ASTM D5635-04a

(Test Method)Standard Test Method for Dynamic Puncture Resistance of Roofing Membrane Specimens

Standard Test Method for Dynamic Puncture Resistance of Roofing Membrane Specimens

SIGNIFICANCE AND USE

An important factor affecting the performance of membrane roofing systems is their ability to resist dynamic puncture loads. This test method provides a means to assess dynamic puncture resistance.

This test method can be used to compare the dynamic puncture resistance of a single type of membrane as a function of a variety of insulation substrates or, conversely, to compare the resistance of a number of membrane specimens set on a single type of insulation.

The effect of temperature on puncture resistance can be studied by conducting the test under controlled conditions using such equipment as an environmental chamber, oven, or freezer.

The test method can be useful in developing performance criteria for membrane roofing systems.

The test method can be useful in developing classifications of dynamic puncture resistance of membrane roofing systems.

While it is considered that the results obtained by this laboratory test can afford a measure of the dynamic puncture resistance of membrane roofing systems in the field, (provided that service loads and temperature conditions are known) no direct correlation has yet been established.

SCOPE

1.1 This test method covers the evaluation of the maximum dynamic puncture load that roofing membrane samples can withstand, without allowing the passage of water, when subjected to impact from a rigid object having a sharp edge.

1.2 This laboratory test can be conducted at any desired temperature using membrane samples manufactured in a factory or prepared in a laboratory.

1.3 Roof membrane specimens to which the test method is applicable include bituminous built-up, polymer-modified bitumens, vulcanized rubbers, non-vulcanized polymeric, and thermoplastic materials.

1.4 This test method is not applicable to aggregate-surfaced membrane specimens; however, it is applicable to specimens having factory-applied granules.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5635 – 04a

Standard Test Method for

Dynamic Puncture Resistance of Roofing Membrane

1

Specimens

This standard is issued under the fixed designation D5635; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 For definitions of terms used in this test method, refer

to Terminology D1079.

1.1 This test method covers the evaluation of the maximum

dynamic puncture load that roofing membrane samples can

4. Summary of Test Method

withstand, without allowing the passage of water, when sub-

4.1 The roofing membrane test specimen, set on a thermal

jected to impact from a rigid object having a sharp edge.

insulation substrate, is subjected to a predetermined dynamic

1.2 This laboratory test can be conducted at any desired

impact load created by a rigid falling puncture head. The head

temperature using membrane samples manufactured in a fac-

falls through a quarter-circle trajectory from a vertical position

tory or prepared in a laboratory.

to horizontal position under gravitational acceleration.

1.3 Roof membrane specimens to which the test method is

4.2 The puncture energy is increased from 5 to 50 J (119 to

applicable include bituminous built-up, polymer-modified bi-

1190 ft·pdl) in 2.5 J (59.4 ft·pdl) increments until puncture of

tumens, vulcanized rubbers, non-vulcanized polymeric, and

themembranespecimenoccursoruntilthemaximumenergyis

thermoplastic materials.

reached.

1.4 This test method is not applicable to aggregate-surfaced

4.3 Puncture of the test specimen is assessed by visual

membrane specimens; however, it is applicable to specimens

examination and verified by conducting a watertightness test.

having factory-applied granules.

1.5 The values stated in SI units are to be regarded as the

5. Principle of the Test Method

standard. The values given in parentheses are for information

5.1 The energy at impact is equated to the potential energy

only.

of the raised puncture head as follows:

1.6 This standard does not purport to address all of the

E 5 mgH (1)

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

where:

priate safety and health practices and determine the applica-

m = mass of the puncture head (in kg or lbm),

bility of regulatory limitations prior to use.

2 2

g = gravitational acceleration (in m/s or ft/s ), and

H = heightthroughwhichthepunctureheadfalls(inmetres

2. Referenced Documents

or feet).

2

2.1 ASTM Standards:

In this test method, the height is fixed at 0.51 m (1.67 ft).

C578 Specification for Rigid, Cellular Polystyrene Thermal

2

With gravitational acceleration being equal to 9.8 m/s (32

Insulation

2

ft/s ), the impact energy is, thus, equal to the following:

D1079 Terminology Relating to Roofing andWaterproofing

E 5 5·m (2)

3. Terminology

where:

3.1 Definitions:

m = kg.

1

or

This test method is under the jurisdiction ofASTM Committee D08 on Roofing

and Waterproofing and is the direct responsibility of Subcommittee D08.20 on

E 5 53.4·m (3)

Roofing Membrane Systems.

Current edition approved July 1, 2004. Published July 2004. Originally approved

where:

in 1994. Last previous edition approved in 2004 as D5635 – 04. DOI: 10.1520/

m = lbm.

D5635-04A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Increasing the mass of the puncture head from 1 to 10 kg (2.2

Standards volume information, refer to the standard’s Document Summary page on

to 22 lbm) in increments of 0.5 kg (1.1 lbm) increases the

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5635 – 04a

puncture energy from 5 to 50 J (119 to 1190 ft·pdl) in so that the puncture head can be secured to it at a distance that

increments of 2.5 J (59.4 ft·pdl). is 0.51 m (1.67 ft), 60.5 %, from the point of rotation at the

base.

