ASTM E982-94(1998)

(Specification)Standard Specification for Laboratory Glass Test Tubes

Standard Specification for Laboratory Glass Test Tubes

SCOPE

1.1 This specification covers glass test tubes suitable for laboratory use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 982 – 94 (Reapproved 1998)

Standard Specification for

Laboratory Glass Test Tubes

This standard is issued under the fixed designation E 982; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

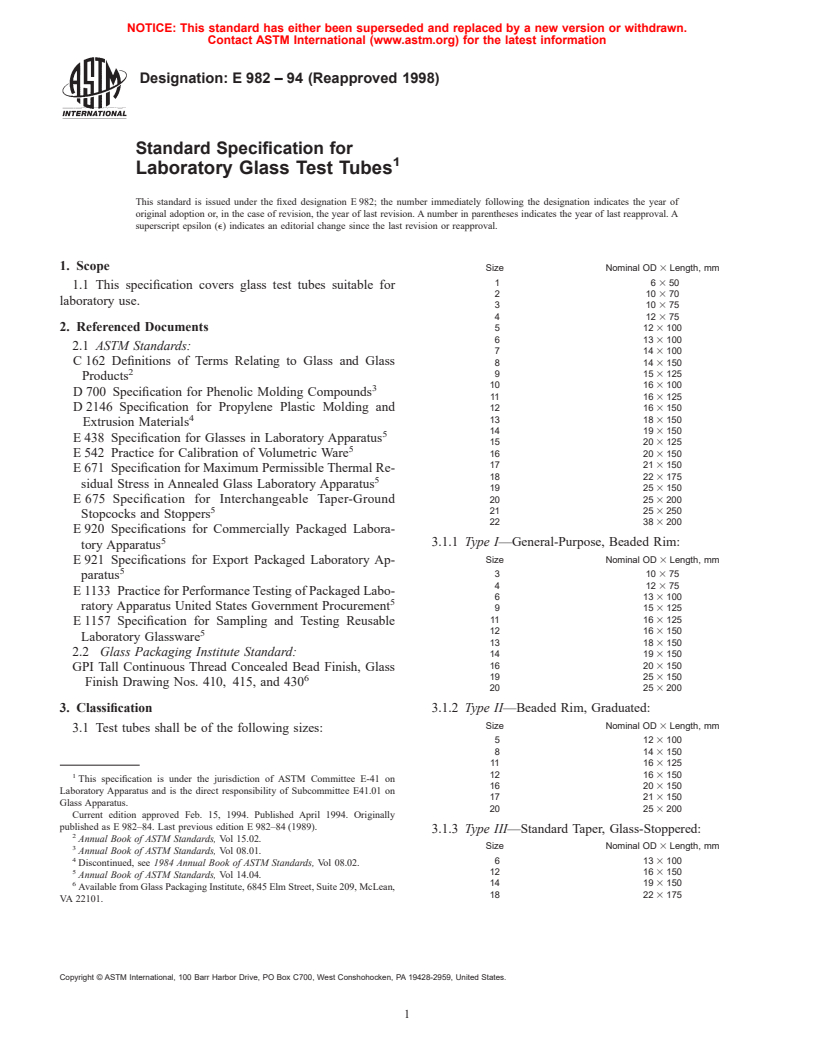

Size Nominal OD 3 Length, mm

16 3 50

1.1 This specification covers glass test tubes suitable for

210 3 70

laboratory use.

310 3 75

412 3 75

2. Referenced Documents

512 3 100

613 3 100

2.1 ASTM Standards:

714 3 100

C 162 Definitions of Terms Relating to Glass and Glass

814 3 150

915 3 125

Products

10 16 3 100

D 700 Specification for Phenolic Molding Compounds

11 16 3 125

D 2146 Specification for Propylene Plastic Molding and 12 16 3 150

4 13 18 3 150

Extrusion Materials

14 19 3 150

E 438 Specification for Glasses in Laboratory Apparatus

15 20 3 125

E 542 Practice for Calibration of Volumetric Ware 16 20 3 150

17 21 3 150

E 671 Specification for Maximum Permissible Thermal Re-

18 22 3 175

sidual Stress in Annealed Glass Laboratory Apparatus

19 25 3 150

20 25 3 200

E 675 Specification for Interchangeable Taper-Ground

21 25 3 250

Stopcocks and Stoppers

22 38 3 200

E 920 Specifications for Commercially Packaged Labora-

3.1.1 Type I—General-Purpose, Beaded Rim:

tory Apparatus

Size Nominal OD 3 Length, mm

E 921 Specifications for Export Packaged Laboratory Ap-

310 3 75

paratus

412 3 75

E 1133 Practice for Performance Testing of Packaged Labo-

613 3 100

ratory Apparatus United States Government Procurement

915 3 125

11 16 3 125

E 1157 Specification for Sampling and Testing Reusable

12 16 3 150

Laboratory Glassware

13 18 3 150

2.2 Glass Packaging Institute Standard:

14 19 3 150

16 20 3 150

GPI Tall Continuous Thread Concealed Bead Finish, Glass

19 25 3 150

Finish Drawing Nos. 410, 415, and 430

20 25 3 200

3. Classification 3.1.2 Type II—Beaded Rim, Graduated:

Size Nominal OD 3 Length, mm

3.1 Test tubes shall be of the following sizes:

512 3 100

814 3 150

11 16 3 125

1 12 16 3 150

This specification is under the jurisdiction of ASTM Committee E-41 on

16 20 3 150

Laboratory Apparatus and is the direct responsibility of Subcommittee E41.01 on

17 21 3 150

Glass Apparatus.

20 25 3 200

Current edition approved Feb. 15, 1994. Published April 1994. Originally

published as E 982–84. Last previous edition E 982–84 (1989).

