ASTM D5329-96

(Test Method)Standard Test Methods for Sealants and Fillers, Hot-Applied, For Joints and Cracks in Asphaltic and Portland Cement Concrete Pavements

Standard Test Methods for Sealants and Fillers, Hot-Applied, For Joints and Cracks in Asphaltic and Portland Cement Concrete Pavements

SCOPE

1.1 These test methods cover tests for hot-applied types of joint and crack sealants and fillers for portland cement concrete and asphaltic concrete pavements. There are numerous standard material specifications that use these test methods. Refer to the respective standard material specification of interest to determine which of the following test methods to use. For sample melting and concrete block preparation see their respective standard practices.

1.2 The test methods appear in the following sections: Section Artificial Weathering 15 Asphalt Compatibility 14 Bond, Non-Immersed 9 Bond, Fuel-Immersed 11 Bond, Water-Immersed 10 Cone Penetration, Non-Immersed 6 Cone Penetration, Fuel-Immersed 7 Flexibility 18 Flow 8 Resilience 12 Resilience, Oven-Aged 13 Solubility (Change in Weight) 17 Tensile Adhesion 16

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5329 – 96

Standard Test Methods for

Sealants and Fillers, Hot-Applied, For Joints and Cracks in

Asphaltic and Portland Cement Concrete Pavements

This standard is issued under the fixed designation D 5329; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 217 Test Methods for Cone Penetration of Lubricating

Grease

1.1 These test methods cover tests for hot-applied types of

D 471 Test Method for Rubber Property-Effect of Liquids

joint and crack sealants and fillers for portland cement concrete

D 1074 Test Method for Compressive Strength of Bitumi-

and asphaltic concrete pavements. There are numerous stan-

nous Mixtures

dard material specifications that use these test methods. Refer

D 1190 Specification for Concrete Joint Sealer, Hot-Poured

to the respective standard material specification of interest to

Elastic Type

determine which of the following test methods to use. For

D 1559 Test Method for Resistance to Plastic Flow of

sample melting and concrete block preparation see their

Bituminous Mixtures Using Marshall Apparatus

respective standard practices.

D 1561 Practice for Preparation of Bituminous Mixture Test

1.2 The test methods appear in the following sections:

Specimens by Means of California Kneading Compactor

Section

D 1985 Practice for Preparing Concrete Blocks for Testing

Artificial Weathering 15

Asphalt Compatibility 14

Sealants, for Joints and Cracks

Bond, Non-Immersed 9

D 3381 Specification for Viscosity-Graded Asphalt Cement

Bond, Fuel-Immersed 11

for Use in Pavement Construction

Bond, Water-Immersed 10

Cone Penetration, Non-Immersed 6

D 3405 Specification for Joint Sealants, Hot-Applied, for

Cone Penetration, Fuel-Immersed 7

Concrete and Asphalt Pavements

Flexibility 18

D 5167 Practice for Melting of Hot-Applied Joint and

Flow 8

Resilience 12

Crack Sealant for Evaluation

Resilience, Oven-Aged 13

E 145 Specification for Gravity-Convection and Forced-

Solubility (Change in Weight) 17

Ventilation Ovens

Tensile Adhesion 16

E 171 Specification for Standard Atmospheres for Condi-

1.3 This standard does not purport to address all of the

tioning and Testing Materials

safety concerns, if any, associated with its use. It is the

G 23 Practice for Operating Light-Exposure Apparatus

responsibility of the user of this standard to establish appro-

(Carbon-Arc Type) With and Without Water for Exposure

priate safety and health practices and determine the applica-

of Nonmetallic Material

bility of regulatory limitations prior to use.

1.4 The values stated in inch-pound units are to be regarded

3. Significance and Use

as the standard. The values given in parentheses are provided

3.1 These test methods describe procedures for determining

for information purposes only.

specification conformance for hot-applied, field-molded joint

and crack sealants and fillers.

2. Referenced Documents

2.1 ASTM Standards:

4. Sample Melting

D 5 Test Method for Penetration of Bituminous Materials

4.1 See Practice D 5167.

These test methods are under the jurisdiction of ASTM Committee D-4 on

Road and Paving Materials and are the direct responsibility of Subcommittee

D04.33 on Formed-In-Place Sealants for Joints and Cracks in Pavements. Annual Book of ASTM Standards, Vol 05.01.