NOTE 1—A counter weight placed on the falling arm opposite to the

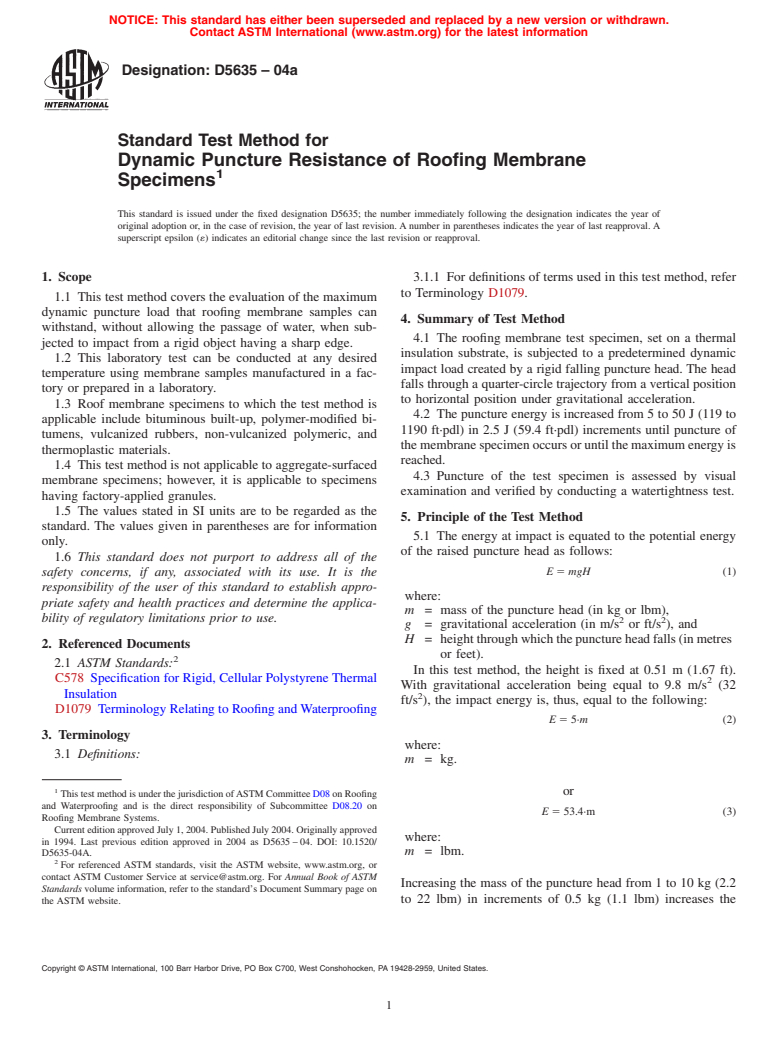

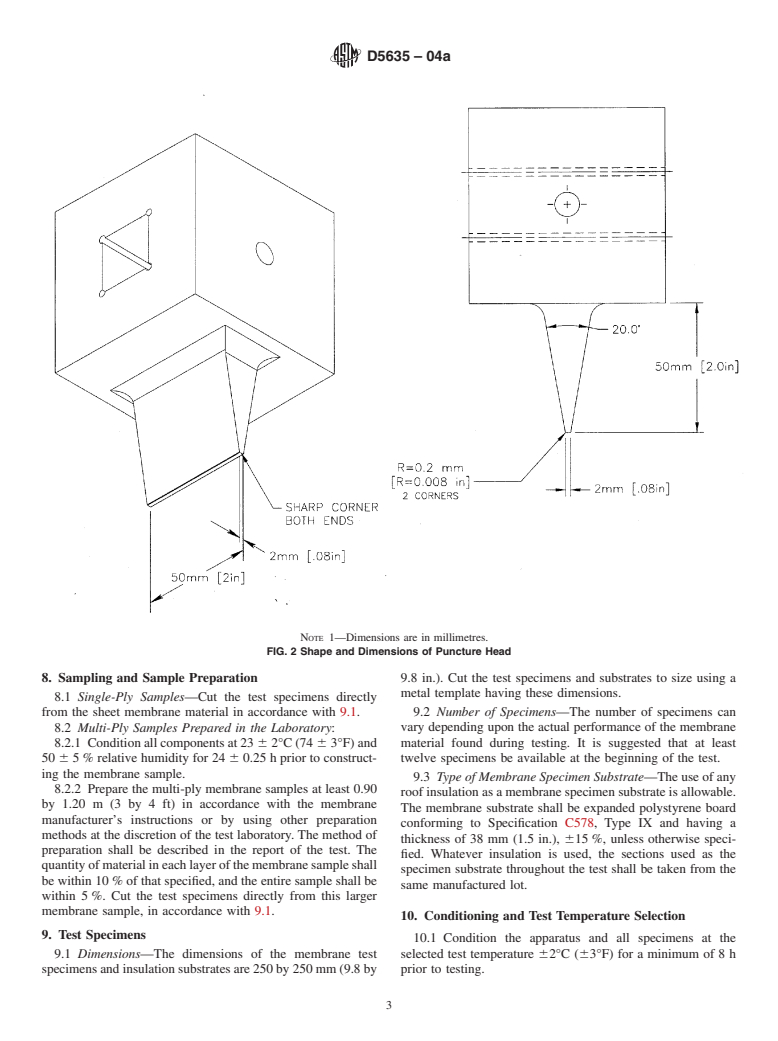

7.1.2 The shape and dimensions of a typical puncture head

axis of rotation eliminates the need to include the mass of the arm in the

are given in Fig. 2. When mounted on the arm, the face of the

determination of the impact energy.

puncture head is parallel to axis of rotation. Several heads of

6. Significance and Use

different mass may be needed. Alternatively, a means for

adding weights to a given puncture head to increase its mass

6.1 An important factor affecting the performance of mem-

can be used. The head and additional weights

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.