ASTM A523/A523M-20

(Specification)Standard Specification for Plain End Seamless and Electric-Resistance-Welded Steel Pipe for High-Pressure Pipe-Type Cable Circuits

Standard Specification for Plain End Seamless and Electric-Resistance-Welded Steel Pipe for High-Pressure Pipe-Type Cable Circuits

ABSTRACT

This specification covers seamless and electric-resistance-welded steel pipe used as conduit for the installation of high-pressure pipe-type electrical cables in NPS 4 to NPS 12, inclusive, with nominal (average) wall thicknesses 0.219 to 0.562 in., depending on size. The steel shall be made by one or more of the following processes: open-hearth, basic-oxygen, or electric-furnace. Tensile strength tests, flattening test, hydrostatic tests shall be made for the materials to conform the requirements as specified. If the results of the mechanical tests do not conform to requirements specified, retests shall be made.

SCOPE

1.1 This specification covers two types, seamless (S) and electric-resistance-welded (E), of steel pipe used as conduit for the installation of high-pressure pipe-type electrical cables in NPS 4 to NPS 12 [DN 100 to DN 300], inclusive, with nominal (average) wall thicknesses 0.219 to 0.562 in. [5.56 to 14.27 mm], depending on size. Pipe having other dimensions (Note 2) may be furnished, provided such pipe complies with all other requirements of this specification.

Note 1: The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as “nominal diameter,” “size,” and “nominal size.”

Note 2: A comprehensive listing of standardized pipe dimensions is contained in ASME B36.10.

1.2 Pipe ordered under this specification is suitable for welding and for forming operations involving flaring, belling, and bending.

1.3 Pipe for this purpose shall be furnished in Grade A or Grade B as specified in the purchase order. Grade A is more suitable for forming operations involving bending, flaring, or belling and this grade is normally preferred. This provision is not intended to prohibit the cold bending, flaring, or belling of Grade B pipe.

1.4 This specification is expressed in both inch-pound units and in SI units; however, unless the purchase order or contract specifies the applicable M specification designation (SI units), the inch-pound units shall apply. The values stated in either inch-pound or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore each system shall be used independently of the other. Combining values from the two systems may results in nonconformance with the standard.

1.5 The following hazard caveat applies to the test method portion, Section 20, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A523/A523M −20

Standard Specification for

Plain End Seamless and Electric-Resistance-Welded Steel

1

Pipe for High-Pressure Pipe-Type Cable Circuits

This standard is issued under the fixed designationA523/A523M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Combining values from the two systems may results in

nonconformance with the standard.

1.1 This specification covers two types, seamless (S) and

1.5 The following hazard caveat applies to the test method

electric-resistance-welded(E),ofsteelpipeusedasconduitfor

portion, Section 20, of this specification: This standard does

the installation of high-pressure pipe-type electrical cables in

not purport to address all of the safety concerns, if any,

NPS4toNPS12[DN100toDN300],inclusive,withnominal

associatedwithitsuse.Itistheresponsibilityoftheuserofthis

(average) wall thicknesses 0.219 to 0.562 in. [5.56 to 14.27

standard to establish appropriate safety, health, and environ-

mm], depending on size. Pipe having other dimensions (Note

mental practices and determine the applicability of regulatory

2) may be furnished, provided such pipe complies with all

limitations prior to use.

other requirements of this specification.

1.6 This international standard was developed in accor-

NOTE 1—The dimensionless designator NPS (nominal pipe size) has

dance with internationally recognized principles on standard-

been substituted in this standard for such traditional terms as “nominal

ization established in the Decision on Principles for the

diameter,” “size,” and “nominal size.”

Development of International Standards, Guides and Recom-

NOTE 2—A comprehensive listing of standardized pipe dimensions is

mendations issued by the World Trade Organization Technical

contained in ASME B36.10.

Barriers to Trade (TBT) Committee.

