ASTM C1108-99

(Test Method)Standard Test Method for Plutonium by Controlled-Potential Coulometry

Standard Test Method for Plutonium by Controlled-Potential Coulometry

SCOPE

1.1 This test method describes the determination of plutonium in solutions of unirradiated nuclear-grade (that is, high-purity) materials by controlled-potential coulometry. Controlled-potential coulometry may be performed in a choice of supporting electrolytes, such as 0.9 HNO 3 , 1 HClO 4 , 1 HCl, 5 HCl, and 0.5 H 2 SO 4 . Limitations on the use of selected supporting electrolytes are discussed in Section 5. Optimum quantities of plutonium for this procedure are 5 to 10 mg.

1.2 Plutonium-bearing materials are radioactive and toxic. Adequate laboratory facilities, such as gloved boxes, fume hoods, controlled ventilation, etc., along with safe techniques must be used in handling specimens containing these materials.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 1108 – 99

Standard Test Method for

Plutonium by Controlled-Potential Coulometry

This standard is issued under the fixed designation C1108; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C1168 Practice for Preparation and Dissolution of Pluto-

nium Materials for Analysis

1.1 This test method describes the determination of pluto-

C1210 Guide for Establishing a Measurement System

nium in solutions of unirradiated nuclear-grade (that is, high-

Quality Control Program for Analytical Chemistry Labo-

purity) materials by controlled-potential coulometry.

ratories Within the Nuclear Industry

Controlled-potential coulometry may be performed in a choice

C1297 Guide for Qualification of Laboratory Analysts for

of supporting electrolytes, such as 0.9 M HNO,1 M HClO,1

3 4

the Analysis of Nuclear Fuel Cycle Materials

M HCl, 5 M HCl, and 0.5 M H SO . Limitations on the use of

2 4

E691 Practice for Conducting an Interlaboratory Study to

selected supporting electrolytes are discussed in Section 5.

Determine the Precision of a Test Method

Optimumquantitiesofplutoniumforthisprocedureare5to10

mg.

3. Summary of Test Method

1.2 Plutonium-bearing materials are radioactive and toxic.

3.1 In a controlled-potential coulometric measurement, the

Adequate laboratory facilities, such as gloved boxes, fume

substancebeingdeterminedreactsatanelectrode,thepotential

hoods, controlled ventilation, etc., along with safe techniques

of which is maintained at such a value that unwanted electrode

mustbeusedinhandlingspecimenscontainingthesematerials.

reactions are precluded under the prevailing experimental

1.3 The values stated in SI units are to be regarded as the

conditions. Those substances which have reduction-oxidation

standard. The values given in parentheses are for information

(redox) potentials near that of the ion being determined

only.

constitute interferences. Electrolysis current decreases expo-

1.4 This standard does not purport to address all of the

nentially as the reaction proceeds, until constant background

safety concerns, if any, associated with its use. It is the

current is obtained. Detailed discussions of the theory and

responsibility of the user of this standard to establish appro-

applications of this technique have been published (1, 2, 3, 4,

priate safety and health practices and determine the applica-

5, 6). The control-potential adjustment technique (7) can be

bility of regulatory limitations prior to use.

used to terminate the electrolysis of the specimen at constant

2. Referenced Documents background current without exhaustive electrolysis with con-

siderable reduction in operating time. Use of the control-

2.1 ASTM Standards:

potential adjustment technique requires that the coulometer

C1009 Guide for Establishing a Quality Assurance Pro-

integrator be capable of operations in a bipolar mode and that

gram for Analytical Chemistry Laboratories Within the

2 the plutonium-containing solution be of high purity, that is,

Nuclear Industry

nuclear grade.

C1068 Guide for Qualification of Measurement Methods

3 3.2 Plutonium(IV) is reduced to Pu(III) at a working elec-

by a Laboratory Within the Nuclear Industry

trode maintained at a potential more negative than the formal

C1128 Guide for Preparation of Working Reference Mate-

redox potential. Plutonium(III) is oxidized to Pu(IV) at a

rials for Use in the Analysis of Nuclear fuel Cycle

potential more positive than the formal redox potential. The

Materials

quantity of plutonium electrolyzed is calculated from the net

C1156 Guide for Establishing Calibration for a Measure-

number of coulombs required for the electrolysis, according to

ment Method Used to Analyze Nuclear Fuel Cycle Mate-

Faraday’s law. Corrections for incomplete reaction, derived

rials

from the Nernst equation, must be applied for electrolysis of

the sample aliquot (7, 8).

