ASTM C906-95

(Test Method)Standard Test Method for T-Peel Strength of Hot Applied Sealants

Standard Test Method for T-Peel Strength of Hot Applied Sealants

SCOPE

1.1 This test method covers a laboratory procedure for determining the peel strength of a hot-applied sealant, hereafter referred to as the sealant, when installed between flexible metal substrates of a T-type configuration. It also provides information on the adhesion of the sealant to the tested substrates.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.3 The committee having jurisdiction for this specification is not aware of any similar ISO standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 906 – 95

Standard Test Method for

T-Peel Strength of Hot Applied Sealants

This standard is issued under the fixed designation C 906; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a laboratory procedure for

determining the peel strength of a hot-applied sealant, hereafter

referred to as the sealant, when installed between flexible metal

substrates of a T-type configuration. It also provides informa-

tion on the adhesion of the sealant to the tested substrates.

1.2 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are provided for

information only.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

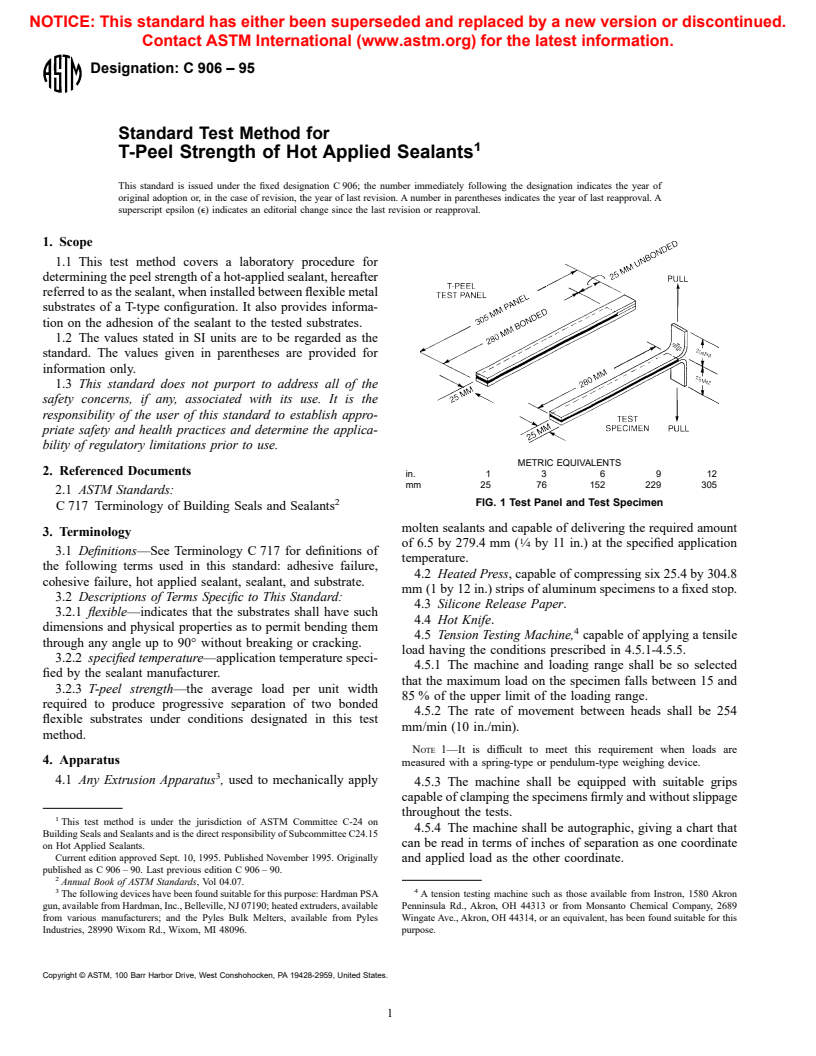

METRIC EQUIVALENTS

2. Referenced Documents

in. 1 3 6 9 12

mm 25 76 152 229 305

2.1 ASTM Standards:

FIG. 1 Test Panel and Test Specimen

C 717 Terminology of Building Seals and Sealants

molten sealants and capable of delivering the required amount

3. Terminology

of 6.5 by 279.4 mm ( ⁄4 by 11 in.) at the specified application

3.1 Definitions—See Terminology C 717 for definitions of

temperature.

the following terms used in this standard: adhesive failure,

4.2 Heated Press, capable of compressing six 25.4 by 304.8

cohesive failure, hot applied sealant, sealant, and substrate.

mm (1 by 12 in.) strips of aluminum specimens to a fixed stop.