1.2 Pipe ordered under this specification is suitable for

welding and for forming operations involving flaring, belling,

2. Referenced Documents

and bending.

2

2.1 ASTM Standards:

1.3 Pipe for this purpose shall be furnished in Grade A or

A370Test Methods and Definitions for Mechanical Testing

Grade B as specified in the purchase order. Grade A is more

of Steel Products

suitable for forming operations involving bending, flaring, or

A751Test Methods, Practices, and Terminology for Chemi-

belling and this grade is normally preferred. This provision is

cal Analysis of Steel Products

not intended to prohibit the cold bending, flaring, or belling of

2.2 ASME Standard:

Grade B pipe. 3

B36.10Welded and Seamless Wrought Steel Pipe

1.4 This specification is expressed in both inch-pound units

3. Ordering Information

and in SI units; however, unless the purchase order or contract

specifies the applicable M specification designation (SI units),

3.1 Orders for material under this specification should

the inch-pound units shall apply. The values stated in either

include the following, as required, to describe the desired

inch-pound or SI units are to be regarded separately as

material adequately:

standard. Within the text, the SI units are shown in brackets.

3.1.1 Quantity (feet [meters] or number of lengths),

Thevaluesstatedineachsystemmaynotbeexactequivalents;

3.1.2 Name of material (steel pipe),

therefore each system shall be used independently of the other.