~Q 2 Q ! M

ThistestmethodisunderthejurisdictionofASTMCommitteeC-26onNuclear s b

W 5 (1)

Fuel Cycle and is the direct responsibility of Subcommittee C26.05 on Methods of nFf

Test.

Current edition approved Jan. 10, 1999. Published February 1999. Originally

published as C1108–88. Last previous edition C1108–93.

2 4

A Julie 100-V precision resistor number NB102A, accurate to 0.0015%, has Annual Book of ASTM Standards, Vol 14.02.

been found satisfactory. Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

Annual Book of ASTM Standards, Vol 12.01. this test method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 1108

direct interference. Iron must be removed by prior separation,

where:

or the effect of its presence must be corrected by a separate

W 5 grams of plutonium,

measurement of the iron concentration in the sample solution.

Q 5 coulombs required by the electrolysis,

s

Q 5 coulombs of background current, In 1 M HCl, 1 M HNO,or1 M HClO , iron interferes to a

b 3 4

M 5 gram-atomic weight of plutonium (must be adjusted

much lesser extent. The effect of iron in these supporting

for isotopic composition),

electrolytes may be minimized by the choice of redox poten-

n 5 numberofelectronsinvolvedintheelectrodereaction

tials, by a secondary titration (10), or by electrochemical

(for Pu(III)→ Pu(IV), n 51),

correction (12, 13).

F 5 Faraday constant, coulombs/equivalent, and

5.5 Nitrites—Nitrites are electrochemically active; there-

f 5 fraction of plutonium electrolyzed.

fore, saturated sulfamic acid solution should be added to the

electrolyte in the cell to destroy any interfering nitrites.

4. Significance and Use

5.6 Sulfate—Becauseofthecomplexingactionofsulfateon

4.1 Factors governing selection of a method for the deter-

Pu(IV) and the resultant shift in the redox potential of the

mination of plutonium include available quantity of sample,

Pu(III)-Pu(IV) couple, only small amounts of sulfate are

sample purity, desired level of reliability, and equipment.

tolerable in HNO , HCl, and HClO electrolytes. When using

3 4

4.1.1 This test method determines 5 to 10 mg of plutonium

these supporting electrolytes, specimens should be fumed to

with prior dissolution using Practice C1168.

dryness to assure adequate removal of excess sulfate (see

4.1.2 This test method calculates plutonium assay using

10.1.3).

physical constants as reference standards.

NOTE 1—Interference from a sulfate concentration of >0.004 M in 1 M

4.1.3 Chemical standards are used for quality control when

HClO has been reported (10).

prior chemical separation of plutonium is necessary to remove

5.7 Fluoride—Freefluoridecannotbetoleratedandmustbe

interferences (9).

removed from the specimen. Evaporation of the specimen in

4.2 Committee C-26 Safeguards Statement :

HNO toalowvolumeandfumingwithH SO areeffectivein

4.2.1 The materials (plutonium metal, plutonium oxide or 3 2 4

removing fluoride.

mixed oxide [(U, Pu) O ] powders and pellets) to which this

5.8 Oxygen—In HNO , HCl, and HClO supporting elec-

test method applies are subject to nuclear safeguards regula- 3 4

trolytes, oxygen may be an interference. In H SO , oxygen

2 4

tions governing their possession and use. Materials for use by

does interfere and must be removed. Purging the specimen

the commercial nuclear community must also meet composi-

with high-purity argon prior to and during the coulometric

tional specifications.

determination is recommended for all electrolytes.

4.2.2 The analytical method in this test method both meets

U. S. Department of Energy guidelines for acceptability of a

6. Apparatus

measurementmethodforgenerationofsafeguardsaccountabil-

6.1 Controlled-Potential Coulometer—A coulometer with

ity measurement data and also provides data that may be used

to demonstrate specification compliance in buyer-seller inter- the following specifications is recommended to achieve highly

precise and accurate results. (Room temperature stability of

actions.

61°C is recommended to ensure optimum instrument perfor-

5. Interferences

mance. Instruments with smaller output current or smaller

voltage span may be satisfactory.)

5.1 Interferenceiscausedbyionsthatareelectrochemically

Potentiostat (6)

active in the range of redox potentials used or by species that

Output voltage >25 V

prevent attainment of 100% current efficiency (for example,

Output current >200 mA

reductants, oxidants, and organic matter).

