ASTM F888-04

(Test Method)Standard Test Method for Measuring Maximum Function Volume of the Primary Dirt Receptacle in a Vacuum Cleaner

Standard Test Method for Measuring Maximum Function Volume of the Primary Dirt Receptacle in a Vacuum Cleaner

SCOPE

1.1 This test method covers household types of upright, canister, and combination vacuum cleaners.

1.2 This test method provides a measurement in dry quarts or litres of the maximum functional volume of the primary dirt receptacle when installed in the vacuum cleaner.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazards statements see 7.2 and 8.5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F888–04

Standard Test Method for

Measuring Maximum Function Volume of the Primary Dirt

1

Receptacle in a Vacuum Cleaner

This standard is issued under the fixed designation F888; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.4 Humidity Measuring Equipment, to provide measure-

ments accurate to within 62% relative humidity.

1.1 This test method covers household types of upright,

4.5 Adapter,tobeattachedtothecleaningnozzleofupright

canister, and combination vacuum cleaners.

cleaners for use in directing granulated cork into the nozzle.

1.2 This test method provides a measurement in dry quarts

See Fig. 1.

or litres of the maximum functional volume of the primary dirt

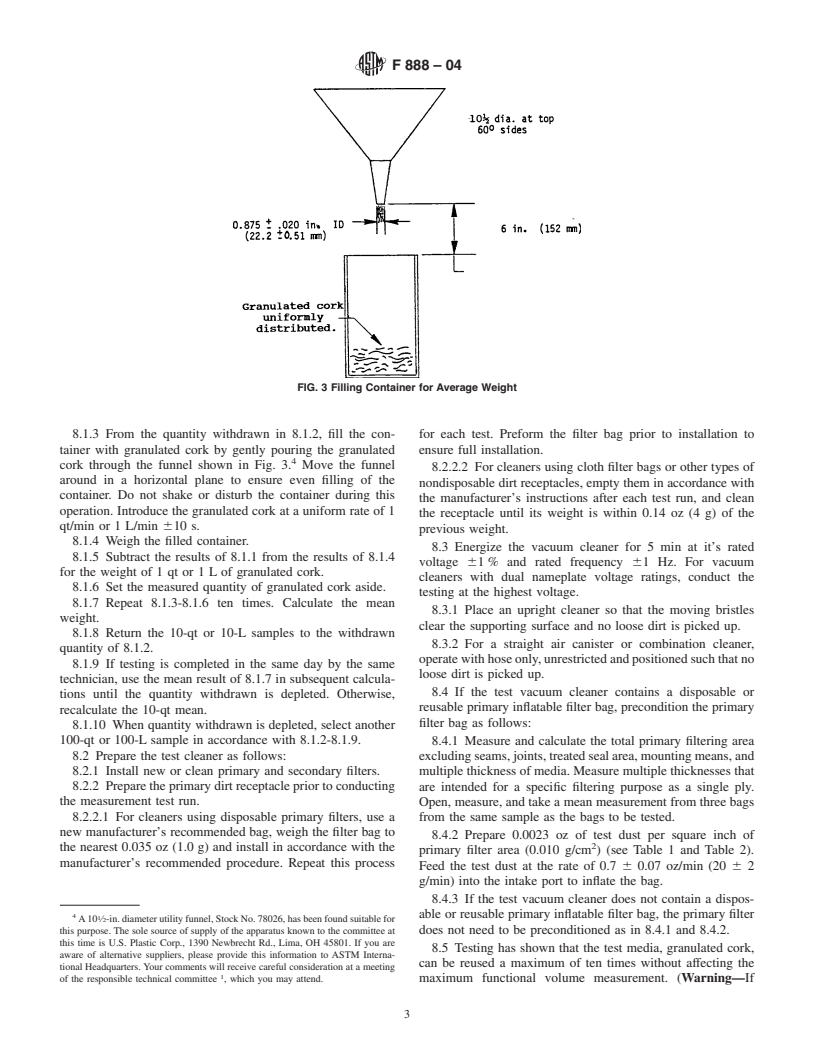

4.6 Volume Measuring Container, to measure volume of

receptacle when installed in the vacuum cleaner.

granulated cork. This shall have a capacity of one dry quart.