Current edition approved Jan. 10, 1996. Published March 1996. Originally Annual Book of ASTM Standards, Vol 09.01.

published as D 5329 – 92. Last previous edition D 5329 – 95. Annual Book of ASTM Standards, Vol 14.02.

2 6

Annual Book of ASTM Standards, Vol 04.03. Annual Book of ASTM Standards, Vol 15.09.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5329

NOTE 1—A release agent should be used to coat molds and spacers to

5. Standard Conditions

prevent them from bonding to the sealants. Extreme care should be

5.1 The laboratory atmospheric conditions, hereinafter re-

exercised to avoid contaminating the area where the joint sealant makes

ferred to as standard conditions, shall be in accordance with

contact with the blocks. A non-toxic release agent is recommended for this

Specification E 171 (73.4 6 3.6°F (23 6 2°C)).

purpose. Two examples that have been found suitable for this purpose are

KY jelly (available at drug stores) and a release agent prepared by

grinding a mixture of approximately 50 % talc, 35 % glycerine, and 15 %

6. Cone Penetration, Non-Immersed

by weight, of a water-soluble medical lubricant into a smooth paste.

6.1 Apparatus—Conduct this test using the apparatus de-

8.1.2 Oven—Forced draft type conforming to Specification

scribed in Test Method D 5, except as specified herein. Use a

E 145 and capable of controlling its temperature6 2°F.

penetration cone in place of the standard penetration needle.

8.2 Specimen Preparation—Pour a portion of the sample

The cone shall conform to the requirements given in Test

prepared in accordance with Practice D 5167 for melting

Methods D 217, except that the interior construction may be

samples into the mold described in 8.1. Fill the mold with an

modified as desired. The total moving weight of the cone and

excess of material. Allow the test specimen to cool at standard

attachments shall be 150.0 6 0.1 g.

conditions for at least ⁄2h, then trim the specimen flush with

6.2 Specimen Preparation—Pour a portion of the sample

the face of the mold with a heated metal knife or spatula and

prepared in accordance with Practice D 5167 into one 6 oz

remove the mold. Allow the specimen to cure under standard

(177 mL) tin measuring approximately 2.76 in. in diameter and

conditions as specified in its respective material specification.

1.77 in. in depth and fill flush with the rim of the tin. Allow the

8.3 Procedure—Mark reference lines on the panel at the

specimen to cure under standard conditions as specified in its

bottom edge of the sealant. Then place the panel containing the

respective material specification.

sample in a forced-draft oven maintained for the time and at the

6.3 Procedure—Place the specimen in a water bath main-

temperature specified in its respective material specification.

tained at 77 6 0.2°F (25 6 0.1°C) for 2 h immediately before

During the test, mount the panel so that the longitudinal axis of

testing. Remove the specimen from the bath and dry the

the specimen is at an angle of 75 6 1° with the horizontal, and

surface. Using the apparatus described in 6.1, make determi-

the transverse axis is horizontal. After the specified test period,

nations at three locations on 120° radii, and halfway between

remove the panel from the oven and measure the movement of

the center and outside of the specimen. Take care to ensure the

the specimen below the reference lines in millimeters.

cone point is placed on a point in the specimen that is

8.4 Report—Report the measurement obtained in 8.3 in

representative of the material itself and is free of dust, water,

millimeters.

bubbles or other foreign material. Clean and dry the cone point

after each determination.

9. Bond, Non-Immersed

6.4 Report—Average the three results and record the value

as the penetration of the specimen in ⁄10 mm units.

9.1 Apparatus:

9.1.1 Extension Machine—The extension machine used in

7. Cone Penetration, Fuel-Immersed

the bond test shall be so designed that the specimen can be

extended a minimum of 0.50 in. (12.7 mm) at a uniform rate of

7.1 Apparatus—Same as described in 6.1.

⁄8 6 0.010 in. (3.2 6 0.26 mm) per hour. It shall consist

7.2 Specimen Preparation—Pour a portion of the sample

essentially of one or more screws rotated by an electric motor

prepared in accordance with Practice D 5167 into one 6 oz tin,

through suitable gear reductions. Self aligning plates or grips,

then proceed as in 6.2.

one fixed and the other carried by the rotating screw or screws,

7.3 Specimen Preparation—Immerse the specimen pre-

shall be provided for holding the test specimen in position

pared as described in 6.2 for 24 h in approximately 0.53 qt (500

during the test.

mL) to provide a minimum of 0.50 in. cover of clean test fuel

9.1.2 Cold Chamber—The cold chamber shall be capable of

conforming to the requirements of Reference Fuel B of Test

maintaining the required cold test temperature within 62°F.

