ASTM D2505-88(2004)e1

(Test Method)Standard Test Method for Ethylene, Other Hydrocarbons, and Carbon Dioxide in High-Purity Ethylene by Gas Chromatography

Standard Test Method for Ethylene, Other Hydrocarbons, and Carbon Dioxide in High-Purity Ethylene by Gas Chromatography

SIGNIFICANCE AND USE

High-purity ethylene is required as a feedstock for some manufacturing processes, and the presence of trace amounts of carbon dioxide and some hydrocarbons can have deleterious effects. This method is suitable for setting specifications, for use as an internal quality control tool and for use in development or research work.

SCOPE

1.1 This test method covers the determination of carbon dioxide, methane, ethane, acetylene, and other hydrocarbons in high-purity ethylene. Hydrogen, nitrogen, oxygen, and carbon monoxide are determined in accordance with Test Method D2504. The percent ethylene is obtained by subtracting the sum of the percentages of the hydrocarbon and nonhydrocarbon impurities from 100. The method is applicable over the range of impurities from 1 to 500 parts per million volume (ppmV).

1.2 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For some specific hazard statements, see Section 6.

1.3 The values stated in acceptable metric units are to be regarded as the standard. The values in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

´1

Designation:D2505–88 (Reapproved 2004)

Standard Test Method for

Ethylene, Other Hydrocarbons, and Carbon Dioxide in High-

Purity Ethylene by Gas Chromatography

This standard is issued under the fixed designation D2505; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Warning notes were moved into text editorially in November 2004.

1. Scope 3. Summary of Test Method

1.1 This test method covers the determination of carbon 3.1 The sample is separated in a gas chromatograph system

dioxide, methane, ethane, acetylene, and other hydrocarbons in utilizing four different packed chromatographic columns with

high-purity ethylene. Hydrogen, nitrogen, oxygen, and carbon helium as the carrier gas. Methane and ethane are determined

monoxide are determined in accordance with Test Method by using a silica gel column. Propylene and heavier hydrocar-

D2504. The percent ethylene is obtained by subtracting the bons are determined using a hexamethylphosphoramide

sum of the percentages of the hydrocarbon and nonhydrocar- (HMPA) column. Acetylene is determined by using, in series,

bon impurities from 100. The method is applicable over the a hexadecane column and a squalane column. Carbon dioxide

range of impurities from 1 to 500 parts per million volume is determined using a column packed with activated charcoal

(ppmV). impregnated with a solution of silver nitrate in b,b8-

1.2 This standard does not purport to address all of the oxydipropionitrile. Columns other than those mentioned above

safety concerns, if any, associated with its use. It is the may be satisfactory (see 5.3). Calibration data are obtained

responsibility of the user of this standard to establish appro- using standard samples containing the impurities, carbon

priate safety and health practices and determine the applica- dioxide, methane, and ethane in the range expected to be

bility of regulatory limitations prior to use. For some specific encountered. Calibration data for acetylene are obtained as-

hazard statements, see Section 6. suming that acetylene has the same peak area response on a

1.3 The values stated in acceptable metric units are to be weight basis as methane. The acetylene content in a sample is

regarded as the standard. The values in parentheses are for calculatedonthebasisoftheratioofpeakareaoftheacetylene

information only. peak to the peak area of a known amount of methane.

Calculations for carbon dioxide, methane, and ethane are

2. Referenced Documents

carried out by the peak-height measurement method.

2.1 ASTM Standards:

4. Significance and Use

D2504 Test Method for Noncondensable Gases in C and

Lighter Hydrocarbon Products by Gas Chromatography 4.1 High-purity ethylene is required as a feedstock for some

D4051 Practice for Preparation of Low-Pressure Gas manufacturing processes, and the presence of trace amounts of

Blends carbon dioxide and some hydrocarbons can have deleterious

E260 Practice for Packed Column Gas Chromatography effects. This method is suitable for setting specifications, for

F307 Practice for Sampling Pressurized Gas for GasAnaly- use as an internal quality control tool and for use in develop-

sis ment or research work.