Open-loop response d-c gain >10

Unity-gain bandwidth >300 kHz

5.2 Polymer—Polymerized plutonium is not electrochemi-

Full-power response >10 kHz (slewing rate 0.5 V/µs)

cally active (10) and thus is neither reduced nor oxidized. The

Voltage zero offset stability >1-mV long term

presence of polymerized plutonium will give low results. The

Input d-c resistance >50 MV

polymer may be converted to electrochemically active species Input d-c current <50 nA

d-c control voltage span 64V

by HF treatment (10).

Resolution, hum, and drift <1 mV

5.3 Pu(VI)—Plutonium(VI) is only partially reduced to

Stability through extreme of line and 65mV

load variation

Pu(III) in 1 M HNO , HCl, or HClO supporting electrolyte

3 4

Digital Integrator (14)

solutions; therefore, the presence of Pu(VI) can lead to

Nonlinearity of V/F converter <0.01 % full scale

inaccurate results when present even as a small fraction of the

Full scale error adjustable to zero

Input offset voltage error adjustable to zero

totalplutonium.Plutonium(VI)iscompletelyreducedin0.5 M

Output readability <1 µg Pu

H SO (10) or 5.5 M HCl (11) supporting electrolyte.

2 4

Integrating capacity >10 C

5.4 Iron—In 0.5 M H SO supporting electrolyte, iron is

2 4 Accuracy <0.01 %

reduced and oxidized at essentially the same formal redox

6.2 Digital Voltmeter, 15-V range, 5 ⁄2digits accurate to

potentials as the Pu(III)-Pu(IV) couple and thus constitutes a

10 7

0.01% of full scale on all ranges. Input resistance >10 V.

Based upon Committee C-26 Safeguards Matrix (C1009, C1068, C1128,

C1156, C1210, and C1297). AHewlett-Packard3455ADVMhasbeenfoundtoexceedthesespecifications.

C 1108

6.3 Cell Assembly—The success of controlled-potential (SCE). The salt bridge is identical to the salt bridge described

coulometricmethodsisstronglydependentonthedesignofthe in 6.3.2 and is also filled with supporting electrolyte solution.

cell. The cell dimensions, electrode area, spacing, and stirring 6.3.4 Working Electrode, fabricated from either 8Au8-5/0

rateareimportantparametersinadesignthatwillminimizethe expanded annealed-gold metal or from 45-mesh platinum

time required for titration. The following components are gauze (Fig. 2). Storage of either electrode in 8 M HNO when

required for the recommended cell assembly (Fig. 1). not in use and rinsing with 8 M HNO between specimens are

6.3.1 Cell—The coulometry cell is fabricated from a cut-off normally adequate to maintain satisfactory electrode response.

50-mL borosilicate glass beaker with an inside diameter of 38 (Satisfactory response may be defined as the ability of the

mm and a height of 42 mm; the cut edges are rounded and electrode to oxidize and reduce the supporting electrolyte to 1

polished smooth. Other cells conforming to these dimensions to 2 µA in about 3 min with the current following an

are satisfactory. exponential curve.) If such electrode response is not obtained,

6.3.2 CounterElectrodeandSaltBridgeTube—Thecounter the following electrode reconditioning treatments, in increas-

electrode is a coiled length of 0.51-mm (0.020-in.) diameter ing order of severity, have been found to be successful in

platinumwire.Thesaltbridgetubeisunfiredhigh-silicaglass restoring response.

filled with the supporting electrolyte solution. 6.3.4.1 Thegoldelectrodemaybe:(1)brieflydippedincold

6.3.3 Reference Electrode and Salt Bridge Tube—The ref- concentrated HCl and thoroughly rinsed with 8 M HNO;(2)

erence electrode is a miniature saturated-calomel electrode briefly dipped in hot HCl and thoroughly rinsed with HNO ;

(3) briefly dipped in aqua regia and thoroughly rinsed with

HNO;or(4) soaked 10 min in the sulfuric acid-hydrofluoric

EitheratesttubewithunfiredVycorbottomsofType7930glassobtainedfrom acid mixture (7.16), the residual acid removed by fuming and

Corning Glass Works, or a 0.5 cm long, 0.5-cm diameter rod of unfired Vycor Type

thehotelectrodequenchedin8 MHNO .Aftereachtreatment,

7930 sealed into one end of a glass tube with heat-shrinkable TFE-fluorocarbon

the electrode is stored in 8 M HNO overnight. Following

tubing, has been found satisfactory for this application.

overnight storage, conditioning, that is, alternating reduction

AFisher Calomel Reference Electrode Catalog No. 13-639-79 has been found

satisfactory.