Method D 471, maintained in a water bath at a constant

9.2 Concrete-Block Preparation:

temperature of 120 6 2°F (40 6 1°C). Discard the test fuel

9.2.1 The concrete blocks shall be prepared in accordance

after each specimen immersion. After the 24 h immersion, dry

with Practice D 1985.

the specimen under a draft of an approximately 12 in. (30.5

9.3 Specimen Preparation:

mm) diameter electric fan at standard conditions for 1 h. The

9.3.1 Prepare three test specimens (3 specimens 3 2 5 6

placement of the fan shall be such as to maintain air velocity of

blocks) as follows: On removal from the storage water, again

150 to 500 ft/min (0.76 to 2.54 m/s) over the sample.

scrub the 2 by 3-in. (50 by 75-mm) saw-cut faces of the blocks

7.4 Procedure—Test as described in 6.3.

under running water. When this operation is completed on

7.5 Report—Record as described in 6.4.

individual blocks, again place them under clean, fresh water

8. Flow until all blocks to be used are prepared. When all blocks are

scrubbed, remove them from the water and lightly blot them

8.1 Apparatus:

with an oil-free, soft, absorbent cloth or paper to remove all

8.1.1 Mold—Construct a mold (see Note 1) 1.57 in. wide by

2.36 in. long by 0.125 in. deep (40 by 60 by 3.2 mm) and place

it on a bright tin panel. The tin plate must be free of dirt, oil,

etc. and be between 0.010 and 0.025 in. in thickness (0.25 to

A machine suitable for testing a minimum of three specimens simultaneously

0.64 mm). can be obtained from such sources as Applied Test Systems of Butler, PA.

D 5329

free surface water and condition them according to their

respective material specification.

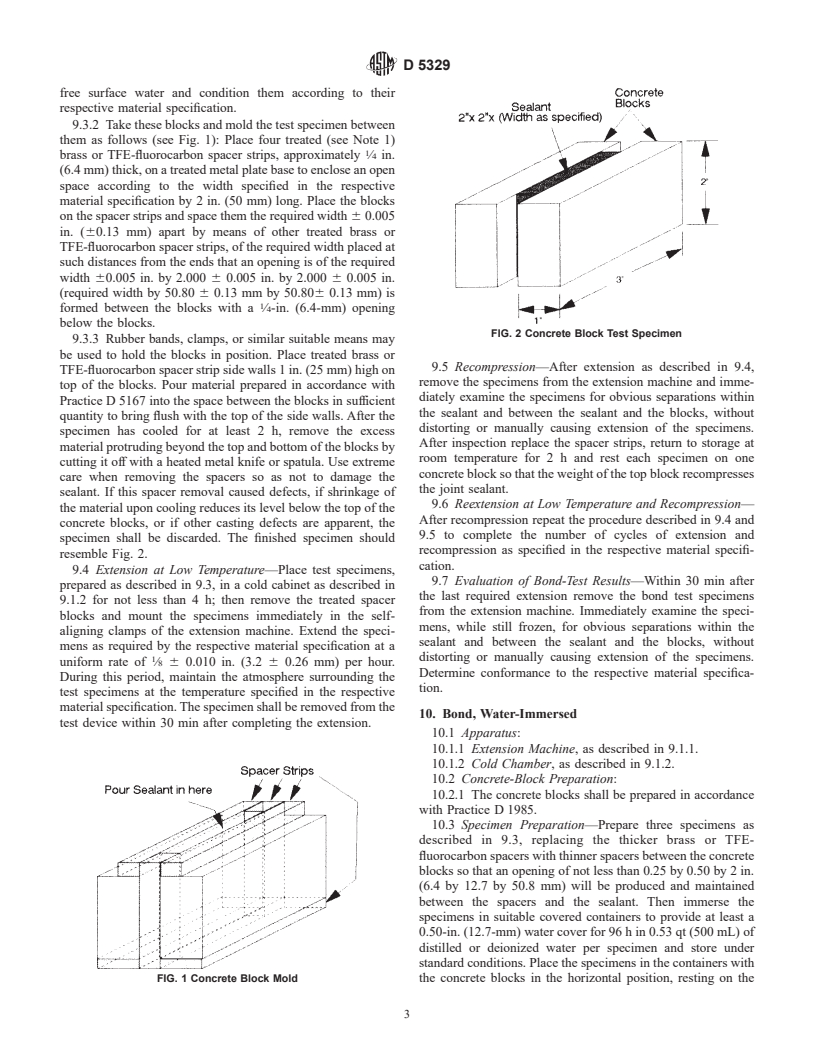

9.3.2 Take these blocks and mold the test specimen between

them as follows (see Fig. 1): Place four treated (see Note 1)

brass or TFE-fluorocarbon spacer strips, approximately ⁄4 in.

