ASTM B138/B138M-11(2017)

(Specification)Standard Specification for Manganese Bronze Rod, Bar, and Shapes

Standard Specification for Manganese Bronze Rod, Bar, and Shapes

ABSTRACT

This specification establishes the requirements for rods, bars, and shapes of manganese bronze with Copper Alloy UNS Nos. C67000, C67500, and C67600. The materials for manufacture shall be cast billets of such purity and soundness as to be suitable for processing by hot working (extrusion, forging, or rolling) to produce a uniform wrought structure in the finished product. Tempers available under this specification are O60 (soft anneal temper), M20 (as hot rolled temper), M30 (as hot extruded temper), H02 (half-hard temper), and H04 (hard temper). Products shall be tested (including by residual stress test and ammonia vapor test) and shall adhere to dimensional (diameter, width, thickness, shape, length, straightness, and edge contour), mechanical (tensile and yield strength, and elongation), and chemical composition requirements.

SCOPE

1.1 This specification establishes the requirements for manganese bronze rod, bar and shapes produced in Copper Alloy UNS Nos. C67000, C67500, or C67600.

1.2 Units—The values stated in inch-pound units or SI units are to be regarded separately in the standard. Within the text, the SI values are shown in brackets. The values stated in each system of units may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 Warning—Mercury has been designated by many regulatory agencies as a hazardous material that can cause serious medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Safety Data Sheet (SDS) for additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

Note 1: Product suitable for hot forging applications is available under Specification B124/B124M.

1.4 The following safety hazard caveat pertains only to the Performance Requirements section of this specification.

1.4.1 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B138/B138M −11 (Reapproved 2017)

Standard Specification for

Manganese Bronze Rod, Bar, and Shapes

This standard is issued under the fixed designation B138/B138M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

1.1 This specification establishes the requirements for man- 2.1 ASTM Standards:

ganese bronze rod, bar and shapes produced in Copper Alloy B124/B124M Specification for Copper and Copper Alloy

Forging Rod, Bar, and Shapes

UNS Nos. C67000, C67500, or C67600.

B154 Test Method for Mercurous Nitrate Test for Copper

1.2 Units—The values stated in inch-pound units or SI units

Alloys

are to be regarded separately in the standard. Within the text,

B249/B249M Specification for General Requirements for

the SI values are shown in brackets. The values stated in each

Wrought Copper and Copper-Alloy Rod, Bar, Shapes and

system of units may not be exact equivalents; therefore, each

Forgings

system shall be used independently of the other. Combining

B858 Test Method forAmmoniaVaporTest for Determining

values from the two systems may result in nonconformance

Susceptibility to Stress Corrosion Cracking in Copper

with the standard.

Alloys

1.3 Warning—Mercury has been designated by many regu-

E8/E8M Test Methods for Tension Testing of Metallic Ma-

latory agencies as a hazardous material that can cause serious

terials

medical issues. Mercury, or its vapor, has been demonstrated to

E54 Test Methods for ChemicalAnalysis of Special Brasses

be hazardous to health and corrosive to materials. Caution

and Bronzes (Withdrawn 2002)

should be taken when handling mercury and mercury contain-

E62 Test Methods for Chemical Analysis of Copper and

ing products. See the applicable product Safety Data Sheet

CopperAlloys (Photometric Methods) (Withdrawn 2010)

(SDS) for additional information. Users should be aware that

E478 Test Methods for ChemicalAnalysis of CopperAlloys

selling mercury and/or mercury containing products into your

state or country may be prohibited by law.

3. General Requirements

3.1 The following sections of Specification B249/B249M

NOTE1—Productsuitableforhotforgingapplicationsisavailableunder

Specification B124/B124M.

constitute a part of this specification:

3.1.1 Terminology,

1.4 The following safety hazard caveat pertains only to the

3.1.2 Materials and Manufacture,

Performance Requirements section of this specification.

