ASTM C473-00

(Test Method)Standard Test Methods for Physical Testing of Gypsum Panel Products

Standard Test Methods for Physical Testing of Gypsum Panel Products

SCOPE

1.1 These test methods cover the physical testing of gypsum board products and gypsum lath.

1.2 The test methods appear in the following order: Sections Flexural Strength (Method A) 4 to 8 Core, End, and Edge Hardness (Method A) 9 to 17 Nail Pull Resistance (Method A) 18 to 23 Flexural Strength (Method B) 25 to 32 Core, End, and Edge Hardness (Method B) 33 to 40 Nail Pull Resistance (Method B) 41 to 48 Humidified Deflection 49 to 53 End Squareness 54 to 56 Nominal Thickness 57 to 61 Recessed- or Tapered-Edge Depth 62 to 66 Width 67 to 71 Length 72 to 76 Water Resistance of Core-Treated Water-Repellent Gypsum Boards 77 to 81 Surface Water Resistance of Gypsum Boards with Water- Repellent Face Paper 82 to 86

1.3 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 473 – 00

Standard Test Methods for

Physical Testing of Gypsum Panel Products

This standard is issued under the fixed designation C 473; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * with Terminology C 11.

3.2 Definitions of Terms Specific to This Standard:

1.1 These test methods cover the physical testing of gypsum

3.2.1 edge, n—the paper-bound edge, or long edge, as

panel products.

manufactured.

1.2 The test methods appear in the following order:

3.2.2 ends, n—the end perpendicular to the paper-bound

Section

edge or long edge.

Flexural Strength (Method A) 7

Core, End and Edge Hardness (Method A) 8

Nail Pull Resistance (Method A) 9

4. Sampling

Flexural Strength (Method B) 11

4.1 For use in these test methods, a sample shall consist of

Core, End and Edge Hardness (Method B) 12

Nail Pull Resistance (Method B) 13

not less than 0.25 % of the number of gypsum panel products

Humidified Deflection 14

in a shipment, but not less than three gypsum panel products.

End Squareness 15

Test specimens shall be taken from the sample lot as indicated

Nominal Thickness 16

Recessed- or Tapered Edge Depth 17

in each method.

Width 18

Length 19

5. Conditioning

Water Resistance of Core-Treated Water-Repellent

Gypsum Panel Products 20

5.1 Condition specimens to constant weight at a temperature

Surface Water Resistance of Gypsum Panel Products

of 85 6 15°F (29.5 6 8.5°C) and relative humidity of 50 6

with Water-Repellent Surfaces 21

2 % (Note 1). Test specimens individually after constant

1.3 The text of these test methods references notes and

weight is reached and within 10 min upon removal from the

footnotes that provide explanatory material. These notes and

conditioning chamber.

footnotes, excluding those in tables and figures, shall not be

NOTE 1—Laboratory test results indicated that conditioning tempera-

considered as requirements of these test methods.

tures may range from 70 to 100°F (21 to 38°C) without significantly

1.4 This standard does not purport to address all of the

affecting the results. However, relative humidity is critical. This is the

safety concerns, if any, associated with its use. It is the

reason for testing specimens within 10 min upon removal from the

responsibility of the user of this standard to establish appro-

conditioning chamber.

priate safety and health practices and determine the applica-

Method A—Constant Rate of Loading

bility of regulatory limitations prior to use.

INTRODUCTION

2. Referenced Documents

The following procedures are applicable to so-called “shot

2.1 ASTM Standards:

machines” that utilize lead or steel shot that applies a load to

C 11 Terminology Relating to Gypsum and Related Build-

the specimen at a constant stress rate or any other device that

ing Materials and Systems

applies the load at a constant stress rate.