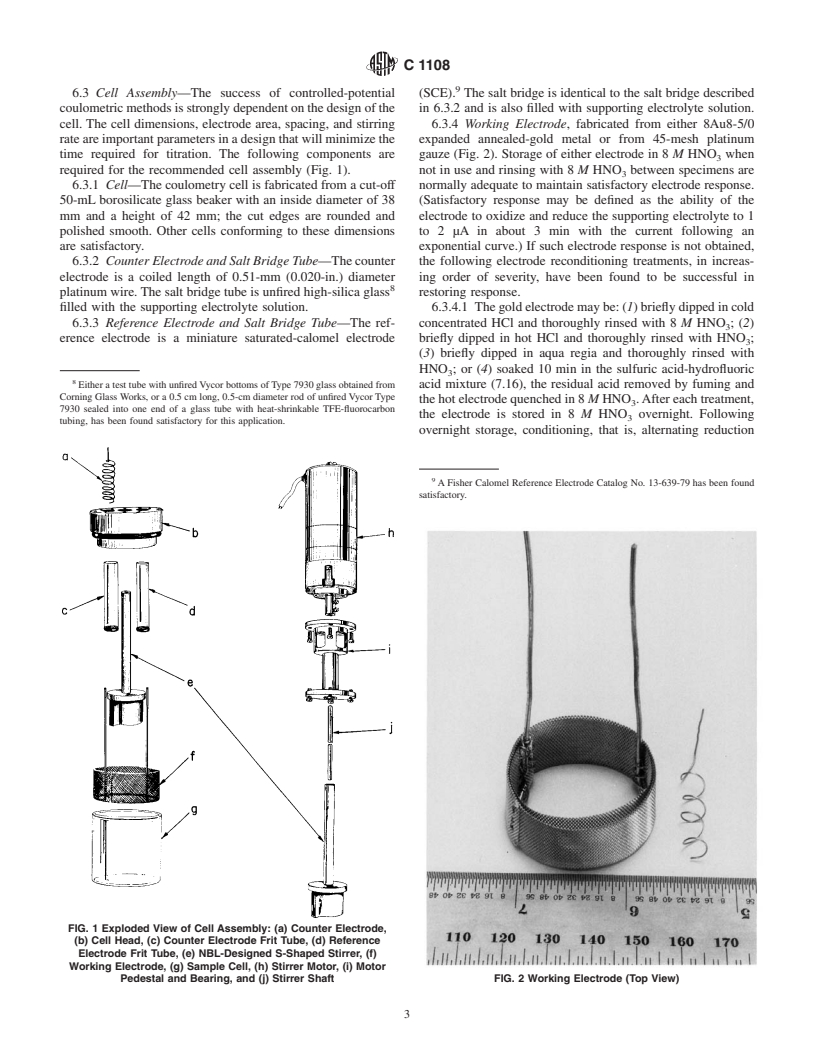

FIG. 1 Exploded View of Cell Assembly: (a) Counter Electrode,

(b) Cell Head, (c) Counter Electrode Frit Tube, (d) Reference

Electrode Frit Tube, (e) NBL-Designed S-Shaped Stirrer, (f)

Working Electrode, (g) Sample Cell, (h) Stirrer Motor, (i) Motor

Pedestal and Bearing, and (j) Stirrer Shaft FIG. 2 Working Electrode (Top View)

C 1108

and oxidation of the supporting electrolyte with and without obtained using overhead heating with quartz heat lamps

plutonium, may be required to achieve desired electrode controlled by a variable power supply. However, with proper

performance. care, other conventional means of heating may be used.

6.3.4.2 The platinum electrode may be subjected to any of 6.5 Hot Plate—Recommended for heating during the plu-

the above treatments, or it may be: (1) heated to red heat in a tonium oxidation state adjustment with hydrogen peroxide.

gasflameandquenchedin8MHNO or(2)heatedinafurnace 6.6 Quartz Clock Timer, accurate to 0.001 s.

to 900°C and quenched in 8 M HNO . Do not use these latter 6.7 100-V Precision Resistor, accurate to better than

treatments on gold electrodes as melting may occur. 0.01%.

6.3.5 Stirrer—Several types of stirrers have performed sat-

7. Reagents and Materials

isfactorily. A paddle-type stirrer capable of being driven at

1800 r/min by a synchronous motor, or a magnetically driven 7.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

stirring bar, is adequate. Magnetic stirring slightly simplifies

thearrangementofthecellcap.Foroptimumstirringefficiency all reagents conform to the specifications of the Committee on

Analytical Reagents of theAmerican Chemical Society where

with freedom from losses due to splashing, an S-shap

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.