3.1.3 Workmanship, Finish and Appearance,

1.4.1 This standard does not purport to address all of the

3.1.4 Sampling,

safety concerns, if any, associated with its use. It is the

3.1.5 Number of Tests and Retests,

responsibility of the user of this standard to establish appro-

3.1.6 Specimen Preparation,

priate safety and health practices and determine the applica-

3.1.7 Test Methods,

bility of regulatory limitations prior to use.

3.1.8 Significance of Numerical Limits,

1.5 This international standard was developed in accor-

3.1.9 Inspection,

dance with internationally recognized principles on standard-

3.1.10 Rejection and Rehearing,

ization established in the Decision on Principles for the

3.1.11 Certification,

Development of International Standards, Guides and Recom-

3.1.12 Test Report,

mendations issued by the World Trade Organization Technical

3.1.13 Packaging and Package Marking, and

Barriers to Trade (TBT) Committee.

3.1.14 Supplementary Requirements.

1 2

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and CopperAlloys and is the direct responsibility of Subcommittee B05.02 on Rod, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Bar, Wire, Shapes and Forgings. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 1, 2017. Published April 2017. Originally the ASTM website.

approvedin1941.Lastpreviouseditionapprovedin2011asB138/B138M-11.DOI: The last approved version of this historical standard is referenced on

10.1520/B0138_B0138M-11R17. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B138/B138M − 11 (2017)

TABLE 1 Chemical Requirements

3.2 In addition, when a section with a title identical to one

of those referenced in 3.1 above, appears in this specification, Element, % Copper Alloy UNS No.

it contains additional requirements which supplement those C67000 C67500 C67600

A

appearing in Specification B249/B249M. Copper 63.0–68.0 57.0–60.0 57.0–60.0

Tin 0.50 max 0.50–1.5 0.50–1.5

Lead 0.20 max 0.20 max 0.50–1.0

4. Ordering Information

Zinc remainder remainder remainder

4.1 Include the following when placing orders for product

Iron 2.0–4.0 0.8–2.0 0.40–1.3

Aluminum 3.0–6.0 0.25 max . . .

under this specification, as applicable:

Manganese 2.5–5.0 0.05–0.50 0.05–0.50

4.1.1 ASTM designation and year of issue,

A

Includes silver.

4.1.2 Copper Alloy UNS No. designation (for example,

C67000),

4.1.3 Temper,

4.1.4 Form of product (for example, round, hexagonal),

6.2.1 When all elements in Table 1 are determined, the sum

4.1.5 Dimensions (for example, diameter, distance between

of results shall be 99.5 % min.