D 3285 Test Method for Water Absorptiveness of Nonbibu-

lous Paper and Paperboard (Cobb Test)

6. Apparatus—Method A

E 4 Practices for Force Verification of Testing Machines

6.1 Testing Machine—Apply the test load at a uniform rate

3. Terminology

of 1 lbf/s (4.45 N/s) 610 %. Apply the load with a device

independent of manual control of the rate of loading during an

3.1 Definitions used in these test methods are in accordance

individual sample test (see Fig. 1). The deformation of the

1 specimen controls the cross head speed.

These test methods are under the jurisdiction of ASTM Committee C-11 on

Gypsum and Related Building Materials and Systems and are the direct responsi-

7. Flexural Strength (Method A)

bility of Subcommittee C11.01 on Specifications and Test Methods for Gypsum

Products.

7.1 Summary of Test Method—Flexural properties of gyp-

Current edition approved Jan. 10, 2000. Published March 2000. Originally

e1

sum panel products are evaluated by supporting the specimen

published as C 473 – 61. Last previous edition C 473 – 99 .

Annual Book of ASTM Standards, Vol 04.01.

near the ends and applying a transverse load midway between

Annual Book of ASTM Standards, Vol 15.09.

the supports.

Annual Book of ASTM Standards, Vol 03.01.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 473

edge, test one specimen from each gypsum panel product face

up and the other face down. For specimens with the long

dimension perpendicular to the edge, test one specimen from

each gypsum panel product face up and the other face down.