3.1.3 Type III—Standard Taper, Glass-Stoppered:

Annual Book of ASTM Standards, Vol 15.02.

3 Size Nominal OD 3 Length, mm

Annual Book of ASTM Standards, Vol 08.01.

613 3 100

Discontinued, see 1984 Annual Book of ASTM Standards, Vol 08.02.

12 16 3 150

Annual Book of ASTM Standards, Vol 14.04.

6 14 19 3 150

Available from Glass Packaging Institute, 6845 Elm Street, Suite 209, McLean,

18 22 3 175

VA 22101.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 982

to Specification D 2146. Screw caps shall not deform, crack,

20 25 3 200

turn color, or become tacky; and liners shall not detach or

3.1.4 Type IV—Culture Tubes, Rimless:

become tacky when autoclaved the first time.

Size Nominal OD 3 Length, mm

4.3 Liners—Liners for Class A screw caps shall be fabri-

16 3 50

cated of resilient white rubber. Class B caps shall have a

310 3 75

412 3 75

polytetrafluoroethylene liner interface firmly bonded to the

613 3 100

glued-in white rubber liner as described for Class A caps.

915 3 125

10 16 3 100 4.4 Annealing—Maximum thermal residual stress shall be

11 16 3 125

such as to conform to Specification E 671.

12 16 3 150

13 18 3 150

14 19 3 150 5. Design

16 20 3 150

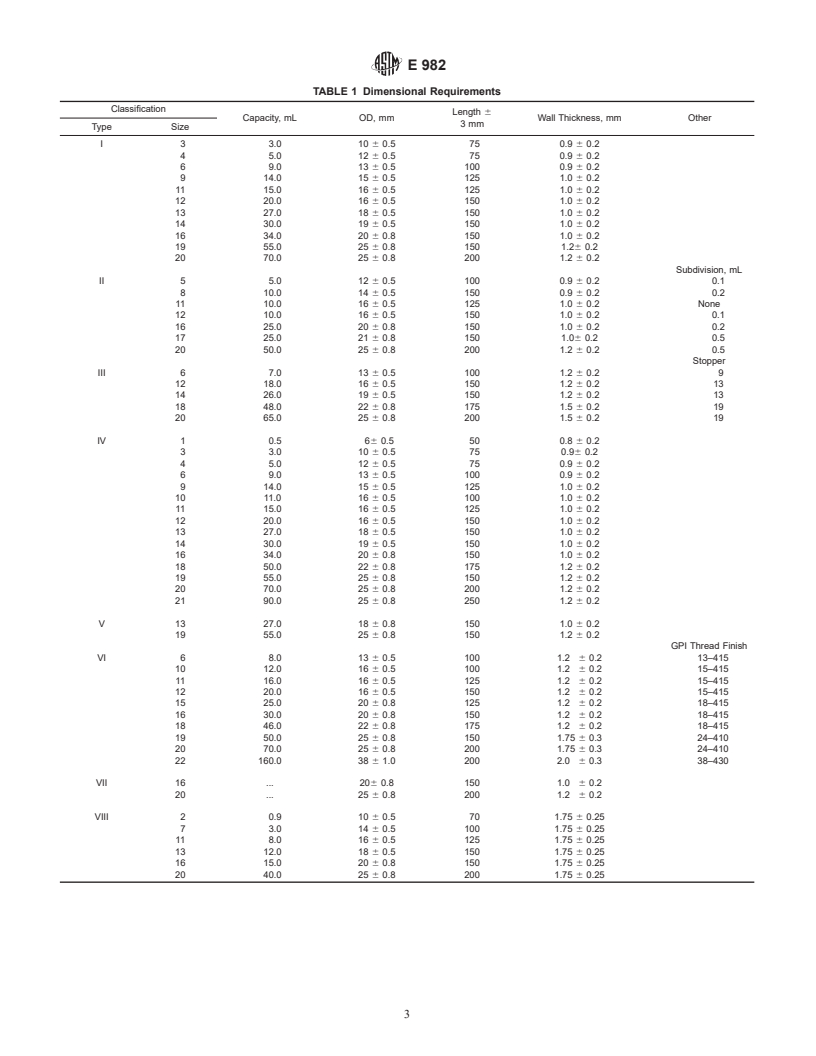

5.1 Shape—Test tubes covered by this specification shall be

18 22 3 125

19 25 3 150

tubular, with one end having a rounded closure.

20 25 3 200

5.2 Capacity—Capacities on ungraduated tubes are only

21 25 3 250

approximate, but any graduation on Type II tubes shall indicate

3.1.5 Type V—Culture Tubes, Filtered for Wave Lengths in

the contained capacity within 65 % of nominal tube capacity.

the 3 000 to 5 000-Å Range:

5.3 Types I and II—The open end of Types I and II test tubes

Size Nominal OD 3 Length, mm

shall have a beaded rim; dimensions shall be as specified in

13 18 3 150

Table 1.

19 25 3 150

5.4 Type III—The open end of Type III test tubes shall have

3.1.6 Type VI—Culture Tubes, Screw Caps:

a standard taper stopper. The joint and stopper shall conform to

Size Nominal OD 3 Length, mm

Specification E 675 and Table 1.

613 3 100

5.5 Types IV, V, and VIII—The open end of Types IV, V and

10 16 3 100

VIII test tubes shall be rimless and fire polished, dimensions

11 16 3 125

12 16 3 150

shall be as specified in Table 1.

15 20 3 125

5.6 Type VI—The open end of Type VI test tubes shall have

16 20 3 150

18 22 3 175

a standard GPI thread finish made to accommodate a plastic

19 25 3 150

screw-on type cap. The inner edge of the cap shall be

20 25 3 200

sufficiently threaded with a continuous thread formed as an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.