1.3 This standard does not purport to address all of the

See Fig. 2.The container shall be made of transparent material

safety concerns, if any, associated with its use. It is the

to ensure no voids when filled with granulated cork. As an

responsibility of the user of this standard to establish appro-

option, a 1-L container can be used.

priate safety and health practices and determine the applica-

4.7 Weighing Scale— The scale shall be accurate to 0.035

bilityofregulatorylimitationspriortouse.Forspecifichazards

oz (1 g) and have a weighing capacity of at least 15 lb (6.82

statements see 7.2 and 8.5.

kg).

2. Referenced Documents

5. Materials

2

2.1 SAE Standard:

5.1 New Granulated Cork—Premium Grade 6 to 14 sieve

SAE J726b Air Cleaner Test Code

3

size.

3. Significance and Use

5.2 Coarse-GradeAir Cleaner Test Dust, seeTable 1.As an

option, talc may be used. See Table 2.

3.1 This test method covers a procedure to determine the

maximum functional volume of the primary dirt receptacle

6. Sampling

when installed in the vacuum cleaner.

6.1 Determination of Sample Size—A sample of sufficient

3.2 This test method provides the maximum amount of test

sizeofeachmodelshallbetesteduntila90%confidencelevel

media that the primary dirt receptacle will hold and may be

is established within 65% of the mean value. A minimum of

more than the volume obtained when filled to the manufactur-

three samples shall be tested. All samples shall be selected at

er’s recommended fill line.

random in accordance with good statistical practices.

4. Apparatus 6.2 DeterminationofMaximumFunctionalVolumeforEach

Unit—The maximum functional volume for each unit shall be

4.1 Voltmeter, to measure input voltage to the cleaner, to

anaverageofthreerunswithaspreadmeetingtherepeatability

provide measurements accurate to within 61%.

statement in 9.2. (See Appendix X1 for example.)

4.2 VoltageRegulatorSystem,tocontroltheinputvoltageto

the vacuum cleaner. The regulator system shall be capable of

7. Conditioning

maintaining the vacuum cleaners rated voltage of 61% and

7.1 Maintain the test room at 70 6 5°F (216 3°C) and 45

rated frequency 61 Hz having a wave form that is essentially

to 55% relative humidity.

sinusoidal with 3% maximum harmonic distortion for the

7.2 Expose all components involved in the test to the

duration of the test.

controlled environment for at least 16 h prior to the start of the

4.3 Temperature Measuring Equipment, to provide mea-

test.(Warning—Storesufficient100qtor100-Lincrementsof

surements accurate to within 61°F (0.5°C).

1

ThistestmethodisunderthejurisdictionofASTMCommitteeF11onVacuum

3

Cleaners and is the direct responsibility of Subcommittee F11.23 on Filtration. The sole source of supply of the test material known to the committee at this

Current edition approved Oct. 1, 2004. Published November 2004. Originally time is Wiley Cork, Inc., 16th Locust Street, Wilmington, DE 19802. If you are

approved in 2004. Last previous edition approved in 1999 as F888–94(1999). aware of alternative suppliers, please provide this information to ASTM Interna-

2

Available from Society of Automotive Engineers (SAE), 400 Commonwealth tional Headquarters.Your comments will receive careful consideration at a meeting

3

Dr., Warrendale, PA 15096-0001. of the responsible technical committee , which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F888–04

FIG. 1 Adapter Plate for Uprights

FIG. 2 Volume Measuring Container

A

TABLE 1 Analysis of Coarse Grade Air Cleaner F11 Test Dust TABLE 2 Analysis of Unscented Commercial Grade Talcum

Particle Size Distribution by Vo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.