7.6.3 For gypsum panel products with surfacing material,

the load is determined at the time of transverse failure of the

surfacing material and core through the thickness of the

specimen. The specimens shall not show a break in the bond

between the surfacing and the core before transverse failure of

the gypsum panel product. If a single specimen fails, test two

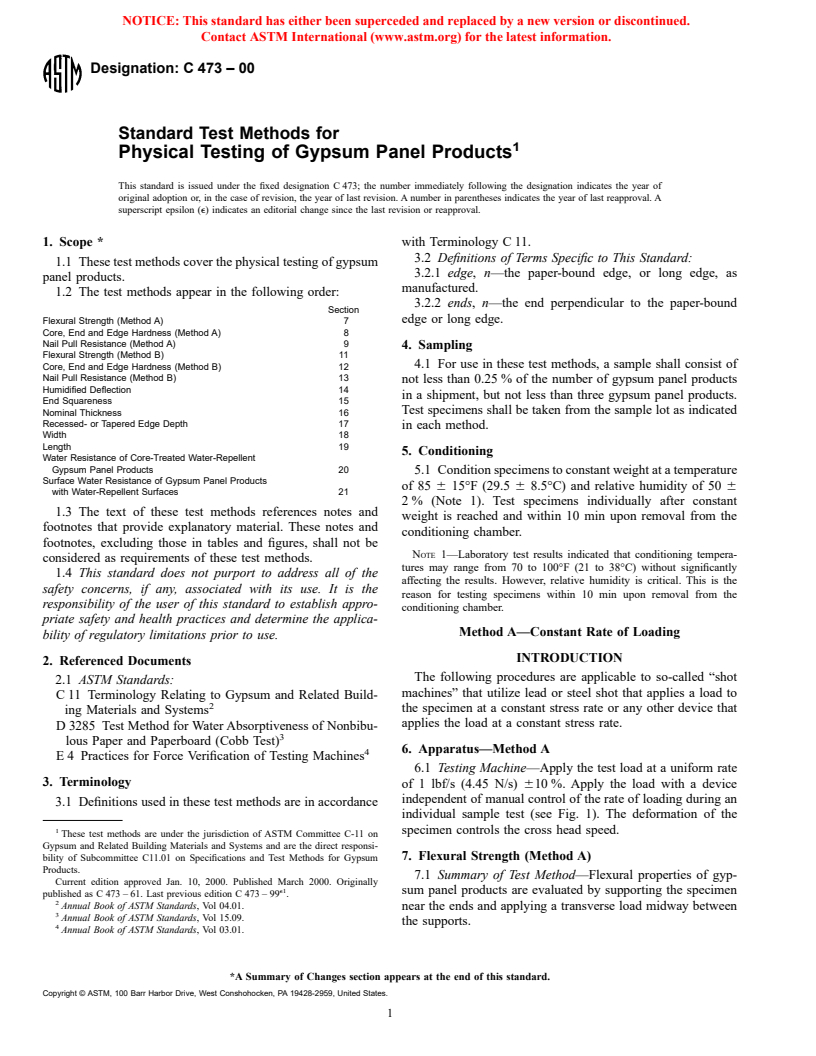

FIG. 1 Apparatus Schematic for Core, End, and Edge Hardness

additional specimens from the same sample, and, if either one

Test

of the two specimen fail, the sample has failed. For gypsum

7.2 Significance and Use—This test method covers a pro-

panel products without surfacing material, the load is deter-

cedure for evaluating the ability of gypsum panel products to

mined at the time of transverse failure through the thickness of

withstand flexural stresses during handling or use of the

the specimen.

material. This test method is used to determine compliance

7.7 Report—Calculate and report the average breaking load

with gypsum panel product specifications. The degree of

in pound-force or newtons for each test condition, rounded to

correlation between this test and service performance has not

the nearest 1 lbf (N). The test conditions are: (1) parallel, face

been fully determined.

up; (2) parallel, face down; (3) perpendicular, face up; and, (4)

7.3 Apparatus—See Section 6.1.

perpendicular, face down.

7.3.1 Specimen Supports—All specimen bearing supports

7.8 Precision and Bias—The precision and bias for this test

and load surfaces shall be true, shall engage the full width of

method has not been determined.

the test specimen, shall be of such strength they will not

8. Core, End, and Edge Hardness (Method A)

deform under the test load, and shall be rounded to a radius of

0.125 in. (3.2 mm). The specimen supports shall be spaced 14 8.1 Summary of Test Method—The core, end, and edge

6 0.016 in. (356 6 0.41 mm) on centers measured at the points hardness of gypsum panel products is evaluated by determining

of surface contact with the specimen. The supports shall be the force required to push a steel punch into the area of test.

attached to a plate that shall be rigidly attached to the test 8.2 Significance and Use—This test method covers a pro-

apparatus. The supports shall be parallel to each other and cedure for evaluating the ability of the gypsum panel product

perpendicular to the long dimension of the test specimen. The core, ends, and edges to resist crushing during handling or use

bearing surface of the end supports shall be on the same plane of the material. This test method is used to determine compli-

to ensure contact along the entire bearing surfaces. Supports

ance with gypsum panel product specifications. The degree of

shall be not less than 12 in. (305 mm) in length. When a load correlation between these test methods and service perfor-

is being applied, the loading bar shall be in contact with the full mance has not been determined.

width of the specimen. The load-bearing surface shall be 8.3 Apparatus—See 6.1. Clamp or secure the specimen to

parallel to the bearing surface of the specimen supports. The the base of the test apparatus shown in Fig. 1 with the face of

specimen and supports shall be located so that the vertical axis the specimen perpendicular to the base of the test apparatus and

through the center of the load-bearing surface passes through parallel to the movement of the steel punch. Secure the steel

the specimen at one half of the specimen width and one half of punch to the moving head of the test apparatus, positioned so

the distance between the supports. that its center axis is parallel eith the line of travel and so that

7.4 Sampling—Sampling shall be in accordance with Sec- the punch is inserted into the core equidistant from the surfaces

tion 4. of the specimen. Use a steel punch 0.099 6 0.003 in. (2.515 6

7.5 Test Specimens: 0.076 mm) in diameter and more than ⁄2 in. (12.7 mm) long

7.5.1 Cut four specimens, each 12 in. (305 mm) by approxi- with the bearing surface machined to a 90° angle in reference

mately 16 in. (406 mm) from each gypsum panel product in the to the punch center line (see Fig. 1 for test setup schematic).

sample, two having the 16-in. dimension parallel to the edge 8.4 Sampling—Sampling shall be in accordance with Sec-

and two having the 16-in. dimension perpendicular to the edge. tion 4.

