ASTM B101-96

(Specification)Standard Specification for Lead-Coated Copper Sheet and Strip for Building Construction

Standard Specification for Lead-Coated Copper Sheet and Strip for Building Construction

SCOPE

1.1 This specification establishes the requirements for lead-coated copper sheet and strip in flat lengths (or in coils) in ounce-weight thicknesses for roofing, flashing, gutters, downspouts, and for the general sheet metalwork in building construction. The lead coating is applied by hot dipping.

1.2 Materials made to this specification are not intended for electrical applications.

1.3 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units, which are provided for information only and are not considered standard.

Note 1—A companion specification for copper sheet and strip for building construction is Specification B 370.

1.4 The following hazard caveat pertains to the test method portion, Section 17, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 101 – 96

Standard Specification for

Lead-Coated Copper Sheet and Strip for Building

Construction

This standard is issued under the fixed designation B 101; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E 46 Test Methods for Chemical Analysis of Lead- and

Tin-Base Solders

1.1 This specification establishes the requirements for lead-

E 478 Test Methods for Chemical Analysis of Copper

coated rolled copper sheet and strip in flat lengths (or in coils)

Alloys

in ounce-weight thicknesses for roofing, flashing, gutters,

downspouts, and for the general sheet metalwork in building

3. Terminology

construction. The lead coating is applied by hot dipping.

3.1 Definitions:

1.2 Materials made to this specification are not intended for

3.1.1 coil—a length of the product wound into a series of

electrical applications.

connected turns.

1.3 The values stated in inch-pound units are to be regarded

3.1.1.1 Discussion—The unqualified term “coil” as applied

as the standard. The values given in parentheses are for

to “flat product” usually refers to a coil in which the product is

information only.

spirally wound, with the successive layers on top of one

NOTE 1—A companion specification for copper sheet and strip for

another. (Sometimes called a “roll”.)

building construction is Specification B 370.

3.1.2 lead-coated copper sheet (for building

1.4 The following hazard caveat pertains to the test method

construction)—a rolled flat product over 24 in. (610 mm) in

portion, Section 15, of this specification. This standard does

width and of ounce-weight thickness from 8 (226.7) to 48 oz

not purport to address all of the safety concerns, if any,

(1361 g), furnished in flat lengths of not over 10 ft (3.1 m).

associated with its use. It is the responsibility of the user of this

3.1.3 lead-coated strip (for building construction)—a rolled

standard to establish appropriate safety and health practices

flat product up to and including 24 in. (610 mm) in width and

and determine the applicability of regulatory limitations prior

of ounce-weight thickness from 8 oz (227 g) to 48 oz (1361 g).

to use.

3.1.3.1 Discussion—Strip shall be furnished in flat lengths

of not over 10 ft (3.1 m) or in rolls of one single continuous

2. Referenced Documents

length of not less than 25 ft (7.6 m) wound into a cylindrical

2.1 The following documents of the issue in effect on the

spiral.

date of material purchase form a part of this specification to the

3.1.4 lengths—straight pieces of the product.

extent referenced herein.

3.1.4.1 ends—straight pieces, shorter than the nominal

2.2 ASTM Standards:

length, left over after cutting the product into mill lengths,

B 248 Specification for General Requirements for Wrought

stock lengths or specific lengths. They are subject to minimum

Copper and Copper-Alloy Plate, Sheet, Strip and Rolled

length and maximum weight requirements.

Bar

3.1.4.2 lengths, mill—straight lengths, including ends, that

B 370 Specification for Copper Sheet and Strip for Building

are conveniently manufactured in the mills.

Construction

3.1.4.3 Discussion—Full length pieces are usually 8, 10, or

B 601 Practice for Temper Designations for Copper and

12 ft (2.44, 3.05, or 3.66 m) and subject to established length

Copper Alloys—Wrought and Cast

tolerances.