5. Apparatus

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee 5.1 Any chromatographic instrument with an overall sensi-

D02.D0 on Hydrocarbons for Chemical and Special Uses.

tivity sufficient to detect 2 ppmV or less of the compounds

Current edition approved Nov. 1, 2004. Published November 2004. Originally

listed with a peak height of at least 2 mm without loss of

approved in 1966. Last previous edition approved in 1998 as D2505 – 88 (1998).

resolution.

DOI: 10.1520/D2505-88R04E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.2 Detectors—Thermal Conductivity—If a methanation re-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

actor is used, a flame ionization detector is also required. To

Standards volume information, refer to the standard’s Document Summary page on

determine carbon dioxide with a flame ionization detector, a

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D2505–88 (2004)

methanation reactor must be inserted between the column and

the detector and hydrogen added as a reduction gas (see Test

Method D2504, Appendix X1, Preparation of Methanation

Reactor).

5.3 Column—Any column or set of columns can be used

that separates carbon dioxide, methane, acetylene and C and

heavier compounds. There may be tailing of the ethylene peak

but do not use any condition such that the depth of the valleys

ahead of the trace peak is less than 50 % of the trace peak

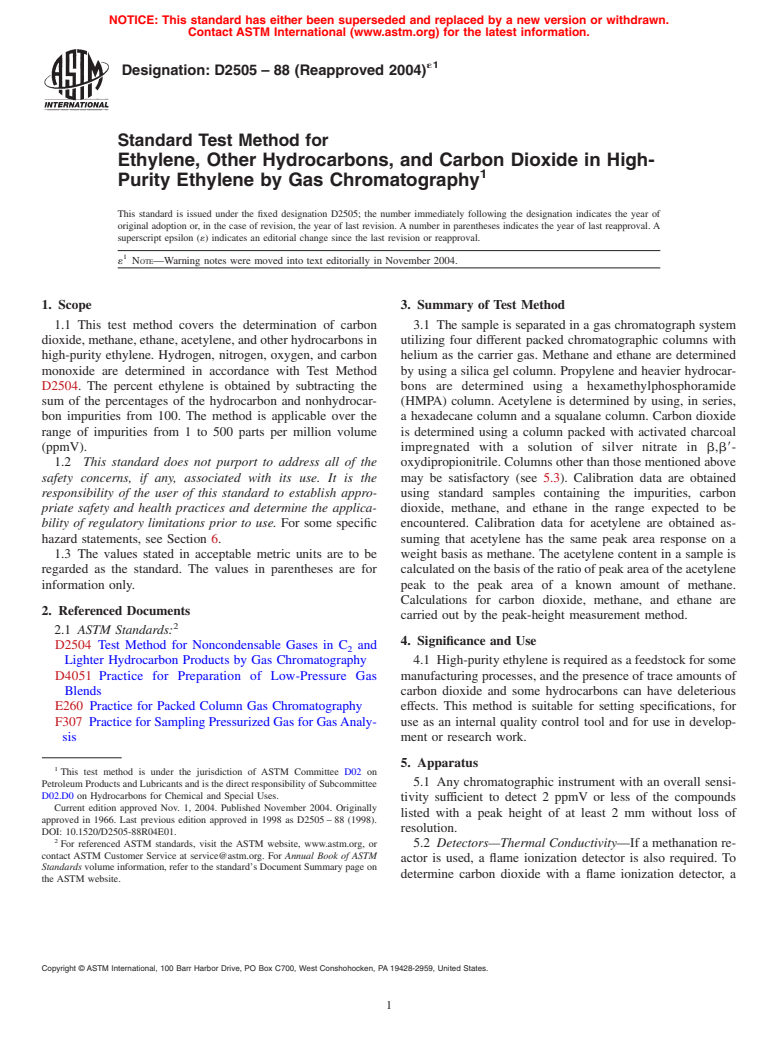

height. (See Fig. 1 for example.)

5.4 Recorder—A recorder with a full-scale response of 2 s

or less and a maximum rate of noise of 60.3 % of full scale.