Cut the specimens not less than 4 in. (102 mm) away from the 8.5 Test Specimens:

ends and edges of the gypsum panel product except where the 8.5.1 Specimens for Core Hardness—Using a table or band

product is 24-in. or less in width, where it is impossible to do saw, cut one specimen from the center of each of the three

so.

gypsum panel product samples approximately 12 by not less

7.5.2 Condition specimens in accordance with Section 5. than 3 in. (305 by 76 mm), with the 12-in. dimension

7.6 Procedure: perpendicular to the edges of the products, for a total of not less

7.6.1 Use the apparatus in 7.3, supporting each specimen than three specimens. The smaller, not less than 3 in., dimen-

centrally on the fixed parallel bearings, 14-in. (356 mm) on sion will vary depending on the specific punch length and

centers, and apply the load on a similar bearing midway opening in the testing machines. Place the sample in the tester,

between the supports. Position perforated gypsum lath so the with the loading arm in a horizontal position and with the

load is not applied over perforations. punch resting on the specimen. Saw cuts along the 12-in.

7.6.2 For specimens with the long dimension parallel to the dimension shall be smooth and square with the smaller (not

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 473

less than 3-in.) dimension, as well as with the specimen. force a standard nail head through the product. This test

8.5.2 Specimens for End Hardness—Cut specimens the method is used to determine compliance with gypsum panel

same size and method as described in 8.5.1 from one mill-cut product specifications. The degree of correlation between these

end of the gypsum panel product, with the 12-in. (305-mm) test methods and service performance has not been determined.

dimension perpendicular to the edges, for a total of not less 9.3 Apparatus—See 6.1. This apparatus shall be used with

than three specimens, and run tests only on the mill-cut end of either of the specimen support plates in 9.3.1 or 9.3.2.

