ASTM D6099-13

(Test Method)Standard Test Method for Polyurethane Raw Materials: Determination of Acidity in Moderate to High Acidity Aromatic Isocyanates

Standard Test Method for Polyurethane Raw Materials: Determination of Acidity in Moderate to High Acidity Aromatic Isocyanates

SIGNIFICANCE AND USE

5.1 This test method can be used for research or for quality control to characterize aromatic isocyanates and prepolymers of moderate to high acidity. Acidity correlates with performance in some polyurethane systems.

SCOPE

1.1 This test method determines the acidity, expressed as parts per million (ppm) of HCl, in aromatic isocyanate samples of greater than 100–ppm acidity. The test method is applicable to products derived from toluene diisocyanate and methylene-bis-(4–phenylisocyanate) (see Note 1).Note 1—This test method is equivalent to ISO 14898, Test Method A.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6099 − 13

Standard Test Method for

Polyurethane Raw Materials: Determination of Acidity in

1

Moderate to High Acidity Aromatic Isocyanates

This standard is issued under the fixed designation D6099; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* during urethane formation. The acid is titrated potentiometri-

cally with methanolic KOH, and the acidity present in the

1.1 This test method determines the acidity, expressed as

isocyanate sample is calculated from the titer.

partspermillion(ppm)ofHCl,inaromaticisocyanatesamples

of greater than 100–ppm acidity.The test method is applicable

5. Significance and Use

to products derived from toluene diisocyanate and methylene-

5.1 This test method can be used for research or for quality

bis-(4–phenylisocyanate) (see Note 1).

control to characterize aromatic isocyanates and prepolymers

NOTE 1—This test method is equivalent to ISO 14898, Test MethodA.

of moderate to high acidity. Acidity correlates with perfor-

mance in some polyurethane systems.

2. Referenced Documents

2

6. Apparatus

2.1 ASTM Standards:

D883Terminology Relating to Plastics

6.1 250-mL Beakers.

E180Practice for Determining the Precision of ASTM

6.2 50-mL Pipet or Repipet, Class A volumetric.

Methods for Analysis and Testing of Industrial and Spe-

3

6.3 100-mL Pipet or Repipet, Class A volumetric.

cialty Chemicals (Withdrawn 2009)

E691Practice for Conducting an Interlaboratory Study to

6.4 Automatic Titration Equipment, capable of inflection

Determine the Precision of a Test Method

detection and stirring the sample while, titrating, such as:

2.2 ISO Standards:

6.4.1 Commerically-available Automatic Titration

ISO 14898Plastics—Aromatic isocyanates for use in the

Apparatus,

4

production of polyurethane—Determination of acidity

6.4.2 Reference Electrode, with saturated LiCl/ethanol so-

lution in both chambers.

3. Terminology

6.4.3 pH Glass Electrode, (see Note 2).

3.1 Definitions—Terms used in this test method are in

NOTE 2—Acombination pH electrode with internal reference also may

accordance with Terminology D883.

be used.

3.2 Definitions of Terms Specific to This Standard:

6.5 Magnetic Stirrer.

3.2.1 acidity, n—the acid strength of a sample expressed in

6.6 Stir Bars.

ppm HCl.

6.7 Watch Glasses.

4. Summary of Test Method

6.8 Analytical Balance,capableofweighingtothenearest1

4.1 Theisocyanateismixedwithanexcessofmethanoland

mg.

a cosolvent.Additional acid is released into the solvent system

7. Reagents and Materials

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

7.1 0.02 N KOH in Methanol—1.32 g KOH pellets (85%

and is the direct responsibility of Subcommittee D20.22 on Cellular Materials -

Plastics and Elastomers.

KOH)/1000mLmethanol,standardizedwithpotassiumhydro-

Current edition approved Sept. 1, 2013. Published September 2013. Originally

gen phthalate (KHP).

approved in 1997. Last previous edition approved in 2008 as D6099-08. DOI:

10.1520/D6099-13.

7.2 Tolueneor1,2,4–Trichlorobenzene(TCB),driedfor24h

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

over molecular sieves.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on 7.3 Anhydrous Methanol.

the ASTM website.

3

The last approved version of this historical standard is referenced on 8. Sampling

www.astm.org.

4

8.1 Since organic isocyanates react with atmospheric

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. moisture,takespecialprecautionsinsampling.Usualsampling