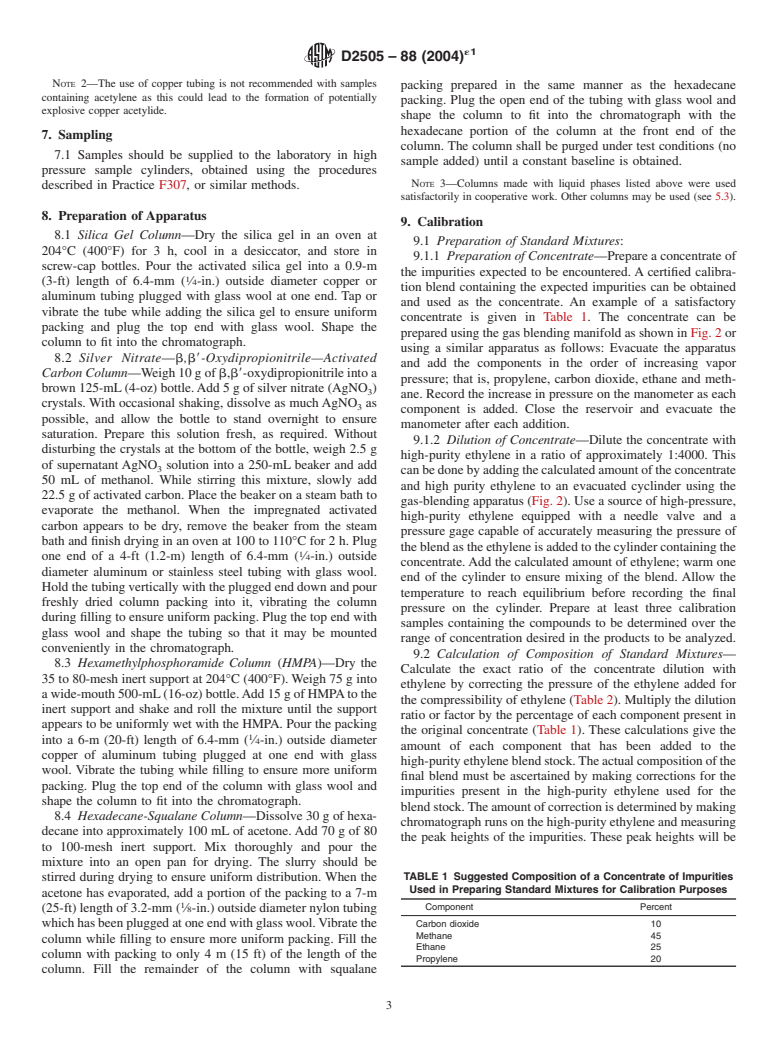

5.5 Gas-BlendingApparatus—Atypical gas-blending appa-

ratus is shown in Fig. 2. A high-pressure manifold equipped

withagagecapableofaccuratelymeasuringethylenepressures

up to 3.4 MN/m gage (500 psig) is required. Other types of

gas-blending equipment, such as described in Practice D4051,

can be used.

FIG. 2 Gas-Blending Manifold

NOTE 1— Practice E260 contains information that will be helpful to

those using this method.

6.3 Active Solids—Activated carbon, 30 to 40-mesh, silica

6. Reagents and Materials

gel, 100 to 200-mesh. Other sizes may be satisfactory.

6.1 CopperorAluminum,orStainlessSteelTubing, 6.4-mm 6

6.4 Liquid Phases—Hexamethylphosphoramide (HMPA ),

1 1

( ⁄4-in. ) outside diameter, and nylon tubing, 3.2-mm ( ⁄8-in.) 6 6

hexadecane. Squalene, silver nitrate, and b,b8-

outside diameter. 7

oxydipropionitrile. Other liquid phases may be satisfactory.

6.2 Solid Supports—Crushed firebrick or calcined diatoma-

(Warning—Combustible solvents. See A1.7.) (Warning—

ceous earth, such as Chromosorb P, 35 to 80-mesh and 80 to

HMPAmaybeharmfulifinhaled.Causesirritation.Apotential

100-mesh. Other supporting materials or mesh sieves can be

carcinogen (lungs). See A1.5.)

satisfactory.