E 37 Test Methods for Chemical Analysis of Pig Lead

3.1.4.4 lengths, specific—straight lengths that are uniform

in length, as specified, and subject to established length

tolerances.

This specification is under the jurisdiction of Committee B-5 on Copper and

3.1.4.5 lengths, stock—straight lengths that are mill cut and

Copper Alloys and is the direct responsibility of Subcommittee B05.01 on Plate,

Sheet, and Strip.

stored in advance of orders.

Current edition approved April 10, 1996. Published June 1996. Originally

3.1.4.6 Discussion—They are usually 8, 10, or 12 ft (2.44,

published as B 101 – 35 T. Last previous edition B 101 – 92.

2 3.05 or 3.66 m) and subject to established length tolerances.

Annual Book of ASTM Standards, Vol 02.01.

3.1.5 ounce-weight—the weight of uncoated copper sheet or

Annual Book of ASTM Standards, Vol 03.05.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

B 101

A

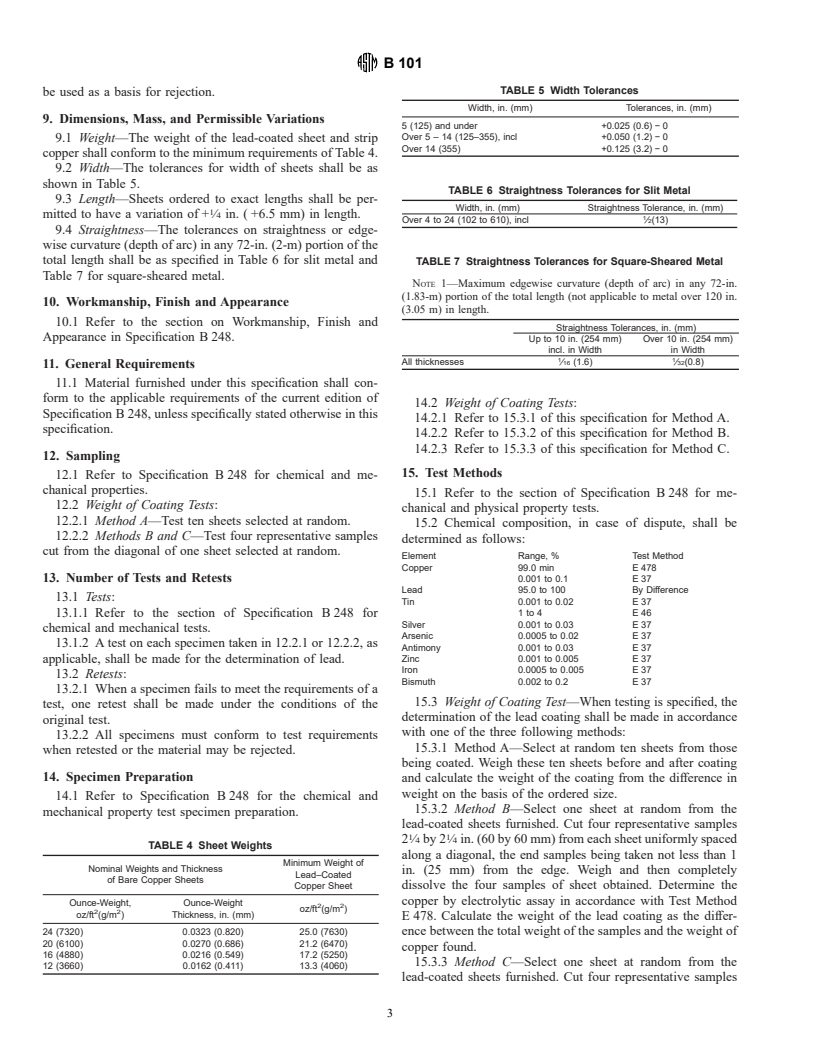

TABLE 2 Weight of Lead Coating, lb (kg)

strip expressed in ounces per square foot.