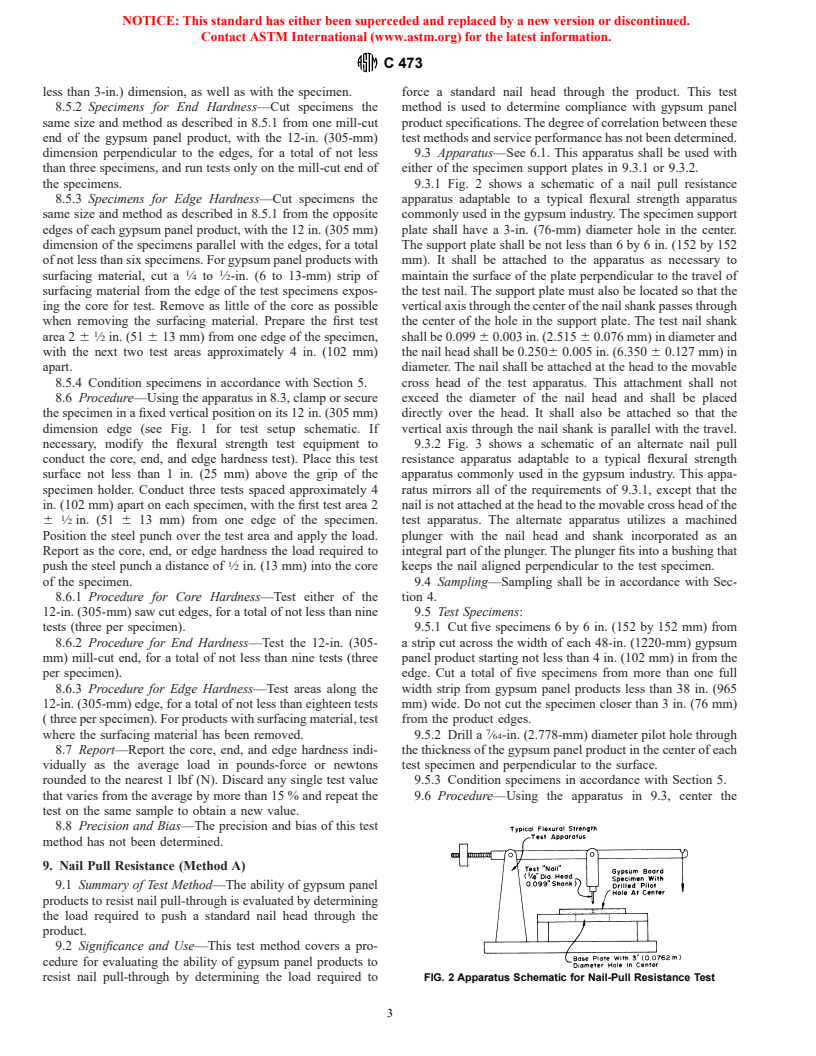

the specimens. 9.3.1 Fig. 2 shows a schematic of a nail pull resistance

8.5.3 Specimens for Edge Hardness—Cut specimens the apparatus adaptable to a typical flexural strength apparatus

same size and method as described in 8.5.1 from the opposite commonly used in the gypsum industry. The specimen support

edges of each gypsum panel product, with the 12 in. (305 mm) plate shall have a 3-in. (76-mm) diameter hole in the center.

dimension of the specimens parallel with the edges, for a total The support plate shall be not less than 6 by 6 in. (152 by 152

of not less than six specimens. For gypsum panel products with mm). It shall be attached to the apparatus as necessary to

1 1

surfacing material, cut a ⁄4 to ⁄2-in. (6 to 13-mm) strip of maintain the surface of the plate perpendicular to the travel of

surfacing material from the edge of the test specimens expos- the test nail. The support plate must also be located so that the

ing the core for test. Remove as little of the core as possible vertical axis through the center of the nail shank passes through

when removing the surfacing material. Prepare the first test the center of the hole in the support plate. The test nail shank

area 2 6 ⁄2 in. (51 6 13 mm) from one edge of the specimen, shall be 0.099 6 0.003 in. (2.515 6 0.076 mm) in diameter and

with the next two test areas approximately 4 in. (102 mm) the nail head shall be 0.2506 0.005 in. (6.350 6 0.127 mm) in

apart. diameter. The nail shall be attached at the head to the movable

8.5.4 Condition specimens in accordance with Section 5. cross head of the test apparatus. This attachment shall not

8.6 Procedure—Using the apparatus in 8.3, clamp or secure exceed the diameter of the nail head and shall be placed

the specimen in a fixed vertical position on its 12 in. (305 mm) directly over the head. It shall also be attached so that the

dimension edge (see Fig. 1 for test setup schematic. If vertical axis through the nail shank is parallel with the travel.

necessary, modify the flexural strength test equipment to 9.3.2 Fig. 3 shows a schematic of an alternate nail pull

conduct the core, end, and edge hardness test). Place this test resistance apparatus adaptable to a typical flexural strength

surface not less than 1 in. (25 mm) above the grip of the apparatus commonly used in the gypsum industry. This appa-

specimen holder. Conduct three tests spaced approximately 4 ratus mirrors all of the requirements of 9.3.1, except that the

in. (102 mm) apart on each specimen, with the first test area 2 nail is not attached at the head to the movable cross head of the

6 ⁄2 in. (51 6 13 mm) from one edge of the specimen. test apparatus. The alternate apparatus utilizes a machined

Position the steel punch over the test area and apply the load. plunger with the nail head and shank incorporated as an

Report as the core, end, or edge hardness the load required to integral part of the plunger. The plunger fits into a bushing that

push the steel punch a distance of ⁄2 in. (13 mm) into the core keeps the nail aligned perpendicular to the test specimen.

of the specimen. 9.4 Sampling—Sampling shall be in accordance with Sec-

8.6.1 Procedure for Core Hardness—Test either of the tion 4.

12-in. (305-mm) saw cut edges, for a total of not less than nine 9.5 Test Specimen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.