6.5 Helium.(Warning—Compressed Gas, Hazardous Pres-

sure. See A1.2.)

6.6 Hydrogen.(Warning—Flammable Gas, Hazardous

Pressure. See A1.6.)

6.7 Acetone.(Warning—Extremely Flammable. SeeA1.1.)

6.8 Gases for Calibration—Pure or research grade carbon

dioxide, methane, ethane, acetylene, ethylene, propane, and

propylene. Certified calibration blends are commercially avail-

able from numerous sources and may be used. (Warning—

Flammable Gases, Hazardous Pressure. See A1.2 and A1.3.)

6.9 Methanol.(Warning—Flammable. Vapor Harmful. See

A1.4.)

A fraction sieved in the laboratory to 30 to 40 mesh from medium activity

charcoal, 20 to 60 mesh, sold by Central Scientific Co., 1700 Irving Park Road,

Chicago, IL60613, has been found satisfactory for this purpose. If you are aware of

alternative suppliers, please provide this information to ASTM International

Headquarters.Your comments will receive careful consideration at a meeting of the

responsible technical committee , which you may attend.

The sole source of supply of the apparatus known to the committee at this time

is Silica gel Code 923 available from the Davison Chemical Co., Baltimore,

Md.21203.Ifyouareawareofalternativesuppliers,pleaseprovidethisinformation

to ASTM International Headquarters. Your comments will receive careful consid-

erationatameetingoftheresponsibletechnicalcommittee ,whichyoumayattend.

FIG. 1 Typical Chromatogram for Propylene

The sole source of supply of the apparatus known to the committee at this time

is available from the Fisher Scientific Co., St. Louis, MO. If you are aware of

alternative suppliers, please provide this information to ASTM International

Headquarters.Your comments will receive careful consideration at a meeting of the

responsible technical committee , which you may attend.

3 7

ThesolesourceofsupplyoftheapparatusisavailablefromtheCeliteDivision, b,b8-oxydipropionitrile, sold by Distillation Products Industries, Division of

Johns Mansville Co., NewYork, NY. f you are aware of alternative suppliers, please Eastman Kodak Co., Rochester, NY, has been found to be satisfactory. If you are

provide this information toASTM International Headquarters. Your comments will aware of alternative suppliers, please provide this information to ASTM Interna-

receive careful consideration at a meeting of the responsible technical committee , tional Headquarters.Your comments will receive careful consideration at a meeting

which you may attend. of the responsible technical committee , which you may attend.

´1

D2505–88 (2004)

NOTE 2—The use of copper tubing is not recommended with samples

packing prepared in the same manner as the hexadecane

containing acetylene as this could lead to the formation of potentially

packing. Plug the open end of the tubing with glass wool and

explosive copper acetylide.

shape the column to fit into the chromatograph with the

hexadecane portion of the column at the front end of the

7. Sampling

column. The column shall be purged under test conditions (no

7.1 Samples should be supplied to the laboratory in high

sample added) until a constant baseline is obtained.

pressure sample cylinders, obtained using the procedures

NOTE 3—Columns made with liquid phases listed above were used

described in Practice F307, or similar methods.

satisfactorily in cooperative work. Other columns may be used (see 5.3).

8. Preparation of Apparatus

9. Calibration

8.1 Silica Gel Column—Dry the silica gel in an oven at

9.1 Preparation of Standard Mixtures:

204°C (400°F) for 3 h, cool in a desiccator, and store in

9.1.1 PreparationofConcentrate—Prepare a concentrate of

screw-cap bottles. Pour the activated silica gel into a 0.9-m

the impurities expected to be encountered. A certified calibra-

(3-ft) length of 6.4-mm ( ⁄4-in.) outside diameter copper or

tion blend containing the expected impurities can be obtained

aluminum tubing plugged with glass wool at one end. Tap or

and used as the concentrate. An example of a satisfactory

vibrate the tube while adding the silica gel to ensure uniform

concentrate is given in Table 1. The concentrate can be

packing and plug the top end with glass wool. Shape the

prepared using the gas blending manifold as shown in Fig. 2 or

column to fit into the chromatograph.

