittee

(T )(seeTestMethodsE399,E1820,andE1921,respectively).

o

E10.02 on Behavior and Use of Nuclear Structural Materials.

These test methods generally apply to elastic, ductile-to-brittle

Current edition approved Jan. 1, 2014. Published February 2014. Originally

transition, or fully plastic behavior. The rate of specimen

approved in 1983. Last previous edition approved in 2010 as E636–10. DOI:

10.1520/E0636-14E01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American Society of Mechanical Engineers, 345 E. 47th St.,

the ASTM website. New York, NY 10017.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

E636 − 14

loading or stress intensity increase required for test classifica-

tion as quasi-static or dynamic is indicated by the referenced

test methods. All three test methods specify a lower limit on

loading rate for dynamic tests.

4.2 Fracture Toughness Test at Impact Loading Rates—This

test involves impact testing of Char

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E636 − 14 E636 − 14

Standard Guide for

Conducting Supplemental Surveillance Tests for Nuclear

1

Power Reactor Vessels, E 706 (IH)Vessels

This standard is issued under the fixed designation E636; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—The title of this guide was updated editorially in May 2017.

1. Scope

1.1 This guide discusses test procedures that can be used in conjunction with, but not as alternatives to, those required by

Practices E185 and E2215 for the surveillance of nuclear reactor vessels. The supplemental mechanical property tests outlined

permit the acquisition of additional information on radiation-induced changes in mechanical properties of the reactor vessel steels.

1.2 This guide provides recommendations for the preparation of test specimens for irradiation, and identifies special precautions

and requirements for reactor surveillance operations and post-irradiation test planning. Guidance on data reduction and

computational procedures is also given. Reference is made to other ASTM test methods for the physical conduct of specimen tests

and for raw data acquisition.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E23 Test Methods for Notched Bar Impact Testing of Metallic Materials

E185 Practice for Design of Surveillance Programs for Light-Water Moderated Nuclear Power Reactor Vessels

E399 Test Method for Linear-Elastic Plane-Strain Fracture Toughness K of Metallic Materials

Ic

E1253 Guide for Reconstitution of Irradiated Charpy-Sized Specimens

E1820 Test Method for Measurement of Fracture Toughness

E1921 Test Method for Determination of Reference Temperature, T , for Ferritic Steels in the Transition Range

o

E2215 Practice for Evaluation of Surveillance Capsules from Light-Water Moderated Nuclear Power Reactor Vessels

E2298 Test Method for Instrumented Impact Testing of Metallic Materials

3

2.2 ASME Standards:

ASME Boiler and Pressure Vessel Code, Section III Subsection NB (Class 1 Components)

3. Significance and Use

3.1 Practices E185 and E2215 describe a minimum program for the surveillance of reactor vessel materials, specifically

mechanical property changes that occur in service. This guide may be applied in order to generate additional information on

radiation-induced property changes to better assist the determination of the optimum reactor vessel operation schemes.

4. Supplemental Mechanical Property Test

4.1 Fracture Toughness Test—This test involves the dynamic or static testing of a fatigue-precracked specimen during which

a record of force versus displacement is used to determine material fracture toughness properties such as the plane strain fracture

1

This guide is under the jurisdiction of ASTM Committee E10 on Nuclear Technology and Applications and is the direct responsibility of Subcommittee E10.02 on

Behavior and Use of Nuclear Structural Materials.

Current edition approved Jan. 1, 2014. Published February 2014. Originally approved in 1983. Last previous edition approved in 2010 as E636 – 10. DOI:

10.1520/E0636-14.10.1520/E0636-14E01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Society of Mechanical Engineers, 345 E. 47th St., New York, NY 10017.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

E636 − 14

toughness (K ), the J-integral fracture toughness (J ), the J-R curve, and the reference temperature (T ) (see Test Methods E399,

Ic Ic o

E1820, and E1921, respectively). These test methods generally apply to elastic, ductile-to-brittle transition, or fully plastic

behav

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.