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6099 − 13

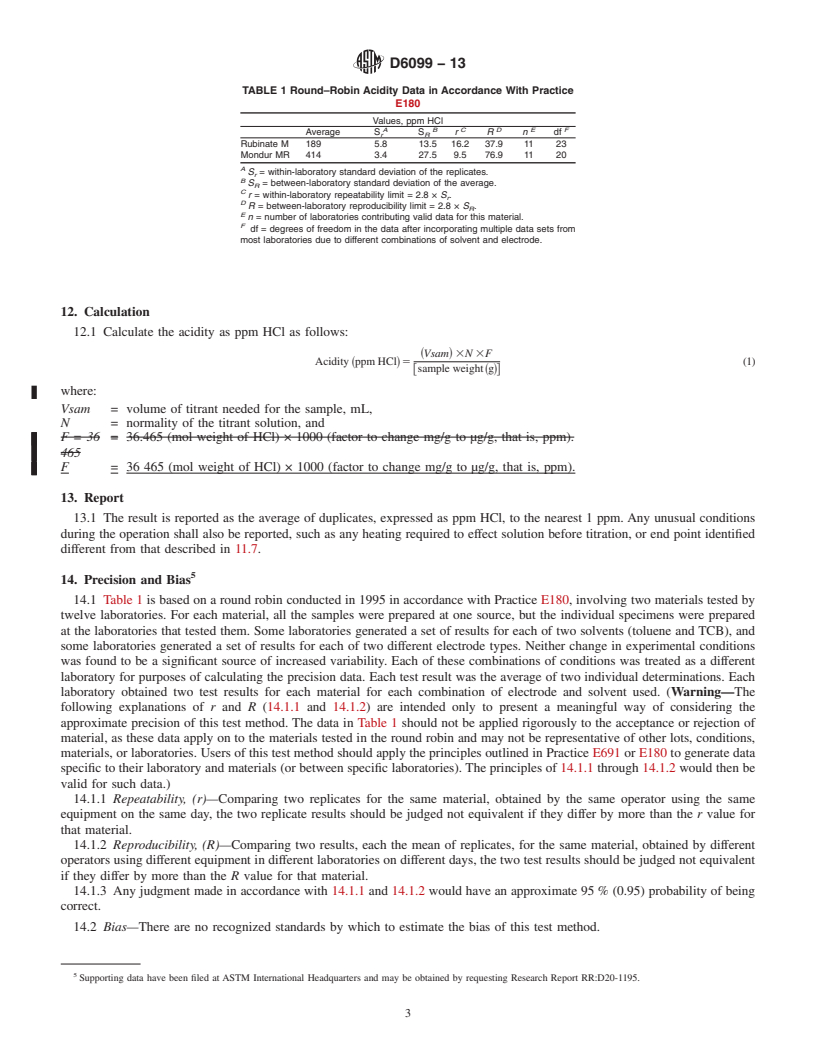

TABLE 1 Round–Robin Acidity Data in Accordance With Practice

methods, even when conducted rapidly, can cause contamina-

E180

tion of the sample with insoluble urea. Therefore, blanket the

Values, ppm HCl

sample with dry air or nitrogen at all times.

A B C D E F

Average S S r R n df

r R

Rubinate M 189 5.8 13.5 16.2 37.9 11 23

NOTE 3—Many diisocyanates are known or suspected sensitizers.

Mondur MR 414 3.4 27.5 9.5 76.9 11 20

Over-exposure to diisocyanates can lead to adverse health effects which

A

may include the development of occupational asthma and other

S = within-laboratory standard deviation of the replicates.

r

B

respiratory, skin and eye effects. Engineering controls and/or personal S = bet

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6099 − 08 D6099 − 13

Standard Test Method for

Polyurethane Raw Materials: Determination of Acidity in

1

Moderate to High Acidity Aromatic Isocyanates

This standard is issued under the fixed designation D6099; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method determines the acidity, expressed as parts per million (ppm) of HCl, in aromatic isocyanate samples of

greater than 100–ppm acidity. The test method is applicable to products derived from toluene diisocyanate and methylene-bis-

(4–phenylisocyanate) (see Note 1).

NOTE 1—This test method is equivalent to ISO 14898, Test Method A.

2. Referenced Documents

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

E180 Practice for Determining the Precision of ASTM Methods for Analysis and Testing of Industrial and Specialty Chemicals

3

(Withdrawn 2009)

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2.2 ISO Standards:

4

ISO 14898 Plastics—Aromatic isocyanates for use in the production of polyurethane—Determination of acidity

3. Terminology

3.1 Definitions—Terms used in this test method are in accordance with Terminology D883.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 acidity, n—the acid strength of a sample expressed in ppm hydrochloric acid.HCl.

4. Summary of Test Method

4.1 The isocyanate is mixed with an excess of methanol and a cosolvent. Additional acid is released into the solvent system

during urethane formation. The acid then is titrated potentiometrically with methanolic KOH, and the acidity present in the

isocyanate sample is calculated from the titer.

5. Significance and Use

5.1 This test method can be used for research or for quality control to characterize aromatic isocyanates and prepolymers of

moderate to high acidity. Acidity correlates with performance in some polyurethane systems.

6. Apparatus

6.1 250-mL Beakers.

6.2 50-mL Pipet or Repipet, Class A volumetric.

6.3 100-mL Pipet or Repipet, Class A volumetric.

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.22 on Cellular Materials - Plastics

and Elastomers.

Current edition approved Nov. 15, 2008Sept. 1, 2013. Published November 2008September 2013. Originally approved in 1997. Last previous edition approved in

20032008 as D6099 - 03.D6099 - 08. DOI: 10.1520/D6099-08.10.1520/D6099-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

4

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6099 − 13

6.4 Automatic Titration Equipment, capable of inflection detection and stirring the sample while, titrating, such as:

6.4.1 Commerically-available Automatic Titration Apparatus,

6.4.2 Reference Electrode, with saturated LiCl/ethanol solution in both chambers.

6.4.3 pH Glass Electrode, (see Note 2).

NOTE 2—A combination pH electrode with internal reference also may be used.

6.5 Magnetic Stirrer.

6.6 Stir Bars.

6.7 Watch Glasses.

6.8 Analytical Balance, capable of weighing to the nearest 1 mg.

7. Reagents and Materials

7.1 0.02 N KOH in Methanol—1.32 g KOH pellets (85 % KOH)/1000 mL methanol, standardized with potassium hydrogen

phthalate (KHP).

7.2 Toluene or 1,2,4–Trichlorobenzene (TCB), dried for 24 h over molecular sieves.

7.3 Anhydrous Methanol.

8. Sampling

8.1 Since organic isocyanates react with atmospheric moisture, take special precautions in sampling. Usual sampling methods,

even when conducted rapidly, can cause contamination of the sample with insoluble urea. Therefore, blanket the sample with dry

air or nitrogen at all times.

NOTE 3—Warning:Many diisocyanates are known or suspected sensitizers. Over-exposure to diisocyanates can l

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.