3.1.3 Type S or E (seamless or electric-resistance-welded),

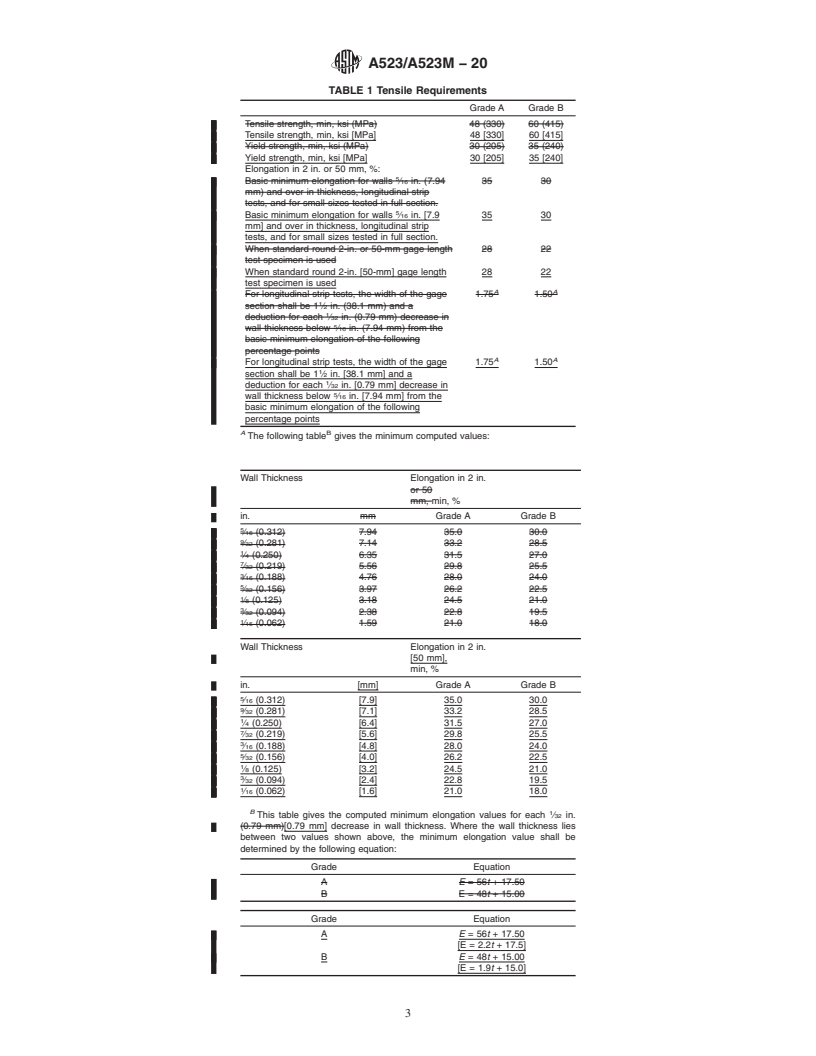

3.1.4 Grade (Table 1),

3.1.5 Size (NPS [DN] or diameter and nominal wall thick-

ness or pounds per foot [kg/m]),

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.09 on Carbon Steel Tubular Products.

2

Current edition approved March 1, 2020. Published March 2020. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 1964. Last previous edition approved in 2012 as A523–96 (2012). contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

DOI: 10.1520/A0523_A0523M-20. Standards volume information, refer to the standard’s Document Summary page on

This specification was initiated by the IEEE Insulated Conductors Committee in the ASTM website.

3

recognition of the need for a specification embodying the special requirements of Available from American Society of Mechanical Engineers (ASME), ASME

pipeforhigh-voltageelectricalcircuits.ItwaspreparedforacceptanceasanASTM International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

specification by a task group of Subcommittee A01.09 of ASTM Committee A01. www.asme.org.

*A Summary of Changes section appears at the end of thi

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A523 − 96 (Reapproved 2012) A523/A523M − 20

Standard Specification for

Plain End Seamless and Electric-Resistance-Welded Steel

1

Pipe for High-Pressure Pipe-Type Cable Circuits

This standard is issued under the fixed designation A523;A523/A523M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This specification covers two types, seamless (S) and electric-resistance-welded (E), of steel pipe used as conduit for the

installation of high-pressure pipe-type electrical cables in NPS 4 to NPS 12, 12 [DN 100 to DN 300], inclusive, with nominal

(average) wall thicknesses 0.219 to 0.562 in., in. [5.56 to 14.27 mm], depending on size. Pipe having other dimensions (Note 2)

may be furnished, provided such pipe complies with all other requirements of this specification.

NOTE 1—The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as “nominal diameter,”

“size,” and “nominal size.”

NOTE 2—A comprehensive listing of standardized pipe dimensions is contained in ANSIASME B36.10.

1.2 Pipe ordered under this specification is suitable for welding and for forming operations involving flaring, belling, and

bending.

1.3 Pipe for this purpose shall be furnished in Grade A or Grade B as specified in the purchase order. Grade A is more suitable

for forming operations involving bending, flaring, or belling and this grade is normally preferred. This provision is not intended

to prohibit the cold bending, flaring, or belling of Grade B pipe.

1.4 This specification is expressed in both inch-pound units and in SI units; however, unless the purchase order or contract

specifies the applicable M specification designation (SI units), the inch-pound units shall apply. The values stated in either

inch-pound or SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units

that are provided for information only and are not considered separately as standard. Within the text, the SI units are shown in

brackets. The values stated in each system may not be exact equivalents; therefore each system shall be used independently of the

other. Combining values from the two systems may results in nonconformance with the standard.

1.5 The following hazard caveat applies to the test method portion, Section 20, of this specification: This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability of regulatory

limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

3

E59 Practice for Sampling Steel and Iron for Determination of Chemical Composition (Withdrawn 1996)

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.09

on Carbon Steel Tubular Products.

Current edition approved March 1, 2012March 1, 2020. Published November 2012March 2020. Originally approved in 1964. Last previous edition approved in 20052012

as A523 – 96 (2012). (2005). DOI: 10.1520/A0523-96R12.10.1520/A0523_A0523M-20.

This specification was initiated by the IEEE Insulated Conductors Committee in recognition of the need for a specification embodying the special requirements of pipe

for high-voltage electrical circuits. It was prepared for acceptance as an ASTM specification by a task group of Subcommittee A01.09 of ASTM Committee A01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.