3.2 Descriptions of Terms Specific to This Standard:

4.3 Silicone Release Paper.

3.2.1 flexible—indicates that the substrates shall have such

4.4 Hot Knife.

dimensions and physical properties as to permit bending them

4.5 Tension Testing Machine, capable of applying a tensile

through any angle up to 90° without breaking or cracking.

load having the conditions prescribed in 4.5.1-4.5.5.

3.2.2 specified temperature—application temperature speci-

4.5.1 The machine and loading range shall be so selected

fied by the sealant manufacturer.

that the maximum load on the specimen falls between 15 and

3.2.3 T-peel strength—the average load per unit width

85 % of the upper limit of the loading range.

required to produce progressive separation of two bonded

4.5.2 The rate of movement between heads shall be 254

flexible substrates under conditions designated in this test

mm/min (10 in./min).

method.

NOTE 1—It is difficult to meet this requirement when loads are

4. Apparatus

measured with a spring-type or pendulum-type weighing device.

4.1 Any Extrusion Apparatus , used to mechanically apply

4.5.3 The machine shall be equipped with suitable grips

capable of clamping the specimens firmly and without slippage

throughout the tests.

This test method is under the jurisdiction of ASTM Committee C-24 on

4.5.4 The machine shall be autographic, giving a chart that

Building Seals and Sealants and is the direct responsibility of Subcommittee C24.15

can be read in terms of inches of separation as one coordinate

on Hot Applied Sealants.

Current edition approved Sept. 10, 1995. Published November 1995. Originally

and applied load as the other coordinate.

published as C 906 – 90. Last previous edition C 906 – 90.

Annual Book of ASTM Standards, Vol 04.07.

3 4

The following devices have been found suitable for this purpose: Hardman PSA A tension testing machine such as those available from Instron, 1580 Akron

gun, available from Hardman, Inc., Belleville, NJ 07190; heated extruders, available Penninsula Rd., Akron, OH 44313 or from Monsanto Chemical Company, 2689

from various manufacturers; and the Pyles Bulk Melters, available from Pyles Wingate Ave., Akron, OH 44314, or an equivalent, has been found suitable for this

Industries, 28990 Wixom Rd., Wixom, MI 48096. purpose.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

C 906

NOTE 4—This speed will cause separation of the bond at a rate of 127

4.5.5 The applied tension as measured and recorded shall be

mm (5 in.) per min.

accurate within 61%.

4.6 Room or Desiccators, capable of maintaining a relative

8.2 During the peel test, make an autographic recording of

humidity of 50 6 5 % at 23 6 2°C (73.4 6 3.6°F).

load versus head movement or load versus distance peeled.

8.3 Determine the peel strength over at least a 279.4 mm (11

NOTE 2—A saturated solution of calcium nitrate will provide approxi-

mately a 51 % relative humidity at the testing temperature. in.) length of bond line after the initial peak. Ignore the first and

last 25.4 mm (1 in.) of sample.

4.7 Aluminum Alloy Strips, 12 required, measuring 25.4 by

304.8 by 0.635 mm (1 by 12 by 0.025 in.). Alloy #5052-H32.

9. Calculation

4.8 Planimeter, recommended, but optional.

9.1 Disregard the first and last 25.4 mm (1 in.) and deter-

5. Sampling

mine from the autographic curve for 228.6 mm (9 in.) of

5.1 Sealant shall be free of external surface contaminants

peeling after the initial peak the average peeling load in lb/in.

such as talc, oil, dust, and moisture. Handling of the sealant of the specimen width required to separate the adherents. It is

s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.