using a similar apparatus as follows: Evacuate the apparatus

8.2 Silver Nitrate—b,b8-Oxydipropionitrile—Activated

and add the components in the order of increasing vapor

CarbonColumn—Weigh10gof b,b8-oxydipropionitrileintoa

pressure; that is, propylene, carbon dioxide, ethane and meth-

brown 125-mL(4-oz) bottle.Add5gof silver nitrate (AgNO )

ane. Record the increase in pressure on the manometer as each

crystals. With occasional shaking, dissolve as muchAgNO as

component is added. Close the reservoir and evacuate the

possible, and allow the bottle to stand overnight to ensure

manometer after each addition.

saturation. Prepare this solution fresh, as required. Without

9.1.2 Dilution of Concentrate—Dilute the concentrate with

disturbing the crystals at the bottom of the bottle, weigh 2.5 g

high-purity ethylene in a ratio of approximately 1:4000. This

of supernatant AgNO solution into a 250-mL beaker and add

canbedonebyaddingthecalculatedamountoftheconcentrate

50 mL of methanol. While stirring this mixture, slowly add

and high purity ethylene to an evacuated cyclinder using the

22.5 g of activated carbon. Place the beaker on a steam bath to

gas-blending apparatus (Fig. 2). Use a source of high-pressure,

evaporate the methanol. When the impregnated activated

high-purity ethylene equipped with a needle valve and a

carbon appears to be dry, remove the beaker from the steam

pressure gage capable of accurately measuring the pressure of

bath and finish drying in an oven at 100 to 110°C for 2 h. Plug

theblendastheethyleneisaddedtothecylindercontainingthe

one end of a 4-ft (1.2-m) length of 6.4-mm ( ⁄4-in.) outside

concentrate.Add the calculated amount of ethylene; warm one

diameter aluminum or stainless steel tubing with glass wool.

end of the cylinder to ensure mixing of the blend. Allow the

Hold the tubing vertically with the plugged end down and pour

temperature to reach equilibrium before recording the final

freshly dried column packing into it, vibrating the column

pressure on the cylinder. Prepare at least three calibration

during filling to ensure uniform packing. Plug the top end with

samples containing the compounds to be determined over the

glass wool and shape the tubing so that it may be mounted

range of concentration desired in the products to be analyzed.

conveniently in the chromatograph.

9.2 Calculation of Composition of Standard Mixtures—

8.3 Hexamethylphosphoramide Column (HMPA)—Dry the

Calculate the exact ratio of the concentrate dilution with

35 to 80-mesh inert support at 204°C (400°F). Weigh 75 g into

ethylene by correcting the pressure of the ethylene added for

awide-mouth500-mL(16-oz)bottle.Add15gofHMPAtothe

the compressibility of ethylene (Table 2). Multiply the dilution

inert support and shake and roll the mixture until the support

ratio or factor by the percentage of each component present in

appears to be uniformly wet with the HMPA. Pour the packing

the original concentrate (Table 1). These calculations give the

into a 6-m (20-ft) length of 6.4-mm ( ⁄4-in.) outside diameter

amount of each component that has been added to the

copper of aluminum tubing plugged at one end with glass

high-purityethyleneblendstock.Theactualcompositionofthe

wool. Vibrate the tubing while filling to ensure more uniform

final blend must be ascertained by making corrections for the

packing. Plug the top end of the column with glass wool and

impurities present in the high-purity ethylene used for the

shape the column to fit into the chromatograph.

blendstock.Theamountofcorrectionisdeterminedbymaking

8.4 Hexadecane-SqualaneColumn—Dissolve 30 g of hexa-

chromatograph runs on the high-purity ethylene and measuring

decane into approximately 100 mL of acetone.Add 70 g of 80

the peak heights of the impurities. These peak heights will be

to 100-mesh inert support. Mix thoroughly and pour the

mixture into an open pan for drying. The slurry should be

TABLE 1 Suggested Composition of a Concentrate of Impurities

stirred during drying to ensure uniform distribution. When the

Used in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.