3.1.6 ounce-weight thickness—the metal thickness that cor- Min Max

12 (5.4) 15 (6.8)

responds to the ounce weight.

A

The weight of coating specified is the total weight of lead applied to two sides

2 2

of 100 ft (9.3 m ) of copper sheet, approximately one half of the coating to be on

4. Ordering Information

each side of the sheet.

4.1 Orders for material under this specification shall include

the following information:

TABLE 3 Chemical Requirements for Lead

4.1.1 Temper (Section 7 and Table 1),

Used to Coat Copper Sheet

4.1.2 How furnished: flat lengths or in coils (see 3.1.5 and

Element Composition, max, %

3.1.6),

Silver 0.020

4.1.3 Quantity: total weight or number of sheets of each

Copper 0.08

A

Arsenic plus antimony 0.005

size,

A

Zinc 0.002

4.1.4 Ounce-weight or ounce-weight thickness of the un-

Iron 0.002

coated copper sheet or strip (Table 2),

Bismuth 0.050

Lead remainder

4.1.5 Dimensions: width and length (Section 9),

Tin 4.0

4.1.6 Certification, where required (Section 19),

Phosphorus 0.03

4.1.7 Mill test report, where required (Section 20), and

A

Provision for 4 % of tin makes necessary provision for possible higher amounts

4.1.8 ASTM designation and date of issue.

of these elements than generally required for pig lead.

4.2 If the material being purchased is intended for use by

agencies of the U.S. Government refer to 5.3.

6.1.1 Any copper that complies with 6.1 shall be acceptable.

6.2 If limits for unnamed elements are required, they shall

5. Materials and Manufacture

be established and analysis required by agreement between

5.1 Materials:

manufacturer or supplier and purchaser.

5.1.1 The lead coating shall conform to the chemical re-

6.3 The lead coating shall conform to the chemical require-

quirements of Table 3.

ments of Table 3.

5.1.2 The copper sheet or strip to be lead coated shall be

6.4 Uncoated copper sheet and strip covered by this speci-

manufactured by any process that provides a finished product

fication is commercially available in the following tempers as

that conforms to the requirements of Specification B 370.

defined by Practice B 601; O60 (soft annealed), H01 (quarter

5.2 Manufacture:

hard, cold-rolled high yield), H00 (eighth hard, cold-rolled)

5.2.1 The lead coating shall be applied to the copper sheet or

and O60 (soft annealed) (see Table 1).

strip by hot dipping in a bath of molten lead.

7. Physical Properties

5.2.2 Unless otherwise specified, the lead coating shall be

applied to the copper sheet or strip after slitting and cutting to

7.1 Although no minimum grain size is specified for soft-

the specified length. The coating shall be commercially accept-

temper material, it shall be fully recrystallized.

able in terms of thickness uniformity, freedom from pinholes,

8. Mechanical Properties

voids or unwetted areas.

5.2.3 The weight of the lead coating shall conform to the

8.1 The materials shall conform to the requirements speci-

requirements of Table 2 except as may be specified in 5.2.4.

fied in Table 1 for the tempers listed.

5.2.4 Other variations in coating or texture shall be fur-

8.2 Tensile Strength—The tension test shall be the standard

nished by agreement in writing between the purchaser and the

test for all tempers, and acceptance or rejection shall depend on

manufacturer or supplier.

the tensile requirements specified in Table 1. Tension test

5.3 Materials purchased for agencies of the U.S. Govern-

specimens shall be taken so that the longitudinal axis of such

ment shall conform to the Supplementary Requirements of

specimens is parallel to the direction of rolling.

Specification B 248.

8.3 Rockwell Hardness—Since Rockwell hardness tests of-

fer a quick and convenient method of checking the conformity

6. Chemical Composition

of the material to the requirements for tensile strength, approxi-

6.1 The copper sheet or strip shall have a minimum copper mate Rockwell hardness values

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.