parallel surfaces, width, thickness),

4.1.6 Tolerances for shapes,

7. Temper

4.1.7 Edge contours,

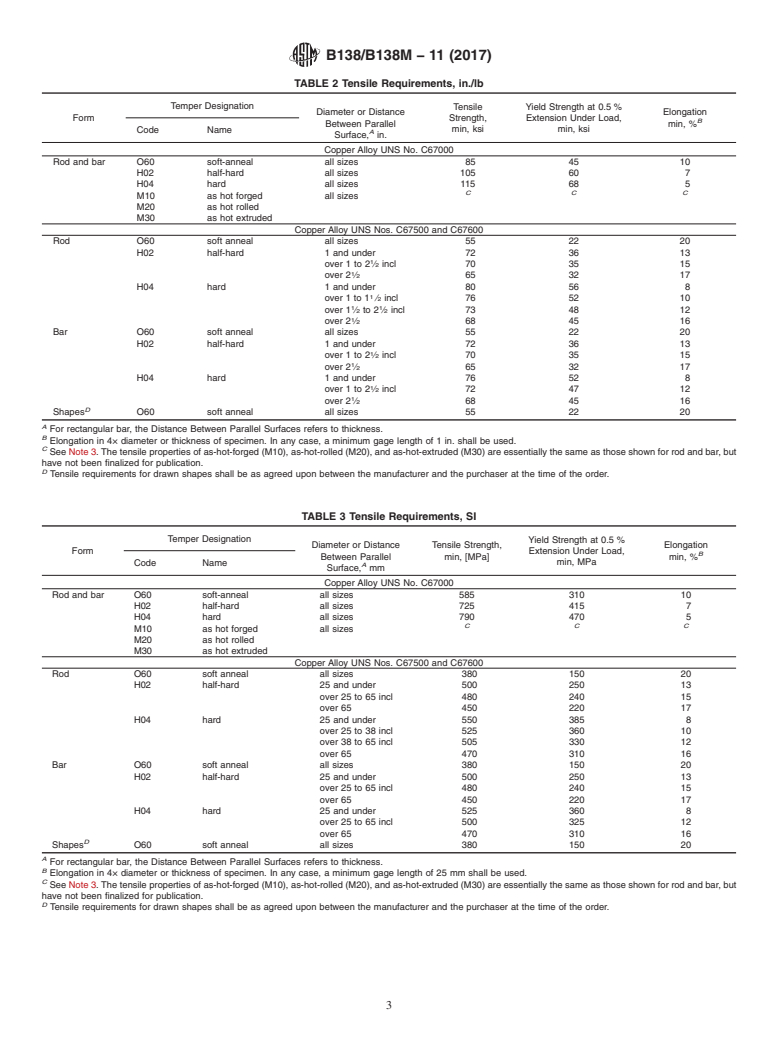

7.1 The standard tempers for products described in this

4.1.8 Length,

specification are given in Tables 2 and 3.

4.1.9 Quantity (total weight, footage or number of pieces),

7.1.1 Soft Anneal Temper (O60),

4.2 The following options are available and should be

7.1.2 As Hot Rolled Temper (M20),

specified at the time of placing the order when required:

7.1.3 As Hot Extruded Temper (M30),

4.2.1 Piston finish (Performance Requirements section),

7.1.4 Half-Hard Temper (H02), and

4.2.2 Residual stress test (Performance Requirements

7.1.5 Hard Temper (H04).

section),

4.2.2.1 Ammonia Vapor Test or Mercurous Nitrate Test,

8. Mechanical Property Requirements

4.2.2.2 For Ammonia Vapor Test, pH value other than 10.

8.1 Tensile Requirements:

4.2.3 Certification (Specification B249/B249M),

8.1.1 Product furnished under this specification shall con-

4.2.4 Mill Test Report (Specification B249/B249M), and

form to the tensile requirements prescribed in Table 2 or Table

4.2.5 If product is purchased for agencies of the U.S.

3 when tested in accordance with Test Methods E8/E8M.

Government (see Other Requirements section).

9. Performance Requirements

5. Material and Manufacture

9.1 Residual Stress Test:

5.1 Material—The material of manufacture shall be cast

9.1.1 When specified in the contract or purchase order, the

billets of CopperAlloy UNS No. C67000, C67500, or C67600

product shall be tested for residual stress according to the

as specified in the ordering information, and shall be of such

requirements of Test Method B154 or Test Method B858 and

purity and soundness as to be suitable for hot working.

show no signs of cracking. (Warning—Mercury is a definite

5.2 Manufacture:

health hazard. With the mercurous nitrate test, equipment for

5.2.1 The product shall be manufactured by hot working

the detection and removal of mercury vapor produced in

(extrusion, forging, or rolling) to produce a uniform wrought

volatilizationisrecommended.Theuseofprotectiveglovesfor

structure in the finished product.

this test is recommended.)

5.2.2 The product shall be finished by such cold working,

9.1.2 When the ammonia vapor test is used, the test pH

annealing, and straightening as may be necessary to achieve

value appropriate for the intended application shall be 10

the temper properties specified.

unless otherwise specified by the purchaser.

NOTE 2—Aresidual stress test provides information about the adequacy

6. Chemical Composition

of the stress relief of the material. Bar straightening is a method of

6.1 The material shall conform to the chemical composition mechanical stress relief. Stress relief annealing is a method of thermal

stre

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.