(6.4 mm) thick, on a treated metal plate base to enclose an open

space according to the width specified in the respective

material specification by 2 in. (50 mm) long. Place the blocks

on the spacer strips and space them the required width 6 0.005

in. (60.13 mm) apart by means of other treated brass or

TFE-fluorocarbon spacer strips, of the required width placed at

such distances from the ends that an opening is of the required

width 60.005 in. by 2.000 6 0.005 in. by 2.000 6 0.005 in.

(required width by 50.80 6 0.13 mm by 50.806 0.13 mm) is

formed between the blocks with a ⁄4-in. (6.4-mm) opening

below the blocks.

FIG. 2 Concrete Block Test Specimen

9.3.3 Rubber bands, clamps, or similar suitable means may

be used to hold the blocks in position. Place treated brass or

9.5 Recompression—After extension as described in 9.4,

TFE-fluorocarbon spacer strip side walls 1 in. (25 mm) high on

remove the specimens from the extension machine and imme-

top of the blocks. Pour material prepared in accordance with

diately examine the specimens for obvious separations within

Practice D 5167 into the space between the blocks in sufficient

the sealant and between the sealant and the blocks, without

quantity to bring flush with the top of the side walls. After the

distorting or manually causing extension of the specimens.

specimen has cooled for at least 2 h, remove the excess

After inspection replace the spacer strips, return to storage at

material protruding beyond the top and bottom of the blocks by

room temperature for 2 h and rest each specimen on one

cutting it off with a heated metal knife or spatula. Use extreme

concrete block so that the weight of the top block recompresses

care when removing the spacers so as not to damage the

the joint sealant.

sealant. If this spacer removal caused defects, if shrinkage of

9.6 Reextension at Low Temperature and Recompression—

the material upon cooling reduces its level below the top of the

After recompression repeat the procedure described in 9.4 and

concrete blocks, or if other casting defects are apparent, the

9.5 to complete the number of cycles of extension and

specimen shall be discarded. The finished specimen should

recompression as specified in the respective material specifi-

resemble Fig. 2.

cation.

9.4 Extension at Low Temperature—Place test specimens,

9.7 Evaluation of Bond-Test Results—Within 30 min after

prepared as described in 9.3, in a cold cabinet as described in

the last required extension remove the bond test specimens

9.1.2 for not less than 4 h; then remove the treated spacer

from the extension machine. Immediately examine the speci-

blocks and mount the specimens immediately in the self-

mens, while still frozen, for obvious separations within the

aligning clamps of the extension machine. Extend the speci-

sealant and between the sealant and the blocks, without

mens as required by the respective material specification at a

1 distorting or manually causing extension of the specimens.

uniform rate of ⁄8 6 0.010 in. (3.2 6 0.26 mm) per hour.

Determine conformance to the respective material specifica-

During this period, maintain the atmosphere surrounding the

tion.

test specimens at the temperature specified in the respective

material specification. The specimen shall be removed from the

10. Bond, Water-Immersed

test device within 30 min after completing the extension.

10.1 Apparatus:

10.1.1 Extension Machine, as described in 9.1.1.

10.1.2 Cold Chamber, as described in 9.1.2.

10.2 Concrete-Block Preparation:

10.2.1 The concrete blocks shall be prepared in accordance

with Practice D 1985.

10.3 Specimen Preparation—Prepare three specimens as

described in 9.3, replacing the thicker brass or TFE-

fluorocarbon spacers with thinner spacers between the concrete

blocks so that an opening of not less than 0.25 by 0.50 by 2 in.

(6.4 by 12.7 by 50.8 mm) will be produced and maintained

between the spacers and the sealant. Then immerse the

specimens in suitable covered containers to provide at least a

0.50-in. (12.7-mm) water cover for 96 h in 0.53 qt (500 mL) of

distilled or deionized water per specimen and store under

standard conditions. Place the specimens in the containers with

FIG. 1 Concrete Block Mold the concrete blocks in the horizontal position, resting on the

D 5329

block faces measuring 2 by 3 in. (50 by 76 mm). Three contact with the surfac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.